Contents

Manufacturing Insight: Welded Sheet Metal

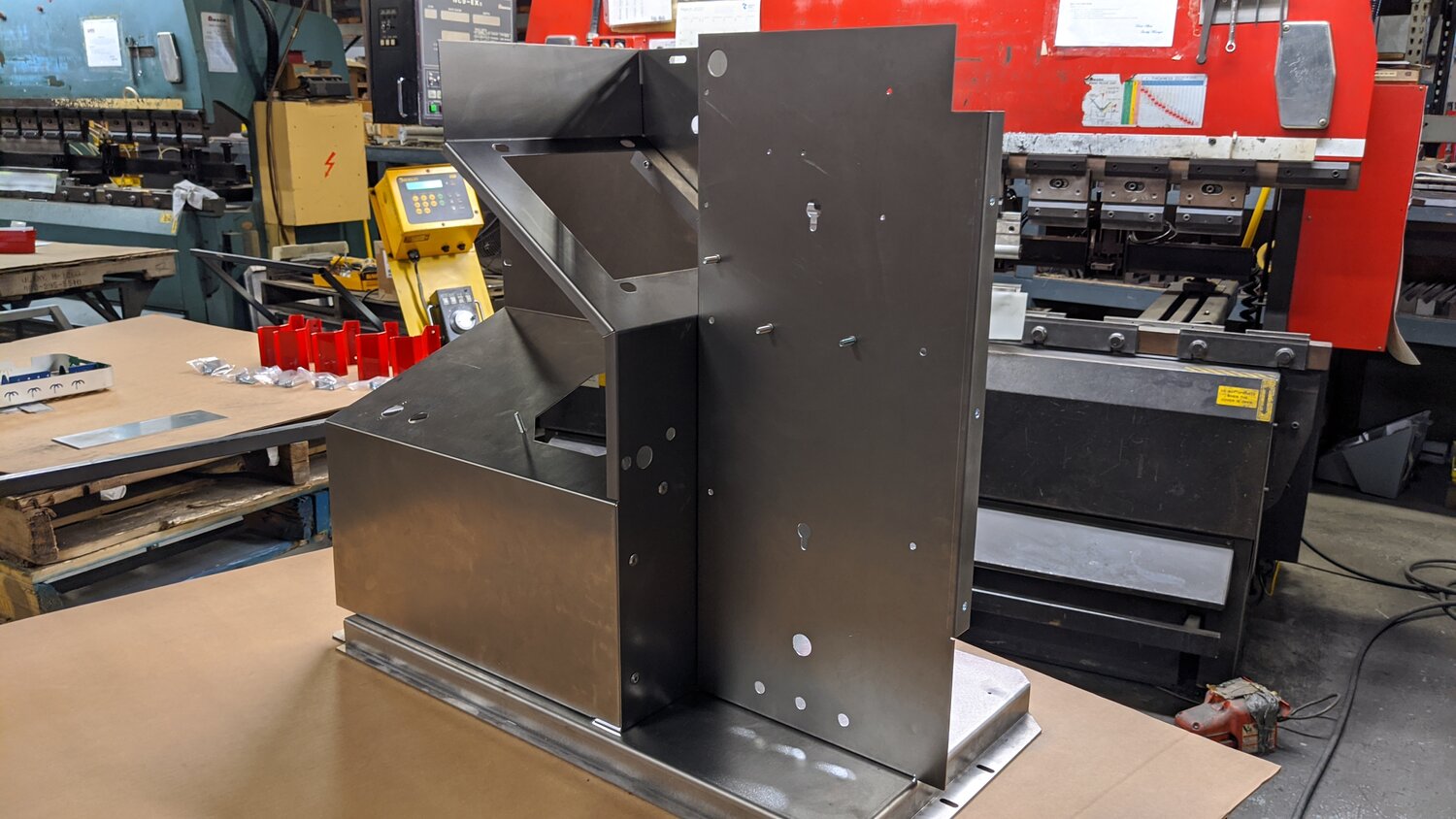

Welded Sheet Metal Fabrication Expertise at Honyo Prototype

Complex welded sheet metal assemblies present significant challenges in precision, material integrity, and production speed—especially for prototyping and low-to-mid volume production. Honyo Prototype addresses these challenges with integrated sheet metal fabrication services engineered for demanding industrial applications. Our end-to-end capabilities encompass precision laser cutting, CNC bending, and expert welding across materials including stainless steel, aluminum, and mild steel. We specialize in TIG and MIG welding processes to ensure structurally sound, dimensionally accurate assemblies meeting tight tolerances of ±0.005 inches, critical for aerospace, medical, and robotics sectors.

