Introduction: Navigating the Global Market for wire edm services

In today’s competitive manufacturing landscape, sourcing wire EDM services can be a daunting task for international B2B buyers. As industries evolve and the demand for precision components increases, understanding how to effectively navigate this global market becomes critical. Wire Electrical Discharge Machining (EDM) is renowned for its ability to produce intricate parts with tight tolerances and superior surface finishes, making it an invaluable process in sectors such as aerospace, automotive, and medical device manufacturing. However, the challenge lies in identifying reliable suppliers who can deliver consistent quality and meet diverse production needs.

This comprehensive guide is designed to empower B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, including Brazil and Saudi Arabia. It delves into various aspects of wire EDM services, including types of machining, applications across industries, and critical supplier vetting strategies. Additionally, the guide covers cost considerations and the factors influencing pricing, helping buyers make informed decisions that align with their project requirements and budget constraints.

By equipping buyers with actionable insights and expert knowledge, this guide aims to streamline the sourcing process, mitigate risks, and foster successful partnerships in the wire EDM sector. Embrace the opportunity to enhance your manufacturing capabilities and drive innovation by navigating the global market for wire EDM services with confidence.

Understanding wire edm services Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Wire EDM | Utilizes a single strand of wire; ideal for general precision cutting. | Tool and die manufacturing, automotive parts. | Pros: Fast turnaround, minimal tooling required. Cons: Limited to conductive materials. |

| Fine Wire EDM | Employs very thin wire (as small as 0.004”) for ultra-precise cuts. | Medical devices, microelectronics. | Pros: Exceptional precision for small parts. Cons: Higher costs due to specialized equipment. |

| High-Volume EDM | Designed for large-scale production runs with consistent quality. | Aerospace components, mass-produced parts. | Pros: Cost-effective for bulk orders. Cons: Setup time may be longer for initial runs. |

| Submerged Wire EDM | Operates with the workpiece submerged in deionized water for thermal stability. | Complex geometries, intricate designs. | Pros: Reduces thermal distortion, improves accuracy. Cons: Requires specific setup and conditions. |

| Multi-Axis Wire EDM | Capable of complex geometries with 4-axis and 5-axis machining. | Aerospace, automotive, and custom tooling. | Pros: High flexibility for intricate designs. Cons: More expensive and requires skilled operators. |

What Are the Characteristics of Standard Wire EDM Services?

Standard Wire EDM services are characterized by their use of a single strand of wire to cut conductive materials. This method is widely applicable across various industries, particularly in tool and die manufacturing and automotive parts production. Buyers should consider the quick turnaround times and minimal tooling requirements, making it an efficient choice for projects with tight deadlines. However, it is limited to conductive materials, which may restrict its use in certain applications.

How Does Fine Wire EDM Differ from Other Types?

Fine Wire EDM utilizes extremely thin wire electrodes, allowing for highly precise machining of small parts. This technique is particularly suitable for industries like medical devices and microelectronics, where precision is paramount. Buyers should evaluate the cost implications, as the specialized equipment and processes may lead to higher prices. However, the exceptional accuracy provided can justify the investment for critical components.

What Are the Benefits of High-Volume EDM Services?

High-Volume EDM services are tailored for large-scale production, offering consistent quality and efficiency in manufacturing. This type of service is ideal for industries such as aerospace, where mass production of components is common. Buyers benefit from cost-effective pricing for bulk orders, although the initial setup time may be longer. It’s essential for businesses to assess their production needs and volume requirements when considering this option.

What Makes Submerged Wire EDM a Unique Choice?

Submerged Wire EDM operates with the workpiece submerged in deionized water, enhancing thermal stability and minimizing distortion during the cutting process. This method is particularly effective for complex geometries and intricate designs. Buyers should note that while this technique improves accuracy, it requires specific setups and conditions, which may not be feasible for all projects.

Why Choose Multi-Axis Wire EDM for Complex Designs?

Multi-Axis Wire EDM allows for intricate machining with the capability to operate on 4-axis and 5-axis configurations. This flexibility makes it suitable for industries requiring complex geometries, such as aerospace and custom tooling. While the benefits include high design versatility, buyers should consider the increased costs and the need for skilled operators to handle the advanced machinery.

Key Industrial Applications of wire edm services

| Industry/Sector | Specific Application of wire edm services | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing complex components like turbine blades | High precision and reliability in critical components | Certification (AS9100D), lead times, and material specifications |

| Automotive | Production of dies and molds for vehicle parts | Cost efficiency and reduced lead times for prototyping | Volume capacity, tooling capabilities, and ISO certifications |

| Medical Devices | Creating intricate parts for surgical instruments | Enhanced precision and safety in medical applications | Compliance with medical standards (ISO 13485), material traceability |

| Electronics | Fabrication of connectors and circuit components | Improved performance and reliability of electronic devices | Expertise in fine wire EDM and rapid prototyping capabilities |

| Tool and Die Manufacturing | Development of precise tooling for manufacturing | Optimized production processes and reduced waste | Ability to handle complex geometries and tight tolerances |

How is Wire EDM Used in Aerospace Manufacturing?

In the aerospace sector, wire EDM services are critical for producing complex components such as turbine blades and engine parts. The precision required in these applications is paramount, as even minor inaccuracies can lead to significant operational issues. Wire EDM eliminates the need for custom tooling, allowing for faster prototyping and production. Buyers should consider sourcing from ISO 9001:2015 and AS9100D certified suppliers to ensure adherence to industry standards and reliability in delivery times.

