Introduction: Navigating the Global Market for wood cnc machine 5 axis

Navigating the complexities of the global market for wood CNC machines, particularly 5-axis models, presents a significant challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe seek to enhance their production capabilities, sourcing reliable and efficient 5-axis CNC machines becomes crucial. These advanced machines offer unparalleled flexibility and precision, enabling businesses to tackle intricate designs and complex machining tasks that traditional models cannot accommodate.

This comprehensive guide delves into various aspects of the wood CNC machine 5-axis market. From understanding the different types of machines available and their specific applications—ranging from cabinetry to intricate wood sculptures—to assessing supplier credibility and pricing structures, this resource equips buyers with the knowledge needed for informed purchasing decisions.

Moreover, the guide addresses common concerns such as maintenance, training, and support, ensuring that buyers not only choose the right machine but also maximize their investment through effective utilization. By empowering B2B buyers with actionable insights and practical information, this guide serves as an essential tool for those looking to thrive in a competitive landscape, ultimately leading to enhanced productivity and profitability in their operations.

Understanding wood cnc machine 5 axis Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Articulating Arm CNC | Features a multi-axis articulating arm for complex geometries. | Furniture design, intricate carvings | Pros: High precision; great for detailed work. Cons: Higher initial investment; requires skilled operators. |

| Fixed Gantry CNC | Sturdy frame with a fixed table; ideal for heavy materials. | Cabinet making, architectural elements | Pros: Stability; excellent for large pieces. Cons: Limited mobility; may require larger workspace. |

| Rotary Axis CNC | Incorporates a rotary axis for cylindrical and curved profiles. | Sign making, custom woodworking | Pros: Versatile; can produce complex shapes. Cons: More complex setup; potential learning curve. |

| Hybrid CNC | Combines CNC machining with laser cutting capabilities. | Prototyping, small-scale production | Pros: Multi-functionality; reduces need for multiple machines. Cons: Higher maintenance; can be costly. |

| Pod & Rail CNC | Features modular design for quick tool changes and flexible setups. | Mass production, repetitive tasks | Pros: Efficient for high-volume jobs; customizable. Cons: Initial setup time; may require additional training. |

What are the Characteristics of Articulating Arm CNC Machines?

Articulating arm CNC machines are designed to handle intricate designs that require high levels of precision. The unique feature of a multi-axis articulating arm allows for complex geometries to be machined, making it ideal for detailed woodworking projects such as furniture design and intricate carvings. For B2B buyers, the investment can be significant, but the ability to produce high-quality, detailed work can lead to increased customer satisfaction and competitive advantage.

How Do Fixed Gantry CNC Machines Stand Out?

Fixed gantry CNC machines are characterized by their robust construction and stability, often featuring a fixed table that supports heavy materials. This design is particularly beneficial for applications like cabinet making and architectural elements, where precision and durability are paramount. Buyers should consider the spatial requirements and the potential need for larger workspaces, as well as the capability to handle substantial workloads.

What Advantages Do Rotary Axis CNC Machines Offer?

Rotary axis CNC machines include an additional axis that allows for machining cylindrical and curved profiles, making them particularly useful in sign making and custom woodworking. Their versatility enables manufacturers to create complex shapes that would be challenging with standard 3-axis machines. While they can increase production capabilities, buyers should be prepared for a more complex setup and possible learning curves associated with their operation.

Why Choose Hybrid CNC Machines?

Hybrid CNC machines combine traditional CNC machining with laser cutting capabilities, offering a multifunctional solution for businesses involved in prototyping or small-scale production. This combination allows for greater flexibility in manufacturing processes, as it reduces the need for multiple machines. However, buyers should weigh the benefits of versatility against potential higher maintenance costs and the complexity of managing dual technologies.

What Makes Pod & Rail CNC Machines Efficient?

Pod & rail CNC machines are designed for high-volume production with a modular setup that allows for quick tool changes. This flexibility makes them ideal for repetitive tasks in mass production environments. B2B buyers can benefit from the efficiency and customization options these machines offer, but should consider the initial setup time and necessary training for their teams to fully leverage the technology.

Key Industrial Applications of wood cnc machine 5 axis

| Industry/Sector | Specific Application of wood cnc machine 5 axis | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Custom furniture design and production | Enhanced design flexibility and reduced lead times | Consider machine size, tooling options, and software compatibility. |

| Cabinet Making | Precision cabinetry with intricate joinery | Improved accuracy and reduced material waste | Evaluate support services and availability of spare parts. |

| Signage and Display | Production of complex signage and display fixtures | High-quality finishes and intricate designs | Assess the machine’s capability for different materials. |

| Musical Instrument Fabrication | Crafting high-quality wooden instruments | Consistent quality and intricate detailing | Ensure machine can handle specific wood types and thicknesses. |

| Architectural Models | Creation of detailed architectural models | Realistic representations and faster prototyping | Look for compatibility with CAD software and training support. |

How is the 5-Axis CNC Machine Used in Furniture Manufacturing?

In the furniture manufacturing sector, a 5-axis CNC machine allows for the creation of custom designs with intricate details that would be challenging to achieve manually. This capability not only enhances aesthetic appeal but also reduces production lead times significantly. B2B buyers in this sector should consider the machine’s ability to handle various wood types and its compatibility with design software to ensure seamless integration into existing workflows.

