Introduction: Navigating the Global Market for wood lathe tools names

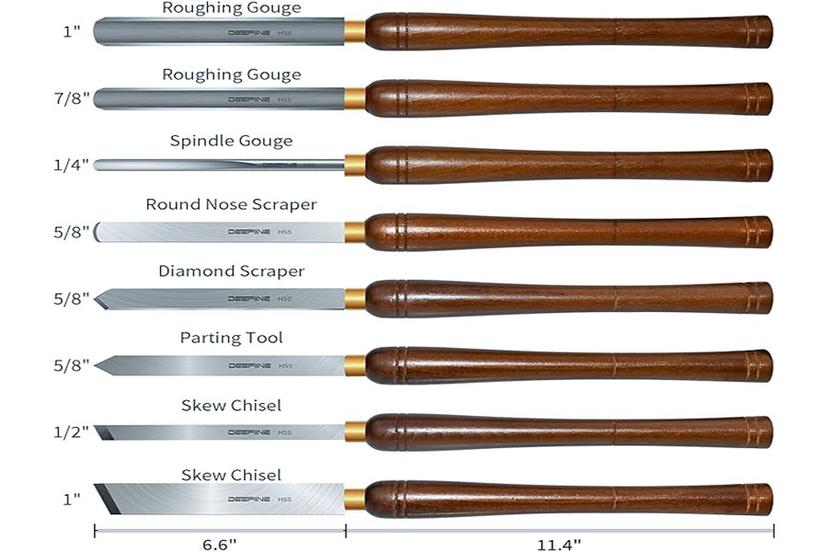

In today’s competitive landscape, sourcing quality wood lathe tools names can pose significant challenges for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, understanding which tools are essential for your operations is crucial. With a plethora of options available, from roughing gouges to bowl gouges, the key lies in recognizing the right tools for your specific woodturning needs and projects.

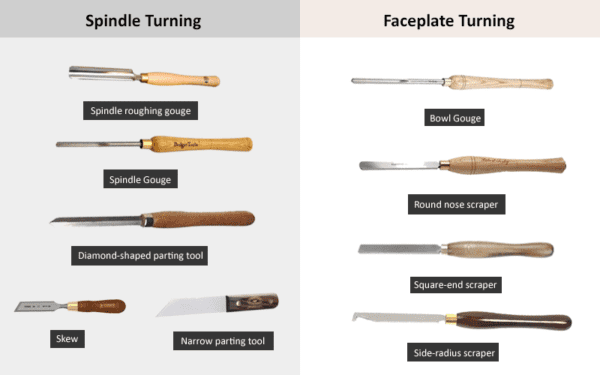

This comprehensive guide addresses the essential wood lathe tools, categorizing them based on their applications—ranging from spindle turning to faceplate turning. Insights into the specific functions of each tool will help you make informed decisions when adding to your inventory or equipping your workshop. Additionally, we emphasize critical factors such as supplier vetting processes, pricing strategies, and market trends to aid in selecting reliable partners and ensuring you receive high-quality products.

Empowering B2B buyers with actionable data, this guide will facilitate thoughtful purchasing decisions by dissecting the complexities surrounding wood lathe tools names. With a thorough understanding of the tools, their uses, and market dynamics, you can confidently navigate the global market and establish a competitive edge in your woodturning endeavors. By arming yourself with knowledge, you can ensure the success of your business and enhance the quality of your offerings.

Understanding wood lathe tools names Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Roughing Gouge | Wide “U” shaped flute for rapid stock removal | Initial shaping of larger materials | Pros: Quick material removal; Cons: Rougher finish, may require further tools for fine work. |

| Spindle Gouge | Shallow flute for detailed shaping | Creating intricate designs in spindles | Pros: Versatile for shaping and detailing; Cons: Requires skill for effective use. |

| Skew Chisel | Angled cutting edge for smooth finishes | Planing wood and creating bevels | Pros: Leaves a glassy finish; Cons: Difficult for beginners to master. |

| Parting Tool | Thin blade for separation | Final cuts and sizing projects | Pros: Essential for parting off; Cons: Limited use for rough work. |

| Bowl Gouge | Deep fluted design for interior and exterior shaping | Bowl turning and hollow forms | Pros: Versatile for various bowl sizes; Cons: Requires knowledge for optimal use. |

How Do Roughing Gouges Benefit Initial Woodturning Projects?

Roughing gouges are essential for transforming square timber into round shapes quickly. Their distinctive “U” shaped flutes allow for aggressive stock removal, making them a primary choice for initial shaping tasks. However, the finish they provide is not the finest, necessitating follow-up tools for smoothing. B2B buyers looking for efficiency in production should prioritize this tool but must be aware that it works best as a first-step tool rather than a final finishing implement.

What Makes Spindle Gouges Ideal for Detailed Woodturning Work?

Spindle gouges feature a shallow flute, optimal for creating intricate details such as beads and coves in spindle work. Their design allows for both curvature and straight cuts, making them versatile in crafting. For businesses focused on artisanal and decorative wood products, investing in quality spindle gouges can enhance design capabilities. However, they require a certain level of skill to use effectively, which buyers should consider, particularly when training new staff.

Why Are Skew Chisels Considered a Must-Have Despite Their Learning Curve?

Skew chisels are renowned for their ability to produce smooth, glassy surfaces and for their versatility in various applications, including planing and detail work. Their unique angling allows woodworkers to create sharp, precise cuts, essential for high-quality finishes. However, they can present a steep learning curve for inexperienced turners. B2B buyers should weigh the advantages of acquiring these chisels against the potential training costs for new users to maximize their effectiveness.

