Contents

Manufacturing Insight: Wcb Steel

Precision CNC Machining for WCB Steel Components

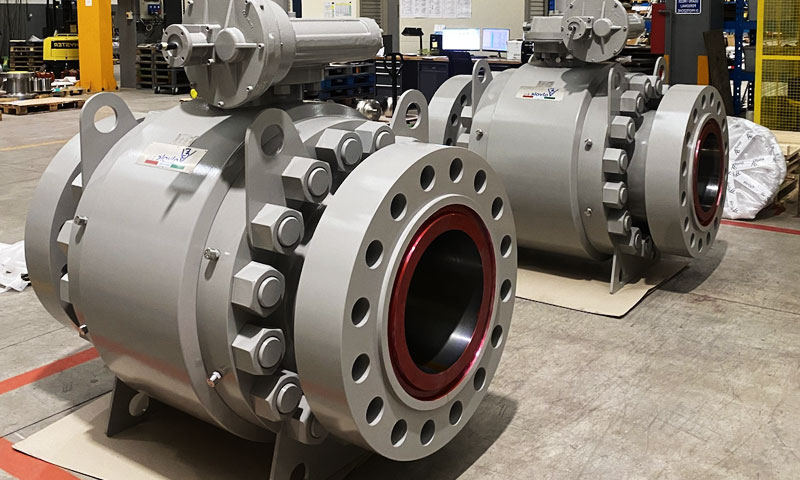

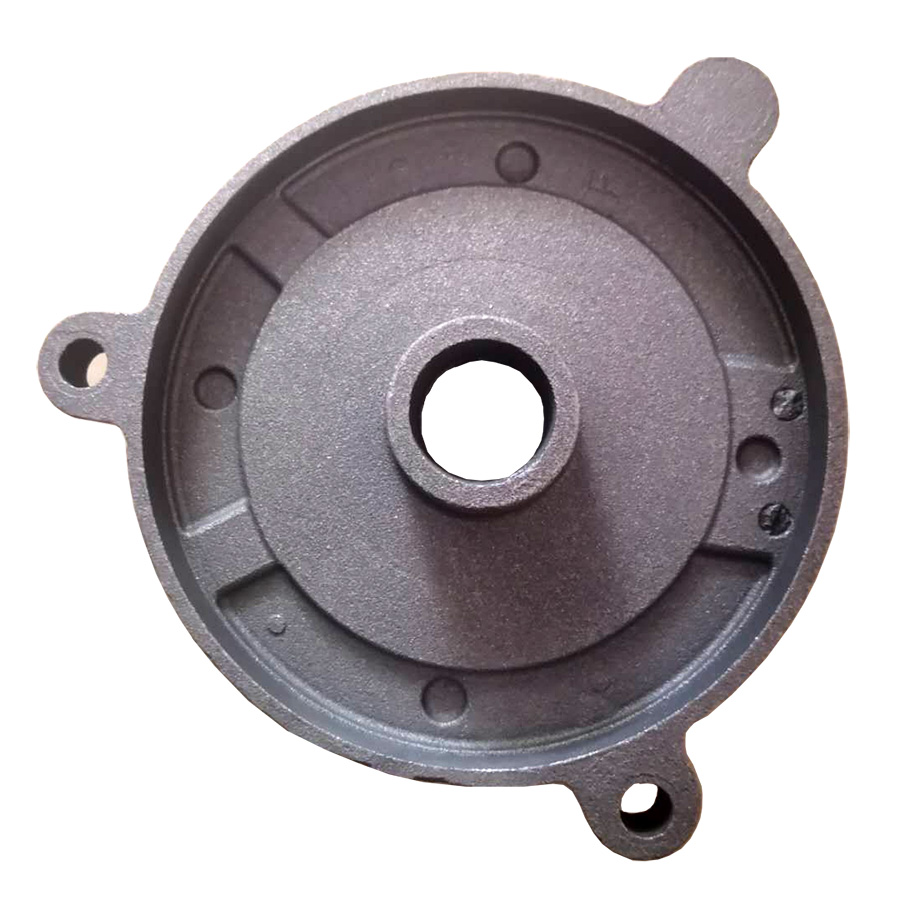

WCB steel, conforming to ASTM A216 standards, is the foundational material for critical pressure-containing applications across oil and gas, power generation, and industrial valve systems. Its balanced composition of carbon, manganese, and silicon delivers robust weldability, impact resistance at moderate temperatures, and reliable performance under high-pressure service conditions. Successfully machining WCB demands precise control over cutting parameters, thermal management, and surface integrity to prevent microstructural alterations that could compromise component longevity in demanding operational environments.

