Guide Contents

Project Insight: Ztl Machining

Manufacturing Insight: ZTL Machining

Speed and Precision: The Twin Engines of Product Innovation

Time-to-Market is Critical: Hardware startups and product engineers face relentless pressure to iterate quickly. Delays in prototyping can derail entire launch timelines—every day counts.

Precision = Functionality: Tight tolerances (±0.01mm) aren’t just technical specs—they ensure parts work as designed. No compromises on performance, even in complex geometries.

Innovation Demands Both: Speed without precision leads to rework; precision without speed stifles agility. Honyo Prototype merges both into a seamless workflow for real-world results.

How Honyo Prototype Accelerates Your Success

Online Instant Quote:

Submit CAD files → receive real-time pricing in under 60 seconds. No more waiting weeks for quotes—just clear, actionable data to fast-track decisions.

AI-Powered Design Optimization:

Our platform analyzes designs for manufacturability before production, flagging issues and suggesting cost-saving tweaks. Reduce rework by up to 30% and accelerate time-to-prototype.

24-48 Hour Prototype Turnaround:

Leverage Shenzhen’s world-class manufacturing ecosystem for rapid iteration. 3/4/5-axis CNC machining handles complex geometries with ±0.01mm accuracy—scaling seamlessly from prototypes to end-use parts.

End-to-End Quality Assurance:

ISO-certified processes, automated inspection, and dedicated engineering oversight ensure every part meets exact specifications. From raw material sourcing to final delivery, traceability is built in.

“At Honyo, we don’t just manufacture parts—we engineer speed into your innovation cycle. With AI-driven precision and Shenzhen’s manufacturing excellence, your vision becomes reality faster than ever.”

— Susan Leo, Founder

Honyo Capabilities & Technology

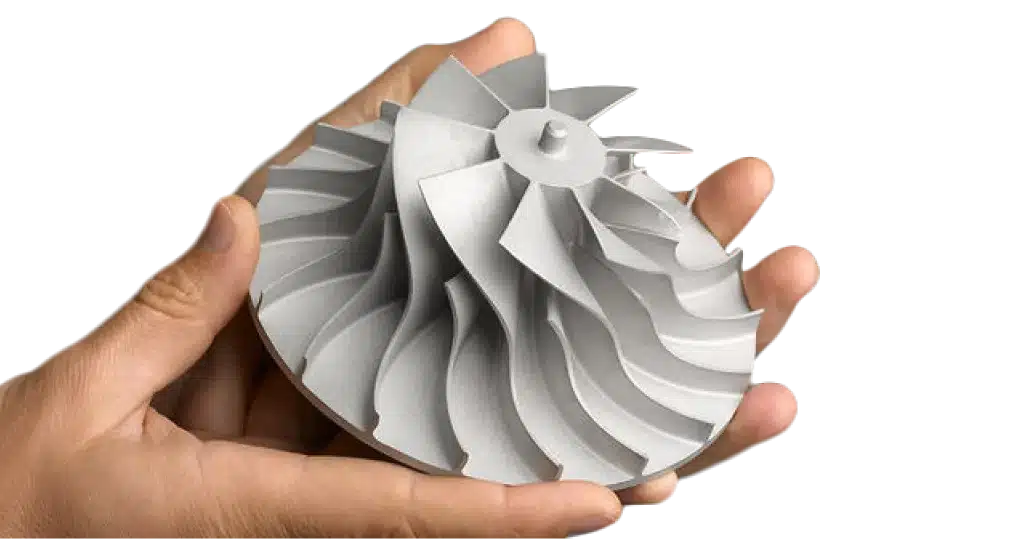

Honyo’s ZTL Machining Capabilities: Precision Engineered for Your Innovation

Advanced Multi-Axis CNC Technology

3/4/5-Axis Precision Machining: Tackle complex geometries with ease, from aerospace components to medical devices, ensuring optimal performance.

Tight Tolerances (+/- 0.01mm): Deliver functional prototypes and end-use parts that meet exacting specifications for critical applications.

