Contents

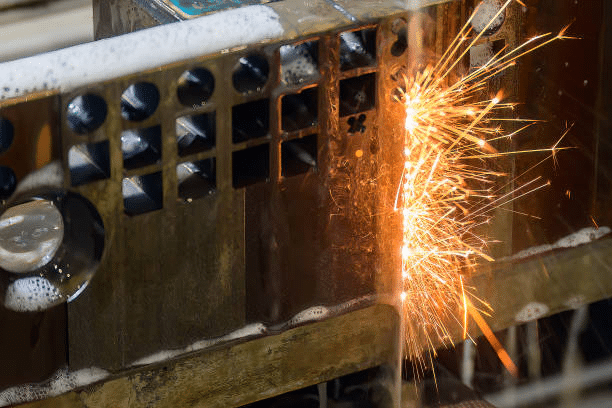

Manufacturing Insight: Wire Cutting Steel

Precision Wire EDM for Complex Steel Components

Wire electrical discharge machining (EDM) remains the definitive solution for fabricating intricate steel components where conventional machining reaches its physical limits. At Honyo Prototype, our CNC wire cutting services specialize in processing hardened tool steels, stainless alloys, and exotic metals with micron-level accuracy—achieving tolerances down to ±0.0001″ and surface finishes below Ra 0.4 µm. This capability is critical for aerospace seals, medical device components, and die/mold cavities requiring zero thermal distortion and exceptional geometric fidelity.

Our advanced wire EDM fleet features multi-axis AgieCharmilles and Sodick systems, utilizing deionized water dielectric and precision-guided electrode wire to maintain consistent kerf width while cutting complex contours in materials up to 16″ thick. Unlike laser or plasma alternatives, wire EDM eliminates recast layers and micro-cracking in hardened steel, ensuring structural integrity for mission-critical applications. Every operation adheres to ISO 9001:2015 protocols, with real-time process monitoring to guarantee first-article compliance.

Accelerate your prototyping or low-volume production timeline through Honyo Prototype’s Online Instant Quote platform. Upload CAD files to receive a detailed manufacturability analysis and competitive pricing within hours—not days—enabling faster iteration cycles without compromising on precision engineering standards.

Technical Capabilities

Technical specifications for wire cutting, also known as Wire Electrical Discharge Machining (Wire EDM), involve high-precision thermal machining processes that use a thin electrified wire (typically brass or coated brass) to cut conductive materials with exceptional accuracy. While Wire EDM is not a milling or turning process per se, it is often used in conjunction with 3-, 4-, and 5-axis CNC machining workflows to achieve tight tolerances and complex geometries—especially in hardened steels and difficult-to-machine alloys.

Wire EDM excels in secondary operations where tight tolerances (±0.0002″ or ±0.005 mm) and fine surface finishes are critical. It is typically used after primary milling or turning to produce intricate contours, sharp internal corners, and precision apertures.

Below is a comparison of material suitability and typical performance metrics for Wire EDM in high-precision manufacturing environments:

| Material | Conductivity | Machinability (Wire EDM) | Typical Tolerance (±) | Max Aspect Ratio | Surface Finish (Ra) | Notes |

|---|---|---|---|---|---|---|

| Aluminum | High | Excellent | 0.0002″ (0.005 mm) | 10:1 | 8–16 µin (0.2–0.4 µm) | Fast cutting rates; minimal recast layer |

| Steel (Mild) | Moderate | Very Good | 0.0002″ (0.005 mm) | 12:1 | 12–20 µin (0.3–0.5 µm) | Consistent results; moderate speed |

| Steel (Hardened, e.g., D2, H13) | Moderate | Excellent | 0.0002″ (0.005 mm) | 15:1 | 10–16 µin (0.25–0.4 µm) | Ideal for tooling; no mechanical stress |

| ABS | Non-Conductive | Not Compatible | N/A | N/A | N/A | Cannot be processed via Wire EDM |

| Nylon | Non-Conductive | Not Compatible | N/A | N/A | N/A | Requires conductive additive for EDM use |

Notes on 3/4/5-Axis Integration:

While Wire EDM is inherently a 2-axis (X-Y) or 4-axis (X-Y, U-V taper) process, modern machines support programmable tapers and multi-axis synchronization. True 5-axis Wire EDM is rare but emerging in advanced tool and die applications. In hybrid workflows, Wire EDM complements 5-axis milling by finishing complex dies, inserts, and electrodes originally roughed out on multi-axis CNC mills.