What Role Does the 5-Axis CNC Machine Play in Cabinet Making?

Cabinet makers utilize 5-axis CNC machines to produce precision cabinetry featuring complex joinery. The machines offer enhanced accuracy, which minimizes material waste and allows for the production of high-quality, durable products. Buyers should prioritize sourcing machines that provide robust support services and easy access to spare parts, especially in regions with limited technical support infrastructure.

How is the 5-Axis CNC Machine Beneficial for Signage and Display?

In the signage and display industry, the 5-axis CNC machine is invaluable for creating complex signage and display fixtures with high-quality finishes. This technology enables businesses to offer customized solutions that can attract customers and enhance brand visibility. Key considerations for sourcing include assessing the machine’s versatility to work with different materials, such as acrylic and wood, to meet diverse client needs.

Why is the 5-Axis CNC Machine Important for Musical Instrument Fabrication?

Musical instrument manufacturers leverage 5-axis CNC machines to craft high-quality wooden instruments that require intricate detailing and consistent quality. The precision offered by these machines ensures that sound quality and aesthetics are maintained. Buyers in this sector should ensure that the machines can accommodate specific wood types and thicknesses to align with their production requirements.

How Does the 5-Axis CNC Machine Support Architectural Model Creation?

Architects and designers use 5-axis CNC machines to create detailed architectural models that serve as realistic representations of their projects. This capability accelerates the prototyping process, allowing for quicker iterations and client feedback. When sourcing machines, buyers should consider compatibility with CAD software and the availability of training support to maximize the machine’s utility in model-making.

3 Common User Pain Points for ‘wood cnc machine 5 axis’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision Cuts

The Problem: B2B buyers often struggle with achieving the desired precision in their wood machining projects. This issue becomes especially pronounced when working with complex designs that require intricate details and multi-faceted cuts. Users may find that their current equipment, particularly 3-axis CNC machines, cannot handle the geometric complexities of advanced woodwork, leading to subpar finishes and wasted materials. This not only affects product quality but also increases operational costs due to rework and material waste.

The Solution: To overcome precision challenges, investing in a high-quality 5-axis CNC machine is essential. When sourcing a machine, buyers should prioritize features such as a robust frame, high-speed spindles, and advanced control systems that allow for simultaneous movement across multiple axes. It’s also critical to select machines that come with comprehensive training and technical support, ensuring that operators are well-equipped to utilize the machine’s capabilities fully. Furthermore, adopting a systematic approach to programming and utilizing CAM software designed for 5-axis machining can enhance precision. By integrating these practices, businesses can achieve the intricate detailing required for high-quality wood products, thereby improving overall efficiency and reducing waste.

Scenario 2: High Initial Investment and Operating Costs

The Problem: Many companies, especially startups and small to medium enterprises, face significant financial hurdles when considering the purchase of a 5-axis CNC machine. The initial investment can be substantial, and buyers may be uncertain about whether they will see a return on that investment. Additionally, operational costs, including maintenance, tooling, and software licenses, can add up, leading to hesitancy in making the leap to advanced machining technology.

The Solution: To navigate financial concerns, buyers should explore flexible financing options offered by manufacturers, which may include leasing arrangements or payment plans. This can make the acquisition of a 5-axis machine more manageable. Additionally, buyers should conduct a thorough cost-benefit analysis to project potential savings and revenue increases that could result from improved machining capabilities. It’s also advisable to look for machines that offer lower operating costs through energy efficiency and require less frequent maintenance. Engaging with vendors who provide comprehensive after-sales support can also reduce long-term operational costs by minimizing downtime and ensuring the machine remains in optimal condition. By strategically planning the investment and operational costs, businesses can position themselves for sustainable growth.

Scenario 3: Lack of Skilled Operators and Training Resources

The Problem: A common pain point for B2B buyers is the shortage of skilled operators capable of efficiently using 5-axis CNC machines. The complexity of these machines often requires specialized training, which may not be readily available in many regions. This skill gap can lead to underutilization of the machine’s capabilities, negatively impacting production timelines and quality.

The Solution: To address the skills gap, businesses should prioritize partnering with equipment suppliers who offer extensive training programs, both on-site and virtually. This ensures that operators receive hands-on experience and knowledge directly related to the specific machine they will be using. Additionally, investing in comprehensive training programs for current employees can create a more skilled workforce over time. Companies can also consider collaborating with local vocational schools or technical colleges to create internship programs or apprenticeships that introduce students to advanced machining techniques. By fostering a culture of continuous learning and skill development, businesses can maximize the effectiveness of their 5-axis CNC machines and ensure they remain competitive in the market.

Strategic Material Selection Guide for wood cnc machine 5 axis

What Are the Key Materials for Wood CNC Machines in 5-Axis Operations?

When selecting materials for a wood CNC machine with 5-axis capabilities, it is essential to consider their properties, advantages, and limitations. This guide analyzes four common materials used in wood CNC machining: hardwoods, softwoods, engineered wood, and composites. Each material has unique characteristics that influence performance, cost, and application suitability.

How Do Hardwoods Perform in 5-Axis CNC Machining?

Key Properties: Hardwoods, such as oak, maple, and cherry, are dense and durable, with a high resistance to wear and tear. Their temperature and pressure ratings are generally high, making them suitable for intricate designs that require precision.

