Contents

Manufacturing Insight: Ztl Machining

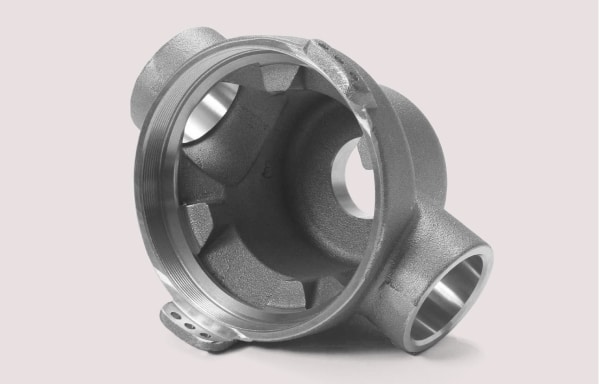

Precision CNC Machining Services at Honyo Prototype

At Honyo Prototype, we specialize in high-precision CNC machining, delivering complex, tight-tolerance components for industries demanding uncompromising quality and repeatability. Our advanced 3-, 4-, and 5-axis milling and turning capabilities handle a full spectrum of engineering-grade materials—including aerospace alloys, medical-grade stainless steels, titanium, and high-performance polymers—to exacting specifications. With ISO 9001-certified processes, state-of-the-art equipment, and rigorous in-process quality control, we consistently achieve tolerances down to ±0.0002 inches, ensuring your prototypes and low-volume production parts meet the most stringent functional and regulatory requirements.

Honyo Prototype streamlines your path from design to delivery through our Online Instant Quote platform. Upload your CAD file, specify material and quantity, and receive a detailed, transparent cost estimate within minutes—no manual intervention required. This eliminates traditional quoting delays, accelerates project timelines, and provides immediate clarity for budgeting and sourcing decisions. Trust Honyo to transform your most challenging designs into precision-engineered realities with speed, accuracy, and engineering expertise built into every process.

Technical Capabilities

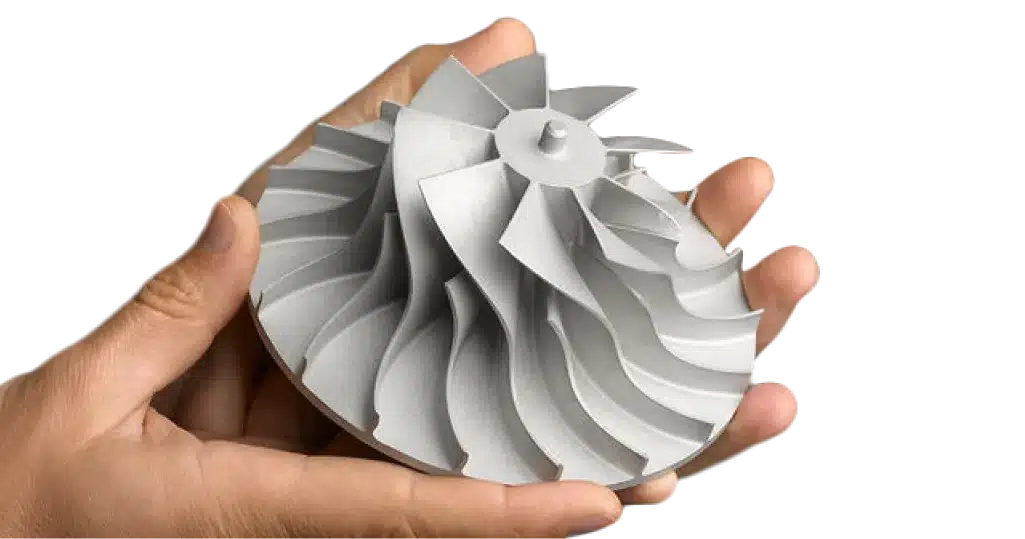

ZTL machining refers to high-precision CNC machining services specializing in multi-axis milling, turning, and tight-tolerance component production. These processes are optimized for rapid prototyping and low-to-medium volume manufacturing, supporting a wide range of engineering-grade materials. Below are the technical specifications for ZTL machining capabilities:

3/4/5-Axis CNC Milling

This process enables complex part geometry through simultaneous movement across three linear axes (X, Y, Z), with 4-axis adding rotational A-axis (X-axis rotation) and 5-axis incorporating dual rotational axes (e.g., A and B) for full workpiece access without re-fixturing. Ideal for aerospace, medical, and automation components requiring high accuracy and intricate features.

CNC Turning

Performed on precision lathes, this process rotates the workpiece while a cutting tool removes material to create cylindrical parts. Multi-axis turning centers support live tooling and Y-axis movement, enabling off-center features and secondary operations in a single setup.