How Do Parting Tools Facilitate Efficient Woodworking Processes?

Parting tools, characterized by their thin blades, are pivotal in the woodturning process, particularly when it comes to separating finished pieces from excess wood. They allow for precise cuts that can be essential for high-volume production, making them a staple in any professional shop. While incredibly useful, their primary function is limited compared to other tools, which buyers should consider in the context of their broader tool inventories.

In What Ways Do Bowl Gouges Enhance Woodturning Projects?

Bowl gouges have a deep, fluted design that allows for efficient shaping of both the interior and exterior of bowls, making them the go-to tool for bowl turners. Their versatility enables users to tackle a variety of bowl sizes and styles, offering opportunities for customization in product lines. However, buyers should ensure they understand the flute shapes and sizes available, as these factors can significantly influence the gouge’s performance based on their specific project requirements.

Key Industrial Applications of wood lathe tools names

| Industry/Sector | Specific Application of wood lathe tools names | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Creating spindle legs and table bases | Durability and aesthetic value in end products | Quality of materials, precision of tools, bulk purchasing options |

| Artisan Woodworking | Producing custom decor items and sculptures | Ability to create unique, high-value products | Customization options, availability of specialty tools |

| Musical Instrument Production | Crafting wooden instrument bodies | Enhancing sound quality and craftsmanship | Material compatibility, tooling precision, supplier expertise |

| Construction and Building Supplies | Turning architectural elements like columns | Adds value to construction projects with bespoke items | Compliance with safety standards, tool durability, production capacity |

| Export and Import of Wood Products | Preparing timber for international shipments | Ensures quality and preservation of product integrity | Tool performance reliability, maintenance support, cost efficiency |

How Do Wood Lathe Tools Optimize Furniture Manufacturing?

In the furniture manufacturing sector, wood lathe tools are pivotal for creating components like spindle legs and table bases. These tools allow manufacturers to produce durable and aesthetically pleasing products, enhancing overall furniture design and durability. International buyers, particularly from regions like Europe and the Middle East, should focus on sourcing high-quality materials and precision tools that can withstand rigorous use in production lines. Moreover, bulk purchasing options can lead to significant cost savings, making a well-planned investment in lathes crucial for maintaining competitive pricing.

In What Ways Do Artisan Woodworkers Benefit from Wood Lathe Tools?

Artisan woodworking heavily relies on specialized lathe tools to produce custom decor items and sculptures, focusing on a blend of craftsmanship and creativity. The versatility of wood lathe tools enables artisans to experiment with various designs, allowing for the creation of unique, high-value products that stand out in the market. B2B buyers in this sector must consider customization options offered by suppliers and the availability of specialty tools, which can help them achieve their design ambitions. The ability to source unique tools can also differentiate their offerings in a crowded marketplace.

How Are Wood Lathe Tools Essential in Musical Instrument Production?

In the production of musical instruments, wood lathe tools are integral for crafting wooden instrument bodies, especially in achieving the precise dimensions required for optimal acoustics. By ensuring a high level of craftsmanship, these tools improve the sound quality and aesthetic appeal of the instruments. For international buyers, it is essential to evaluate material compatibility with the specific types of wood used in musical instruments and to ensure tool precision. Engaging suppliers with expertise in the music industry can provide insights into sourcing the best tools for heightened performance.

What Role Do Wood Lathe Tools Play in Construction and Building Supplies?

Wood lathe tools find significant applications in the construction industry, particularly for turning architectural elements like columns. By creating bespoke items that meet specific design needs, wood turners contribute to the added value of construction projects. Buyers in this industry should prioritize tools that comply with safety standards and demonstrate high durability under industrial conditions; therefore, thoroughly vetting suppliers for reliability and technical support is essential for long-term success.

How Do Wood Lathe Tools Enhance Export and Import of Wood Products?

When preparing timber for international shipments, wood lathe tools play a crucial role in maintaining product integrity and quality. Ensuring that wood products are properly finished and meet international standards is vital for successful exports. Buyers in this sector should consider the reliability and performance of sourcing tools, as consistent tool performance can greatly affect production efficiency. Furthermore, they should seek out suppliers who offer maintenance support and cost-effective solutions to maximize their operational efficiency in wood processing.

3 Common User Pain Points for ‘wood lathe tools names’ & Their Solutions

Scenario 1: Selecting the Right Wood Lathe Tools for Specific Projects

The Problem: B2B buyers, particularly in the woodworking sector, often face a significant challenge when attempting to identify the appropriate wood lathe tools for specific projects. With a plethora of options available in the market, the wrong choice can result in wasted material, increased costs, and inefficiencies in the production process. For instance, a manufacturer may need to create intricate decorative pieces that require fine detail, but purchasing only roughing gouges may hinder this ability, thereby affecting the overall quality and competitiveness in the market.

The Solution: To alleviate this challenge, buyers should first conduct a thorough assessment of their intended projects to understand the necessary cuts and finishes. Creating a project flowchart or a checklist can help buyers map out the tools needed for each phase of the process. Additionally, consulting with trusted suppliers who can offer expert advice on tool suitability is essential. Look for suppliers that provide tool sets specifically tailored for different types of woodturning, such as spindle or faceplate work. By investing in comprehensive sets that include spindle gouges, skew chisels, and bowl gouges, buyers can ensure they have the right tools on hand, reducing the risk of costly mistakes and improving operational efficiency.

