Introduction: Navigating the Global Market for water jet cnc price

In an increasingly competitive global market, sourcing water jet CNC machines at the right price can pose significant challenges for international B2B buyers. With diverse applications ranging from precision cutting in manufacturing to intricate designs in artistic projects, understanding the various water jet CNC price points and their implications is essential for making informed purchasing decisions. This guide delves into the complexities of water jet CNC pricing, covering essential factors such as types of machines, operational costs, and the nuances of supplier vetting.

As buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—seek to optimize their investments, the need for clarity becomes paramount. This comprehensive resource empowers businesses to navigate the intricacies of water jet CNC cutting technology, offering insights into both abrasive and pure water jet applications. Additionally, it highlights the key considerations that influence costs, including operational efficiency and maintenance.

By equipping buyers with the knowledge needed to evaluate their options effectively, this guide aims to facilitate smarter purchasing decisions that align with both budgetary constraints and project requirements. Whether you are a fabricator, manufacturer, or creative professional, understanding the landscape of water jet CNC pricing can significantly enhance your operational capabilities and competitive edge.

Understanding water jet cnc price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Abrasive Waterjet Cutting | Utilizes abrasive materials like garnet to enhance cutting | Metal fabrication, aerospace, automotive | Pros: Versatile, can cut hard materials. Cons: Higher operational costs due to abrasive use. |

| Pure Waterjet Cutting | Uses only water for cutting, ideal for softer materials | Food processing, rubber, foam manufacturing | Pros: Lower operational costs, less wear on parts. Cons: Limited to softer materials. |

| Direct Drive Waterjet | Simpler design; mechanically driven pump | Small-scale operations, DIY projects | Pros: Lower initial investment. Cons: Higher maintenance and operating costs. |

| Intensifier Waterjet | Hydraulic-driven pump, more efficient and less maintenance | High-volume production, industrial applications | Pros: Lower long-term costs, reliable performance. Cons: Higher upfront cost. |

| Multi-Head Waterjet Cutting | Equipped with multiple cutting heads for increased efficiency | Large-scale manufacturing, complex designs | Pros: Increased cutting speed, higher productivity. Cons: Higher initial investment and complexity. |

What Are the Characteristics of Abrasive Waterjet Cutting Machines?

Abrasive waterjet cutting machines are designed to handle tough materials through the addition of abrasives, typically garnet, to the high-pressure water stream. This type is highly effective for industries such as aerospace and automotive, where precision and material integrity are paramount. When considering this option, B2B buyers should evaluate operational costs, as the abrasives contribute significantly to the overall expense, along with the wear on components requiring regular replacement.

How Does Pure Waterjet Cutting Differ from Abrasive Cutting?

Pure waterjet cutting relies solely on the high-pressure water stream, making it suitable for softer materials such as rubber and foam. It is commonly used in industries like food processing, where material purity is crucial. B2B buyers should note that while the initial and operational costs are lower compared to abrasive systems, the range of applications is limited, which may affect overall utility in diverse manufacturing processes.

What Are the Advantages of Direct Drive Waterjet Systems?

Direct drive waterjet systems feature a mechanically driven pump, making them a simpler and more cost-effective choice for smaller operations or hobbyists. These machines are advantageous for those with limited budgets. However, B2B buyers must consider the higher maintenance requirements and operational costs associated with this type, which can impact long-term profitability.

Why Choose Intensifier Waterjet Systems for Industrial Applications?

Intensifier waterjet systems utilize hydraulic pumps, offering enhanced efficiency and lower maintenance needs. They are ideal for high-volume production environments where reliability and cost-effectiveness are critical. B2B buyers should weigh the higher initial investment against the long-term savings on maintenance and operational costs, especially in demanding industrial applications.

How Do Multi-Head Waterjet Cutting Machines Enhance Production?

Multi-head waterjet cutting machines are equipped with several cutting heads, allowing for simultaneous operations and significantly increased cutting speed. This feature is particularly beneficial for large-scale manufacturing where time and efficiency are crucial. However, B2B buyers should be prepared for a higher initial investment and the complexity of managing such advanced systems, which may require specialized training and support.

Key Industrial Applications of water jet cnc price

| Industry/Sector | Specific Application of water jet cnc price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Cutting complex components from composites | Precision cuts without heat distortion | Need for high-quality, durable machines; certifications for aerospace standards |

| Automotive | Manufacturing intricate metal parts | High-speed production with minimal material waste | Consider machine size for large parts; availability of abrasive materials |

| Construction | Fabrication of architectural elements | Versatile cutting for various materials | Local sourcing of garnet abrasives; machine adaptability for different materials |

| Metal Fabrication | Custom metal part production | Cost-effective for low and high-volume runs | Maintenance support; options for multi-head cutting systems |

| Stone and Tile Industry | Cutting natural stone and tiles | Ability to cut hard materials with precision | Sourcing of high-pressure pumps; compatibility with various stone types |

How is Water Jet CNC Price Applied in Aerospace Manufacturing?

In the aerospace sector, water jet CNC technology is invaluable for cutting complex components from composite materials. The precision of water jet cutting ensures that parts maintain their integrity without the heat distortion associated with traditional cutting methods. This is crucial in an industry where material properties can affect safety and performance. Buyers should prioritize sourcing machines that meet strict aerospace certifications and are capable of handling high-pressure cutting for intricate designs.

What Role Does Water Jet CNC Price Play in Automotive Production?

In automotive manufacturing, water jet CNC machines are used extensively for producing intricate metal parts, such as brackets and housings. The ability to achieve high-speed production with minimal material waste translates to significant cost savings. For international buyers, especially in regions like South America and Europe, sourcing machines that can accommodate larger parts and offer a variety of abrasive materials is essential for optimizing production efficiency.

Why is Water Jet CNC Price Important in the Construction Industry?

