Contents

Manufacturing Insight: Welding Sheet Steel

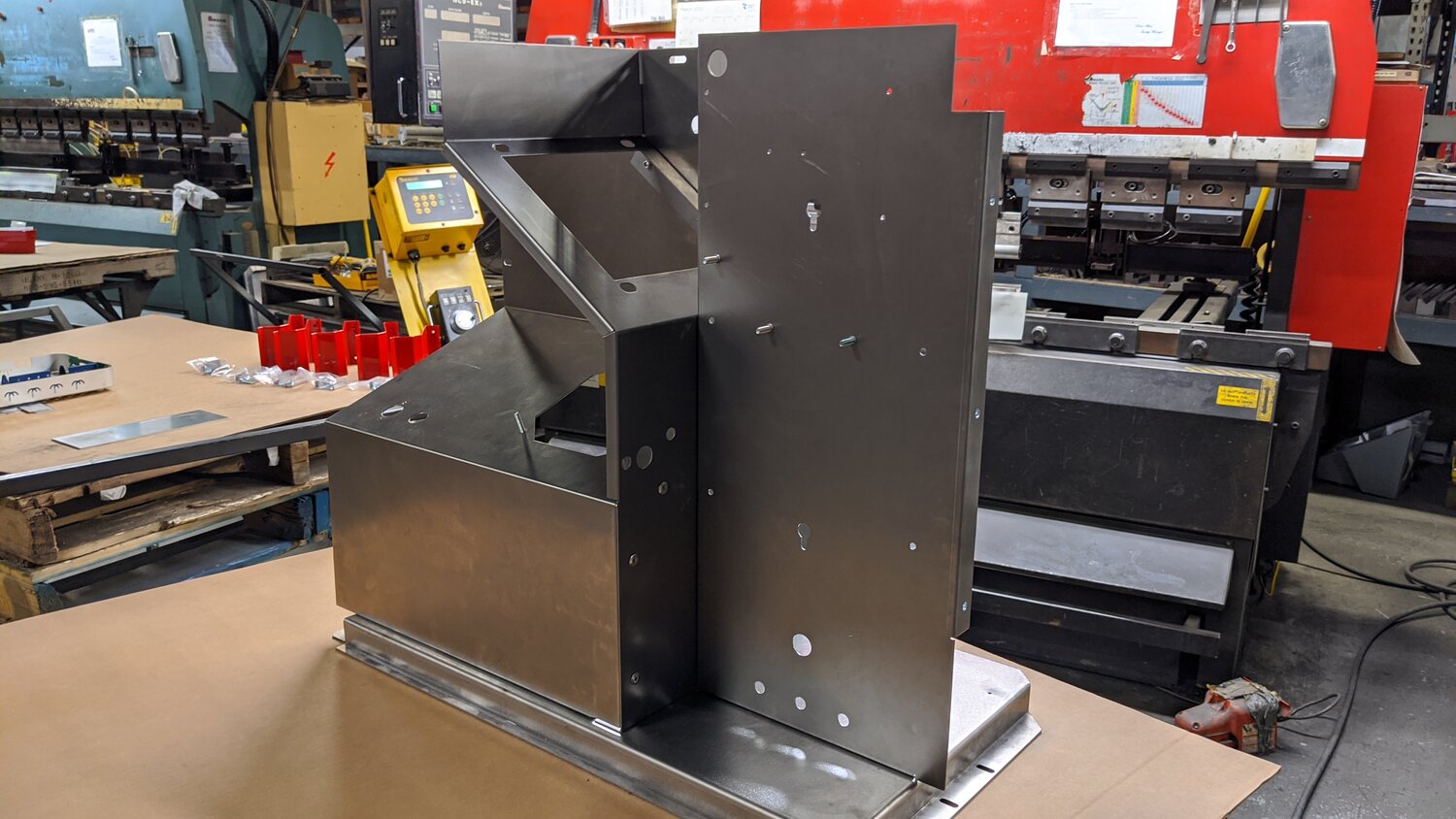

Precision Sheet Steel Welding for Demanding Applications

Honyo Prototype delivers expert sheet steel welding as a core competency within our comprehensive Sheet Metal Fabrication services. We specialize in joining low-carbon, stainless, and specialty alloy sheets with stringent attention to dimensional integrity, weld aesthetics, and structural performance. Our engineered approach mitigates common challenges like warpage and heat distortion through controlled parameters, optimized fixturing, and certified welding procedures tailored to material grades and thicknesses ranging from 0.5mm to 6mm.