Honyo Prototype leverages advanced 3-, 4-, and 5-axis CNC machining centers with rigorous in-process metrology to transform WCB steel billets into mission-critical components with exacting dimensional accuracy and superior surface finishes. Our manufacturing engineers optimize toolpaths and material removal rates specifically for WCB’s machinability profile, ensuring consistent conformance to ASME B16.34, API 602, and customer-specified tolerances down to ±0.0005 inches. Every WCB part undergoes comprehensive first-article inspection and final quality validation against material certs and geometric dimensioning requirements.

Accelerate your sourcing cycle with Honyo’s Online Instant Quote platform. Upload your WCB steel part CAD file to receive a detailed manufacturability analysis, precise cost breakdown, and lead time estimate within minutes—eliminating procurement delays while validating design feasibility for high-integrity applications.

| Material Property | ASTM A216 WCB Typical Value | Relevance to CNC Machining |

|---|---|---|

| Tensile Strength (min) | 60,000 psi (415 MPa) | Requires rigid fixturing to prevent deflection during heavy cuts |

| Yield Strength (min) | 36,000 psi (250 MPa) | Influences feed rate selection to manage chip load |

| Elongation in 2 in (min) | 24% | Indicates ductility; necessitates sharp tooling to avoid built-up edge |

| Hardness Range | 160-240 HB | Dictates optimal cutting speeds and coolant application |

Partner with Honyo to convert your WCB steel designs into certified, high-reliability components with engineering-driven precision and streamlined quoting efficiency.

Technical Capabilities

WCB steel is a common material specification for carbon steel castings, defined under the ASTM A216 standard. It is widely used in industrial applications due to its good strength, weldability, and machinability. When machining WCB steel—particularly in precision 3/4/5-axis milling and turning operations—its mechanical properties and thermal behavior must be considered to achieve tight tolerances (±0.0005″ to ±0.005″, depending on feature and geometry). WCB is often compared to WCA and WCC grades, with WCB offering a balanced combination of tensile strength and ductility.

While WCB steel is a primary focus in high-integrity structural and valve components, it is frequently machined alongside other materials such as Aluminum (e.g., 6061-T6, 7075-T6), tool steels, ABS, and engineering thermoplastics like Nylon (e.g., PA6, PA66) in prototyping and end-use part production. Each material presents distinct challenges and optimal parameters in multi-axis CNC environments.

Below is a comparative technical specification table highlighting key properties and machining characteristics relevant to precision CNC operations:

| Material | Tensile Strength (psi) | Hardness (HB) | Thermal Conductivity (BTU/hr·ft·°F) | Machinability Rating (%) | Typical Applications in Precision Machining | Notes for 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|---|---|

| WCB Steel | ~70,000 | 170–210 | 25 | 60 | Valves, pump housings, structural fittings | Requires rigid setups; use carbide tooling with positive rake; moderate cutting speeds; ideal for tight-tolerance features with proper cooling |

| Aluminum 6061-T6 | ~45,000 | 95 | 120 | 90 | Enclosures, aerospace components, jigs | High MRR possible; sharp tools essential to avoid built-up edge; low thermal deformation allows micron-level tolerances |

| 4140 Steel | ~100,000 | 230–280 | 27 | 65 | Shafts, tooling, high-strength components | Pre-hardened condition common; slow speeds and high feed rates recommended; stress-relieved stock preferred for stability |

| ABS (Thermoplastic) | ~6,000 | 80 (Shore D) | 1.2 | 85 | Prototypes, housings, non-structural parts | Low melting point; sharp, polished tools; high spindle speeds with light depth of cuts; minimal clamping force |

| Nylon (PA6) | ~10,000 | 70–80 (Shore D) | 0.7 | 70 | Gears, bushings, insulators | Prone to moisture absorption and creep; pre-dry material; avoid excessive heat build-up; use non-cooled air blast |

Key Considerations for Tight Tolerance Machining:

Tooling: Solid carbide end mills with specialized coatings (e.g., TiAlN) are recommended for WCB and steel alloys. Polished flutes reduce chip adhesion in sticky materials like nylon.