Pros & Cons: The primary advantage of hardwoods is their durability and aesthetic appeal, which makes them ideal for high-end furniture and cabinetry. However, they can be more expensive than other materials and may require specialized tooling for machining due to their density.

Impact on Application: Hardwoods are compatible with various finishes and adhesives, allowing for versatile end products. However, their machining can produce more waste due to the need for careful handling to avoid splitting or chipping.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local availability and import regulations regarding hardwoods. Compliance with standards such as ASTM D198 for wood structural design may also be necessary.

What Are the Advantages of Using Softwoods in CNC Machining?

Key Properties: Softwoods, including pine, fir, and cedar, are lighter and typically easier to machine than hardwoods. They have lower density and are often more cost-effective.

Pros & Cons: The primary advantage of softwoods is their affordability and ease of machining, making them suitable for projects requiring large quantities of material. However, they are less durable than hardwoods and may not hold up as well under stress or in high-traffic applications.

Impact on Application: Softwoods are often used in construction and furniture-making, where weight and cost are critical factors. They are also well-suited for projects that involve intricate designs, as they can be easily shaped and carved.

Considerations for International Buyers: Buyers in Europe and the Middle East should consider the availability of sustainable softwood options, as there are strict regulations regarding forestry practices. Compliance with local standards, such as EN 14081 for structural timber, is also essential.

How Do Engineered Woods Compare for 5-Axis CNC Applications?

Key Properties: Engineered woods, such as plywood, MDF, and particleboard, are manufactured from wood fibers or veneers bonded together. They offer consistent density and dimensional stability, making them ideal for CNC machining.

Pros & Cons: The main advantage of engineered wood is its uniformity, which allows for predictable machining outcomes. However, it may not have the same aesthetic appeal as natural wood and can be less durable in certain applications.

Impact on Application: Engineered woods are widely used in cabinetry, furniture, and decorative applications. They are compatible with various finishes, but care should be taken with adhesives to avoid delamination.

Considerations for International Buyers: Buyers should ensure compliance with standards such as CARB for formaldehyde emissions, especially in regions like North America and Europe. Availability may vary, so understanding local supply chains is crucial.

What Role Do Composites Play in Wood CNC Machining?

Key Properties: Composite materials, such as wood-plastic composites (WPC), combine wood fibers with plastic. They offer excellent resistance to moisture and decay, making them suitable for outdoor applications.

Pros & Cons: The primary advantage of composites is their durability and low maintenance requirements. However, they can be more expensive and may require specialized tools for machining due to their mixed material composition.

Impact on Application: Composites are often used in outdoor furniture, decking, and decorative features. They can be machined to achieve intricate designs, but their unique properties may require different machining strategies.

Considerations for International Buyers: Buyers should be aware of local regulations regarding composite materials, particularly in terms of recycling and environmental impact. Compliance with standards like ASTM D7031 for wood-plastic composites is also important.

Summary Table of Material Selection for Wood CNC Machines

| Material | Typical Use Case for wood cnc machine 5 axis | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Hardwoods | High-end furniture and cabinetry | Durability and aesthetic appeal | Higher cost and specialized tooling | High |

| Softwoods | Construction and furniture-making | Affordability and ease of machining | Less durable than hardwoods | Medium |

| Engineered Wood | Cabinetry and decorative applications | Uniformity and dimensional stability | Less aesthetic appeal | Medium |

| Composites | Outdoor furniture and decking | Moisture resistance and durability | Higher cost and specialized tools | High |

This strategic material selection guide provides B2B buyers with essential insights into the suitability of various materials for wood CNC machining, enabling informed purchasing decisions tailored to their specific operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for wood cnc machine 5 axis

What Are the Key Manufacturing Processes for Wood CNC Machine 5 Axis?

The manufacturing of a wood CNC machine with 5-axis capabilities involves several critical stages, each designed to ensure precision, durability, and functionality. Understanding these processes can help B2B buyers make informed decisions when evaluating suppliers.

Material Preparation: What Materials Are Used and How Are They Processed?

The foundation of any CNC machine is its materials. High-quality steel, aluminum, and composite materials are commonly used for the frame and structural components. The selection of materials is pivotal; for instance, an 8600 lb. all-welded steel frame provides the necessary rigidity and stability for precision machining.

-

Material Sourcing: Suppliers should be vetted for their material quality, ensuring they source from reputable mills. Certifications regarding the origin and quality of the raw materials can add significant value.

-

Cutting and Shaping: Before assembly, materials undergo cutting and shaping processes, often utilizing laser or plasma cutting technology to ensure precision. This stage may also involve CNC machining to create parts that fit together seamlessly.

Forming: How Are Components Shaped and Assembled?

After material preparation, the next step is forming the components that will make up the CNC machine. This involves:

-

Machining: Components are machined to exact specifications using CNC machines. This step ensures that every part meets the design requirements for compatibility and functionality.

-

Welding and Joining: For steel frames, welding is a common technique to join components. This process must be executed with high precision to maintain the structural integrity of the machine.

-

Final Assembly: Once all components are formed, they are assembled into the final machine. Assembly techniques often include bolting and fastening, ensuring that all parts are securely attached and aligned.

Finishing: What Processes Ensure Quality and Aesthetics?