Your projects benefit from seamless integration of welding within our end-to-end workflow, including precision laser cutting, CNC bending, finishing, and assembly. All welds undergo rigorous in-process inspection and final validation per AWS D1.1 or client-specified standards, ensuring compliance for aerospace, medical, and industrial equipment applications where failure is not an option.

Accelerate your prototyping or low-volume production with Honyo’s Online Instant Quote platform. Upload your STEP or DXF files to receive a detailed, binding quotation for complete sheet metal fabrication—including welding—within hours, not days. Eliminate procurement delays with transparent pricing, real-time design for manufacturability feedback, and rapid turnaround from quote to shipped parts. Request your quote today and experience fabrication precision engineered for speed.

Technical Capabilities

Laser cutting, bending, and welding are critical processes in sheet metal fabrication, each with specific technical requirements depending on the material used. Below are the technical specifications and considerations for common materials—Steel, Aluminum, ABS, and Nylon—used in these processes. Note that ABS and Nylon are non-metallic thermoplastics and are generally not suitable for laser welding or bending in the same way as metals; their processing differs significantly.

| Process | Material | Thickness Range | Laser Cutting Compatibility | Bending Compatibility | Welding Compatibility | Key Technical Notes |

|---|---|---|---|---|---|---|

| Laser Cutting | Steel | 0.5 mm – 25 mm | Excellent | N/A | N/A | High-power fiber lasers preferred; nitrogen or oxygen assist depending on finish requirements. Minimal heat-affected zone (HAZ). |

| Aluminum | 0.5 mm – 15 mm | Good | N/A | N/A | Reflective material; requires high-power laser with anti-reflective optics. Use nitrogen assist for clean edges. | |

| ABS | 1 mm – 10 mm | Moderate | Limited | Not applicable | Can be laser cut with CO₂ lasers; may produce toxic fumes. Not suitable for structural bending or welding. | |

| Nylon | 1 mm – 8 mm | Poor to Moderate | Limited | Not applicable | Tends to melt and char during laser cutting. Not recommended for precision cutting. | |

| Bending | Steel | 0.5 mm – 12 mm | N/A | Excellent | N/A | Standard V-die air bending; typical minimum bend radius 0.5× material thickness for mild steel. Tooling must account for springback (2–5°). |

| Aluminum | 0.5 mm – 10 mm | N/A | Good | N/A | Softer than steel; prone to cracking if bent below recommended bend radii. 6061-T6 requires annealing for tight bends. | |

| ABS | 1–6 mm | N/A | Fair | N/A | Can be heat-bent using strip heaters; limited structural use. Not compatible with metal-forming tools. | |

| Nylon | 1–5 mm | N/A | Fair | N/A | Requires controlled heating; susceptible to warping. Not recommended for tight radii. | |

| Welding | Steel | 0.8 mm – 20 mm | N/A | N/A | Excellent | MIG, TIG, and laser welding all effective. Pre-cleaning required. Carbon steel may require post-weld treatment to prevent rust. |

| Aluminum | 2 mm – 15 mm | N/A | N/A | Good | TIG and MIG preferred; requires shielding gas (argon). High thermal conductivity demands higher heat input. Sensitive to contamination. | |

| ABS | Not applicable | N/A | N/A | Limited | Solvent or ultrasonic welding possible; not compatible with arc or laser welding. Used only for low-stress joints. | |

| Nylon | Not applicable | N/A | N/A | Limited | Can be joined via hot plate or vibration welding. Not suitable for traditional welding methods. |

Notes:

Steel and aluminum are the primary materials used in industrial laser cutting, bending, and welding workflows.