The construction industry utilizes water jet CNC technology for fabricating architectural elements, such as custom facades and intricate designs. The versatility of water jet cutting allows for precise cuts in a variety of materials, including metals and composites. B2B buyers in construction should consider local sourcing of garnet abrasives and ensure that the machines can adapt to different material types to meet project specifications efficiently.

How Does Water Jet CNC Price Benefit Metal Fabrication?

In metal fabrication, water jet CNC machines facilitate the custom production of metal parts, catering to both low and high-volume runs. The cost-effectiveness of water jet cutting is enhanced by its ability to minimize material waste while maintaining high precision. Buyers should look for machines with robust maintenance support and options for multi-head cutting systems to maximize productivity and versatility in their operations.

What Advantages Does Water Jet CNC Price Offer the Stone and Tile Industry?

The stone and tile industry relies on water jet CNC technology for cutting hard materials like granite and marble. The precision of water jet cutting allows for intricate designs without chipping or cracking the stone. For B2B buyers, it is crucial to source high-pressure pumps that are compatible with various stone types to ensure efficiency and quality in production. Additionally, understanding the local market for abrasives can help in optimizing operating costs.

3 Common User Pain Points for ‘water jet cnc price’ & Their Solutions

Scenario 1: Unpredictable Total Costs of Ownership for Water Jet CNC Machines

The Problem: B2B buyers often encounter unexpected costs associated with the purchase and operation of water jet CNC machines. Initial pricing may seem attractive, but hidden expenses related to maintenance, parts wear, and consumables can significantly inflate the total cost of ownership. For instance, a company in Brazil may initially invest in a mid-range abrasive water jet cutter, only to later discover high costs for replacement parts and garnet abrasives, which can add up to thousands of dollars annually. These unforeseen expenses can strain budgets and hinder the financial forecasting necessary for long-term projects.

The Solution: To mitigate unpredictable costs, buyers should conduct a comprehensive cost analysis before making a purchase. This analysis should include not only the upfront price of the water jet CNC machine but also an estimation of ongoing costs such as electricity, water consumption, and the replacement of wear parts. Engaging with suppliers who provide detailed breakdowns of operating costs can help buyers make informed decisions. Additionally, considering machines with lower maintenance requirements or those that feature more durable components can lead to long-term savings. For instance, opting for high-quality garnet abrasives can initially seem more expensive but may reduce the frequency of replacements and downtime, ultimately enhancing productivity.

Scenario 2: Difficulty in Comparing Water Jet CNC Prices Across Suppliers

The Problem: International buyers, especially those in regions like Africa and the Middle East, often struggle to compare prices of water jet CNC machines across different suppliers. Variations in pricing structures, added features, and the potential for hidden fees can create confusion. For example, a buyer in South Africa might see a competitive price for a machine but overlook additional shipping costs or service fees that significantly alter the total expenditure.

The Solution: To effectively compare prices, buyers should request detailed quotes from multiple suppliers, ensuring that each quote includes a comprehensive list of features, warranties, and service agreements. It’s beneficial to create a standardized template for comparison that covers all essential aspects, such as the type of cutting (abrasive vs. pure waterjet), included accessories, and estimated operational costs. Leveraging online platforms that aggregate machine listings and prices can also facilitate better comparisons. Additionally, engaging with industry forums or trade shows can provide insights into average market rates and help identify reputable suppliers, further enhancing the decision-making process.

Scenario 3: Uncertainty in Selecting the Right Water Jet CNC for Specific Applications

The Problem: Buyers often face uncertainty when selecting the appropriate water jet CNC machine for their specific cutting needs. This is particularly true for businesses involved in diverse industries, such as metal fabrication or stone cutting, where the requirements can differ vastly. For example, a manufacturing firm in Germany may be unsure whether to invest in a high-capacity abrasive water jet or a more cost-effective pure water jet system for cutting soft materials.

The Solution: To address this challenge, buyers should conduct a thorough assessment of their operational needs and project specifications. This includes evaluating the types of materials they intend to cut, the necessary thickness, and production volumes. Consulting with technical experts or suppliers who can provide tailored recommendations based on specific applications can be invaluable. Additionally, investing in a flexible water jet system that can accommodate both abrasive and pure water cutting methods may offer the versatility needed for varied projects, thus ensuring the buyer is well-equipped for future opportunities. Engaging in demonstrations or pilot projects with potential suppliers can also clarify performance capabilities and help buyers make confident decisions.

Strategic Material Selection Guide for water jet cnc price

How Do Different Materials Affect Water Jet CNC Pricing?

When considering the procurement of water jet CNC machines, the choice of material significantly influences both the operational costs and the overall effectiveness of the cutting process. Below, we analyze four common materials used in water jet cutting, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Steel in Water Jet Cutting?

Steel is one of the most frequently processed materials in water jet cutting due to its widespread use in various industries. It exhibits excellent strength and durability, with a temperature rating that can withstand high pressures. Steel also has good corrosion resistance when treated properly, making it suitable for various environments.

Pros & Cons: Steel’s durability ensures that it can withstand heavy use, but it can be more expensive than softer materials. The manufacturing complexity is moderate, as it requires precise cutting to achieve desired shapes. While steel is suitable for a wide range of applications, it may require additional finishing processes to achieve the desired surface quality.

Impact on Application: Steel is commonly used in construction, automotive, and aerospace applications. Buyers must consider the specific grade of steel, as different grades may have varying properties and costs.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is crucial when sourcing steel. Buyers from regions like Africa and South America should also consider local availability and tariffs that may affect pricing.

How Does Aluminum Compare in Water Jet Cutting?

Aluminum is another popular material due to its lightweight nature and excellent corrosion resistance. It has a lower melting point than steel, which makes it easier to cut but may require careful handling to avoid warping.

Pros & Cons: The primary advantage of aluminum is its lightweight, making it ideal for applications where weight is a concern, such as in aerospace and automotive sectors. However, aluminum can be more expensive than steel and may require specialized abrasives to achieve clean cuts.