The finishing stage not only enhances the machine’s aesthetic appeal but also adds a layer of protection against wear and corrosion.

-

Surface Treatment: Techniques such as powder coating or anodizing are used to protect metal surfaces and improve durability. This is particularly important for machines that will operate in diverse environments.

-

Calibration and Testing: After assembly, machines undergo calibration to ensure all axes are functioning correctly. This includes adjusting the spindle speeds, tool paths, and ensuring that the machine operates within specified tolerances.

What Are the Quality Assurance Standards for Wood CNC Machines?

Quality assurance is a crucial aspect of manufacturing wood CNC machines. International standards like ISO 9001 and industry-specific certifications play a vital role in maintaining high-quality production.

Which International Standards Should B2B Buyers Consider?

-

ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing processes. Suppliers with ISO 9001 certification demonstrate a commitment to quality and customer satisfaction.

-

CE Marking: For machines sold in Europe, CE marking signifies compliance with health, safety, and environmental protection standards. This certification is crucial for B2B buyers in Europe, as it ensures that the machinery meets EU regulations.

-

API Certification: For suppliers targeting specific industries, API (American Petroleum Institute) certification may be relevant, particularly for machines used in oil and gas applications.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is implemented at various stages of the manufacturing process to ensure that each machine meets the required standards.

How Are QC Checkpoints Structured?

-

Incoming Quality Control (IQC): At this initial stage, raw materials and components are inspected for quality before they enter the production line. This prevents defects from the outset.

-

In-Process Quality Control (IPQC): During manufacturing, QC personnel conduct regular inspections to monitor the quality of components being produced. This may include measuring tolerances and checking for consistency.

-

Final Quality Control (FQC): After assembly, the completed machine undergoes rigorous testing. This may involve running the machine through various cycles to test its performance and ensure all features function correctly.

What Testing Methods Are Commonly Used for Wood CNC Machines?

Various testing methods are employed to validate the performance and durability of wood CNC machines. These methods are critical for ensuring that machines meet the expectations of B2B buyers.

-

Functional Testing: This involves running the machine through its full range of operations to ensure all axes move correctly and that the machine produces the expected results.

-

Load Testing: Machines are subjected to stress tests to evaluate their performance under maximum load conditions. This helps identify potential weaknesses in the design or assembly.

-

Precision Testing: Using calibrated measuring tools, manufacturers check that the machine meets specified tolerances in cutting accuracy and repeatability.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those in regions like Africa, South America, and the Middle East, verifying supplier quality control is essential. Here are some actionable steps:

-

Audits: Conducting on-site audits of suppliers can provide firsthand insight into their manufacturing processes and quality control practices. This is particularly important for large purchases.

-

Quality Reports: Requesting detailed quality reports, including testing results and compliance certifications, can help assess a supplier’s reliability.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures, ensuring they meet international standards.

What Are the Unique QC Considerations for International B2B Buyers?

B2B buyers from diverse regions must be aware of specific quality control nuances that may affect their purchasing decisions.

-

Compliance with Local Regulations: Different countries have varying regulations regarding machinery safety and performance. Understanding these requirements is essential for compliance.

-

Cultural and Communication Barriers: Buyers should be prepared to navigate potential language barriers and cultural differences that may impact negotiations and quality assurance processes.

-

Logistical Challenges: International shipping can introduce risks, such as damage during transport. Ensuring that suppliers have robust packaging and handling processes is crucial for maintaining quality.

By understanding the manufacturing processes and quality assurance measures associated with wood CNC machines, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wood cnc machine 5 axis’

When sourcing a 5-axis wood CNC machine, it’s essential to follow a structured approach to ensure you select the right equipment that meets your business needs. This guide provides a step-by-step checklist to streamline your procurement process.

Step 1: Define Your Technical Specifications

Establishing your technical requirements is the foundation of your sourcing process. Consider the types of wood you will be processing, the complexity of designs, and the production volume. Additionally, specify the desired cutting speeds, spindle power, and the machine’s overall dimensions to ensure it fits within your workshop.

- Consider material types: Different machines may excel with specific materials, such as hardwoods versus softwoods.

- Identify production needs: Higher volumes may require more robust machines with faster processing capabilities.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers specializing in 5-axis CNC machines. Look for manufacturers with a solid reputation in the industry, positive customer reviews, and a history of supplying similar machines.

- Utilize online directories: Platforms like ThomasNet or Alibaba can help you find a variety of suppliers.

- Attend trade shows: Industry exhibitions can provide insights into the latest technologies and direct interactions with manufacturers.

Step 3: Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications and industry standards compliance. Certifications can indicate quality control measures and adherence to safety regulations.

- Look for ISO certifications: These assure you that the supplier meets international quality standards.

- Check for relevant machine certifications: This includes CE marking for compliance with European safety standards, which is crucial for buyers in Europe.

Step 4: Request Detailed Quotes

Once you have shortlisted suppliers, request detailed quotations that include pricing, specifications, warranties, and delivery timelines. Ensure that quotes are comprehensive to facilitate comparison.

- Clarify additional costs: Inquire about shipping, installation, and training fees to avoid unexpected expenses.

- Review warranty terms: A robust warranty can protect your investment and reduce long-term costs.

