Contents

Manufacturing Insight: Water Jet Cutting Aluminum

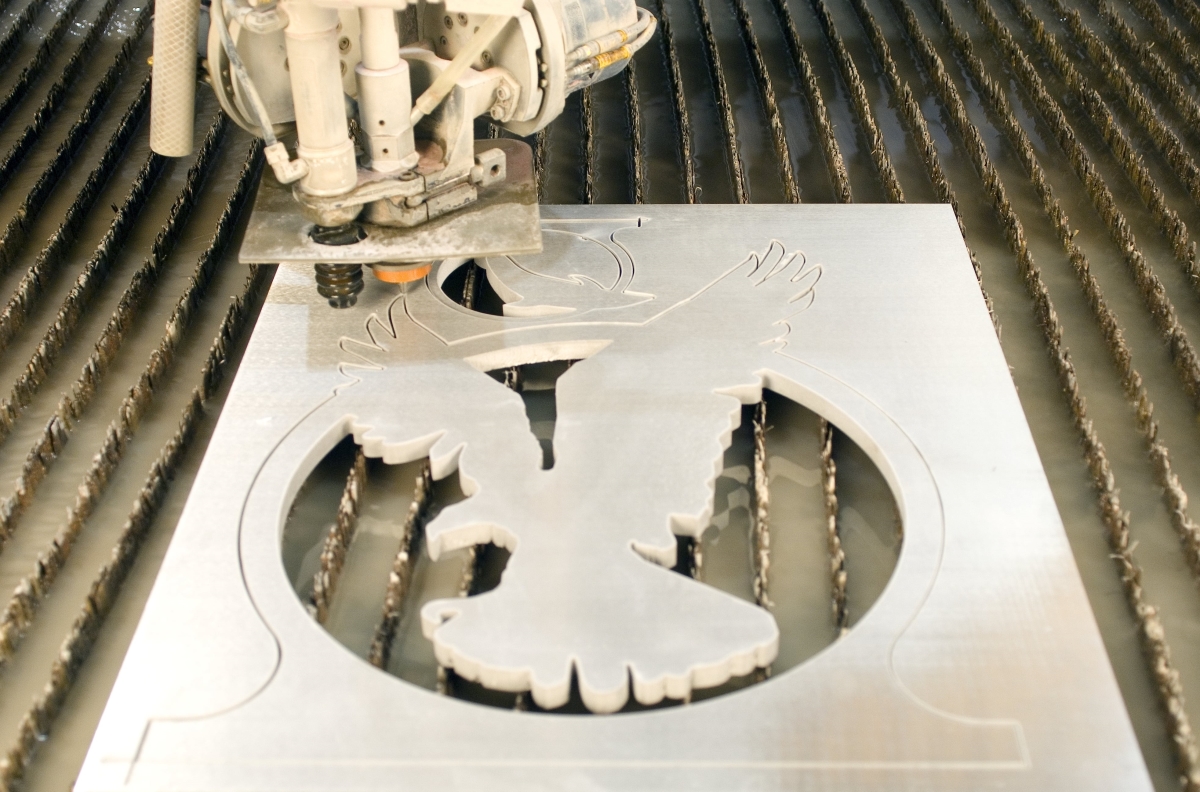

Precision Aluminum Fabrication Through Advanced Water Jet Cutting

Honyo Prototype delivers exceptional aluminum components via state-of-the-art CNC water jet cutting, engineered for applications demanding zero thermal distortion and micron-level accuracy. Unlike thermal cutting methods, our high-pressure abrasive water jets process aluminum alloys—including 6061-T6 and 7075-T73—without heat-affected zones, material hardening, or structural compromise. This cold-cutting process ensures pristine edge quality for critical aerospace, defense, and industrial parts, supporting thicknesses from 1mm to 150mm with tolerances held to ±0.13mm.