Impact on Application: Aluminum is often used in the manufacturing of components that require a balance of strength and weight. The choice of aluminum grade can significantly impact cutting efficiency and cost.

Considerations for International Buyers: Buyers should ensure that the aluminum grades meet local standards and specifications. Additionally, the cost of aluminum can fluctuate based on international market conditions, which may affect budgeting.

What Are the Benefits of Using Stone in Water Jet Cutting?

Stone, including granite and marble, is commonly processed using water jet cutting due to its ability to create intricate designs without generating heat that could crack the material. Stone has high compressive strength and is resistant to heat, making it suitable for various applications.

Pros & Cons: The main advantage of stone is its aesthetic appeal and durability. However, cutting stone can be more complex and may require specialized equipment and abrasives, leading to higher operational costs.

Impact on Application: Stone is often used in architectural applications, countertops, and decorative elements. The need for precision in cutting stone makes water jet technology particularly valuable.

Considerations for International Buyers: Compliance with local building codes and standards is essential, especially in regions like Europe where regulations can be stringent. Buyers should also be aware of the sourcing and transportation costs associated with heavy stone materials.

Why Choose Composites for Water Jet Cutting?

Composites, such as fiberglass and carbon fiber, are increasingly popular in industries like aerospace and automotive due to their high strength-to-weight ratio and resistance to corrosion. They can be cut efficiently using water jet technology without producing harmful dust or fumes.

Pros & Cons: Composites offer excellent durability and can be tailored for specific applications. However, they can be more expensive than traditional materials and may require specialized cutting techniques to achieve desired results.

Impact on Application: Composites are ideal for applications requiring lightweight and strong materials, but they may not be suitable for all cutting methods, making water jet cutting a preferred choice.

Considerations for International Buyers: Buyers should verify that composite materials meet applicable international standards. The complexity of sourcing high-quality composites can also affect pricing and availability.

Summary Table of Material Selection for Water Jet CNC Pricing

| Material | Typical Use Case for water jet cnc price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction, automotive, aerospace | High strength and durability | Higher cost compared to softer materials | Medium |

| Aluminum | Aerospace, automotive components | Lightweight and corrosion-resistant | More expensive and requires special abrasives | High |

| Stone | Architectural applications, countertops | Aesthetic appeal and durability | Cutting complexity and higher operational costs | Medium |

| Composites | Aerospace, automotive, specialized parts | High strength-to-weight ratio | Higher cost and specialized cutting techniques | High |

This analysis provides a comprehensive overview of the materials commonly used in water jet cutting, allowing international B2B buyers to make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for water jet cnc price

What Are the Main Stages in the Manufacturing Process of Water Jet CNC Machines?

The manufacturing process of water jet CNC machines involves several critical stages, each essential for ensuring the final product meets the required specifications and quality standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first stage involves selecting high-quality materials, typically stainless steel or aluminum, which are known for their strength and durability. Materials are cut into manageable sizes using preliminary cutting techniques. This stage also includes the inspection of raw materials to ensure they meet the required standards, such as hardness and tensile strength.

Forming Techniques

Once the materials are prepared, the forming process begins. This usually involves CNC machining, where computer-controlled tools shape the components with high precision. Techniques such as laser cutting or plasma cutting may also be employed to create intricate parts that will later be assembled into the water jet system. The accuracy of this stage is crucial, as any defects can lead to performance issues.

Assembly Process

The assembly stage is where the various components, including pumps, cutting heads, and control systems, are brought together. Skilled technicians ensure that each part is fitted correctly, following predefined assembly protocols. This step may involve both manual assembly and automated processes, depending on the complexity of the machine.

Finishing Techniques

Finally, the finishing stage involves surface treatments to enhance the durability and aesthetic appeal of the machines. This can include anodizing, painting, or applying protective coatings to prevent corrosion. Quality checks are conducted at this stage to confirm that all components meet the design specifications and functional requirements.

How Is Quality Assurance Implemented in the Manufacturing of Water Jet CNC Machines?

Quality assurance is a fundamental aspect of manufacturing water jet CNC machines, ensuring that they perform reliably and efficiently. Manufacturers adhere to various international standards, such as ISO 9001, which outlines the criteria for a quality management system. This standard emphasizes continuous improvement and customer satisfaction.

Relevant International Standards

In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for manufacturers aiming to serve global markets. CE certification is particularly important for machines sold in Europe, as it signifies compliance with health, safety, and environmental protection standards.

Quality Control Checkpoints

Quality control (QC) checkpoints are integrated throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This initial inspection verifies that raw materials meet predefined specifications before they enter the production process.

- In-Process Quality Control (IPQC): Conducted during the manufacturing stages, IPQC ensures that each phase adheres to quality standards. This includes monitoring the forming and assembly processes.

- Final Quality Control (FQC): At the end of the manufacturing process, the completed water jet CNC machines undergo rigorous testing to assess their performance, accuracy, and reliability.

What Common Testing Methods Are Used in Quality Assurance for Water Jet CNC Machines?

Manufacturers employ various testing methods to ensure that water jet CNC machines operate efficiently and meet quality standards. Common testing methods include:

- Hydrostatic Testing: This method checks for leaks and assesses the structural integrity of the machine under pressure, ensuring it can withstand operational demands.

- Performance Testing: Machines are tested under real operational conditions to evaluate cutting speed, precision, and overall performance.

- Dimensional Inspection: Precision measurement tools are used to verify that all components meet the specified dimensions and tolerances.

How Can B2B Buyers Verify the Quality Control Processes of Water Jet CNC Suppliers?

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential to ensure they receive reliable products. Here are some strategies:

- Conduct Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. This can include reviewing their compliance with international standards and certifications.

- Request Quality Assurance Reports: Suppliers should provide documentation that details their quality control measures and results from recent testing. This transparency is crucial for building trust.

- Engage Third-Party Inspection Services: Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices and the integrity of the products.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control and certification nuances when sourcing water jet CNC machines. These include:

- Understanding Regional Standards: Different regions may have varying standards and certifications. Buyers should familiarize themselves with local regulations to ensure compliance.