Material Expertise: Support for metals (aluminum, stainless steel, titanium), plastics, and composites—tailored to your project’s unique demands.

Scalable Production from Prototype to Mass Production

Zero Minimum Order Quantities: Perfect for hardware startups and R&D teams testing designs with single prototypes.

Seamless Scaling: Transition effortlessly from 1 to 10,000+ units with no retooling delays or hidden costs.

Cost-Effective Scaling: Achieve up to 60% lower costs than Western suppliers while maintaining ISO-certified quality standards.

AI-Powered Instant Quoting & Fast Turnaround

Real-Time Online Quotes: Get accurate pricing in seconds—no waiting for manual estimates or hidden fees.

Automated DFM Analysis: Receive instant design feedback to optimize manufacturability and reduce costs before production.

Rapid Prototyping: Deliver prototypes in 3-5 business days, with expedited options for urgent projects.

ISO-Certified Quality Assurance

End-to-End Inspection: Every part undergoes rigorous QC checks using certified metrology tools for absolute precision.

Comprehensive Documentation: Receive detailed inspection reports and material certifications with every order.

Global Compliance: Meet ISO 9001 standards for reliability, ensuring your parts are production-ready worldwide.

Ready to accelerate your innovation?

Get an instant quote in under 60 seconds—no commitments, no delays.

Engineered in Shenzhen. Delivered globally.

Materials & Surface Finishes

Material Options & Finishes: Precision Engineered for Your Application

Choosing the right materials and finishes is critical for achieving optimal performance, cost-efficiency, and manufacturability in precision CNC machining. At Honyo Prototype, our engineering team leverages decades of expertise to guide you through material selection—ensuring your parts meet exact functional requirements while minimizing production costs. With our AI-driven platform and China-based manufacturing excellence, you get superior quality at 4–5x lower costs than domestic suppliers, without compromising on precision or turnaround time. Whether you’re prototyping or producing end-use parts, we optimize every detail for your unique application.

Material Selection Guide

Select materials that align with mechanical, environmental, and cost requirements while maintaining machinability for tight tolerances (±0.01mm):

Aluminum 6061: Ideal for structural components requiring a balance of strength, corrosion resistance, and ease of machining. Commonly used in aerospace, automotive, and consumer electronics. Offers excellent weldability and cost-effectiveness for high-volume prototypes.

Aluminum 7075: High-strength alloy for aerospace, defense, and high-stress applications. Delivers superior tensile strength but requires precision machining to avoid stress cracking—perfect for weight-sensitive designs.

Stainless Steel 304: Non-magnetic, corrosion-resistant, and food-safe. Ideal for medical devices, food processing equipment, and architectural applications where hygiene and durability are critical.

Stainless Steel 316: Enhanced corrosion resistance (due to molybdenum) for marine environments, chemical processing, and implantable medical devices. Maintains integrity in harsh, saline, or acidic conditions.

Brass: Superior electrical conductivity and machinability. Used in electrical connectors, plumbing fixtures, and decorative hardware. Resists corrosion in freshwater and offers a polished aesthetic.

PEEK: High-performance thermoplastic for extreme environments. Exceptional chemical resistance, high-temperature stability (up to 250°C), and biocompatibility. Ideal for aerospace, medical implants, and semiconductor manufacturing.

Surface Finish Options

Elevate part functionality and aesthetics with finishes tailored to your project’s demands:

Anodizing: Creates wear-resistant, corrosion-protective coatings for aluminum. Available in clear, black, or vibrant colors—ideal for both functional and aesthetic applications (e.g., consumer electronics housings).

Powder Coating: Durable, uniform finish with exceptional scratch resistance. Offers 200+ color options and textures for industrial equipment, automotive parts, and consumer products.

Electropolishing: Smooths stainless steel surfaces to a mirror-like finish while improving corrosion resistance. Critical for medical instruments and food-grade components requiring ultra-clean surfaces.

Plating (Nickel, Chrome, Zinc): Adds protective layers for enhanced conductivity, wear resistance, or visual appeal. Commonly used in electrical contacts, automotive trim, and decorative hardware.