Fixturing: 5-axis setups minimize datum shifts and enable complex geometries with sub-0.001″ positional accuracy.

Thermal Management: Coolant strategies (flood, mist, or through-spindle) are critical when machining WCB and steels to maintain dimensional stability.

Metrology: In-process probing and post-machining CMM validation are standard for verifying tight tolerances, especially in mixed-material assemblies.

At Honyo Prototype, WCB steel components are routinely produced with tolerances down to ±0.001″ (±0.025 mm), with secondary features held to ±0.0005″ using precision-ground stock and thermal-stable workholding.

From CAD to Part: The Process

Honyo Prototype executes a streamlined, quality-focused workflow for WCB steel (ASTM A216 Grade WCB) components, integrating digital tools with metallurgical expertise to ensure castings meet demanding industrial specifications. This process guarantees dimensional accuracy, mechanical properties, and compliance with pressure-containing applications.

CAD Upload & Validation

Clients submit 3D models in STEP, IGES, or native CAD formats via our secure portal. Our system performs initial validation checks for file integrity, unit consistency, and basic manufacturability. For WCB—a carbon steel grade used in high-temperature valves, pumps, and fittings—we specifically verify minimum wall thickness against casting solidification requirements to prevent shrinkage defects. Geometry complexity is assessed for sand casting feasibility, the primary method for WCB prototypes.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which calculates costs in under 90 seconds. The algorithm factors WCB-specific variables: current scrap steel surcharges, foundry processing fees (including mandatory heat treatment), and geometry-driven mold complexity. Crucially, it applies material-specific rules—for instance, flagging designs requiring secondary machining beyond standard allowances due to WCB’s as-cast surface finish characteristics. Quotes include traceable material certification costs per ASTM A216.

Metallurgical DFM Analysis

Engineers conduct a rigorous Design for Manufacturability review focused on WCB’s casting behavior. This phase identifies risks like hot tearing in thin sections or improper risering for sound solidification. Key checks include:

| Standard DFM Check | WCB-Specific Requirement |

|---|---|

| Draft angles | Minimum 3° draft for green sand molds to prevent drag defects |

| Wall thickness transitions | Gradual tapers (max 3:1 ratio) to avoid shrink cavities |

| Parting line placement | Avoidance of critical pressure boundaries per ASME B16.34 |

Thermal simulation validates feeder placement, while machining allowance analysis ensures critical surfaces (e.g., flange faces) meet ASME finish standards after cleaning. Non-conformities trigger automated design feedback with corrective recommendations.

Precision Production & Quality Control

Approved designs move to our partner foundries specializing in carbon steel castings. WCB production follows strict protocols:

Pattern creation uses CNC-machined tooling for dimensional repeatability. Molding employs automated green sand systems with real-time moisture control. Melting occurs in induction furnaces with spectral analysis to confirm chemistry (C: 0.25-0.31%, Mn: 0.60-1.00%, max P: 0.040%). Post-casting, all WCB parts undergo normalization (1700°F ±25°F) and tempering (1100°F min) per ASTM A216. Each lot includes destructive testing: tensile, Charpy impact at -20°F, and 100% MPI for surface cracks. Pressure-containing parts receive radiographic inspection.

Certified Delivery & Traceability

Completed parts undergo final dimensional verification against CAD models using CMM reports. Every shipment includes:

Material Test Report (MTR) with actual chemistry and mechanical properties

NDT documentation (RT/MPI)

Heat treatment certification

ASME BPVC Section II Part D compliance statement

Parts are packaged with anti-corrosion protection, and full traceability (heat number, process logs) is accessible via our client portal. Typical lead time from CAD approval to delivery is 15-20 business days for prototypes under 200 lbs.

Start Your Project

Looking for high-quality WCB steel components? Contact Susan Leo today at [email protected] to discuss your project requirements. With our precision manufacturing facility located in Shenzhen, we deliver reliable, on-time prototyping and production solutions tailored to your specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.