- Evaluating Supplier Capabilities: Buyers should assess whether suppliers have the necessary certifications to operate in their specific markets. For example, a supplier with ISO certification may be more reliable than one without.

- Cultural and Communication Factors: Effective communication is essential to clarify quality expectations and standards. Buyers should consider cultural differences that may affect negotiations and supplier relationships.

By understanding the manufacturing processes and quality assurance measures involved in water jet CNC machines, B2B buyers can make informed decisions when selecting suppliers, ensuring they invest in reliable, high-quality equipment that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water jet cnc price’

In the competitive landscape of manufacturing and fabrication, sourcing the right water jet CNC machine at the right price is paramount. This guide will walk you through essential steps to ensure you make informed purchasing decisions that align with your operational needs and budget.

Step 1: Define Your Technical Specifications

Before diving into the market, clearly outline what you need from a water jet CNC machine. Consider factors such as the type of materials you will be cutting (e.g., metal, stone, glass), the thickness of these materials, and whether you require abrasive or pure waterjet cutting capabilities. This specificity will help narrow your options and ensure that the machine you select can handle your production requirements efficiently.

Step 2: Research the Market Prices

Understanding the market price for water jet CNC machines is crucial. Prices can vary widely based on brand, capabilities, and whether the machine is new or used. Use online resources, industry reports, and supplier websites to gather data on average costs. This will empower you to identify fair pricing and avoid overpaying.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request company profiles, case studies, and references from other clients in your industry or region. Look for suppliers who have a strong reputation and offer warranties or service agreements, which can be indicative of their reliability and product quality.

Step 4: Assess Total Cost of Ownership (TCO)

When evaluating machines, consider not just the upfront price but the total cost of ownership, which includes operating costs like electricity, maintenance, and replacement parts. Be sure to ask about wear parts, such as nozzles and seals, which can add significantly to long-term expenses. Understanding these costs will help you budget more accurately.

Step 5: Request Quotes and Compare Offers

Once you have a shortlist of potential machines and suppliers, request detailed quotes. Ensure that each quote includes specifications, warranties, delivery options, and payment terms. Comparing these offers side-by-side will help you identify the best value while ensuring that all necessary features and services are included.

Step 6: Verify Certifications and Compliance

Ensure that the suppliers and machines comply with relevant industry standards and regulations. Look for certifications that demonstrate quality and safety, such as ISO certifications. This step is critical for minimizing risks associated with equipment performance and safety in your operations.

Step 7: Plan for Installation and Training

Finally, consider the logistics of installation and operator training. Some suppliers may offer installation services, while others might require you to manage this process independently. Training is essential to maximize the efficiency of your new machine and ensure your team can operate it safely and effectively. Clarify these aspects with your supplier before finalizing your purchase.

By following these steps, you can navigate the complexities of sourcing a water jet CNC machine with confidence, ensuring that you find a solution that meets your operational needs while staying within budget.

Comprehensive Cost and Pricing Analysis for water jet cnc price Sourcing

What Are the Key Cost Components in Water Jet CNC Pricing?

When evaluating the cost structure of water jet CNC machines, several components come into play.

-

Materials: This includes the cost of the water used, abrasives (like garnet), and any additional materials required for specific cutting projects. Abrasive costs can be significant, typically around $0.25 per pound, affecting overall project budgets.

-

Labor: Skilled operators are essential for efficient water jet cutting. Labor costs can vary widely by region, with higher costs in developed countries compared to regions like Africa and South America. Training and expertise also factor into this cost.

-

Manufacturing Overhead: This encompasses expenses related to facility maintenance, utilities, and equipment depreciation. Businesses should consider the lifespan of their machines and the associated costs over time.

-

Tooling: Regular maintenance and replacement of cutting heads, nozzles, and other components are necessary to ensure optimal performance. The wear and tear of these parts directly impacts operational costs.

-

Quality Control (QC): Implementing rigorous QC processes is essential to maintain cutting precision and quality. This can include both human oversight and automated systems, which contribute to overall costs.

-

Logistics: The transportation of machines and materials to and from the job site adds another layer of expenses. International buyers should consider shipping costs, customs duties, and local taxes.

-

Margin: Suppliers typically include a margin that reflects the risk and investment involved in providing equipment and services. This can vary based on supplier reputation and market dynamics.

What Influences Pricing in Water Jet CNC Machines?

Several factors can influence the pricing of water jet CNC machines, particularly in international markets.

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to significant discounts. Buyers should negotiate for better rates based on volume commitments.

-

Specifications and Customization: Unique requirements for cutting dimensions, materials, and capabilities can drive up costs. Customization often requires additional engineering work, affecting the final price.

-

Materials Used: The type of materials being cut can influence the choice of water jet cutter, impacting both the initial investment and operational costs. For instance, machines designed for abrasive cutting generally cost more than those for pure water cutting.

-

Quality and Certifications: Machines that meet international standards or possess specific certifications may command higher prices. Buyers should verify supplier credentials to ensure compliance with local regulations.

-

Supplier Factors: The reputation, experience, and location of the supplier can affect pricing. Established suppliers may charge more due to perceived reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. They define responsibilities for shipping, insurance, and tariffs, influencing overall costs.

How Can Buyers Negotiate Better Prices for Water Jet CNC Machines?

To achieve cost efficiency, buyers should consider the following strategies:

-

Understand Total Cost of Ownership (TCO): Evaluate the long-term operational costs, including maintenance, labor, and consumables, rather than focusing solely on the purchase price. This holistic view can lead to better purchasing decisions.

-

Leverage Competitive Quotes: Request quotes from multiple suppliers to create competition. This can help in negotiating better terms and prices.

-

Negotiate Based on Volume: If planning to make multiple purchases, discuss volume discounts upfront. Suppliers are often willing to negotiate on bulk orders.