What Role Does Wire EDM Play in Automotive Production?

In automotive manufacturing, wire EDM is utilized for the production of dies and molds used in forming vehicle parts. This method provides a cost-effective solution with reduced lead times, especially for prototyping new components. The ability to produce complex geometries without the need for custom tooling enhances flexibility. Buyers should prioritize suppliers with high-volume production capabilities and relevant certifications, such as IATF 16949:2016, to ensure quality and consistency.

Why is Wire EDM Essential for Medical Device Manufacturing?

Wire EDM services are essential in the medical device industry for crafting intricate parts used in surgical instruments and implants. The high precision and smooth finishes provided by wire EDM are crucial for the safety and effectiveness of these devices. Buyers in this sector must focus on sourcing from ISO 13485 certified manufacturers to ensure compliance with stringent medical standards, as well as material traceability to maintain high-quality production.

How Does Wire EDM Benefit Electronics Fabrication?

In the electronics sector, wire EDM is employed to fabricate connectors and intricate circuit components. This technique allows for the creation of precise parts that enhance the performance and reliability of electronic devices. International buyers should seek suppliers with expertise in fine wire EDM and rapid prototyping capabilities to meet the fast-paced demands of the electronics market. Ensuring that suppliers have a track record of quality and compliance will further mitigate risks in sourcing.

What Advantages Does Wire EDM Offer in Tool and Die Manufacturing?

Wire EDM is a cornerstone in tool and die manufacturing, providing the precision necessary for developing tooling used in various manufacturing processes. This method optimizes production, reduces waste, and enhances the overall efficiency of the manufacturing cycle. When sourcing wire EDM services for tooling, buyers should look for suppliers that can handle complex geometries and offer tight tolerances, ensuring that the tools produced will meet the rigorous demands of production environments.

3 Common User Pain Points for ‘wire edm services’ & Their Solutions

Scenario 1: Prototyping Delays Due to Complex Designs

The Problem: Many manufacturers face significant delays when prototyping intricate designs using traditional machining methods. When working with complex geometries, the limitations of conventional tools can lead to extended lead times and increased costs. This issue is especially pronounced in industries such as aerospace and medical devices, where precision is critical. B2B buyers often find themselves frustrated when they need to meet tight deadlines but their current machining capabilities cannot accommodate the intricate specifications of their designs.

The Solution: To alleviate this challenge, buyers should consider leveraging the capabilities of wire EDM services, which excel in producing high-precision parts without the need for custom tooling. When sourcing a wire EDM provider, it’s essential to look for companies with a robust portfolio that demonstrates their ability to handle complex geometries and tight tolerances. By engaging with a supplier early in the design process, manufacturers can receive valuable insights on design modifications that enhance manufacturability and reduce production time. Moreover, opting for a supplier with a diverse range of machines and technologies allows for flexibility in accommodating varying project sizes, from prototypes to high-volume production runs.

Scenario 2: Inconsistent Quality and Tolerances Across Orders

The Problem: Quality consistency is a significant concern for B2B buyers relying on wire EDM services, especially when dealing with multiple orders over time. Variations in part quality, surface finish, and tolerances can lead to downstream issues, including assembly challenges and product failures. This inconsistency can result in increased costs due to rework, returns, and damage to the buyer’s reputation in their market.

The Solution: To ensure consistent quality, buyers should prioritize working with ISO-certified wire EDM service providers who adhere to strict quality management systems. When placing orders, clearly communicate the required tolerances and finishes to the supplier. Establishing a comprehensive quality assurance plan, which includes regular inspections and feedback loops, can help maintain high standards throughout the production process. Additionally, leveraging advanced technologies such as real-time monitoring and automated inspection systems can enhance quality control, reducing variability in output. By forging strong partnerships with suppliers that prioritize quality, buyers can mitigate risks associated with inconsistent part quality.

Scenario 3: High Costs Associated with Material Waste

The Problem: Material waste is a critical concern for manufacturers, particularly those working with expensive metals or specialized alloys. Traditional machining processes often generate significant scrap material, leading to inflated production costs. B2B buyers may struggle with budget constraints while trying to maintain the integrity of their manufacturing processes, especially when producing parts in low volumes or from high-value materials.

The Solution: Wire EDM services present a cost-effective alternative to conventional machining by minimizing material waste through their precise cutting techniques. Buyers should engage with suppliers that offer capabilities such as submerged cutting and auto-threading, which optimize the use of material and reduce waste. When discussing project specifications with potential suppliers, consider requesting recommendations on how to design parts for maximum material efficiency. Additionally, suppliers experienced in working with different materials can offer insights into the best practices for minimizing waste, which can lead to significant cost savings. By adopting a strategic approach to sourcing wire EDM services, buyers can not only reduce material waste but also enhance their overall profitability.

Strategic Material Selection Guide for wire edm services

What Are the Key Properties of Common Materials Used in Wire EDM Services?

When selecting materials for wire EDM services, understanding the properties of each material is crucial for ensuring optimal performance in various applications. Here, we analyze four common materials: stainless steel, aluminum, titanium, and tool steel.

Stainless Steel: A Versatile Choice for Wire EDM

Stainless steel is renowned for its excellent corrosion resistance and high strength, making it suitable for a variety of applications, including medical devices, automotive components, and food processing equipment. Its temperature rating can reach up to 800°C, which is beneficial for high-heat environments.