Every welded component undergoes rigorous in-process inspection and final QA validation, including weld penetration testing and geometric dimensioning checks, to guarantee compliance with ISO 9001 standards. This commitment to precision ensures your assemblies perform reliably under operational stress while minimizing post-weld rework. For engineering teams accelerating time-to-market, our Online Instant Quote system eliminates procurement delays: simply upload your STEP or DWG file to receive a detailed, geometry-validated quote with lead time and DFM feedback in under 60 seconds. Reduce RFQ cycles from days to minutes and transition seamlessly from design to certified production.

Upload your design today to experience Honyo’s welded sheet metal fabrication—where technical precision meets rapid prototyping agility.

Technical Capabilities

Technical specifications for welded sheet metal fabrication involve multiple stages including laser cutting, bending, and welding. These processes are critical in producing precision enclosures, brackets, chassis, and structural components in low to medium volume production. Below is a summary of key technical parameters and material compatibility for commonly used substrates: Aluminum, Steel, ABS, and Nylon.

Laser Cutting

Laser cutting provides high-precision profile cutting with tight tolerances. It is suitable for both ferrous and non-ferrous metals but has limitations with certain plastics due to thermal degradation.

Bending

Bending is performed using CNC press brakes to achieve accurate angles and consistent bend radii. Material ductility and thickness directly influence bend allowance and minimum bend radius.

Welding

Welding joins cut and bent components into assemblies. Common methods include MIG, TIG, and spot welding for metals. Plastics such as ABS and Nylon are typically joined using adhesive bonding or ultrasonic welding rather than traditional arc welding.

| Parameter | Aluminum (e.g., 5052, 6061) | Steel (e.g., 1018, CRCA) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (Polyamide) |

|---|---|---|---|---|

| Laser Cutting | Yes, with nitrogen assist for clean edges | Yes, with oxygen or nitrogen assist | Limited – prone to melting and charring | Not recommended – high thermal deformation |

| Typical Thickness Range | 0.5 mm – 6.0 mm | 0.8 mm – 10.0 mm | 1.0 mm – 10.0 mm (laser cutting not ideal) | 1.0 mm – 10.0 mm (not suitable for laser) |

| Bending | Yes – good formability, minimum bend radius ~1× thickness | Yes – excellent bendability, min radius ~0.5× thickness | Limited – possible with heated tooling, springback issues | Poor – low stiffness, high elasticity |

| Welding | Yes – TIG or MIG with filler (e.g., 4043) | Yes – MIG, TIG, spot welding | Adhesive bonding or ultrasonic welding only | Adhesive or mechanical fastening |

| Surface Finish | Bare, anodized, powder coated | Bare, painted, powder coated, galvanized | As-molded or machined | As-molded or machined |

| Tolerances (Cutting) | ±0.1 mm | ±0.1 mm | ±0.2 mm (if cut via CNC routing) | ±0.2 mm (CNC preferred) |

| Tolerances (Bending) | ±0.2° angular, ±0.2 mm linear | ±0.2° angular, ±0.2 mm linear | Not applicable | Not applicable |

| Joint Strength | High – metallurgical bond | High – metallurgical bond | Medium – dependent on adhesive or method | Medium – mechanical or adhesive |

| Notes | Requires proper fixturing to prevent warping during welding | May require post-weld finishing to prevent rust | Not compatible with metal welding processes | Susceptible to moisture absorption; not weldable via arc methods |

Summary

Aluminum and steel are ideal for full welded sheet metal fabrication involving laser cutting, bending, and welding. ABS and nylon are engineering thermoplastics better suited for non-metallic fabrication techniques such as CNC machining, molding, or adhesive assembly. They are not compatible with traditional welding or high-energy laser processing in standard sheet metal workflows.