-

Explore Financing Options: Many suppliers offer financing plans that can spread the cost over time, making high-quality machines more accessible.

-

Be Informed About Market Trends: Understanding current market conditions, technological advancements, and pricing trends can empower buyers in negotiations.

Final Thoughts on Water Jet CNC Pricing

Pricing for water jet CNC machines can be complex, influenced by numerous factors from material costs to supplier reputation. International buyers should approach sourcing with a comprehensive understanding of the cost structure and pricing influencers. While indicative prices can provide a baseline, due diligence is essential for making informed purchasing decisions. Engaging with multiple suppliers and negotiating based on total cost of ownership will ultimately lead to more favorable outcomes.

Alternatives Analysis: Comparing water jet cnc price With Other Solutions

Exploring Alternatives to Water Jet CNC Cutting

When considering cutting technologies, it’s essential for B2B buyers to evaluate not only the price of water jet CNC systems but also alternative solutions that may better align with specific operational needs and budget constraints. This analysis will compare water jet CNC cutting with laser cutting and plasma cutting, two prevalent alternatives in the manufacturing sector.

| Comparison Aspect | Water Jet CNC Price | Laser Cutting | Plasma Cutting |

|---|---|---|---|

| Performance | Excellent for thick materials; no heat-affected zone (HAZ) | Fast cutting speed; ideal for thin metals | Good for thick metals but can create HAZ |

| Cost | Higher initial cost; lower operational costs for soft materials | Moderate initial cost; lower operational costs | Lower initial cost; higher operational costs due to consumables |

| Ease of Implementation | Requires skilled operators; setup can be complex | Easier setup; user-friendly software | Simple setup; requires ventilation and safety measures |

| Maintenance | Moderate maintenance; wear parts need regular replacement | Lower maintenance; optics can require replacement | Higher maintenance; consumable parts need frequent replacement |

| Best Use Case | Cutting complex shapes in various materials, especially thick | Precision cutting in metals, particularly thin sheets | Cutting thicker metals in industrial applications |

Understanding Laser Cutting as an Alternative

Laser cutting employs a focused beam of light to melt or vaporize materials. This technology is favored for its speed and precision, making it ideal for thin metals and intricate designs. However, it creates a heat-affected zone (HAZ), which can alter the material properties at the cut edges, potentially complicating subsequent processing. While the initial investment is moderate, the ongoing costs can be lower compared to water jet cutting, particularly for high-volume production. Overall, laser cutting is best suited for applications requiring high precision and speed, especially in metal fabrication.

Evaluating Plasma Cutting as a Competitor

Plasma cutting utilizes an ionized gas (plasma) to cut through conductive materials. This method is advantageous for its lower initial cost and ability to handle thicker materials efficiently. However, similar to laser cutting, it generates a heat-affected zone, which can impact the material’s integrity. Maintenance can be more demanding due to frequent replacement of consumables, such as nozzles and electrodes. Plasma cutting is most effective in heavy industrial environments where speed and cost are critical, making it less suitable for applications requiring high precision or cutting of heat-sensitive materials.

Making the Right Choice for Your Cutting Needs

In conclusion, when selecting a cutting technology, B2B buyers should consider their specific operational requirements, including material types, thicknesses, and desired cutting quality. Water jet CNC cutting offers unique advantages, such as the ability to cut a wide range of materials without altering their properties, making it a compelling choice for complex applications. However, if speed and cost are top priorities for thinner materials, laser or plasma cutting may be more suitable. Ultimately, the decision should be guided by a comprehensive evaluation of performance, cost, maintenance, and the intended use case to ensure the chosen solution aligns with the business’s strategic goals.

Essential Technical Properties and Trade Terminology for water jet cnc price

What Are the Key Technical Properties Influencing Water Jet CNC Pricing?

Understanding the essential technical properties of water jet CNC machines is critical for B2B buyers evaluating their options. Here are some key specifications that significantly influence the pricing and operational efficiency of these machines:

-

Material Grade: The type and grade of materials that a water jet cutter can process is crucial. Water jet machines can cut various materials, including metals, composites, glass, and stone. The capability to handle diverse material grades not only affects the machine’s versatility but also its price. High-performance machines that can cut harder materials typically cost more but offer greater ROI for businesses needing to process a wide range of materials.

-

Cutting Tolerance: This refers to the precision level of the cuts made by the machine. Tolerance is often measured in millimeters or microns, and tighter tolerances usually indicate higher-quality machinery. For industries like aerospace and automotive, where precision is paramount, investing in machines that can achieve tighter tolerances can justify a higher upfront cost due to reduced waste and improved quality of finished products.

-

Pump Type: Water jet machines typically utilize two types of pumps: direct drive and intensifier. Direct drive pumps are generally less expensive but may incur higher maintenance costs over time. In contrast, intensifier pumps, while more costly initially, offer lower operating costs and reduced maintenance needs. The choice of pump type significantly influences the overall pricing and operational expenses of water jet cutting.

-

Cutting Speed: The speed at which a machine can cut material directly impacts productivity and, consequently, the cost per part. Faster machines can process more material in less time, which is a vital consideration for companies with high-volume production needs. Understanding the trade-off between speed and cutting quality will help buyers make informed decisions.

-

Operating Costs: Beyond the initial purchase price, ongoing operational costs such as electricity consumption, maintenance, and the cost of consumables (e.g., abrasives) can significantly affect the total cost of ownership. Buyers should consider machines that offer a balance between efficiency and cost-effectiveness to optimize their long-term investment.

What Are Common Trade Terms Related to Water Jet CNC Pricing?

Navigating the trade terminology associated with water jet CNC pricing is essential for B2B buyers. Here are some common terms that may arise in discussions or negotiations:

-

OEM (Original Equipment Manufacturer): This term refers to the company that produces the water jet cutting machine. Understanding who the OEM is can help buyers assess the quality, reliability, and support they can expect post-purchase.