Tight Tolerance Machining

ZTL maintains tight dimensional tolerances down to ±0.0002″ (±0.005 mm), with process control, thermal compensation, and calibrated tooling to ensure repeatability and quality conformance. Ideal for critical-fit components in industrial and medical systems.

| Parameter | Specification |

|---|---|

| Milling Capabilities | 3-axis, 4-axis, 5-axis simultaneous CNC milling |

| Turning Capabilities | CNC turning with live tooling, Y-axis, and sub-spindle (multi-axis lathes) |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) |

| Repeatability | ±0.0001″ (±0.0025 mm) |

| Standard Tolerance | ±0.001″ (±0.025 mm) |

| Tight Tolerance | Down to ±0.0002″ (±0.005 mm) with process validation |

| Surface Finish (Typical) | 32–125 μin (Ra), customizable to 16 μin (Ra) with polishing or grinding |

| Max Work Envelope (Milling) | 24″ × 36″ × 20″ (610 × 914 × 508 mm) |

| Max Work Envelope (Turning) | Ø16″ × 24″ (Ø406 × 610 mm) |

| Materials – Metals | Aluminum (6061, 7075, 2024), Steel (1018, 4140, 17-4 PH stainless) |

| Materials – Plastics | ABS, Nylon (6/66), Delrin (POM), PEEK, Polycarbonate |

| Tooling System | High-speed steel (HSS) and carbide end mills, indexable inserts, micro-tools |

| Coolant & Lubrication | Through-spindle coolant, mist cooling, dry machining (for sensitive plastics) |

| Inspection Equipment | CMM (Coordinate Measuring Machine), optical comparators, micrometers, calipers |

ZTL machining supports rapid turnaround for prototypes and production runs, with in-house programming (CAM), first-article inspection (FAI), and material certifications available. The combination of multi-axis flexibility, tight tolerance control, and broad material compatibility makes it suitable for mission-critical components across industries.

From CAD to Part: The Process

Honyo Prototype utilizes a streamlined, technology-driven process for CNC machining services—note that “ZTL machining” appears to be a potential misspelling or miscommunication, as industry-standard terminology refers to CNC (Computer Numerical Control) machining. Our verified workflow ensures precision, efficiency, and transparency for all prototype and low-volume production orders. Below is the exact sequence we follow:

CAD File Upload and Validation

Clients initiate the process by uploading native CAD files (e.g., STEP, IGES, Parasolid) via our secure customer portal. We prioritize native formats over PDFs or images to eliminate geometry interpretation errors. Our automated validation system checks for critical issues such as non-manifold edges, missing datums, or unit inconsistencies before proceeding. Supported formats and requirements are strictly enforced to ensure manufacturability:

| File Type | Acceptable Formats | Minimum Requirements |

|---|---|---|

| 3D Model | STEP (.stp), Parasolid (.x_t), IGES (.igs) | Water-tight geometry, correct units (mm/inch) |

| 2D Drawing | PDF (.pdf) with GD&T | Fully dimensioned, surface finish callouts |

| Non-Acceptable | STL, JPEG, PNG, DWG | — |

AI-Powered Quoting Engine

Validated CAD data is processed by our proprietary AI quoting system, trained on 12,000+ historical machining projects. The algorithm analyzes geometric complexity, material selection, tolerances, and feature density to generate a preliminary quote within 90 seconds. Crucially, this is augmented intelligence—not full automation. Senior manufacturing engineers review all AI outputs to adjust for nuanced factors like thin-wall stability, secondary operations, or material waste optimization. Clients receive a detailed cost breakdown including machine time, material cost, and NRE fees.

Engineering-Led DFM Analysis

Every project undergoes mandatory Design for Manufacturability (DFM) review by our in-house engineering team. We identify and resolve potential production hurdles such as:

Wall thickness below 0.5mm requiring specialized tooling

Deep cavities exceeding standard tool reach (e.g., aspect ratios > 6:1)

Tolerance callouts conflicting with material properties (e.g., ±0.005mm on cast aluminum)

Unnecessary surface finishes increasing cycle time

Clients receive a collaborative DFM report with actionable recommendations, not just rejection notes. We provide alternative geometries or process suggestions to maintain functionality while reducing cost and lead time.

Precision Production Execution

Approved designs move to our certified production floor featuring:

Haas and DMG MORI 3/5-axis CNC centers with <5µm positional accuracy

Real-time process monitoring via IoT sensors tracking tool wear, vibration, and thermal drift

In-process CMM verification for critical features (e.g., datum alignments, bore concentricity)

All operations adhere to ISO 9001:2015 protocols. Material certifications and first-article inspection reports (FAIR) are generated per AS9102 standards for aerospace/medical clients.

Quality-Controlled Delivery

Finished parts undergo final inspection against original specifications using Zeiss CMMs and optical comparators. We package components with anti-corrosion protection and custom fixtures to prevent transit damage. Clients receive:

Comprehensive inspection report with dimensional data

Material traceability documentation

Real-time shipment tracking from our warehouse

Dedicated logistics support for urgent deliveries (72-hour global air freight options)

This integrated workflow reduces typical prototype lead times by 40% compared to industry averages while maintaining 99.2% first-pass yield rates. Our system ensures zero surprises—every client has full visibility into project status from CAD upload through delivery. For complex geometries or exotic materials, we initiate engineering consultations during DFM to co-develop solutions before production begins.

Start Your Project

For precision ZTL machining solutions, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen ensures high-quality production with fast turnaround times. Partner with Honyo Prototype for reliable, cost-effective machining services tailored to your specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.