Scenario 2: Ensuring Long-Term Quality and Durability of Wood Lathe Tools

The Problem: Many B2B buyers encounter issues with the quality and durability of wood lathe tools purchased from unreliable suppliers. Low-quality tools can quickly dull, bend, or chip, leading to poor finishes and frustrating user experiences. This becomes particularly problematic in countries with harsher conditions or lower access to quality maintenance. For businesses focused on delivering high-quality products, the continual need to replace tools can severely impact workflow and profitability.

The Solution: To combat durability issues, buyers should prioritize sourcing tools made from high-quality materials, such as M2 high-speed steel (HSS), known for retaining sharpness longer than lower-grade steel options. Additionally, consider suppliers that provide warranties or quality guarantees, as this indicates confidence in their product. Engaging in workshops or training sessions offered by manufacturers can also empower users with the knowledge on how to maintain their tools effectively, prolonging their lifespan. Encourage regular maintenance routines such as sharpening and cleaning tools after use, as installing a disciplined maintenance schedule ensures tools remain in optimal condition and reduces replacement costs.

Scenario 3: Balancing Budget Constraints While Purchasing Essential Wood Lathe Tools

The Problem: Budget constraints are a common pain point for B2B buyers, particularly in emerging markets in Africa and South America, where financial resources may be limited. Many buyers struggle with the decision between purchasing affordable, lower-quality tools and investing in more expensive, high-quality options. This decision can lead to either financial loss or poor production quality, significantly influencing a company’s long-term market position.

The Solution: A strategic approach is essential for balancing quality with budget considerations. Buyers should start by establishing a prioritized list of must-have tools based on their specific production needs. Instead of purchasing an entire inventory of tools at once, focusing on acquiring essential tools first and gradually expanding the collection can be effective. Suppliers that offer rental programs or trial periods can allow buyers to test quality without committing to a purchase upfront. Further, exploring bulk purchasing or referral programs may provide discounts, helping businesses maximize their investment while ensuring they have the necessary tools to maintain high production standards. Additionally, educating the workforce on the importance of careful tool handling can reduce damage, extending the life of purchased items and offering better return on investment.

Strategic Material Selection Guide for wood lathe tools names

What Materials Are Commonly Used in Wood Lathe Tools?

When choosing wood lathe tools, the selection of materials significantly influences performance, durability, and cost-efficiency. Understanding the advantages and limitations of these materials aids international B2B buyers in selecting the right tools for their specific applications. Below, we explore three common materials used in wood lathe tools: High-Speed Steel (HSS), Carbon Steel, and Cobalt Steel.

How Does High-Speed Steel (HSS) Enhance Tool Performance?

High-Speed Steel (HSS) is a popular choice for wood lathe tools due to its excellent hardness, wear resistance, and ability to withstand high temperatures without losing its edge. HSS tools can easily handle the high speeds typically used in woodturning, making them a top choice among professionals.

Pros: HSS tools maintain sharpness longer, minimizing maintenance and allowing for prolonged working times. They are also relatively easy to sharpen, a significant advantage for users who emphasize efficiency.

Cons: On the downside, HSS tools can be more expensive than their carbon steel counterparts. Additionally, they may be less durable when subjected to specific conditions such as high-impact scenarios.

For B2B buyers, particularly in regions like Europe and the Middle East, sourcing HSS tools that comply with the relevant international standards (e.g., DIN or ASTM) is crucial. Buyers should ensure that tools come with certifications verifying their properties, particularly the HSS grade.

What Are the Benefits and Drawbacks of Carbon Steel in Wood Lathe Tools?

Carbon Steel is another prominent material used for manufacturing wood lathe tools. It comprises an alloy of steel with a higher carbon content, which enhances hardness.

Pros: The primary advantage of carbon steel tools is their cost-effectiveness. They are generally cheaper to produce and purchase compared to HSS. Additionally, they offer good cutting capabilities for a variety of woodworking projects.

Cons: Carbon steel tools require more frequent sharpening, which can lead to increased downtime. They are also more susceptible to rust and corrosion if not properly maintained, especially in humid environments.

B2B buyers from regions such as South America and Africa should pay particular attention to corrosion resistance features, especially considering the local environmental conditions. Buyers would benefit from checking for protective coatings or treatments that extend the tool’s lifespan.

How Does Cobalt Steel Compare as a Material for Wood Lathe Tools?

Cobalt Steel tools are an advanced type of HSS, typically enriched with cobalt to enhance hardness and high-temperature performance.

Pros: Cobalt tools tend to be more resistant to wear than standard HSS tools, making them suitable for more demanding applications. They also maintain their sharpness and edge geometries longer under high-speed usage.

Cons: The cost of cobalt steel is generally higher than both HSS and carbon steel, which can be a deciding factor for budget-conscious buyers. Additionally, specific techniques in sharpening might be required to maintain their edges effectively.

For international B2B buyers, especially in regions with stringent manufacturing regulations like Germany, it’s essential to verify compliance with quality and safety standards associated with cobalt tools. Certification of material composition and performance standards (such as JIS standards) is crucial.

Overview of Material Choices for Wood Lathe Tools

Based on the preceding analysis, here is a concise overview in table format that can aid B2B buyers in making informed decisions regarding material selection in wood lathe tools:

| Material | Typical Use Case for wood lathe tools names | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Speed Steel (HSS) | General woodturning, detail work | Superb edge retention and heat resistance | Higher cost, less durable under impact | High |

| Carbon Steel | Entry-level projects, basic woodturning | Cost-effective and good for beginners | Requires frequent sharpening, rust-prone | Low |

| Cobalt Steel | High-performance applications, professional use | Enhanced wear resistance and longevity | Higher purchase cost, complex sharpening | Medium |

In summary, the selection of material for wood lathe tools has significant implications for performance and cost-effectiveness. By understanding the properties and applications of HSS, carbon steel, and cobalt steel, international B2B buyers can make more informed purchasing decisions tailored to their specific needs and operational standards.