Tight Tolerance Capability:

Wire EDM is capable of holding ±0.0001″ (±0.0025 mm) in controlled environments with high-accuracy machines. This makes it ideal for aerospace components, medical devices, and mold cores/cavities requiring micron-level precision.

Material Constraints:

Only electrically conductive materials can be processed. Plastics such as ABS and nylon are non-conductive and therefore incompatible with standard Wire EDM unless loaded with conductive fillers—though even then, results are inconsistent and not recommended for production use.

In summary, Wire EDM is a critical process for achieving tight-tolerance features in conductive metals like aluminum and steel, especially when integrated into a broader precision manufacturing strategy involving 3-, 4-, or 5-axis milling and turning.

From CAD to Part: The Process

Honyo Prototype Wire Electrical Discharge Machining (WEDM) Process for Steel Components

Honyo Prototype employs a rigorous, technology-driven workflow for Wire EDM of precision steel components, ensuring dimensional accuracy, surface integrity, and rapid turnaround. This process begins with CAD file submission and culminates in certified delivery, integrating automation and engineering expertise at each phase.

CAD File Upload and Validation

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid) via Honyo’s secure customer portal. Our system performs immediate validation checks for file integrity, unit consistency, and geometric completeness. Critical parameters such as material specification (e.g., AISI 4140, D2, or custom tool steels), required tolerances (±0.0001″ typical), and surface finish (Ra 0.4–1.6 μm) are extracted. Incomplete submissions trigger automated alerts for client clarification, preventing downstream delays.

AI-Powered Quoting and Feasibility Assessment

Validated CAD data feeds into Honyo’s proprietary AI quoting engine, which analyzes over 50 manufacturing variables including part complexity, kerf width requirements, taper angles, and electrode path length. The AI cross-references real-time machine availability, material costs, and historical production data to generate a binding quote within 2 hours. Crucially, the system flags high-risk geometries (e.g., sharp internal corners below 0.020″ radius or aspect ratios exceeding 10:1) and proposes preliminary solutions, such as multi-pass strategies or alternative wire diameters (0.004″–0.012″ brass).

Engineering-Led DFM Optimization

All projects undergo mandatory Design for Manufacturability (DFM) review by Honyo’s senior manufacturing engineers. This phase focuses on steel-specific challenges: mitigating recast layer formation, preventing wire breakage in hardened alloys (>50 HRC), and optimizing cutting sequences to minimize thermal distortion. Engineers collaborate with clients via annotated CAD markups to resolve issues like inadequate start holes or non-uniform wall thickness. Typical DFM outcomes include:

| DFM Parameter | Standard Resolution for Steel |

|---|---|

| Internal Corner Radius | Increased to ≥0.015″ to prevent wire deflection |

| Taper Angles | Limited to ≤15° per side for single-pass stability |

| Surface Finish | Specified Ra values adjusted to achievable ranges based on steel grade |

Precision WEDM Production

Approved designs move to Honyo’s climate-controlled WEDM floor, featuring Sodick AQ/AG series and Mitsubishi FA-V machines. Steel processing follows strict protocols:

Material is stress-relieved pre-cut for critical components (e.g., dies/molds)

Deionized water resistivity maintained at 10–18 MΩ·cm to ensure consistent spark erosion

Brass wire tension dynamically adjusted (250–500 gf) based on steel hardness

Multi-pass finishing with adaptive spark control reduces white layer to <2 μm

Real-time metrology via in-process touch probes verifies critical dimensions after roughing and semi-finishing passes, with full CMM inspection post-production.

Certified Delivery and Traceability

Completed steel components undergo final inspection against ASME Y14.5 GD&T requirements. Honyo provides:

First-article inspection reports (FAIR) with CMM data

Material test certificates (MTC) traceable to mill lots

Process validation records including wire consumption logs and dielectric fluid analysis

Parts ship in anti-corrosion packaging with humidity indicators, accompanied by digital delivery confirmation via the client portal. Typical lead time from CAD approval to shipment is 5–10 business days for single-part prototypes, with rush options available for qualified geometries.

This integrated approach ensures Honyo delivers steel WEDM parts with micron-level precision while minimizing client engineering overhead through predictive analytics and domain-specific process control.

Start Your Project

Looking for precision wire cutting steel services? Contact Susan Leo at [email protected] to discuss your project requirements. Our manufacturing facility is located in Shenzhen, ensuring high-quality production with fast turnaround times. Trust Honyo Prototype for reliable, industrial-grade wire cutting solutions tailored to your specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.