Contents

Manufacturing Insight: Waterjet Cutting Stainless Steel

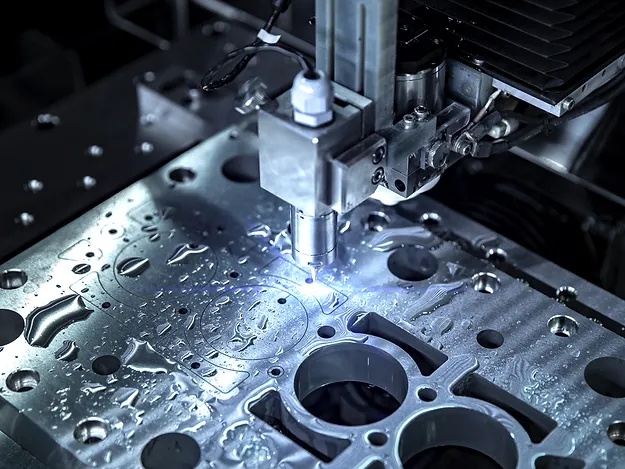

Precision Waterjet Cutting for Stainless Steel: Advanced Capabilities at Honyo Prototype

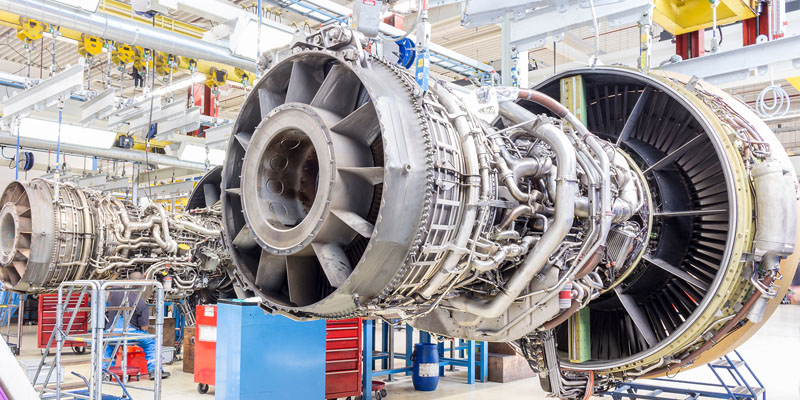

Stainless steel presents unique machining challenges due to its toughness, work-hardening characteristics, and sensitivity to thermal distortion during conventional thermal cutting processes. At Honyo Prototype, our industrial-grade CNC waterjet cutting systems deliver exceptional precision and material integrity for stainless steel components without heat-affected zones, micro-cracking, or dimensional instability. This cold-cutting process ensures clean edges, tight tolerances, and full compatibility with critical applications in aerospace, medical devices, and high-performance industrial equipment where material properties must remain uncompromised.

Our integrated manufacturing ecosystem combines waterjet cutting with complementary CNC milling, turning, and finishing services under one roof. This allows seamless transition from complex 2D/3D waterjet profiles to fully machined, tight-tolerance assemblies—eliminating supply chain delays and quality inconsistencies. We routinely process all common stainless grades including 304, 316, 17-4 PH, and duplex alloys up to 6 inches thick with certified repeatability. Key performance metrics for our stainless steel waterjet cutting include:

| Parameter | Capability |

|---|---|

| Material Thickness | Up to 152 mm (6 inches) |

| Tolerance | ±0.13 mm (±0.005 inches) |

| Kerf Width | 0.76–1.02 mm (0.03–0.04 inches) |

| Surface Finish | Ra 3.2–6.3 μm (125–250 μin) |

Leverage Honyo Prototype’s technical expertise for your next stainless steel project. Our online instant quoting platform provides validated pricing and lead times within minutes—no manual RFQs or waiting for engineering reviews. Simply upload your DXF, DWG, or STEP file to receive a detailed manufacturability analysis and competitive quote backed by AS9100 and ISO 9001-certified production controls. Accelerate prototyping and low-volume production with precision-cut stainless steel parts delivered on schedule.

Technical Capabilities

Waterjet cutting is a non-thermal process that utilizes a high-pressure stream of water, often mixed with abrasive particles, to cut through various materials including stainless steel. While waterjet cutting excels in versatility and material compatibility, it is important to distinguish its capabilities from those of 3/4/5-axis CNC milling and turning, especially when tight tolerances are required. Waterjet cutting can achieve good precision, typically within ±0.005″ to ±0.010″, depending on setup and material thickness, but may not consistently match the sub-micron tolerances of high-precision CNC milling or turning operations. Taper and edge squareness can be controlled using advanced 5-axis waterjet heads, which allow for dynamic tilting to compensate for the natural taper inherent in the process.

The following table compares key technical aspects of waterjet cutting with multi-axis CNC machining processes, focusing on stainless steel but including other common materials for context:

| Parameter | Waterjet Cutting | 3/4/5-Axis CNC Milling | CNC Turning | Typical Materials |

|---|---|---|---|---|

| Cutting Method | High-pressure abrasive water stream (non-thermal) | Rotating cutting tools with multi-directional movement | Rotational cutting of cylindrical parts | Stainless Steel, Aluminum, Steel, ABS, Nylon |

| Max Material Thickness (Stainless Steel) | Up to 10 inches | Limited by tool reach and setup (typically up to 24″) | Limited by chuck and bed length (up to 30″+) | N/A |

| Typical Tolerance | ±0.005″ – ±0.010″ | ±0.0005″ – ±0.001″ (tight tolerance capable) | ±0.0005″ – ±0.001″ (precision turning) | Varies by process and material |