-

MOQ (Minimum Order Quantity): This specifies the smallest quantity of a product that a supplier is willing to sell. In the context of water jet machines, knowing the MOQ can help buyers plan their budgets and inventory more effectively, especially if they are considering purchasing multiple units or additional parts.

-

RFQ (Request for Quotation): An RFQ is a document that a buyer sends to suppliers to request pricing and terms for a specific quantity of goods. When considering water jet CNC machines, an RFQ allows buyers to gather multiple quotes and compare pricing, which is crucial for making informed purchasing decisions.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in shipping and delivery. Understanding Incoterms is vital for B2B transactions involving water jet machines, as they dictate who bears the cost and risk at various stages of the shipping process.

-

Lead Time: This refers to the time it takes from placing an order to receiving the product. In the context of water jet CNC machines, lead time can vary significantly based on machine specifications and supplier capabilities. Knowing the expected lead time helps buyers plan their production schedules accordingly.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when evaluating water jet CNC machines, ultimately leading to better investment outcomes.

Navigating Market Dynamics and Sourcing Trends in the water jet cnc price Sector

What Are the Current Drivers Influencing Water Jet CNC Prices Globally?

The water jet CNC sector is currently experiencing a notable shift driven by technological advancements and evolving market demands. The proliferation of automation and Industry 4.0 technologies has enhanced the capabilities of water jet cutting machines, allowing for greater precision and efficiency. This trend is particularly relevant for international B2B buyers, as enhanced functionality can lead to lower operational costs and improved production timelines. Additionally, the growing adoption of water jet cutting in diverse sectors such as aerospace, automotive, and construction is propelling market growth.

Emerging sourcing trends also highlight the importance of versatility in water jet systems. Buyers are increasingly seeking equipment that can handle both abrasive and pure water jet cutting, catering to a wide range of materials from metals to composites. Moreover, the rise of e-commerce platforms and online marketplaces is reshaping how buyers source machinery, enabling easier access to international suppliers and competitive pricing. For regions like Africa and South America, where manufacturing infrastructure is developing, these trends present significant opportunities for cost-effective procurement and enhanced operational efficiencies.

How Are Sustainability and Ethical Sourcing Impacting Water Jet CNC Procurement?

Sustainability is becoming a critical factor in the decision-making processes of B2B buyers in the water jet CNC sector. The environmental impact of manufacturing practices is under scrutiny, prompting companies to adopt more sustainable methods. Water jet cutting, recognized for its minimal waste and recyclable materials, aligns well with these sustainability goals. Furthermore, the use of recycled water in water jet systems helps reduce the overall environmental footprint, making it an appealing choice for eco-conscious businesses.

Ethical sourcing is equally important, with buyers increasingly favoring suppliers who demonstrate commitment to sustainable practices. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming essential in supplier evaluations. Buyers should seek partners who prioritize responsible sourcing of materials, including high-quality garnet abrasives, which have a lower environmental impact compared to other cutting materials. By aligning procurement strategies with sustainability objectives, companies can enhance their brand reputation and meet the growing demand for eco-friendly solutions in their markets.

What Is the Evolution of Water Jet CNC Technology and Its Relevance to Today’s Market?

Water jet cutting technology has evolved significantly since its inception in the 1960s. Initially used for soft materials, advancements in pump technology and the introduction of abrasive cutting have expanded its applicability to a wider range of materials, including metals and composites. The development of computer numerical control (CNC) technology has further refined the precision and efficiency of water jet systems, allowing for intricate designs and complex shapes.

This evolution is particularly relevant for B2B buyers today, as it underscores the importance of investing in advanced machinery that can adapt to changing market demands. Modern water jet systems offer features such as multi-axis cutting, automation capabilities, and enhanced control systems, making them indispensable in competitive manufacturing environments. Understanding the historical context and advancements in water jet technology can help buyers make informed decisions about their equipment investments, ensuring they choose solutions that will meet their needs for years to come.

Frequently Asked Questions (FAQs) for B2B Buyers of water jet cnc price

-

How do I determine the cost-effectiveness of a water jet CNC machine?

To evaluate the cost-effectiveness of a water jet CNC machine, consider both initial investment and operational costs. Look at factors such as energy consumption, maintenance needs, and the cost of consumables like abrasives. Compare these costs against the machine’s cutting capabilities and the types of materials you intend to work with. Additionally, assess potential savings from reduced material waste and faster production times. Always factor in your specific application needs to make an informed decision. -

What are the main factors influencing the price of water jet CNC machines?

The price of water jet CNC machines is influenced by several factors, including the type (abrasive vs. pure waterjet), cutting size capacity, pump type (direct drive vs. intensifier), and brand reputation. Additional considerations include technological features such as multi-head configurations, control systems, and automation options. Supplier location and shipping costs can also impact the final price, especially for international buyers. Always obtain quotes from multiple suppliers to find the best deal. -

How can I vet suppliers for water jet CNC machines?

To vet suppliers, start by researching their reputation in the market through reviews and testimonials. Check their experience in manufacturing and selling water jet CNC machines, and ask for references from previous clients. Verify their certifications and compliance with international quality standards. Additionally, inquire about their after-sales support, warranty policies, and whether they offer training for machine operation. Engaging in direct communication with potential suppliers can also help gauge their responsiveness and reliability. -

What customization options are typically available for water jet CNC machines?

Customization options for water jet CNC machines can include modifications in cutting size, pump types, and software capabilities tailored to specific industry needs. Some suppliers offer custom configurations for multiple cutting heads to enhance productivity. Additional options may involve specialized nozzle designs or the integration of automation features. Always discuss your specific requirements with potential suppliers to ensure that the machine can be tailored to meet your operational needs. -

What is the minimum order quantity (MOQ) for purchasing water jet CNC machines?

The minimum order quantity (MOQ) for water jet CNC machines can vary significantly among suppliers. Some may sell single units, especially for smaller or used machines, while others may require a MOQ for larger, customized orders. It’s essential to clarify the MOQ during initial discussions with suppliers, as it could affect your purchasing decision. In some cases, negotiating terms for smaller orders may be possible, particularly if you have plans for future purchases. -

What payment terms are commonly offered by suppliers of water jet CNC machines?