Pros: Stainless steel offers durability, aesthetic appeal, and resistance to oxidation. Its versatility allows it to be used in both structural and decorative applications.

Cons: The material can be costly compared to other metals, and its machining can be more complex due to its toughness, potentially leading to longer lead times.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive environments, making it an ideal choice for industries requiring hygiene and durability.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A240 for stainless steel sheets and plates.

Aluminum: Lightweight and Cost-Effective

Aluminum is a lightweight material that offers excellent machinability and corrosion resistance, making it a popular choice for industries such as aerospace, automotive, and consumer electronics. Its temperature resistance is lower than that of stainless steel, typically around 600°C.

Pros: The primary advantage of aluminum is its low density, making it easier to handle and transport. Additionally, it is generally more affordable than stainless steel.

Cons: While it is easy to machine, aluminum can deform under high pressure, making it less suitable for high-stress applications.

Impact on Application: Aluminum’s compatibility with various media makes it an excellent choice for applications where weight reduction is critical, such as in aircraft components.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is essential for ensuring quality in aluminum products, particularly in regions like South America where regulatory scrutiny is increasing.

Titanium: Exceptional Strength-to-Weight Ratio

Titanium is celebrated for its high strength-to-weight ratio and excellent corrosion resistance, making it suitable for aerospace and medical applications. It can withstand temperatures up to 1,600°C, which is advantageous for high-performance environments.

Pros: Titanium is incredibly strong yet lightweight, making it ideal for applications where weight is a concern without sacrificing strength.

Cons: The cost of titanium is significantly higher than that of aluminum and stainless steel, and it presents challenges during machining due to its toughness.

Impact on Application: Titanium is particularly effective in environments that require both strength and resistance to extreme conditions, such as in aerospace and marine applications.

Considerations for International Buyers: Buyers must be aware of compliance with standards like ASTM B348 for titanium, especially in regions like Africa where sourcing quality materials can be challenging.

Tool Steel: The Go-To for Precision Components

Tool steel is designed for manufacturing tools and dies, offering high hardness and wear resistance, making it suitable for high-stress applications. Its temperature rating can vary widely depending on the specific type of tool steel used.

Pros: Tool steel is exceptionally durable and can maintain its hardness even at elevated temperatures, making it ideal for cutting tools and dies.

Cons: The complexity of machining tool steel can lead to higher manufacturing costs and longer lead times.

Impact on Application: Tool steel is often used in applications requiring precision and durability, such as molds and dies in the manufacturing sector.

Considerations for International Buyers: Compliance with standards such as ASTM A681 is crucial for tool steel, particularly for buyers in Europe and the Middle East where quality standards are stringent.

Summary Table of Material Selection for Wire EDM Services

| Material | Typical Use Case for wire edm services | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Medical devices, automotive components | Excellent corrosion resistance | Higher cost and complex machining | High |

| Aluminum | Aerospace, automotive, consumer electronics | Lightweight and cost-effective | Can deform under high pressure | Medium |

| Titanium | Aerospace, marine applications | High strength-to-weight ratio | Very high cost and challenging to machine | High |

| Tool Steel | Manufacturing tools, molds, and dies | Exceptional durability | Complex machining increases cost | Medium to High |

This strategic material selection guide provides valuable insights for international B2B buyers looking to optimize their wire EDM services. Understanding the properties, advantages, and limitations of each material will enable informed decision-making tailored to specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for wire edm services

What Are the Key Stages in the Wire EDM Manufacturing Process?

Wire Electrical Discharge Machining (EDM) is a sophisticated manufacturing technique that involves several critical stages to ensure precision and quality. The main stages include material preparation, forming, assembly, and finishing.

How Does Material Preparation Work in Wire EDM?

Material preparation is the first and foremost step in the wire EDM process. It begins with selecting the right type of conductive material, which can include tool steel, titanium, or other exotic materials. The chosen material is then cut into manageable sizes and shapes, ensuring it fits within the wire EDM machine’s operational limits. Additionally, thorough cleaning of the material is crucial to remove any contaminants that could affect the machining process.

Proper material preparation not only ensures better cutting efficiency but also enhances the overall quality of the finished product. B2B buyers should inquire about the supplier’s material sourcing and handling processes to ensure they are using high-quality, consistent materials.

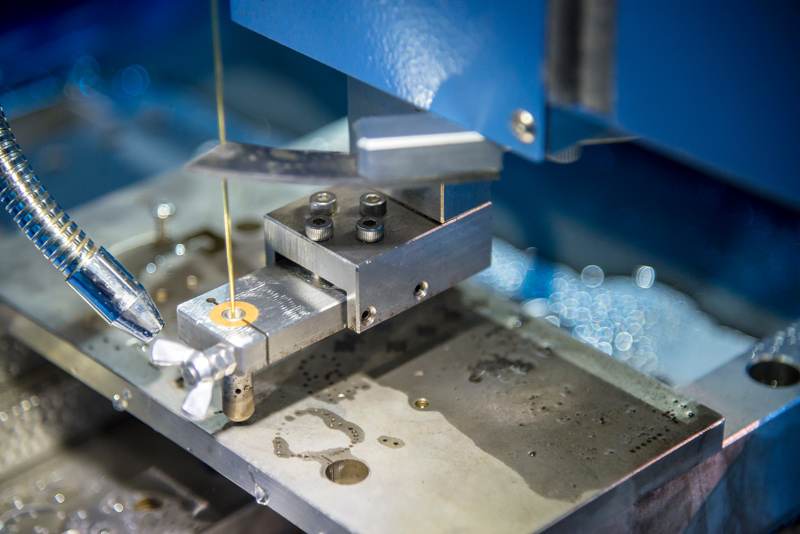

What Techniques Are Involved in the Forming Stage of Wire EDM?