Water jet cutting complements Honyo’s broader CNC machining ecosystem, enabling seamless transitions from complex 2D profiles to multi-axis milled assemblies. The table below clarifies key advantages over conventional methods:

| Method | Aluminum Impact | Best For |

|---|---|---|

| Water Jet | Zero thermal distortion, no burrs | Thick sections, intricate geometries, heat-sensitive alloys |

| Laser Cutting | HAZ risk, dross on thicker material | Thin sheets, high-speed production |

| Plasma Cutting | Significant HAZ, rough edges | Non-critical structural steel |

Honyo integrates water jet cutting within end-to-end CNC machining workflows, from rapid prototyping to low-volume production. Eliminate thermal distortion risks while accelerating time-to-part with our optimized digital manufacturing pipeline. Request an Online Instant Quote today to validate feasibility, cost, and lead time for your aluminum project—submitted designs receive automated DFM feedback and pricing within minutes.

Technical Capabilities

Water jet cutting is a non-thermal process that uses a high-pressure stream of water, often mixed with abrasive particles, to cut through various materials with precision. While water jet cutting differs from 3/4/5-axis milling and turning—being a subtractive process without rotating tools—it complements these CNC manufacturing methods, especially when dealing with materials sensitive to heat or requiring tight tolerance without mechanical stress.

Water jet cutting is particularly effective for aluminum, where it avoids thermal distortion and maintains material integrity. It can also process steel, ABS, and nylon, though parameters vary significantly by material type. For applications requiring tight tolerances (±0.005″ to ±0.010″), water jet systems with advanced motion control (including 4- and 5-axis heads) allow for bevel compensation and complex contour cutting, bridging the gap between traditional water jet capabilities and multi-axis CNC precision.

Below is a comparison of water jet cutting performance across common materials, with emphasis on compatibility with tight tolerance requirements and integration with multi-axis motion systems.

| Material | Thickness Range (in) | Abrasive Required | Typical Tolerance (± in) | Surface Finish (Ra, µin) | Multi-Axis Compatibility | Notes |

|---|---|---|---|---|---|---|

| Aluminum | 0.062 – 6.0 | Yes (for >0.25″) | 0.005 – 0.010 | 250 – 500 | Yes (4/5-axis heads) | No heat-affected zone; ideal for aerospace components requiring tight tolerances |

| Steel (Mild) | 0.125 – 8.0 | Yes | 0.008 – 0.015 | 300 – 600 | Yes | Slower cut speeds; abrasive wear increases with thickness |

| Stainless Steel | 0.125 – 6.0 | Yes | 0.010 – 0.020 | 350 – 650 | Yes | Maintains corrosion resistance; suitable for medical and food-grade parts |

| ABS | 0.062 – 2.0 | No (water-only) | 0.005 – 0.010 | 200 – 400 | Yes | No melting if properly controlled; excellent for prototypes and enclosures |

| Nylon | 0.125 – 3.0 | No (water-only) | 0.005 – 0.012 | 220 – 450 | Yes | Minimal fraying; good for wear-resistant components |

Notes on Multi-Axis Water Jet Systems:

Advanced 4- and 5-axis water jet heads (e.g., taper compensation or dynamic heads) allow cutting of angled features and complex 3D contours, similar in flexibility to 5-axis CNC milling. These systems are ideal when tight tolerance and part complexity are required without secondary operations. However, due to stream lag and taper effects, achieving milling-grade tolerances consistently requires sophisticated software compensation and slower traverse rates.

Integration with CNC Workflows:

Water jet cutting serves as a primary shaping method before secondary CNC milling or turning operations—especially for aluminum and steel billets—reducing cycle time and material waste. For non-metallic materials like ABS and nylon, water jet provides a clean, precise alternative to routing or laser cutting, particularly in low-volume, high-mix production environments.

At Honyo Prototype, we leverage water jet cutting in conjunction with 3-, 4-, and 5-axis CNC machining and turning centers to deliver tightly toleranced components across aluminum, steel, and engineering plastics with minimal lead time.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for water jet cutting aluminum components, designed to maximize precision, minimize lead time, and ensure manufacturability from initial concept to delivery. This integrated process leverages automation and engineering expertise specifically tailored to the material properties of aluminum and the physics of abrasive water jet cutting.