Step 5: Assess After-Sales Support and Training

Quality after-sales support is vital for the successful operation of your CNC machine. Evaluate the supplier’s commitment to customer service, including training and maintenance support.

- On-site training: Ensure that the supplier provides adequate training for your operators to maximize machine utilization.

- Technical support availability: Check if support is offered through various channels, such as phone, email, or online chat.

Step 6: Conduct a Risk Assessment

Before making a final decision, perform a risk assessment to identify potential challenges related to the procurement process. This includes evaluating suppliers’ reliability, machine performance, and serviceability.

- Review case studies or testimonials: Insights from similar businesses can help gauge supplier reliability.

- Consider local support: Suppliers with local representatives can provide quicker service and support.

Step 7: Finalize the Purchase Agreement

Once you have completed your evaluations and selected a supplier, finalize the purchase agreement. Ensure that all terms are clearly defined, including delivery timelines, payment terms, and installation details.

- Negotiate terms if necessary: Don’t hesitate to discuss terms that can benefit your organization, such as extended warranties or discounted maintenance packages.

- Document everything: Ensure all agreements are in writing to avoid misunderstandings.

By following these steps, you can systematically approach the procurement of a 5-axis wood CNC machine, ensuring that you make a well-informed decision that aligns with your business goals.

Comprehensive Cost and Pricing Analysis for wood cnc machine 5 axis Sourcing

What Are the Key Cost Components of a 5-Axis Wood CNC Machine?

Understanding the cost structure of a 5-axis wood CNC machine is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: High-quality steel and aluminum are typically used in the construction of these machines. The choice of materials directly impacts durability and performance, influencing the overall cost. For instance, an all-steel frame, such as the one seen in the Laguna SmartShop, adds to the machine’s weight and stability but increases raw material costs.

-

Labor: Labor costs encompass both the workforce involved in manufacturing and assembly. Skilled labor is often necessary for the precision assembly of 5-axis machines, which can elevate costs. Additionally, labor rates vary significantly by region, affecting total pricing for buyers based in different countries.

-

Manufacturing Overhead: This includes costs related to the factory, utilities, and equipment maintenance. High overhead costs can be a significant factor in the final pricing, especially in regions with higher operational costs.

-

Tooling: Tooling costs refer to the expenses associated with the various tools and attachments used in the machining process. Depending on the complexity of the projects, specialized tools may be required, which can add to the overall cost.

-

Quality Control (QC): Ensuring that each machine meets stringent quality standards involves additional costs for testing and certification. For international buyers, certifications that comply with local regulations may be necessary, adding to the expense.

-

Logistics: Shipping and handling costs are crucial for international transactions. The mode of transport, distance, and delivery timelines can significantly affect logistics costs. Buyers should consider these factors when evaluating total costs.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on the supplier’s reputation, market demand, and competition.

How Do Price Influencers Affect the Cost of 5-Axis Wood CNC Machines?

Several factors can influence the price of a 5-axis wood CNC machine, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk can lead to significant discounts. Suppliers may offer lower prices per unit when purchasing multiple machines.

-

Specifications and Customization: Customized machines tailored to specific needs will generally cost more than standard models. Buyers should be clear about their requirements to avoid unnecessary expenses.

-

Materials: The choice of materials not only affects performance but also influences pricing. Premium materials will raise costs, while more economical options might lower them.

-

Quality and Certifications: Machines that meet international quality standards and come with certifications may command higher prices. However, they often provide better reliability and support.

-

Supplier Factors: Established suppliers with a track record of quality and service may charge more due to their reputation. Newer suppliers might offer lower prices but could lack the same level of support.

-

Incoterms: Understanding shipping terms and responsibilities is crucial. Incoterms define the costs and responsibilities of buyers and sellers, impacting total landed costs.

What Are the Best Tips for Negotiating Prices on 5-Axis Wood CNC Machines?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, negotiation can be key to achieving favorable pricing. Here are some tips:

-

Research Market Prices: Understanding the market price range for specific models will empower buyers during negotiations. This knowledge can help identify reasonable offers.

-

Leverage Volume: If considering multiple purchases, use this as leverage to negotiate better pricing. Suppliers are often willing to provide discounts for larger orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price, but also the long-term costs associated with maintenance, training, and operation. A higher upfront cost may be justified by lower TCO.

-

Be Open to Alternatives: If a particular model exceeds budget constraints, ask suppliers about alternative models or configurations that may offer similar capabilities at a lower cost.

-

Understand Local Regulations: Familiarity with import duties and taxes can help buyers navigate the total cost landscape effectively. This knowledge can also be leveraged in negotiations.

Conclusion

While indicative prices for 5-axis wood CNC machines can vary widely based on the aforementioned factors, understanding the cost components and price influencers can aid buyers in making informed decisions. By employing effective negotiation strategies, international B2B buyers can secure the best value for their investment in CNC technology.

Alternatives Analysis: Comparing wood cnc machine 5 axis With Other Solutions

Introduction to Alternatives in Woodworking Technology

In the dynamic landscape of woodworking technology, businesses often seek solutions that enhance productivity, precision, and cost-efficiency. The wood CNC machine 5-axis stands out for its ability to perform complex cuts and shapes in a single setup. However, exploring alternatives can provide valuable insights for B2B buyers looking to optimize their operations. This analysis compares the wood CNC machine 5-axis with two viable alternatives: traditional 3-axis CNC machines and manual woodworking methods.