In-depth Look: Manufacturing Processes and Quality Assurance for wood lathe tools names

To ensure the highest quality and reliability of wood lathe tools, the manufacturing processes involved are critical. Buyers, particularly those in diverse markets across Africa, South America, the Middle East, and Europe, must gain insight into these production processes and the quality assurance protocols that accompany them.

What Are the Key Stages in Manufacturing Wood Lathe Tools?

Material Preparation:

The foundation of quality wood lathe tools begins with selecting high-grade materials. Steel often used in manufacturing lathe tools includes M2 High-Speed Steel (HSS) or carbon steel, chosen for their durability and resistance to wear. Materials undergo initial checks to ensure they meet specified chemical and physical properties. The thickness and length are measured, allowing manufacturers to develop tools that meet specific requirements.

Forming Techniques:

Forming the tools usually involves forging, casting, or machining. Forging, a common practice, enhances the structural integrity of the steel through controlled deformation under heat and pressure. This process aligns the grain structure and improves toughness. After forging, tools undergo machining to achieve precise dimensions, which is vital for ensuring accurate and efficient cuts during woodturning. Techniques like CNC milling may be employed for greater accuracy, especially for complex shapes found in specialty tools.

Assembly Process:

While many wood lathe tools are singular units, some may require assembly. Tools with interchangeable parts or those that combine multiple components (like handles with blades) undergo assembly, ensuring that each part fits seamlessly together. Quality checks are performed at this stage to ensure that all components are correctly aligned and functioning as intended.

Finishing Techniques:

The finishing process can significantly influence the performance and longevity of lathe tools. Common techniques include heat treatment to enhance hardness and edge retention, as well as grinding and polishing to achieve a sharp edge and smooth surface. A protective coating may also be applied to prevent rust and corrosion, particularly for tools intended for humid climates.

How Is Quality Assurance Implemented in Wood Lathe Tool Production?

What International Standards Should B2B Buyers Be Aware Of?

ISO 9001 Certification:

This internationally recognized standard sets the framework for an effective quality management system (QMS). Manufacturers with ISO 9001 certification demonstrate their commitment to quality assurance through systematic processes that ensure continual improvement in production. B2B buyers can request proof of certification to verify adherence to quality practices.

CE Certification:

The CE marking indicates that products comply with EU safety, health, and environmental protection standards. For buyers in Europe, ensuring that suppliers provide CE certification for their wood lathe tools is vital for market access and compliance with regulatory requirements.

Specific Industry Certifications:

Manufacturers may also seek compliance with other industry-specific standards. For instance, the American Petroleum Institute (API) certification may be relevant for tools designed for specific industrial applications. Buyers should inquire about these certifications, as they ensure adherence to the rigorous quality controls required for specialized projects.

What Are the QC Checkpoints During the Manufacturing Process?

Incoming Quality Control (IQC):

IQC serves as the first checkpoint in the quality assurance pipeline. Raw materials and components are inspected upon arrival to verify that they meet predefined specifications, including dimensions and material properties. This step reduces the likelihood of defects passed into subsequent production stages.

In-Process Quality Control (IPQC):

During the manufacturing process, IPQC monitors ongoing operations to catch defects early. Techniques include visual inspections, measurement checks, and functional tests at various stages. IPQC helps minimize rework and waste by addressing any issues promptly while maintaining efficiency.

Final Quality Control (FQC):

FQC is the final checkpoint before tools are packaged and shipped. Comprehensive testing is performed to ensure that each tool meets operational specifications, including hardness tests, edge sharpness tests, and performance evaluations. Only products that pass these tests are cleared for shipment.

How Can B2B Buyers Verify Supplier Quality Control?

Conducting Audits:

B2B buyers should consider conducting onsite audits of potential suppliers. This process allows for a firsthand assessment of the manufacturer’s facilities, production processes, quality checks, and compliance with relevant standards. Expecting transparency during audits can significantly enhance mutual trust and establish reliable partnerships.

Requesting Quality Reports:

Buyers should request detailed quality reports that outline the QC processes implemented by the manufacturer. Reports highlighting IQC, IPQC, and FQC activities provide insights into the tools’ production quality and the manufacturer’s commitment to excellence. Analyzing these documents can help in making informed purchasing decisions.

Third-Party Inspections:

Engaging third-party agencies for validation can further ensure that the products meet quality standards. Independent inspections can be conducted during or after production, providing an unbiased view of the products. Buyers are encouraged to collaborate with these agencies to facilitate quality assurance, especially in foreign markets where local regulations may differ.

What Quality Control Nuances Should International Buyers Consider?

Buyers from different regions must be aware of the varying quality standards and practices. It is essential for them to communicate specific requirements clearly, as standards may differ significantly from one country to another. For example, manufacturers in Europe may prioritize stringent environmental standards, while those in other regions may focus more heavily on cost efficiency.

Understanding local compliance requirements for end markets is equally crucial. Buyers should ensure that the tools not only meet critical standards for their local jurisdiction but also align with the expectations of their customers. In regions like Africa and South America, where quality tooling can dramatically impact production processes, emphasizing robust quality assurance becomes imperative.