From CAD to Part: The Process

Honyo Prototype Welded Sheet Metal Fabrication Process

Honyo Prototype executes welded sheet metal projects through a streamlined, technology-integrated workflow designed for precision, speed, and manufacturability. The process begins when a client uploads a native or neutral CAD file (STEP, IGES, Parasolid, or native formats like SLDPRT, IPT, PRT) via our secure customer portal. Our system immediately validates geometric integrity and extracts critical parameters including material type, thickness, bend radii, and feature tolerances. This foundational step ensures data readiness for downstream analysis and prevents format-related delays.

The uploaded CAD model triggers our proprietary AI-driven quoting engine, which rapidly generates a preliminary cost and lead time estimate. This AI system cross-references real-time material pricing, machine availability, labor rates, and historical production data against the part’s geometric complexity, weld length, joint types, and finishing requirements. Crucially, the AI output undergoes mandatory review by a senior manufacturing engineer who validates assumptions, adjusts for nuanced factors like weld distortion risk or fixturing complexity, and ensures the quote reflects achievable shop-floor realities. Clients receive this vetted quote within 4 business hours, including clear annotations for any design elements requiring clarification.

Upon quote acceptance and formal order placement, the project enters our rigorous Design for Manufacturability (DFM) phase led by dedicated sheet metal specialists. Engineers perform a comprehensive manufacturability audit, focusing explicitly on weldability constraints. Key DFM checks include:

| DFM Check Category | Specific Welding Considerations |

|---|---|

| Joint Design & Access | Verification of root gaps, bevel angles, and tooling access for all weld seams; identification of obstructed zones requiring repositioning |

| Material Compatibility | Confirmation of filler metal suitability for base materials (e.g., 304SS to 316SS transitions); avoidance of dissimilar metal issues |

| Distortion Mitigation | Assessment of weld sequencing needs, strategic placement of tack welds, and recommendations for stress-relief features |

| Tolerance Stack-Up | Analysis of cumulative tolerances across welded sub-assemblies; adjustment of critical GD&T callouts |

| Secondary Operations | Coordination of post-weld processes (e.g., stress relieving, grinding, CMM inspection points) with weld locations |

This phase delivers a formal DFM report within 24–48 hours, detailing actionable recommendations to optimize cost, quality, and lead time. Client approval of the DFM report is required before proceeding to production, ensuring alignment on all technical and quality parameters.

Production commences in our climate-controlled facility using calibrated CNC laser cutters, press brakes, and robotic or manual welding cells. Welded sheet metal assemblies are fabricated under strict adherence to AWS D1.1/D1.3 standards. Key production protocols include:

Material is verified via PMI testing upon receipt; laser cutting incorporates kerf compensation and nesting optimization; formed components undergo first-article inspection; welding is executed by certified technicians using TIG for precision joints or MIG for structural seams with documented WPS parameters; all welds undergo 100% visual inspection per ASME B31.3, with penetrant testing applied per DFM requirements. In-process dimensional validation occurs at critical stages using calibrated CMMs or optical comparators to prevent cumulative errors.

Final delivery integrates meticulous post-weld processing and logistics coordination. Assemblies undergo stress-relieving, precision grinding of weld seams, and surface finishing (e.g., bead blasting, powder coating) as specified. A comprehensive final inspection report—including first-article dimensional data, weld certification records, and material traceability—is compiled. Parts are packaged using anti-corrosion VCI films and custom foam cradles to prevent transit damage, with global shipping managed via tracked freight carriers. Standard lead time from DFM approval to delivery is 7–12 business days for low-volume prototypes, with real-time production tracking accessible through the client portal. This closed-loop process ensures welded sheet metal components meet stringent functional and aesthetic requirements while minimizing time-to-market.

Start Your Project

For your welded sheet metal needs, contact Susan Leo at [email protected]. Our dedicated manufacturing facility in Shenzhen ensures precision fabrication, fast turnaround, and consistent quality for prototyping and low-volume production. Reach out today to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.