ABS and nylon are thermoplastic polymers typically processed using alternative methods (e.g., CNC routing, 3D printing, or specialized plastic welding).

For laser cutting, metals require fiber lasers (steel, aluminum), while plastics like ABS are better suited for CO₂ lasers.

Welding of plastics is not equivalent to metal welding and involves fusion techniques specific to polymer chains.

From CAD to Part: The Process

Honyo Prototype executes sheet steel welding through a rigorously defined five-stage workflow optimized for precision, speed, and manufacturability. This integrated process ensures seamless transition from design intent to certified physical delivery while maintaining strict adherence to engineering specifications.

CAD File Upload and Initial Processing

Clients initiate the workflow by uploading native CAD files (STEP, IPT, SLDPRT) or neutral formats via our secure customer portal. Our system immediately performs geometric validation, confirming unit consistency, solid body integrity, and weld joint accessibility. Sheet steel-specific parameters including material grade (e.g., ASTM A36, CR4), thickness range (0.5mm–6mm), and required edge preparation are extracted for downstream processing. File validation occurs within 15 minutes, with automated notifications for any topology errors requiring client correction.

AI-Powered Quoting Engine

Validated designs enter our proprietary AI quotation system trained on 12,000+ historical sheet steel weld builds. The engine analyzes: weld seam length density, joint type distribution (butt, fillet, lap), geometric complexity factors, and material utilization efficiency. Real-time cost drivers include robotic weld path complexity scores, required fixturing iterations, and post-weld processing needs. Quotes detail per-weld-seam costing, anticipated distortion control measures, and NDT requirements—all generated within 2 business hours with ±5% cost accuracy.

DFM Integration with Welding Expertise

Engineers conduct mandatory Design for Manufacturability review focusing exclusively on weld integrity. Critical checks include:

| DFM Parameter | Acceptable Threshold | Common Issue Remediation |

|---|---|---|

| Minimum Bend-to-Weld Distance | ≥3× material thickness | Redesign flange geometry |

| Overlap for Lap Joints | 8–12mm | Adjust part nesting layout |

| Heat Affected Zone (HAZ) Clearance | ≥1.5× weld leg size | Modify cutouts near seams |

| Distortion Risk Score | <7/10 | Add strategic tack sequences |

Clients receive annotated DFM reports with 3D markup of non-compliant features and engineering-approved alternatives. This stage typically reduces production rework by 68% based on 2023 Q4 metrics.

Controlled Production Execution

Approved designs move to our climate-controlled welding facility featuring:

Fiber laser welders (1.5kW–4kW) for high-speed conduction welding on thin gauges

Robotic MIG cells with real-time arc monitoring for structural seams

Helium purge systems for critical root passes on enclosed sections

All weld procedures adhere to AWS D1.1 structural welding code. In-process verification includes thermal imaging between passes to control residual stress and automated seam tracking with 0.1mm positional accuracy. First-article inspection validates dimensional stability against original CAD using CMM before full production release.

Certified Delivery and Documentation

Final assemblies undergo mandatory post-weld processes including stress-relief annealing (where specified) and robotic deburring. Each shipment includes:

Full traceability package with material certs (MTRs) and weld procedure specifications (WPS/PQR)

Dimensional inspection report showing critical weld zone tolerances per ASME Y14.5

NDT documentation (dye penetrant or radiographic) for structural welds

Packaging engineered for zero-movement transit with corrosion-inhibiting VCI paper

Standard delivery cycle is 7–12 business days from DFM sign-off, with expedited 72-hour options for qualified geometries. All deliverables meet ISO 9001:2015 and IATF 16949 quality management standards.

Start Your Project

For all welding sheet steel requirements, contact Susan Leo at [email protected]. Our dedicated manufacturing facility in Shenzhen ensures precision, efficiency, and fast turnaround for your prototyping and production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.