Conclusion

The manufacturing and quality assurance processes for wood lathe tools are fundamental for meeting the needs of global B2B buyers. Understanding these processes enables buyers to make informed decisions, ensuring they procure tools that uphold quality and reliability. By actively engaging with suppliers, verifying certifications, and utilizing third-party audits, buyers can secure a competitive edge in the woodworking industry and contribute to their overall success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wood lathe tools names’

When sourcing wood lathe tools, it is essential to follow a structured checklist to ensure you’re making informed purchasing decisions. This guide will help you navigate the process effectively, focusing on key steps to acquire quality tools that meet your operational needs.

Step 1: Identify Your Specific Needs

Before engaging with suppliers, clearly define the types of wood lathe tools required for your operations. Consider the specific projects you will undertake, such as spindle or faceplate turning, as different tools are suited for different applications. Tools to consider include roughing gouges, skew chisels, and bowl gouges, depending on your production goals.

Step 2: Research Quality Standards

Investigate the quality standards of the tools you wish to purchase. Ensure they are fabricated from high-quality materials such as M2 HSS steel, which maintains sharpness longer and provides better durability than lower-grade materials. This not only affects tool performance but also impacts the longevity of the tools, ensuring cost-effectiveness.

Step 3: Evaluate Supplier Certifications

It’s vital to verify that potential suppliers are recognized and certified within the industry. Look for certifications such as ISO 9001 that indicate a commitment to quality management and consistent performance. Established credentials can provide peace of mind regarding the reliability and safety of the tools you procure.

Step 4: Consider Supplier Location

When sourcing tools from international suppliers, assess the geographical location and its implications on shipping times and costs. Local suppliers may offer quicker delivery and lower shipping costs, while international suppliers might provide a wider range of specialized tools. Understanding the logistics involved will help you make a more efficient purchasing decision.

Step 5: Request Product Samples

Before making large purchases, insist on receiving samples of the wood lathe tools. Testing these samples can help ascertain their quality, ergonomics, and compatibility with your existing equipment. This step allows you to evaluate whether the tools meet your practical needs and aligns with your workers’ skill levels.

Step 6: Compare Pricing and Payment Terms

Gather price quotes from multiple suppliers to ensure competitive pricing. Consider the total cost of ownership, which includes not only the initial purchase price but also potential maintenance and sharpening costs. Equally important are the payment terms; flexible options can improve cash flow and minimize financial pressure during procurement.

Step 7: Read Customer Reviews and Testimonials

Finally, before finalizing your decision, look for reviews and testimonials from other buyers in similar industries. These insights can provide valuable information regarding the tool’s performance and the supplier’s customer service. Understanding the experiences of other buyers can help you gauge reliability and effectiveness in real-world applications.

By following this comprehensive sourcing checklist, you can ensure that your procurement process for wood lathe tools is efficient, informed, and aligned with your business objectives.

Comprehensive Cost and Pricing Analysis for wood lathe tools names Sourcing

In the field of woodturning, understanding the cost structure and pricing for lathe tools is essential for B2B buyers aiming to make informed decisions. This analysis outlines the components influencing costs, the factors that sway pricing, and strategic tips for buyers primarily from Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia.

What Are the Key Cost Components for Wood Lathe Tools?

Pricing for wood lathe tools is built upon several core cost components:

-

Materials: The type of steel used, particularly high-speed steel (HSS) versus carbon steel, significantly impacts the cost. M2 HSS, known for its longevity and cutting efficiency, typically results in higher prices but offers a better return on investment due to the reduced need for frequent sharpening.

-

Labor: The expertise of the workforce in manufacturing and finishing the tools plays a role. Skilled labor is necessary to achieve the precision required in tool grinding and assembly. This cost can vary widely depending on regional wage standards.

-

Manufacturing Overhead: This includes expenses associated with the operational facility, equipment depreciation, utilities, and administrative costs. Manufacturers in regions with lower operational costs may offer more competitive pricing.

-

Tooling and QC (Quality Control): Investments in high-quality tooling and rigorous QC procedures ensure that the tools meet industry standards. However, this can add to the final cost, particularly for brands that emphasize quality assurance.

-

Logistics: Transportation costs, customs duties, and taxes can considerably affect the cost of tools imported from other regions. Incoterms such as CIF (Cost, Insurance, and Freight) or FOB (Free on Board) influence who bears these costs.

-

Margin: Finally, manufacturers apply a profit margin that can fluctuate based on market competition, brand reputation, and perceived product value.

How Do Various Price Influencers Impact Purchasing Decisions?

Several factors can significantly influence pricing in the wood lathe tools market:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often secures lower costs per unit, making it an advantageous option for companies looking to stock inventories.

-

Specifications and Customization: Tools tailored to specific needs or with unique specifications typically cost more due to the additional engineering and manufacturing processes involved.

-

Quality and Certifications: Tools that meet international standards or possess certifications (e.g., ISO) may justify a higher price due to their assured reliability and performance.

-

Supplier Reputation and Location: Established suppliers with a track record of quality may charge a premium. Additionally, sourcing tools from well-regarded manufacturing hubs can mitigate risks associated with quality discrepancies.

What Negotiation Strategies Can Buyers Use to Enhance Cost Efficiency?

International B2B buyers should adopt several strategies during negotiations to optimize cost-efficiency:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term maintenance, longevity, and potential productivity gains from high-quality tools. This broader perspective can justify higher initial costs.

-

Demand Transparency in Pricing: Request detailed breakdowns of pricing structures from suppliers to identify and negotiate specific cost components.

-

Leverage Relationships: Build strong partnerships with suppliers over time. This can lead to better pricing, priority service, and favorable terms for future orders.

-

Be Aware of Currency Fluctuations: Particularly for buyers dealing internationally, keep track of exchange rates and consider negotiating contracts in stable currencies to minimize financial risks.