The forming stage in wire EDM is where the actual machining takes place. A thin, electrically charged wire is used to create precise cuts in the workpiece without direct contact, minimizing distortion and ensuring tight tolerances. The process involves the following key techniques:

-

CNC Control: The wire EDM machine is controlled by a Computer Numerical Control (CNC) system, allowing for complex geometries and intricate designs to be machined with high precision.

-

Spark Erosion: The wire generates sparks that erode the material as it moves along the programmed path. This allows for the machining of delicate and complex parts that would be difficult to achieve using traditional machining methods.

-

Submerged Cutting: In many cases, the workpiece is submerged in deionized water during the cutting process. This not only cools the workpiece but also enhances the stability of the cutting operation, reducing thermal distortion.

By understanding these techniques, B2B buyers can better assess the capabilities of potential suppliers and their ability to meet specific project requirements.

How Is Assembly Handled in Wire EDM Services?

While wire EDM primarily focuses on machining individual parts, assembly may be necessary for certain applications. In this stage, machined components are carefully fitted together, ensuring that tolerances are maintained. Assembly may involve additional processes such as welding or fastening, depending on the design specifications.

B2B buyers should clarify whether the supplier offers assembly services and how they ensure that the assembled parts meet the required specifications. This can be a vital aspect for buyers looking for a one-stop solution.

What Finishing Techniques Are Commonly Used in Wire EDM?

Finishing is a critical stage that can greatly influence the final quality of the parts produced through wire EDM. Common finishing techniques include:

- Electropolishing: This electrochemical process enhances the surface finish by reducing roughness and improving corrosion resistance.

- Anodizing: Particularly for aluminum parts, anodizing adds a protective layer that enhances durability and aesthetics.

- Tumbling: This process removes sharp edges and burrs from the machined parts, improving their overall quality.

B2B buyers should inquire about the finishing options available and how these can be tailored to meet specific application requirements.

What Quality Assurance Standards Should B2B Buyers Expect?

Quality assurance (QA) is paramount in wire EDM services, as the precision of the machined parts is critical to their performance in end-use applications. Key international standards that suppliers should comply with include ISO 9001:2015, which ensures a consistent quality management system, and industry-specific standards like AS9100D for aerospace applications and IATF 16949:2016 for automotive manufacturing.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) checkpoints are integral to the manufacturing process. Common QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the quality of the machining process and ensure adherence to specifications.

- Final Quality Control (FQC): Before shipment, final inspections are performed to verify that the finished parts meet all quality standards.

B2B buyers should ask potential suppliers about their QC processes and how they document compliance with relevant standards.

What Testing Methods Are Commonly Used in Wire EDM?

Testing methods employed in wire EDM services can vary based on the industry and application. Common methods include:

- Dimensional Inspection: Utilizing calipers, micrometers, or coordinate measuring machines (CMM) to verify that parts meet specified dimensions and tolerances.

- Surface Finish Testing: Techniques such as profilometry assess the surface finish of machined parts to ensure they meet quality requirements.

- Functional Testing: Some applications may require functional testing to verify that parts perform as intended in their end-use applications.

By understanding the testing methods used, B2B buyers can make informed decisions about supplier capabilities.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are several strategies:

-

Conduct Audits: Regular audits of suppliers can provide insights into their QC processes and adherence to international standards. Buyers should request audit reports to assess compliance.

-

Request Documentation: Suppliers should provide documentation of their QC processes, including inspection reports and certification records.

-

Utilize Third-Party Inspection Services: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures and the quality of the products manufactured.

-

Understand Certification Nuances: Different regions may have varying certification requirements. B2B buyers should ensure that suppliers’ certifications are recognized in their respective countries to avoid complications.

By leveraging these strategies, B2B buyers can mitigate risks and ensure they partner with suppliers who prioritize quality and compliance in their wire EDM services.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wire edm services’

This guide provides a structured approach for B2B buyers looking to procure wire EDM (Electrical Discharge Machining) services. Understanding the intricacies of wire EDM and selecting the right supplier can significantly impact product quality, delivery timelines, and overall project success. Follow this checklist to ensure a smooth sourcing process.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your wire EDM project. This includes dimensions, tolerances, materials, and surface finishes. Clear specifications help suppliers provide accurate quotes and timelines, ensuring that the final product meets your expectations.

- Considerations:

- What are the exact dimensions and tolerances needed?

- Are there specific materials required (e.g., tool steel, titanium)?

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential wire EDM service providers. Look for companies with a strong reputation and a history of delivering high-quality parts. Online reviews, industry forums, and trade shows can provide insights into their capabilities.

- Tips:

- Check for industry certifications like ISO 9001:2015 or AS9100D.

- Focus on suppliers with experience in your specific industry.

Step 3: Evaluate Supplier Capabilities

Assess the technical capabilities of each supplier. This includes the types of machines they use, their range of services, and the materials they can work with. Understanding their technological edge is crucial for ensuring they can meet your project requirements.

- Key Aspects:

- Do they have advanced machines for intricate designs?