Comparison Table

| Comparison Aspect | Wood CNC Machine 5 Axis | Traditional 3-Axis CNC Machine | Manual Woodworking Methods |

|---|---|---|---|

| Performance | High precision with multiple angles; ideal for complex designs | Good for simpler cuts; limited to flat surfaces | Variable precision; depends on skill level |

| Cost | Higher initial investment; longer-term savings through efficiency | Lower initial cost; may require multiple machines for complex tasks | Minimal upfront cost; labor-intensive |

| Ease of Implementation | Requires skilled operators; software training needed | Easier setup; fewer software requirements | Requires craftsmanship skills; no machinery training |

| Maintenance | Regular maintenance needed for precision; professional support available | Lower maintenance; simpler mechanics | Minimal maintenance; depends on tools used |

| Best Use Case | Complex, intricate designs and high-volume production | Standard woodworking tasks and less complex projects | Custom, one-off projects or artisanal work |

Detailed Breakdown of Alternatives

Traditional 3-Axis CNC Machine

Traditional 3-axis CNC machines provide a cost-effective solution for woodworking, particularly for businesses that primarily work with flat materials. They excel in producing straightforward cuts and are generally easier to operate compared to 5-axis machines. However, their limitations become apparent when attempting to create complex geometries, as they can only move along the X, Y, and Z axes. While the lower initial investment is attractive, businesses may find themselves needing multiple machines to achieve the same versatility offered by a single 5-axis unit.

Manual Woodworking Methods

Manual woodworking relies on traditional hand tools and skilled craftsmanship. This method is often favored for bespoke projects where artisanship and customization are paramount. The primary advantages include lower initial costs and the ability to create unique, one-of-a-kind pieces. However, manual methods can be labor-intensive and time-consuming, leading to inconsistent quality and longer production times. This option is best suited for smaller-scale operations or high-end custom work where precision and artistry are valued over speed.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the best solution for woodworking needs, B2B buyers must consider their specific requirements, including project complexity, production volume, and budget constraints. The wood CNC machine 5-axis offers unparalleled precision and efficiency for intricate designs, making it ideal for high-volume production. On the other hand, traditional 3-axis CNC machines and manual woodworking methods provide viable alternatives for businesses focused on simpler projects or bespoke craftsmanship. By thoroughly evaluating each option’s performance, cost, ease of implementation, maintenance, and best use case, buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for wood cnc machine 5 axis

What Are the Key Technical Properties of a 5-Axis Wood CNC Machine?

Understanding the technical properties of a 5-axis wood CNC machine is crucial for B2B buyers, especially those aiming for precision and efficiency in their operations. Here are some essential specifications:

-

Frame Material and Weight

The structural integrity of a CNC machine is often determined by its frame material and weight. Most high-quality machines feature an all-welded steel frame, often weighing around 8,600 lbs. This robust construction minimizes vibrations during operation, ensuring better precision and stability, which is essential for high-quality finishes in woodworking. -

Axis Configuration and Movement

The ability to manipulate the cutting tool across multiple axes enhances machining capabilities. A 5-axis CNC can move along the X, Y, Z axes while also rotating around two additional axes (A and B). This allows for intricate designs and the ability to cut complex geometries with ease. B2B buyers should note that more axes generally mean greater versatility and efficiency, making it a valuable investment for advanced woodworking projects. -

Spindle Power and Speed

The spindle is the heart of the CNC machine, directly impacting cutting efficiency and material compatibility. A typical 5-axis wood CNC machine may have a spindle rated at 9HP, allowing for rapid cutting speeds—often up to 1,000 inches per minute. Higher spindle power translates to quicker job completion and the ability to work with a variety of materials, from hardwoods to composites. -

Control System

The control system is critical for operational ease and precision. Machines equipped with advanced industrial controls, such as the FANUC 31i-B5, offer features like intuitive interfaces and efficient tool path programming. A reliable control system can significantly reduce setup time and enhance the overall productivity of the machining process. -

Vacuum Table Technology

A universal vacuum table, often featuring multiple zones, is essential for securely holding materials during machining. This technology allows for efficient clamping of various shapes and sizes, which is particularly important when working with different wood types. Effective vacuum systems can enhance machining accuracy and reduce material waste, making them a vital component for B2B buyers.

What Common Trade Terminology Should B2B Buyers Know?

Familiarity with industry jargon can facilitate better communication and understanding in the procurement process. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, working with an OEM can ensure that they receive high-quality, reliable components that meet specific operational needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers to avoid over-purchasing or facing supply shortages, especially when sourcing machinery or components. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. For B2B buyers, issuing an RFQ can help in comparing costs, terms, and conditions across different vendors, ensuring a more informed purchasing decision. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects like shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers engaged in cross-border transactions, as they clarify risks and obligations. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. For B2B buyers, understanding lead times is crucial for planning production schedules and ensuring that projects remain on track. -

Technical Support

This term encompasses the assistance provided by manufacturers or suppliers in resolving technical issues related to the machinery. Reliable technical support is vital for minimizing downtime and ensuring optimal performance, making it a key consideration for B2B buyers when selecting equipment.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, leading to enhanced operational efficiency and competitive advantage in the woodworking industry.