-

Inquire about Incentives: Ask suppliers if they offer discounts for early payments, repeat orders, or referrals, as these can substantially decrease overall costs.

Conclusion: Why Is This Analysis Important for International Buyers?

Understanding the comprehensive cost and pricing analysis for wood lathe tools empowers international buyers to make sound decisions when sourcing products. By interpreting cost components, recognizing price influencers, and employing strategic negotiation tactics tailored for international transactions, buyers can enhance their sourcing efficiency while ensuring high-quality purchases for their woodturning projects.

Disclaimer: Prices and costs mentioned in this analysis are indicative and may vary based on specific supplier agreements, regional economic conditions, and market fluctuations. Always conduct due diligence when negotiating prices.

Alternatives Analysis: Comparing wood lathe tools names With Other Solutions

Understanding Alternatives to Wood Lathe Tools Names for Woodworking Solutions

When considering the best tools for woodturning, it is essential for B2B buyers to explore a range of solutions beyond standard wood lathe tools. Alternatives may offer distinct advantages tailored to specific project requirements or operational contexts. Below is a comparative analysis of traditional wood lathe tools against CNC (Computer Numerical Control) machining and hand carving techniques.

| Comparison Aspect | Wood Lathe Tools Names | CNC Machining | Hand Carving |

|---|---|---|---|

| Performance | High precision for turning cylindrical shapes | Exceptional precision and complexity | Limited precision, but artistic freedom |

| Cost | Moderate, depending on tool quality | High initial investment, but lower long-term costs | Low cost depending on materials |

| Ease of Implementation | Requires skill, trades know-how | Requires programming knowledge | Skill-intensive, craftsmanship needed |

| Maintenance | Moderate; requires regular sharpening and care | Low; maintenance of software and hardware | High; tools need regular upkeep |

| Best Use Case | Spindle and faceplate turning projects | Complex shapes and high-volume production | Artisanal, bespoke creations |

What Are the Advantages of CNC Machining Compared to Wood Lathe Tools?

CNC machining stands out for its unparalleled precision and ability to handle complex shapes and intricate designs with minimal manual intervention. This technology allows businesses to automate woodcutting, reducing labor costs and time. However, the initial investment can be quite high, making it less accessible for smaller operations. Additionally, CNC machines require programming skills, which could necessitate further training for staff.

How Does Hand Carving Compare to Traditional Wood Lathe Tools?

Hand carving offers a unique appeal for artisans who prioritize craftsmanship and originality. This method allows for a high level of artistic expression, making it suitable for bespoke creations. The cost of hand carving tools can be relatively low, but the process demands significant skill and time. For projects where uniqueness and artistry are paramount, hand carving may provide advantages over wood lathe tools. Conversely, it may not be feasible for high-volume production due to variable consistency in outcomes.

Making the Right Choice for Your Business Needs

B2B buyers should carefully assess their specific needs when selecting woodturning solutions. If precision and complex production are primary goals, CNC machining can provide a high return on investment despite upfront costs. For businesses focused on delivering unique, handcrafted pieces, investing in skilled artisans and hand carving may align with their brand ethos. Alternatively, traditional wood lathe tools represent a versatile approach suitable for a variety of projects, especially in workshops emphasizing skillful craftsmanship without overwhelming capital expenses.

By evaluating these alternatives—wood lathe tools, CNC machining, and hand carving—buyers can make informed decisions that fit their operational model, budget constraints, and desired outcomes, ultimately ensuring that they choose the most effective woodworking solution for their circumstances.

Essential Technical Properties and Trade Terminology for wood lathe tools names

What Are the Key Technical Specifications for Wood Lathe Tools?

Understanding the critical specifications of wood lathe tools is essential for B2B buyers looking to optimize their purchasing decisions. Here are several key specs that should be considered:

-

Material Grade

Most wood lathe tools are made from high-speed steel (HSS) or carbide-tipped materials. HSS tools offer excellent edge retention and can withstand high temperatures, making them ideal for various wood types. Carbide-tipped tools, while typically more expensive, maintain their sharpness longer and require less frequent sharpening. B2B buyers should prioritize these materials based on their intended projects and production frequencies. -

Flute Shape and Depth

The flute refers to the groove that runs along the length of the tool and is critical for efficient wood removal. Common shapes include ‘U’ and ‘V’ flutes, with volume affecting chip clearance and finish quality. Tools with deeper flutes tend to remove more material quickly but might leave a rougher finish, while shallow flute options allow for finer cuts. Understanding flute characteristics helps businesses select the right tool for specific tasks, enhancing both productivity and product quality. -

Tool Length and Diameter

The length and diameter of turning tools influence their flexibility and stability during operation. Longer tools are better for deeper cuts while shorter ones provide better control for detailed work. Diameter impacts the amount of wood that can be removed in one pass. B2B buyers should evaluate their workspace and the types of projects they handle to choose appropriately sized tools for optimal efficiency. -

Taper and Edge Design

The taper of the tool affects how it interacts with the wood. A well-designed edge allows for smoother operations and reduces the risk of catches or pulls, which can compromise safety. Different edge designs cater to distinct operations, such as roughing or detailing. It’s vital for purchasing decisions to consider how different tapers and edge designs can impact productivity and safety in the workplace. -

Weight and Balance

The weight and balance of wood lathe tools play a significant role in user control and accuracy. Heavier tools can be more stable, allowing for smoother cuts, while lighter tools offer greater maneuverability. Buyers should consider the type of woodwork being performed and the skill level of the operators, as this can determine the most suited tool in terms of weight and balance.