- What is their maximum material thickness and tolerances?

Step 4: Verify Supplier Certifications

Confirm that potential suppliers hold relevant certifications that demonstrate their commitment to quality and safety standards. This can assure you of their operational reliability and adherence to industry norms.

- Important Certifications:

- ISO 9001:2015 for quality management.

- IATF 16949:2016 if automotive parts are involved.

Step 5: Request Quotes and Compare

Contact shortlisted suppliers to request detailed quotes. Ensure that you provide them with the same set of specifications for accurate comparisons. Look beyond price; consider factors such as delivery times, customer service, and payment terms.

- Comparison Factors:

- What is the lead time for each quote?

- Are there any additional costs (e.g., shipping, tooling)?

Step 6: Assess Communication and Support

Evaluate the responsiveness and support of potential suppliers. Effective communication is vital for addressing any issues that may arise during the production process. A supplier that provides clear, timely updates will enhance your project’s success.

- Communication Tips:

- Are they available for regular check-ins?

- Do they provide clear documentation and updates?

Step 7: Conduct a Trial Order

Before committing to large-scale production, consider placing a small trial order. This allows you to assess the quality of their work, adherence to specifications, and overall service. A successful trial can build confidence in your supplier choice.

- Trial Considerations:

- How well do they meet your specifications?

- Is the delivery on time, and is the part quality satisfactory?

By following this checklist, B2B buyers can make informed decisions when sourcing wire EDM services, ensuring a partnership that aligns with their technical and operational needs.

Comprehensive Cost and Pricing Analysis for wire edm services Sourcing

What Are the Key Cost Components in Wire EDM Services?

When sourcing wire EDM services, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of wire and workpiece material significantly impact costs. High-quality materials, such as tool steels or exotic alloys, may raise expenses but offer better performance and durability.

-

Labor: Skilled labor is essential for operating wire EDM machinery and ensuring quality. Labor costs can vary based on geographic location, availability of skilled workers, and the complexity of the job.

-

Manufacturing Overhead: This includes utilities, facility costs, equipment maintenance, and depreciation. Overhead can vary widely depending on the supplier’s operational efficiency and technology level.

-

Tooling: While wire EDM does not require custom tooling, any specialized fixtures or setups can incur additional costs. Buyers should inquire about any tooling fees upfront.

-

Quality Control (QC): Ensuring precision and adherence to specifications requires robust QC processes. Costs associated with inspection, testing, and certifications should be factored into the overall pricing.

-

Logistics: Shipping and handling fees can add to costs, particularly for international buyers. Factors like distance, shipping method, and Incoterms can influence these expenses.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market demand, competition, and service quality.

How Do Price Influencers Affect Wire EDM Service Costs?

Several factors can influence pricing for wire EDM services:

-

Volume/MOQ: The quantity of parts ordered often affects pricing. Larger volumes may lead to bulk discounts, while smaller orders could incur higher per-unit costs.

-

Specifications and Customization: Highly customized parts with stringent specifications may lead to increased costs due to additional processing time and material requirements.

-

Material Choices: Different materials have varying costs. Buyers should evaluate the cost-benefit ratio of using premium materials versus standard options.

-

Quality and Certifications: Suppliers with higher quality standards and certifications (e.g., ISO) may charge more, but this can result in better reliability and lower long-term risks.

-

Supplier Factors: The supplier’s reputation, technological capabilities, and geographical location can affect pricing. Buyers should assess potential suppliers based on their experience and past performance.

-

Incoterms: Understanding the agreed-upon Incoterms is vital for cost estimation. Different terms can shift responsibilities and costs related to shipping, insurance, and import duties.

What Tips Can Help Buyers Negotiate Better Prices for Wire EDM Services?

B2B buyers can take several steps to enhance cost-efficiency when sourcing wire EDM services:

-

Negotiate Volume Discounts: When feasible, consolidate orders to achieve higher volumes, which can lead to better pricing.

-

Assess Total Cost of Ownership (TCO): Consider the long-term costs associated with the components, including maintenance, potential rework, and logistics, rather than focusing solely on upfront pricing.

-

Request Multiple Quotes: Engaging multiple suppliers can provide a clearer picture of the market rate and leverage during negotiations.

-

Clarify Specifications Early: Providing clear and detailed specifications upfront can minimize misunderstandings and potential cost overruns.

-

Explore Supplier Partnerships: Establishing long-term relationships with reliable suppliers can lead to better pricing, quality assurance, and priority service.

-

Understand Pricing Nuances for International Transactions: When sourcing from regions like Africa or South America, be aware of potential tariffs, exchange rates, and varying shipping costs that can influence the final price.

Conclusion and Disclaimer on Pricing

Pricing for wire EDM services can vary widely based on numerous factors. It is essential for buyers to conduct thorough research and engage in open discussions with potential suppliers to obtain accurate quotes. The insights provided here are intended for guidance; actual prices may differ based on specific project requirements and market conditions.

Alternatives Analysis: Comparing wire edm services With Other Solutions

Exploring Alternatives to Wire EDM Services

In the realm of precision machining, wire EDM (Electrical Discharge Machining) services offer unique advantages, particularly for intricate and delicate parts. However, various alternatives exist that may better suit specific project requirements or budget constraints. This section will analyze wire EDM services in comparison to two viable alternatives: CNC Milling and Laser Cutting.