The process initiates when a client uploads their CAD file through our secure online portal. Our system immediately performs geometric validation, confirming the file format compatibility (STEP, IGES, DXF, DWG) and identifying potential topology errors. Crucially, aluminum-specific parameters are flagged during this stage, including material grade designation if provided, which directly impacts subsequent steps like abrasive selection and pressure settings. This initial upload serves as the single source of truth for all downstream operations.

Following CAD ingestion, our proprietary AI-powered quoting engine generates a comprehensive cost and lead time estimate within minutes. This system utilizes real-time data on aluminum sheet pricing, machine availability, and historical performance metrics for water jet cutting across various aluminum alloys and thicknesses. The AI model incorporates material-specific factors such as the increased garnet consumption rate required for harder aluminum alloys like 7075 versus 6061, and the impact of thickness on cutting speed and edge quality. The quote explicitly details material costs, machine time based on nested part geometry, secondary operations, and applicable tolerances for aluminum water jet cutting.

Prior to production release, every aluminum job undergoes mandatory Design for Manufacturability (DFM) review by our senior manufacturing engineering team. This critical phase focuses on resolving potential issues inherent to water jet cutting aluminum. Key aluminum-specific checks include verifying that feature sizes exceed the minimum achievable kerf width (typically 0.030″ to 0.040″ for aluminum), assessing the risk of excessive taper in thicker sections (common above 1.5″ aluminum), confirming that internal corners have adequate radii to prevent jet lag artifacts, and evaluating part geometry for potential warpage during cutting due to residual stresses in the aluminum sheet. The DFM report provides actionable feedback and tolerance validation specific to aluminum’s behavior under high-pressure water abrasion, ensuring the design aligns with process capabilities.

Once DFM approval is secured, the job enters production scheduling. Our nested cutting paths are optimized for aluminum using advanced software that accounts for the material’s thermal conductivity and lack of heat-affected zone, allowing for tight nesting without distortion concerns. Cutting parameters are precisely calibrated: we typically operate at 55,000 – 60,000 PSI for aluminum, select garnet abrasive with a mesh size appropriate for the alloy and desired surface finish (e.g., 80-mesh for balance of speed and edge quality on 6061-T6), and adjust feed rates based on thickness. All aluminum sheets undergo strict incoming inspection for flatness and grade verification before cutting. Post-cut, parts receive deburring to remove the characteristic water jet striations common on aluminum edges, with options for additional finishing like edge breaking or light sanding based on client specifications.

Final inspection validates critical dimensions against the CAD model using calibrated CMM or optical comparators, with particular attention to aluminum-specific characteristics like edge squareness and surface roughness Ra values. Parts are cleaned to remove residual abrasive and dried thoroughly to prevent water spotting on the aluminum surface. Packaging is customized for aluminum’s susceptibility to scratching, typically using VCI paper and compartmentalized containers. Delivery utilizes our integrated logistics platform, providing real-time tracking with lead times directly influenced by the validated aluminum thickness and complexity established during DFM and quoting.

Typical lead times for aluminum water jet cutting at Honyo Prototype correlate strongly with material thickness, as shown below:

| Aluminum Thickness Range | Typical Lead Time (Ex-Work) |

|---|---|

| 0.063″ – 0.250″ | 3-4 business days |

| 0.251″ – 1.000″ | 4-5 business days |

| 1.001″ – 2.000″ | 5-7 business days |

This structured workflow ensures that aluminum components produced via water jet cutting meet stringent quality standards while providing clients with predictable timelines and costs derived from material-specific process knowledge. The seamless integration between AI-driven quoting, expert DFM for aluminum, and tightly controlled production parameters eliminates common pitfalls in water jet prototyping and low-volume manufacturing.

Start Your Project

Looking for precision water jet cutting services for aluminum? Honyo Prototype offers high-accuracy, burr-free cutting with fast turnaround times. Our advanced water jet technology ensures clean edges and tight tolerances, ideal for prototypes and production runs.

We operate a state-of-the-art manufacturing facility in Shenzhen, China, providing cost-effective solutions without compromising quality.

Contact Susan Leo today to request a quote or discuss your project requirements.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.