What Common Trade Terms Should B2B Buyers Know for Wood Lathe Tools?

Familiarity with industry-specific jargon can enhance communication and negotiation in the B2B environment. Here are several terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer under its brand name. Understanding OEM specifications ensures that buyers seek quality products compatible with existing machinery. -

MOQ (Minimum Order Quantity)

MOQ signifies the smallest amount of a product that a supplier is willing to sell. It helps buyers understand the scale of their purchases. Buyers should negotiate MOQs to align with their production needs without excessive stockpiling. -

RFQ (Request for Quotation)

An RFQ is a document that solicits a suppliers’ pricing for specific products or services. It is an essential part of the procurement process that allows buyers to compare offers and make informed purchasing decisions. -

Lead Time

This indicates the total time it takes from placing an order to receiving the goods. Lead time can directly affect inventory management and production schedules, making it a crucial factor for B2B buyers. -

Incoterms (International Commercial Terms)

These standardized trade terms define the responsibilities of buyers and sellers involved in international shipping. Familiarity with Incoterms helps buyers understand shipping costs, insurance, and the transfer of risk during transportation. -

Certifications

Certifications like ISO or CE mark indicate that a product meets certain safety and quality standards. This can be particularly important when sourcing tools for export markets or adhering to local regulations. Buyers should not only seek certified products to ensure quality but also to enhance their own credibility in international markets.

Understanding these specifications and terms allows B2B buyers in wood lathe tools to make informed purchasing decisions, aligning their tools with operational needs and market requirements.

Navigating Market Dynamics and Sourcing Trends in the wood lathe tools names Sector

Understanding Market Dynamics for Wood Lathe Tools: What Should International Buyers Know?

The global market for wood lathe tools is currently influenced by a myriad of factors that shape sourcing strategies and procurement decisions. Significant drivers include a growing interest in artisanal woodworking and DIY projects, particularly in regions like Africa and South America where traditional crafts are making a resurgence. The increasing adoption of advanced manufacturing technologies, such as CNC lathes and digital designs, is transforming conventional woodturning into a more precise and efficient process. Additionally, heightened demand for custom and bespoke furniture is driving the rise in the production of specialty woodturning tools.

Emerging trends are geared toward the integration of smart technologies in tool production and usage. International buyers are increasingly seeking suppliers who offer enhanced product tracking and advanced customization options. Sustainability is also playing a crucial role in purchasing decisions, with a notable shift toward tools made from responsibly sourced materials. B2B procurement in Europe, especially in countries like Germany, emphasizes compliance with stringent quality standards and guidelines, pushing manufacturers to refine their processes. Trading platforms and online marketplaces increasingly facilitate global B2B transactions, making it easier for buyers from diverse regions to access innovative wood lathe tools.

How Can Businesses Ensure Sustainability and Ethical Sourcing for Wood Lathe Tools?

Sustainability and ethical sourcing are paramount in today’s wood lathe tools market. The environmental impact of raw materials and production processes is under scrutiny, urging manufacturers to adopt eco-friendly practices. This includes sourcing wood from certified sustainable forests and using non-toxic finishes and adhesives in tool production. As buyers become more environmentally conscious, they prioritize companies that demonstrate a commitment to sustainability through transparency and responsible sourcing.

To this end, partners should look for certifications such as the Forest Stewardship Council (FSC) and the Sustainable Forestry Initiative (SFI), which validate adherence to sustainability standards. Furthermore, eco-friendly materials not only appeal to environmentally conscious consumers but also help businesses distinguish themselves in a competitive market. Utilizing materials like responsibly sourced hardwoods or high-speed steel (HSS) promotes longevity and reduces waste, aligning procurement strategies with a growing global trend towards sustainability. As international regulations on environmental impacts become stricter, ensuring that all components of the supply chain adhere to ethical practices is not just prudent; it is essential for long-term viability.

What is the Historical Context Behind Wood Lathe Tools and Their Evolution?

Wood lathe tools have a rich history that dates back to ancient times, where simple, hand-powered lathes were invented to shape wooden blocks into rounded forms. Initially, the tools were basic, largely comprising chisels and gouges. Over centuries, their design evolved with the advent of the Industrial Revolution, introducing steam-powered lathes and later, electric and CNC models that revolutionized woodturning.

In the modern era, advancements in materials science have influenced the construction of lathe tools. High-speed steel and carbide-tipped tools are now standard, offering greater durability and sharper edges compared to traditional carbon steel. This evolution has made woodturning more accessible and encouraged a new generation of woodworkers. As international markets thrive on tradition infused with innovation, those sourcing wood lathe tools can benefit from understanding this historical context, as it aids in recognizing the quality and craftsmanship disparities in various products worldwide.

Conclusion

Navigating the landscape of wood lathe tools requires a keen understanding of market trends, sustainability practices, and historical context. For international buyers from diverse regions, particularly in Africa, South America, the Middle East, and Europe, these insights can significantly influence sourcing decisions and supplier partnerships. Focusing on ethical practices and technological advancements prepares businesses for the future while meeting increasing consumer demands for quality and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of wood lathe tools names

-

How can I determine the right wood lathe tools for my business needs?

To identify the appropriate wood lathe tools for your business, assess the types of projects you plan to undertake. Consider whether you’ll be focusing on spindle turning or faceplate turning, as this will dictate the essential tools required, such as roughing gouges, skew chisels, or bowl gouges. Additionally, consult with suppliers about their tool offerings and seek recommendations based on your intended applications to ensure you select high-quality, durable tools optimized for performance. -

What wood lathe tool names should I focus on for a beginner woodturning setup?