Comparison Table

| Comparison Aspect | Wire EDM Services | CNC Milling | Laser Cutting |

|---|---|---|---|

| Performance | High precision with tight tolerances (+/- 0.0001″) | Good precision; less effective on hard materials | Fast cutting speed; good for thin materials |

| Cost | Generally higher due to setup and expertise | Moderate; varies with complexity and material | Lower for simple cuts, but can increase with thickness |

| Ease of Implementation | Requires skilled operators and setup | Easier setup for simple parts | User-friendly with minimal setup required |

| Maintenance | High maintenance due to delicate machinery | Moderate; regular maintenance needed | Low maintenance; robust machinery |

| Best Use Case | Complex, delicate parts with high hardness | Versatile; suitable for a wide range of materials | Fast prototyping and cutting of sheet materials |

Detailed Breakdown of Alternatives

CNC Milling

CNC Milling is a subtractive manufacturing process that uses rotary cutters to remove material from a workpiece. It is particularly effective for creating complex geometries and can work with a wide range of materials, including metals and plastics. One of the significant advantages of CNC milling is its flexibility in design, allowing for the production of both simple and complex parts.

However, while CNC milling offers good precision, it may not match the accuracy of wire EDM for very tight tolerances. Additionally, CNC milling can generate burrs, necessitating further finishing processes, which may increase the overall production time. It is best suited for projects that require moderate precision and can accommodate a slightly longer lead time.

Laser Cutting

Laser Cutting utilizes focused laser beams to cut through materials, making it one of the fastest methods for creating shapes in thin sheets. This method is particularly advantageous for high-speed production and is well-suited for non-metal materials like plastics and wood, as well as thin metal sheets.

While laser cutting is cost-effective for large volumes of simple designs, it may not be suitable for complex shapes or materials requiring high precision, such as hardened steels. Additionally, laser cutting can produce heat-affected zones, which may compromise the integrity of certain materials. This method is ideal for prototypes or projects where speed is more critical than tight tolerances.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate machining method involves evaluating specific project requirements such as material type, complexity, volume, and budget. Wire EDM services excel in high-precision applications, particularly for intricate geometries and hard materials, but may come at a higher cost and require more maintenance. On the other hand, CNC milling offers versatility and ease of implementation, making it suitable for a range of projects, while laser cutting provides speed and efficiency for simpler designs.

By carefully assessing these factors, B2B buyers can make informed decisions that align with their operational goals and project specifications, ensuring that they choose the most effective machining solution for their needs.

Essential Technical Properties and Trade Terminology for wire edm services

What Are the Critical Technical Properties of Wire EDM Services?

Understanding the essential technical properties of wire EDM services is crucial for B2B buyers looking to optimize their manufacturing processes. Here are some key specifications:

Material Grade

Material grade refers to the specific type of metal or alloy used in the machining process. Common materials include tool steels, stainless steels, and aluminum. The choice of material impacts the part’s durability, performance, and suitability for various applications. For example, hardened tool steels are often used for components requiring high wear resistance.

Tolerance

Tolerance defines the acceptable range of variation in a part’s dimensions. In wire EDM, tolerances can be as tight as ±0.0001 inches. This precision is critical for industries such as aerospace and medical, where components must fit perfectly to ensure safety and functionality. Tight tolerances minimize the risk of assembly issues and improve the overall quality of the final product.

Surface Finish

Surface finish describes the texture and smoothness of a machined part. Wire EDM can produce finishes that eliminate the need for additional polishing, which is essential for reducing production time and costs. Options such as bead blasting or anodizing can enhance both aesthetics and performance, making it important for buyers to specify their surface finish requirements upfront.

Thickness Capability

Wire EDM is capable of machining parts up to 16 inches thick, allowing for versatility in manufacturing. This capability is particularly beneficial for buyers in industries that require large, complex components, such as automotive or heavy machinery. Understanding the maximum thickness a provider can handle is vital for project planning and cost estimation.

Cutting Speed

Cutting speed refers to the rate at which the wire EDM machine can cut through materials. This is influenced by factors such as the wire diameter and the material’s hardness. Faster cutting speeds can lead to reduced lead times, which is advantageous for buyers with tight deadlines. Knowing the cutting speed can help buyers manage expectations and align project timelines.

What Common Trade Terms Should B2B Buyers Know in Wire EDM Services?

Familiarity with industry jargon can facilitate smoother communication between buyers and suppliers. Here are some common terms:

OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products or components that are then sold under another brand’s name. In the context of wire EDM, OEMs often require specialized parts that meet specific performance standards. Understanding this term helps buyers recognize the importance of sourcing high-quality components for their final products.

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. In wire EDM services, MOQs can vary based on the complexity of the part and the production setup. Buyers should inquire about MOQs to ensure they can meet their production needs without incurring unnecessary costs.

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. For wire EDM services, an RFQ should include detailed specifications, quantities, and timelines. This process helps buyers obtain competitive quotes and ensures that they receive accurate information for informed decision-making.

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. For wire EDM services, understanding Incoterms is crucial for clarifying who bears the costs and risks associated with shipping and delivery. This knowledge helps buyers negotiate better terms and manage logistics effectively.

CAD (Computer-Aided Design)

CAD refers to the use of software to create precision drawings or technical illustrations. In wire EDM, CAD files are often used to communicate part specifications to manufacturers. Familiarity with CAD can enhance collaboration between buyers and suppliers, streamlining the design and production process.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when engaging with wire EDM service providers, ensuring that their projects meet both quality and efficiency standards.