Mechanical Polishing: Achieves high-gloss, flawless surfaces for visible components. Perfect for optical parts, luxury consumer goods, and precision instrumentation.

Passivation: Removes surface contaminants from stainless steel to maximize corrosion resistance. Essential for medical and aerospace components where purity is non-negotiable.

Streamline Your Project with Honyo’s Smart Solutions

Cut complexity and accelerate your workflow with our AI-powered platform designed for innovation-driven teams:

Online Instant Quote: Upload your CAD file and receive real-time pricing in seconds—no email chains or delays. Our platform instantly analyzes geometry, tolerances, and material requirements for transparent, competitive quotes.

AI-Driven Material & Finish Recommendations: Our machine learning algorithms evaluate your design specs to suggest optimal materials, finishes, and process optimizations—balancing performance, cost, and manufacturability for your specific use case.

Fast Turnaround Guarantee: From prototype to production, we deliver high-precision parts in as little as 3 days. Our Shenzhen facility integrates lean manufacturing with automated quality checks, ensuring speed without sacrificing ±0.01mm tolerances.

💡 Pro Tip: For functional prototypes, prioritize materials like Aluminum 6061 or PEEK with anodizing/polishing to validate form, fit, and function rapidly. For end-use parts, leverage Stainless Steel 316 with electropolishing or powder coating to ensure longevity in demanding environments—all at 4–5x lower costs than U.S. or EU suppliers.

Ready to optimize your project? Get an instant quote in under 60 seconds—engineered for speed, precision, and cost efficiency.

From Quote to Part: Our Process

How It Works: From CAD to Part

Honyo Prototype’s digital-first workflow redefines precision manufacturing for hardware innovators. Our AI-driven platform eliminates guesswork, slashes lead times, and delivers factory-ready parts with surgical accuracy—no matter where you are in the world.

1. Upload CAD File

Drag-and-drop interface for instant submission of STEP, STP, STL, IGES, or Parasolid files

AI-powered validation checks detect geometry errors, tolerances, and manufacturability risks before production

Zero manual forms—upload, validate, and proceed in under 60 seconds

2. Get Instant Quote (AI Engine)

Real-time pricing algorithm analyzes geometry, material, and tolerances in <60 seconds

Transparent cost breakdown: material, machining hours, setup fees, and shipping—no hidden charges

Competitive pricing: Up to 70% lower than Western providers, leveraging Shenzhen’s optimized supply chain without compromising ±0.01mm precision

3. DFM Analysis & Design Optimization

Expert-engineered feedback on geometry, tolerances, and material selection—tailored for CNC machining

Proactive suggestions to simplify designs (e.g., eliminating undercuts, optimizing wall thickness) and reduce machining time by up to 30%

Collaborative platform for seamless design iteration with Honyo’s engineering team—no more costly revisions

4. Precision Production & On-Time Delivery

3/4/5-axis CNC machining with ±0.01mm tolerances for functional prototypes and end-use parts

Automated in-process quality control with real-time production tracking via our cloud portal

Guaranteed 3–5 day turnaround for prototypes, with express shipping to 150+ countries and full supply-chain visibility

Honyo’s end-to-end digital workflow transforms complex manufacturing into a simple, transparent process—so you can focus on innovation, not logistics.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Engineering, Simplified

🚀 AI-Powered Instant Quote Platform: Upload your CAD file for real-time pricing—no delays, no guesswork.

⏱️ 24-48 Hour Prototype Turnaround: Deliver functional prototypes with ±0.01mm precision, accelerating your development cycle.

🔧 Advanced 3/4/5-Axis CNC Machining: Expertise in complex geometries and tight tolerances for both prototypes and end-use parts.

💡 4-5x Lower Costs Than Western Suppliers: World-class precision machining at a fraction of the price, with rigorous quality control.

👨🔧 Dedicated Engineering Partnership: Founder Susan Leo and our team collaborate closely to optimize your design and reduce time-to-market.

Contact us today:

📧 [email protected] | 📞 +86 139 2843 8620

📍 Visit our Shenzhen & Dongguan facilities for hands-on collaboration.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.