Payment terms for water jet CNC machines can vary widely but typically include options such as full payment upfront, partial payment with a deposit, or financing arrangements. Some suppliers may offer net terms (e.g., net 30, net 60) allowing you to pay after delivery. It’s crucial to negotiate favorable terms that align with your cash flow needs. Always ensure that payment methods are secure and consider using escrow services for large transactions to mitigate risks. -

How can I ensure quality assurance (QA) for my water jet CNC machine?

To ensure quality assurance (QA) for your water jet CNC machine, request detailed specifications and certifications from the supplier, confirming compliance with international standards. Inquire about their QA processes, including testing methods and inspection protocols before shipment. It’s beneficial to establish clear communication about your quality expectations and conduct a factory inspection if possible. Additionally, consider obtaining a warranty that covers defects and performance issues to safeguard your investment. -

What logistics considerations should I be aware of when importing a water jet CNC machine?

When importing a water jet CNC machine, logistics considerations include shipping methods, customs duties, and delivery timelines. Ensure the supplier provides reliable shipping options, and clarify who bears the shipping costs. Familiarize yourself with the import regulations in your country, including any tariffs or taxes applicable to machinery. It’s also wise to work with a freight forwarder or logistics expert to navigate the complexities of international shipping and ensure timely delivery.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Water Jet Cnc Price Manufacturers & Suppliers List

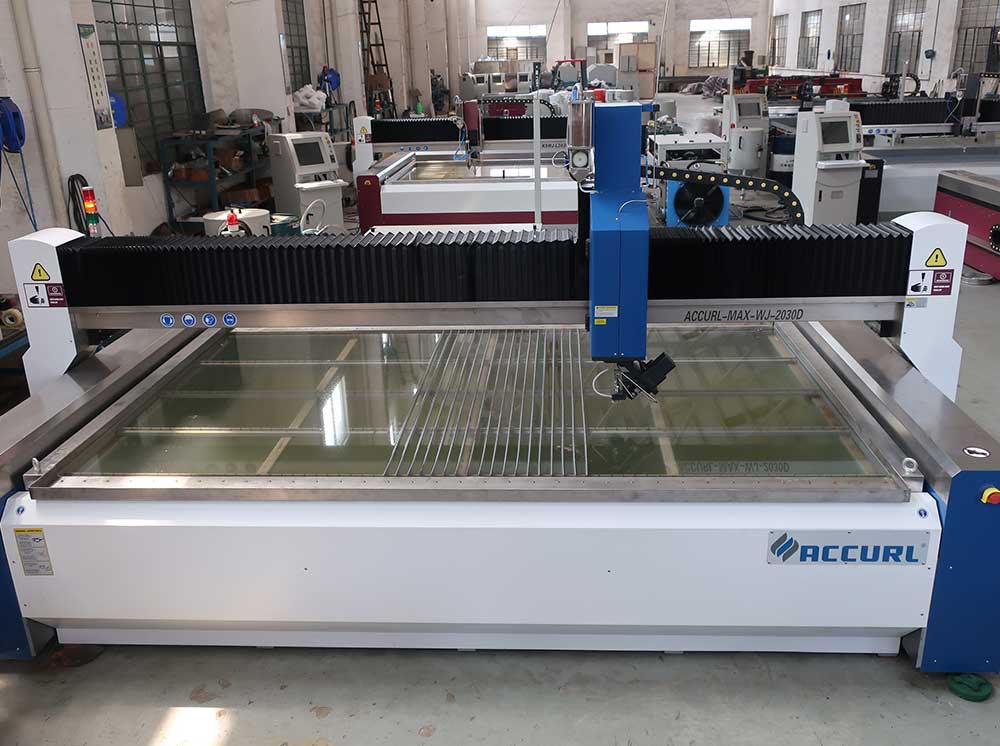

1. OMAX – Water Jet Cutting Machines

Domain: cncmachines.com

Registered: 1997 (28 years)

Introduction: Used Water Jet Cutting Machines available at CNCMachines.com. Categories include: Laser, Waterjet, Grinding, Plasma, Saw, Press Brake, Welder, Punch Press, Shear, Iron Worker, Roller, Tube and Pipe Bender, Gear Stamping Press. Brands include FLOW, OMAX, CALYPSO, KMT, MULTICAM, POLARIS, TECHNI WATERJET. Models include MACH 200 4020, MACH 500, 120X, 3000 SERIES, 4020B, 60120, HAMMERHEAD105, I510G2, …