Navigating Market Dynamics and Sourcing Trends in the wire edm services Sector

What Are the Key Trends Driving the Wire EDM Services Market?

The global wire EDM services market is experiencing dynamic shifts driven by advancements in technology, increasing demand for precision manufacturing, and the growing complexity of components across various industries. One of the primary drivers is the aerospace and automotive sectors, which require high-precision parts that can withstand extreme conditions. Countries in Africa, South America, the Middle East, and Europe, including Brazil and Saudi Arabia, are increasingly investing in these sectors, creating a burgeoning demand for wire EDM services.

Emerging technologies such as automation and AI are enhancing the efficiency and accuracy of wire EDM processes. B2B buyers are now more inclined to partner with suppliers who leverage these technologies to ensure faster turnaround times and reduced costs. Additionally, the rise of Industry 4.0 emphasizes real-time data analytics, allowing manufacturers to optimize their operations and supply chains effectively.

Sourcing trends are also evolving, with international buyers seeking suppliers that offer flexible production capabilities, including rapid prototyping and high-volume runs. This flexibility is crucial for companies looking to respond quickly to market demands without sacrificing quality. Furthermore, the emphasis on local sourcing due to geopolitical uncertainties and supply chain disruptions is prompting buyers to explore regional suppliers that can provide reliable wire EDM services.

How Are Sustainability and Ethical Sourcing Influencing B2B Decisions in Wire EDM Services?

Sustainability is becoming a pivotal concern for B2B buyers in the wire EDM services sector. The environmental impact of manufacturing processes is under scrutiny, leading companies to seek partners committed to reducing waste and energy consumption. Wire EDM, known for its minimal material waste and high efficiency, aligns well with these sustainability goals.

Buyers are increasingly prioritizing suppliers with recognized ‘green’ certifications and those that utilize environmentally friendly materials. Certifications such as ISO 14001 demonstrate a commitment to effective environmental management systems, which can influence purchasing decisions. Additionally, the use of recyclable materials in wire EDM processes not only reduces the environmental footprint but also appeals to eco-conscious buyers.

Ethical sourcing is equally vital, as companies are expected to uphold high standards throughout their supply chains. This includes ensuring fair labor practices and transparency in sourcing materials. B2B buyers are likely to favor suppliers who can provide detailed information about their sourcing practices and sustainability initiatives, reflecting a broader commitment to corporate social responsibility.

How Has Wire EDM Technology Evolved Over Time?

The evolution of wire EDM technology has significantly shaped its role in modern manufacturing. Initially developed in the 1950s, the process has undergone transformative changes, with advancements in CNC technology and materials science enhancing its precision and efficiency. Early machines were limited by speed and accuracy, but today’s wire EDM systems can achieve tolerances of ±0.0001 inches, making them indispensable for industries requiring intricate designs and high-quality finishes.

The introduction of fine wire EDM has further expanded capabilities, allowing for the machining of extremely small and complex parts that were previously unattainable. With ongoing innovations, including automation and improved power supply systems, wire EDM continues to adapt to the ever-evolving demands of the manufacturing landscape. As a result, B2B buyers are now presented with a range of options that cater to diverse requirements, from rapid prototyping to large-scale production. This evolution highlights the importance of staying informed about technological advancements when sourcing wire EDM services.

Frequently Asked Questions (FAQs) for B2B Buyers of wire edm services

-

How do I choose the right wire EDM service provider?

Choosing the right wire EDM service provider involves assessing several key factors. First, verify their certifications, such as ISO 9001 or AS9100, which indicate adherence to quality management standards. Review their experience and capabilities, focusing on their ability to handle your specific materials and tolerances. Request samples of previous work to evaluate quality, and consider their production capacity for your project volume. Lastly, check customer reviews and testimonials to gauge reliability and service quality. -

What are the key benefits of using wire EDM over traditional machining methods?

Wire EDM offers several advantages compared to traditional machining. It can achieve tighter tolerances, often up to +/- .0001 inches, making it ideal for intricate designs. The process generates minimal heat, reducing the risk of material distortion, which is especially beneficial for hard or exotic materials. Additionally, wire EDM does not require custom tooling, allowing for quicker turnaround times and lower costs for small to medium production runs. -

What is the typical lead time for wire EDM services?

Lead times for wire EDM services can vary significantly based on factors such as part complexity, volume, and the service provider’s current workload. Generally, prototyping can be completed in a matter of days, while larger production runs may take several weeks. It’s advisable to communicate your deadlines clearly with potential suppliers and request a detailed timeline to ensure they can meet your project requirements. -

What minimum order quantities (MOQs) should I expect for wire EDM services?

Minimum order quantities for wire EDM services can differ among suppliers. Some may accommodate single prototypes, while others may have MOQs ranging from 10 to 100 pieces, particularly for production runs. It’s crucial to discuss your specific needs upfront to find a supplier that aligns with your project scale, especially if you are operating in regions with varying manufacturing norms. -

How do I ensure quality assurance in wire EDM projects?

To ensure quality assurance in wire EDM projects, start by selecting suppliers with robust quality management systems, such as ISO certification. Discuss their inspection processes, including the use of precision measuring tools and techniques for monitoring tolerances. Request documentation of quality checks and consider implementing a first-article inspection process, where the first item produced is thoroughly checked against specifications before full production begins. -

What payment terms should I negotiate with wire EDM suppliers?

