Contents

Manufacturing Insight: Wcc Steel Material

WCC Steel Machining Expertise at Honyo Prototype

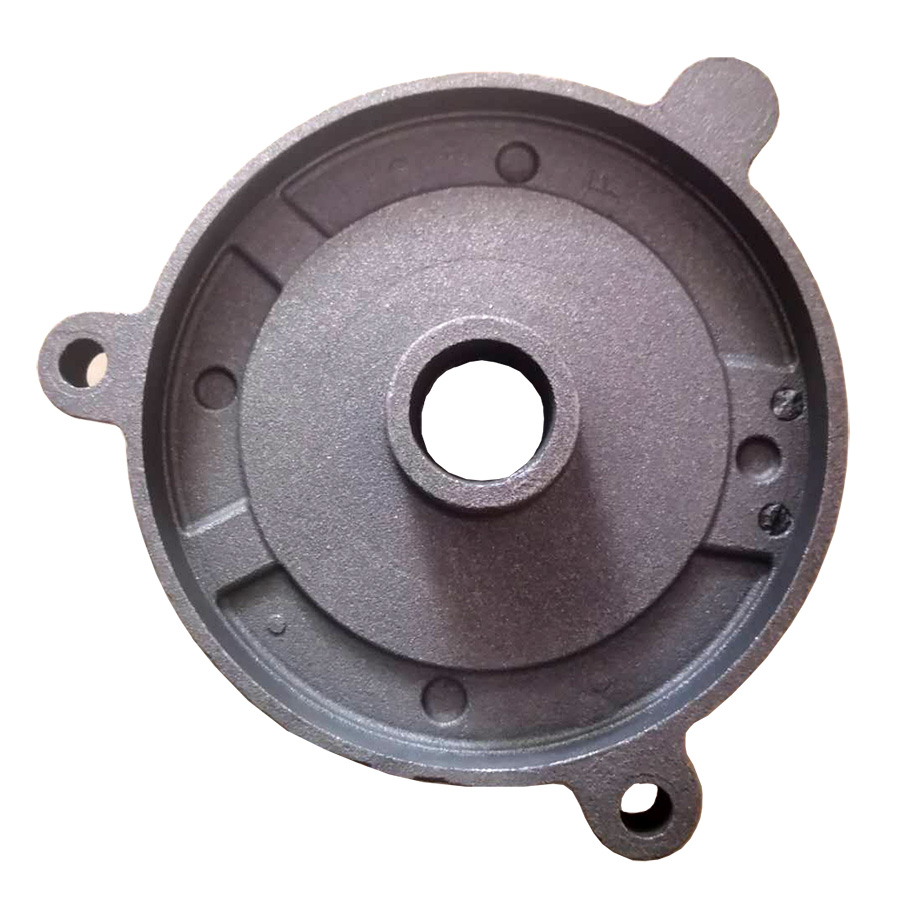

Honyo Prototype delivers precision CNC machining solutions for demanding WCC steel applications, a high-carbon, high-chromium tool steel renowned for exceptional wear resistance, hardness retention at elevated temperatures, and suitability for critical forming, blanking, and stamping tooling. Successfully machining WCC steel requires specialized knowledge of its thermal characteristics, precise control of cutting parameters to manage work hardening, and stringent process validation to achieve tight tolerances and superior surface finishes essential for extended tool life. Our advanced multi-axis CNC milling and turning centers, operated by expert manufacturing engineers, are optimized for the unique challenges posed by WCC steel, ensuring consistent part quality, dimensional accuracy, and material integrity from prototype through low-volume production.

Leveraging our deep metallurgical understanding and process expertise, Honyo Prototype provides end-to-end manufacturing support for WCC steel components, including strategic material sourcing consultation, optimized fixture design, and rigorous in-process inspection. We eliminate procurement delays for time-sensitive projects with our Online Instant Quote system. Simply upload your WCC steel part CAD file to receive a detailed, geometry-based manufacturing assessment and competitive pricing within hours, accelerating your path from design to functional hardware. Partner with Honyo for reliable, high-precision WCC steel machining executed to exacting industrial standards.

Technical Capabilities

The term “WCC steel material” does not correspond to a recognized standard material grade in metallurgy or manufacturing (e.g., AISI, SAE, ASTM, ISO, or DIN). It may be a typographical error, misinterpretation, or internal designation. However, assuming the intent is to discuss high-performance steel materials suitable for precision machining processes such as 3/4/5-axis milling and turning with tight tolerance requirements (±0.005 mm to ±0.025 mm), the following technical specifications are relevant for commonly used engineering materials including aluminum, steel, ABS, and nylon.

Below is a comparative technical specification table focusing on machinability in multi-axis CNC environments and performance under tight tolerance demands:

| Material | Typical Grade/Type | Hardness (HB) | Tensile Strength (MPa) | Thermal Expansion (µm/m·°C) | Machinability Rating | Common Use in Precision Machining | Notes for 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|---|---|---|

| Aluminum | 6061-T6 / 7075-T6 | 95–150 | 310–570 | 23.6 | Excellent (85–90%) | Aerospace, jigs, fixtures | High metal removal rate; low cutting forces; ideal for complex 5-axis contours; prone to chatter if not properly supported |

| Carbon Steel | 1018 / 1045 | 120–200 | 440–630 | 11.7 | Good (55–65%) | Shafts, brackets, tooling | Generates higher cutting forces; requires rigid setup; excellent dimensional stability for tight tolerances |