Navigating Market Dynamics and Sourcing Trends in the wood cnc machine 5 axis Sector

What are the Key Market Dynamics and Trends Affecting the 5-Axis Wood CNC Machine Sector?

The global market for 5-axis wood CNC machines is experiencing significant growth, driven by advancements in technology and increasing demand for precision manufacturing. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly focused on enhancing operational efficiency and product quality. Emerging technologies such as automation, real-time data analytics, and IoT integration are reshaping the landscape, enabling manufacturers to achieve higher productivity levels. Furthermore, the trend towards customization in product offerings is compelling manufacturers to invest in 5-axis machines, which allow for more complex designs and multi-faceted machining processes.

International buyers should also note the growing importance of financing options and flexible payment plans as a means to lower the barrier of entry for acquiring advanced machinery. This trend is especially relevant for businesses in developing markets, where capital investment in technology can be a significant hurdle. Additionally, as the woodworking industry evolves, the demand for training and support services is rising, ensuring that companies can maximize their investment in technology.

How is Sustainability Influencing Sourcing Decisions in the 5-Axis Wood CNC Machine Market?

Sustainability has emerged as a critical factor in the sourcing of wood CNC machines, reflecting a broader global push towards environmentally responsible practices. B2B buyers are increasingly prioritizing suppliers that adhere to ethical sourcing standards and offer sustainable materials. This shift is not only about compliance with regulations but also about enhancing brand reputation and meeting consumer demand for green products.

For companies in the woodworking sector, seeking suppliers with certifications such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) is becoming essential. These certifications ensure that the wood used in manufacturing is sourced from sustainably managed forests. Additionally, the incorporation of eco-friendly practices in machine production, such as energy-efficient operations and reduced waste generation, is gaining traction. B2B buyers who align their sourcing strategies with sustainability goals are likely to benefit from improved market positioning and customer loyalty.

What is the Evolution of 5-Axis Wood CNC Machines and Its Relevance to Current B2B Buyers?

The evolution of 5-axis CNC technology has its roots in the demand for more versatile and efficient machining capabilities. Initially, CNC machines were limited to 3-axis configurations, which constrained their ability to handle complex geometries. The introduction of 4-axis and subsequently 5-axis machines revolutionized the woodworking industry by enabling simultaneous movement across multiple axes, thus allowing for intricate designs and superior finish quality.

This evolution is particularly relevant for current B2B buyers as they look for machines that can provide competitive advantages through enhanced capabilities. The advancements in software and control systems have made 5-axis machining more accessible, with user-friendly interfaces and improved programmability. As manufacturers seek to differentiate their offerings in a crowded market, the ability to produce high-quality, custom products with precision will be a key factor driving their investment decisions. The historical context of these developments underscores the ongoing need for businesses to adapt to technological advancements to stay competitive in the global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of wood cnc machine 5 axis

-

How do I choose the right 5-axis CNC machine for my woodworking business?

Choosing the right 5-axis CNC machine involves assessing your specific business needs, including the types of materials you work with, the volume of production, and the complexity of designs you intend to create. Evaluate the machine’s specifications, such as cutting speed, spindle power, and control software compatibility. Additionally, consider the manufacturer’s reputation, customer support, and warranty services. Engaging with other businesses in your region can provide insights into local requirements and operational considerations. -

What are the key benefits of using a 5-axis CNC machine for woodworking?

A 5-axis CNC machine offers numerous advantages, including the ability to create complex geometries and intricate designs that are difficult to achieve with 3-axis machines. It enables faster machining times and improved surface finishes due to continuous tool engagement. This technology also reduces the need for multiple setups, which minimizes material handling and increases production efficiency. Overall, investing in a 5-axis machine can significantly enhance your competitive edge in the woodworking industry. -

What should I consider regarding international shipping for a 5-axis CNC machine?

When planning for international shipping, consider factors such as shipping costs, customs duties, and import regulations specific to your country. Ensure that the supplier provides detailed documentation, including shipping manifests and compliance certificates. It’s also essential to confirm the machine’s packaging to prevent damage during transit. Collaborating with a logistics provider experienced in heavy machinery can facilitate smoother customs clearance and delivery. -

How can I vet suppliers for 5-axis CNC machines?

To vet suppliers effectively, start by researching their industry reputation through reviews, testimonials, and case studies. Verify their credentials, including certifications and compliance with international standards. Request references from previous clients and assess their response time and customer support capabilities. Visiting the supplier’s facility, if feasible, can provide insights into their manufacturing processes and quality control measures. -

What are the minimum order quantities (MOQ) for 5-axis CNC machines?

Minimum order quantities for 5-axis CNC machines can vary significantly depending on the manufacturer and the specific model. Some suppliers may offer flexible MOQ options, especially for international buyers, while others may require a standard MOQ to ensure cost-effectiveness. It’s advisable to communicate directly with potential suppliers to negotiate terms that align with your business needs and production capacity. -

What payment terms should I expect when purchasing a 5-axis CNC machine?

Payment terms for purchasing a 5-axis CNC machine typically include options like a deposit followed by balance payment upon delivery or installation. Some suppliers may offer financing options to ease upfront costs. It’s crucial to clarify payment methods accepted, such as bank transfers or letters of credit, and ensure that all terms are documented in a purchase agreement to avoid misunderstandings. -

What quality assurance measures should I look for in a 5-axis CNC machine?