| Surface Finish (Ra) | 125 – 250 μin (as-cut); may require secondary finishing | 16 – 63 μin (machined finish) | 16 – 63 μin (machined finish) | Depends on material and parameters |

| Kerf Width | 0.030″ – 0.050″ (abrasive jet) | Tool-dependent (e.g., 0.125″ end mill = 0.125″ kerf) | Tool-dependent | Consistent across materials |

| Heat Affected Zone (HAZ) | None (cold cutting process) | Minimal (with proper coolant and speed) | Minimal (with proper parameters) | Advantageous for heat-sensitive materials |

| 5-Axis Capability | Yes (with tilting head for taper compensation) | Standard capability for complex geometries | Limited (typically 2-axis with live tooling for mill-turn) | Enables complex contours |

| Lead Time | Fast setup, ideal for prototypes and short runs | Moderate to long (depending on complexity) | Fast for rotational parts | Aluminum fastest, stainless steel slower |

| Material Compatibility | Excellent (conductive and non-conductive) | Excellent (metals), limited for soft polymers | Best for metals and rigid plastics | Aluminum, Steel, Stainless Steel, ABS, Nylon all supported |

| Edge Quality | Slightly beveled edges; taper possible | Square, burr-free edges with proper toolpath | High precision edges on cylindrical parts | Post-processing may be needed for waterjet-cut parts |

Note: While waterjet cutting is highly effective for initial shaping and intricate profiles in stainless steel and other materials, achieving tight tolerances and superior surface finishes often requires secondary CNC milling or turning operations. For high-precision components, a hybrid approach—using waterjet for near-net shaping followed by 5-axis milling—is commonly employed to balance speed and accuracy.

From CAD to Part: The Process

Honyo Prototype Waterjet Cutting Process for Stainless Steel

Our end-to-end waterjet cutting process for stainless steel integrates digital efficiency with precision manufacturing to ensure quality, cost-effectiveness, and rapid turnaround. The workflow begins with CAD File Submission, where clients upload industry-standard formats (STEP, IGES, DXF, or DWG) via our secure portal. During submission, critical parameters are specified, including stainless steel grade (e.g., 304, 316, 17-4 PH), material thickness, quantity, and tolerance requirements. Our system validates file integrity and geometry compatibility, flagging potential issues like unsupported file types or missing critical dimensions before proceeding.

The AI-Powered Quoting Engine then generates an instant preliminary quote within minutes. This engine analyzes the CAD geometry, material specifications, and production variables—including abrasive consumption rates, machine time, and material waste—using real-time data from our waterjet fleet. Unlike manual quoting, our AI cross-references historical production data for stainless steel (e.g., cutting speed adjustments for 316L vs. 410 grades) and current material market costs. A Honyo engineer reviews all AI outputs to ensure accuracy, adding notes for complex features like fine details in thin-gauge stainless or multi-layer nesting efficiencies. Clients receive a transparent quote with cost breakdowns and lead time estimates.

Design for Manufacturability (DFM) Review follows immediately post-approval. Our engineers conduct a technical assessment focused on stainless steel-specific challenges: verifying minimum feature sizes (e.g., ensuring holes are ≥3× material thickness to prevent taper distortion), checking for sharp internal corners that may require relief cuts, and optimizing part orientation to minimize dishing or taper in thicker sections (e.g., >1 inch 304 stainless). We also validate nesting efficiency to reduce material waste—critical given stainless steel’s high cost—and confirm abrasive garnet grade suitability (80-mesh for fine details, 50-mesh for high-speed cuts). Clients receive actionable DFM feedback within 4 business hours, often suggesting geometry tweaks that lower costs by 15–25% without compromising function.

Precision Production leverages our 5-axis waterjet systems operating at 60,000 PSI with ultra-high-pressure intensifiers. For stainless steel, we dynamically adjust parameters: slower traverse speeds for thicker materials (e.g., 0.05 in/sec for 3″ 316 stainless) to maintain edge squareness, and optimized abrasive feed rates to prevent slag buildup. All cuts use food-grade garnet abrasive to avoid surface contamination, with taper compensation algorithms ensuring ±0.005″ dimensional accuracy. Parts undergo in-process gauging at critical stages, and stainless steel components are segregated post-cutting to prevent cross-contamination from carbon steel jobs. Material traceability is maintained via serialized job tickets linked to mill test reports.

Quality-Controlled Delivery concludes the process. Every stainless steel part receives post-processing inspection: edge quality verified under 10x magnification for burr-free finishes, dimensional checks via CMM for critical features, and surface roughness validation (typically Ra 125–250 μin for waterjet-cut stainless). Certificates of Conformance (including material grade, heat number, and dimensional report) accompany shipments. Parts are packaged in anti-corrosion VCI paper with desiccants to prevent oxidation during transit. Standard lead times range from 3–7 business days, with expedited options available. All deliveries include digital as-built documentation accessible via our client portal for audit compliance.

This integrated approach ensures stainless steel components meet stringent industry requirements for aerospace, medical, and fluid handling applications while minimizing time-to-part and total project cost.

Start Your Project

Looking for precision waterjet cutting services for stainless steel? Honyo Prototype delivers high-accuracy, burr-free cuts with fast turnaround times. Our advanced waterjet technology ensures clean edges and tight tolerances, ideal for prototypes and production runs.

We operate a state-of-the-art manufacturing facility in Shenzhen, China, supporting global clients with reliable, cost-effective solutions.

Contact Susan Leo today to discuss your project requirements or request a quote.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.