| Tool Steel | A2 / D2 / H13 | 200–600 | 1,500–2,400 | 10.5–12.5 | Moderate to Poor | Molds, dies, precision tooling | Requires pre-hardened machining or EDM; post-heat treatment limits final tolerance adjustments |

| Stainless Steel | 303 / 304 / 17-4 PH | 150–330 | 515–1,300 | 16–18 | Moderate (40–45%) | Medical, aerospace, food processing | Work-hardens rapidly; needs sharp tools and consistent feeds; good corrosion resistance with precision hold |

| ABS | Industrial Grade (3D Print or Bar Stock) | 85–100 (Shore D) | 40–50 | 80–100 | Excellent | Prototypes, enclosures, jigs | Low melting point; requires sharp tools and low heat buildup; excellent for rapid iteration in 4-axis turning |

| Nylon (PA6/PA66) | Cast or Extruded | 70–80 (Shore D) | 70–85 | 80–120 | Very Good | Gears, insulators, bushings | Prone to moisture absorption; needs stress relief; holds tolerances well if conditioned; low friction finish |

Notes on Tight Tolerance Machining:

For achieving tight tolerances (±0.005 mm to ±0.01 mm) in multi-axis CNC operations, material stability is critical. Free-machining steels like 12L14 or 303 stainless are often selected when tight tolerances and high repeatability are required, despite slightly lower strength, due to dimensional consistency during high-speed cutting.

Aluminum alloys such as 6061-T6 and 7075-T6 are widely used in 5-axis milling for aerospace components due to high strength-to-weight ratio and excellent surface finish capability.

Engineering thermoplastics like ABS and nylon are increasingly machined for functional prototypes and low-load components. While they offer ease of machining, their hygroscopic nature and thermal expansion require environmental control during and after machining to maintain dimensional accuracy.

All materials must be stress-relieved prior to precision machining, especially after forging or rolling, to minimize distortion during high-precision operations.

From CAD to Part: The Process

Honyo Prototype maintains a rigorously defined workflow for processing specialty materials like WCC steel (Wear-Resistant Cast Chromium steel), ensuring precision from design inception to final delivery. This structured approach minimizes risk and maximizes quality for demanding industrial applications. Below is the detailed process flow specific to WCC steel components.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. For WCC steel parts, we require explicit material specification within the CAD metadata or accompanying documentation to trigger alloy-specific validation protocols. Our system automatically checks geometric integrity and flags potential material incompatibilities, such as wall thicknesses below minimum castability thresholds for chromium alloys. This initial scan prevents downstream issues related to WCC steel’s high carbon content and susceptibility to cracking during solidification.

AI Quote Generation

Our proprietary AI engine processes the CAD geometry alongside material requirements to generate an instant preliminary quote. For WCC steel, the algorithm factors in critical parameters:

Density and thermal properties unique to chromium cast irons

Required foundry certifications (e.g., ASTM A532)

Secondary machining allowances for hard-facing applications

Minimum order quantities due to specialized furnace scheduling

The quote includes material traceability costs, non-destructive testing (NDT) requirements, and surface finish constraints inherent to wear-resistant alloys. Clients receive a detailed cost breakdown within 2 business hours, highlighting variables affecting WCC steel pricing versus standard carbon steels.

DFM Analysis

Engineering teams conduct a comprehensive Design for Manufacturability review focused on WCC steel’s metallurgical challenges. Key validation points include:

| DFM Parameter | WCC Steel Specific Check | Risk Mitigation Action |

|---|---|---|

| Wall Thickness | Minimum 8mm to prevent hot tearing during casting | Recommend localized ribbing or core redesign |

| Draft Angles | Minimum 3° for complex cores due to low fluidity | Auto-generate draft suggestions in CAD |

| Machining Allowances | +2.5mm standard (vs. +1.5mm for mild steel) for hardness | Adjust tolerances for post-heat-treat grinding |

| Weldability Zones | Flag areas requiring pre-heat above 300°C per AWS D2.1 | Propose thermal relief grooves in design |

This phase requires client sign-off on modified geometry or process adjustments before proceeding. Average DFM cycle time for WCC steel is 3-5 business days due to metallurgical review.

Production Execution

WCC steel fabrication follows a controlled sequence:

Pattern creation using ceramic shell molding to withstand 1450°C pour temperatures. Vacuum-assisted casting to minimize porosity in chromium-rich matrices. Stress-relief annealing at 950°C followed by controlled cooling to prevent microcracking. CNC machining with carbide tooling optimized for 55-65 HRC surfaces, including in-process hardness validation. Final NDT via MPI and ultrasonic testing per ASTM E709/E1444. All material heat numbers are tracked through our ERP system, with chemical composition certificates provided pre-shipment.

Delivery and Documentation

Finished WCC steel components undergo dimensional verification against ASME Y14.5 GD&T standards. Each shipment includes:

Mill test reports with full traceability to ladle analysis

NDT certification with defect maps

As-machined CMM reports showing critical wear surfaces

Packaging engineered for vibration-sensitive cast parts

Standard lead time for WCC steel prototypes is 18-22 business days from DFM approval, with expedited options available for qualifying geometries. All deliveries include digital quality dossiers accessible via client portal for audit compliance in regulated industries.

Start Your Project

Looking for high-quality WCC steel material for your next project? Contact Susan Leo today at [email protected] to discuss your requirements and get expert support from Honyo Prototype. With our advanced manufacturing capabilities and dedicated facility located in Shenzhen, we deliver precision-engineered solutions tailored to your specifications. Trust a reliable partner for superior materials and fast turnaround. Reach out now to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.