Quality assurance measures can include certifications such as ISO 9001, which indicates a commitment to quality management systems. Additionally, inquire about the machine’s testing procedures before shipment, including performance metrics and precision checks. A reliable supplier should provide warranty details, maintenance services, and ongoing support to ensure the machine operates optimally over its lifespan. -

How can I customize a 5-axis CNC machine to fit my specific needs?

Customization options for 5-axis CNC machines often include modifications to software, tooling systems, and hardware configurations. Discuss your requirements with the supplier to explore available upgrades or bespoke solutions that enhance functionality for your specific applications. Ensure that the customization process aligns with your production goals and does not compromise the machine’s performance or reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Wood Cnc Machine 5 Axis Manufacturers & Suppliers List

1. Laguna Tools – SmartShop® 5 Axis CNC Router

Domain: lagunatools.com

Registered: 1996 (29 years)

Introduction: Product Name: SmartShop® 5 Axis CNC Router

Weight: 8600 lbs.

Frame: All Welded Steel Frame & Gantry

Design: Fixed Table, Moving Gantry Design for Easy Access

Tool Changer: Standard 12-Position, Automatic Rotary Tool Changer

Control: FANUC 31i-B5 Industrial Control with 1,500-Watt Servo Package

Vacuum Table: Universal Vacuum Table, Pod Ready with Adjustable Pop-Up Pins

Spindle: HSD 2-Axis 9HP Spind…

2. Haas CNC – 5-Axis Universal Machining Center

Domain: haascnc.com

Registered: 1996 (29 years)

Introduction: This company, Haas CNC – 5-Axis Universal Machining Center, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. PocketNC – Hobbyist 5-Axis Machining

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. PocketNC: Suitable for hobbyist applications (soft metal, wood). Requires expensive software for full 5-axis machining (e.g., Fusion 360 costs $1,600/year). 2. DesktopNC: Comes with free software that can generate simultaneous 5-axis G-code. 3. Considerations: Tiny machines may be weak; vibration affects performance; bolting machines down can improve stability.

4. OMNI – 5-Axis CNC Router Machines

Domain: omni-cnc.com

Registered: 2009 (16 years)

Introduction: OMNI 5-Axis CNC Router Machine designed for woodworking, plastic, and foam cutting. Key features include: 1. Models: OMNI-5AXIS 48 Standard (Gantry Moving), OMNI-5AXIS 48 Standard (Table Moving), OMNI-5AXIS 1013 XL, OMNI-5AXIS 2026 Enterprise, OMNI-5AXIS 33 Compact, OMNI-5AXIS CUSTOM. 2. Spindle Power: Ranges from 10KW to 30KW depending on the model. 3. Processing Areas: Various sizes including 13…

5. JMP Wood – Custom CNC Machining

Domain: jmpwood.com

Registered: 2013 (12 years)

Introduction: Custom CNC Millwork / Machining, 5 Axis – JMP Wood offers advanced CNC machining capabilities, including 3 axis, 4 axis, and 5 axis options. The company specializes in carving, cutting, and machining wood into various shapes and sizes. With over 40 years of experience, JMP Wood utilizes state-of-the-art machinery and software to handle projects of any scale. Customers can request customized quotes…

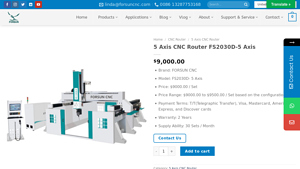

6. Forsun – FS2030D-5 Axis CNC Machine

Domain: forsuncnc.com

Registered: 2020 (5 years)

Introduction: {“Model”:”FS2030D-5 Axis”,”Price”:”$9000.00 / Set”,”Price Range”:”$9000.00 to $9500.00 / Set based on the configuration”,”Payment Terms”:”T/T, Visa, Mastercard, American Express, Discover cards”,”Warranty”:”2 Years”,”Supply Ability”:”30 Sets / Month”,”X, Y-Axis Travel”:”4800*2800*2000mm”,”A and C Axis Travel”:”A:±120°, C:±245°”,”Spindle Power”:”10KW, Option: 15KW”,”Drive System”:”X and Y axis with…

Strategic Sourcing Conclusion and Outlook for wood cnc machine 5 axis

In the rapidly evolving landscape of woodworking and manufacturing, investing in a 5-axis CNC machine presents a significant opportunity for businesses aiming to enhance precision, efficiency, and production capabilities. With the ability to perform intricate cuts and complex designs that traditional machines cannot handle, these advanced tools open new avenues for innovation and market competitiveness. Strategic sourcing of these machines not only involves evaluating technical specifications but also understanding the support and training services offered by manufacturers, ensuring seamless integration into existing workflows.

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the emphasis should be on finding suppliers that provide comprehensive pre-and post-sales support. This includes installation, training, and ongoing technical assistance, which are crucial for maximizing the return on investment. By aligning with reputable manufacturers, businesses can leverage advanced technology while minimizing downtime and operational disruptions.

As you explore the potential of 5-axis CNC machines, consider how they can transform your production processes and meet the demands of a competitive market. Take the next step toward enhancing your manufacturing capabilities—engage with suppliers today to discover tailored solutions that fit your business needs.