For a beginner woodturning setup, prioritize the following tools: roughing gouge, spindle gouge, skew chisel, parting tool, bowl gouge, and scraper. These tools cover the essential functions of shaping, finishing, and detailing your projects, including creating items like pens and bowls. Starting with these tools will provide a comprehensive foundation, allowing you to expand your collection as your skills improve and your project range grows. -

What are the key factors to consider when sourcing wood lathe tools from international suppliers?

Key factors to consider when sourcing wood lathe tools internationally include the supplier’s reputation, product quality, compliance with safety standards, and availability of various tool sizes and types. Investigate customer reviews and testimonials and ensure they offer reliable after-sales support. Additionally, assess their shipping policies, delivery times, and import/export regulations in your country, particularly in regions like Africa and South America. -

How do I verify the quality of wood lathe tools before purchase?

To verify the quality of wood lathe tools before purchase, request product samples or detailed specifications from suppliers, including material types, construction details, and manufacturing processes. Look for tools made from high-speed steel (HSS) or carbide for longevity. Comparing reviews and ratings from other buyers can provide valuable insights regarding durability and performance. It’s also beneficial to check if the supplier offers warranties or guarantees that indicate confidence in their product quality. -

What is the minimum order quantity (MOQ) for wood lathe tools?

Minimum order quantities (MOQs) for wood lathe tools can vary significantly among suppliers. Generally, MOQs may range from a single item to several dozen, depending on the manufacturer and product type. When negotiating with suppliers, inquire about flexible purchasing options to align with your business needs, especially if you are a small-scale operation or entering a new market. Establishing a good relationship with suppliers can sometimes allow for lower MOQs. -

What payment terms should I expect when sourcing wood lathe tools internationally?

Payment terms when sourcing wood lathe tools internationally often depend on the supplier’s policies and the nature of the order. Standard terms may include a partial deposit upfront, with the balance due upon delivery or prior to shipping. Some suppliers may offer full payment before production as a condition for custom orders. It’s crucial to agree on clear payment terms in your contract to avoid misunderstandings and ensure a smooth transaction process. -

How can I ensure timely delivery of my wood lathe tools?

To ensure timely delivery of your wood lathe tools, communicate clearly with your supplier regarding delivery expectations, lead times, and any potential delays due to customs processes. Opt for reliable shipping methods with tracking capabilities and inquire about the logistics options available for your region. Establishing a good working relationship with suppliers and logistics partners can facilitate smoother communication and enhance your overall delivery experience. -

What quality assurance measures should I prioritize when sourcing wood lathe tools?

When sourcing wood lathe tools, prioritize suppliers that adhere to rigorous quality assurance practices. Look for certifications indicating compliance with international standards, such as ISO 9001. Request documentation or reports that showcase quality control processes, including inspections and testing for durability and performance. Regular audits or evaluations of a supplier’s production capabilities can further ensure that the tools meet your quality expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Wood Lathe Tools Names Manufacturers & Suppliers List

1. Carter & Son Toolworks – Essential Lathe Tools

Domain: carterandsontoolworks.com

Registered: 2013 (12 years)

Introduction: 1. Roughing Gouge: 7/8″, first step for turning a piece round, quickly removes stock, not for finishing. 2. Spindle Gouge: 1/2″, shapes spindle work and creates details, shallow flute, great for coves and beads. 3. Skew Chisel: 1/2″, versatile for planing and smooth surfaces, difficult to master. 4. Parting Tool: 1/8″, used for separating work from unwanted material with a plunge cut. 5. Bowl Goug…

2. The Woodturning Store – Wood Turning Tools

Domain: thewoodturningstore.com

Registered: 2012 (13 years)

Introduction: Buy Wood Turning Tools with Fast Shipping | The Woodturning Store. Categories include HOT DEALS, POWER TOOLS, WOODTURNING TOOLS, CHUCKS AND JAWS, PEN MAKING, PROJECTS, BLANKS, LATHE ACCESSORIES, SHARPENING SUPPLIES, ABRASIVES, SHOP SUPPLIES, WOODCARVING TOOLS. Specific tools include traditional tools such as bowl gouges, parting tools, scrapers, skew chisels, spindle gouges, and more. Brands featu…

3. Taytools – Hand Tools & Accessories

Domain: taytools.com

Registered: 2014 (11 years)

Introduction: Turning Hand Tools, Chucks & Jaws, Drive & Centers, Sharpening, Pen Turning Accessories

Strategic Sourcing Conclusion and Outlook for wood lathe tools names

As the global demand for wood lathe tools continues to rise, international B2B buyers must prioritize strategic sourcing to ensure they access quality products that meet their operational needs. Key insights suggest that understanding the diverse range of wood lathe tools—from spindle gouges and roughing gouges to scrapers and bowl gouges—is essential for fostering well-informed purchasing decisions. High-quality materials such as M2 HSS steel can enhance tool longevity, reducing maintenance costs and downtime.

Investing in a complete set of core tools tailored for specific projects not only eases the transition into woodturning but also optimizes production efficiency. Buyers in emerging markets across Africa and South America, alongside established firms in Europe and the Middle East, are encouraged to collaborate with reputable suppliers who can ensure both product reliability and timely delivery.

Looking ahead, the woodturning industry is poised for growth, with increasing potential for innovation and sustainability. By embracing strategic sourcing practices and fostering partnerships with trusted tool manufacturers, buyers can position themselves at the forefront of this evolving market. Consider exploring new suppliers today to enhance your competitive edge in woodturning capabilities.