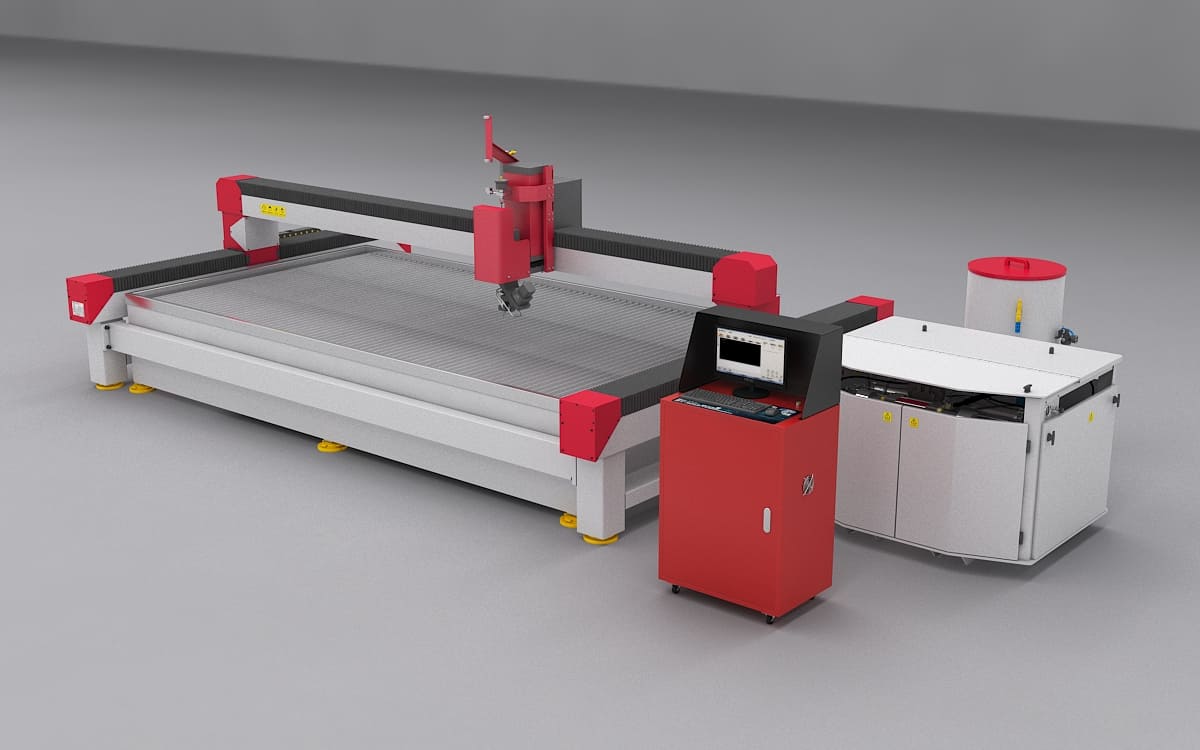

2. TechniWaterjet – Waterjet Cutters and Pumps

Domain: techniwaterjet.com

Registered: 2005 (20 years)

Introduction: TechniWaterjet offers a range of waterjet cutters including the Intec™ G2 Series (i35-G2, i510-G2, i613-G2, i713-G2, i815-G2, i1020-G2, i1033-G2, XLarge Gantry) and Quantum® Series pumps. Prices for small waterjet machines start at $60,000, while the Techniwaterjet G2 CNC waterjet cutters begin at $100,000, with high-end models reaching up to $450,000. Operating costs for waterjet cutting range fr…

3. East Valley Precision – Waterjet Cutters

Domain: eastvalleyprecision.com

Registered: 2005 (20 years)

Introduction: Entry-Level Waterjet Cutters: WAZER Desktop, starting at $9,999. Mid-Range Waterjet Cutters: WAZER Pro, starting at $18,999. Industrial-Grade Waterjet Cutters: BCMC CNC Waterjet Machines, priced between $31,500 and $33,500. Hongyi 2025 CNC Sawjet, priced between $42,013 and $46,521. Hourly Operating Costs: $15 to $30 per hour. High-Pressure Water Generation: 30,000 to 90,000 PSI. Cutting Speed: Up…

4. A & V – 5′ X 10′ CNC Waterjet Cutting Machine

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “A&V 5′ X 10′ CNC Waterjet Cutting Machine”, “Brand”: “A & V”, “Model”: “5′ x 10′”, “MPN”: “75217”, “Condition”: “Used”, “Price”: “$32,500.00 or Best Offer”, “Location”: “NV, United States”, “Shipping”: “Does not ship to Germany”, “Returns”: “Seller does not accept returns”, “Seller”: {“Name”: “Precise CNC Machinery, Inc.”, “Feedback”: “100% positive”, “Items Sold”: “35”, “Joined”…

5. Ivy CNC – Water Jet Cutting Machines

Domain: ivycnc.com

Registered: 2022 (3 years)

Introduction: Water Jet Cutting Machine Price Ranges: 1. Basic Models: $15,000 to $30,000 – Basic functionalities, suitable for commonly used metals, 2D cutting capability, basic CNC control system. 2. Mid-Range Models: $50,000 to $100,000 – More advanced features and high cutting abilities. 3. Premium Models: $200,000 and above – Cutting-edge technologies for complex and high-precision work, 2D and 3D cutting …

6. Flow – Waterjet Cutters

Domain: surplusrecord.com

Registered: 1995 (30 years)

Introduction: Used Waterjet Cutters for Sale | CNC Options | Surplus Record

Manufacturers:

– Flow (111)

– Omax (43)

– Techni (16)

– Mitsubishi (13)

– Wardjet (12)

– Iwm (9)

– Calypso (5)

– Bystronic (4)

– Cms (3)

– Jet (3)

– Multicam (3)

– A&v (2)

– Aks (2)

– Kmt (2)

– Maxiem (2)

– Northwood (2)

– Romeo (2)

– Abrasive (1)

– Accurl (1)

– Advance (1)

– Artwork Iwm (1)

– Baileigh (1)

– Burntables (1)

– Hornet (1)…

Strategic Sourcing Conclusion and Outlook for water jet cnc price

What Are the Key Takeaways for B2B Buyers on Water Jet CNC Pricing?

Understanding the nuances of water jet CNC pricing is crucial for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. Key factors influencing pricing include the type of water jet cutter—whether abrasive or pure—operating costs, and the specific materials being cut. Buyers should also consider the total cost of ownership, which encompasses maintenance, wear parts, and electricity consumption.

How Can Strategic Sourcing Enhance Your Investment?

Strategic sourcing plays a vital role in maximizing the value of your investment in water jet technology. By collaborating closely with suppliers, buyers can negotiate better pricing, secure high-quality materials, and ensure timely delivery. Additionally, understanding local market conditions can lead to more informed purchasing decisions that align with budgetary constraints.

What’s Next for International B2B Buyers?

Looking ahead, the demand for efficient, precise cutting solutions like water jet CNC technology is set to grow. As industries evolve, staying informed about advancements and price trends will empower buyers to make strategic decisions. We encourage you to engage with suppliers and industry experts to explore the best options tailored to your unique needs. Start optimizing your sourcing strategy today to leverage the full potential of water jet cutting technology.