Payment terms can vary widely among wire EDM suppliers, influenced by factors such as order size and customer relationship. Common practices include upfront payments, net 30/60 terms, or progress payments based on project milestones. Negotiate terms that align with your cash flow and project timeline, and ensure all agreements are documented in the contract to avoid misunderstandings later. -

What should I consider regarding logistics and shipping for international wire EDM services?

When sourcing wire EDM services internationally, consider logistics factors like shipping costs, lead times, and customs regulations. Ensure that the supplier can provide reliable shipping options and track the shipment throughout the process. Additionally, familiarize yourself with import tariffs and duties in your country, which can affect overall project costs. Establish clear communication with your supplier to coordinate shipping schedules that align with your project timelines. -

Can wire EDM services accommodate custom designs and modifications?

Yes, wire EDM services can accommodate custom designs and modifications, making it a flexible option for various applications. When discussing your project with potential suppliers, provide detailed drawings and specifications, and be open to their input on manufacturability improvements. Many wire EDM providers have extensive experience with design modifications and can suggest adjustments that enhance production efficiency or reduce costs while maintaining quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Wire Edm Services Manufacturers & Suppliers List

1. XACT Wire EDM – Precision Wire EDM Machining Services

Domain: xactedm.com

Registered: 1997 (28 years)

Introduction: XACT Wire EDM offers precision wire EDM machining services for prototypes, medium-volume runs, and high-volume production. Key capabilities include tolerances to +/-.0001″, machining pieces up to 16″ thick, 4-axis intricate contours, small diameter wires, and submerged cutting for thermal stability. The company utilizes over 45 EDM machines, including models from GF and Sodick, with various travel…

2. eMachineShop – Wire EDM Services

Domain: emachineshop.com

Registered: 1999 (26 years)

Introduction: Wire EDM Services: eMachineShop offers sinker and wire EDM machining services for single parts, prototypes, or production orders. Key features include: 50+ materials available, free shipping in the USA, and 100% quality guaranteed. Advantages of Wire EDM include the ability to produce sharp inside corners, ideal for parts with thin walls, suitable for metals with low machinability, and no burring….

3. KLH Industries – Precision Wire EDM Services

Domain: klhindustries.com

Registered: 1998 (27 years)

Introduction: Wire EDM services with +/- 0.0001″ (0.0025 mm) tolerances; micro wire capabilities down to 0.0012″; work envelope of 29″ X 19″ X 26″; 2 RA surface finish (μ in); capable of cutting all conductive materials including soft/hard metals, graphite, carbide, and polycrystalline diamond; 45° angled taper precision cuts accurate to 3 seconds; 24/7 operational availability; Nadcap certified for Nonconventi…

4. Prototek – High-Precision EDM Services

Domain: prototek.com

Registered: 1996 (29 years)

Introduction: Machining Service: Wire & Sinker EDM

– High-precision wire & sinker EDM services

– Features: Repeatability, High Dimensional Tolerances, Custom Prototypes and End-Use Parts

– Certifications: ISO 9001:2015, AS9100D, ITAR

– Instant and Engineer-Assisted Quotes

– Materials: 100+ materials available, including Aluminum, Inconel, Stainless Steel, Steel, Titanium, and more

– Surface Finishes: 40+ option…

5. United Centerless Grinding – Wire EDM Solutions

Domain: unitedcenterlessgrinding.net

Registered: 2010 (15 years)

Introduction: Wire EDM (Electrical Discharge Machining) is an electrothermal machining process using a thin single-strand metal wire as a tool electrode to cut through metal workpieces with precision. It is suitable for intricate tolerances, material stress limitations, and surface finish specifications. Key capabilities include:

– Wire diameter: .004 to .010 inches

– Tolerances: +/- .0002 inches

– Maximum p…

6. RapidDirect – Wire EDM Machining Services

Domain: rapiddirect.com

Registered: 2010 (15 years)

Introduction: Wire EDM Machining Services: Precision-engineered parts with high accuracy and intricacy, ideal for complex geometries. Certifications: ISO 9001:2015, ISO 13485, ISO 14001:2015, IATF 16949:2016. Key Features: 1. High Quality Parts: Top-tier EDM machinery with precision tolerance up to +/-0.001″. 2. Fast Lead Time: Quick project turnarounds as fast as 1 day. 3. Online Ordering and Quoting: Efficien…

Strategic Sourcing Conclusion and Outlook for wire edm services

What Are the Key Takeaways for Strategic Sourcing of Wire EDM Services?

In conclusion, strategic sourcing of wire EDM services offers numerous advantages for international B2B buyers. The ability to procure high-precision components without the need for custom tooling streamlines production processes, reducing both time and costs. Wire EDM’s unique capabilities—such as handling hard materials, achieving tight tolerances, and delivering superior surface finishes—make it an essential machining method for various industries.

By leveraging a network of certified suppliers, companies can ensure quality and compliance with international standards, thus enhancing their competitive edge in global markets. For buyers in regions like Africa, South America, the Middle East, and Europe, forming partnerships with experienced wire EDM providers can lead to innovation and efficiency in manufacturing.

How Can You Prepare for Future Opportunities in Wire EDM Services?

As the demand for precision engineering grows, investing in strategic sourcing of wire EDM services will be crucial. This approach not only addresses immediate production needs but also positions businesses for future advancements in technology and manufacturing processes. Take the initiative to explore potential partnerships today, and unlock the full potential of wire EDM services to drive your business forward.