Contents

Manufacturing Insight: Water Cutting Service

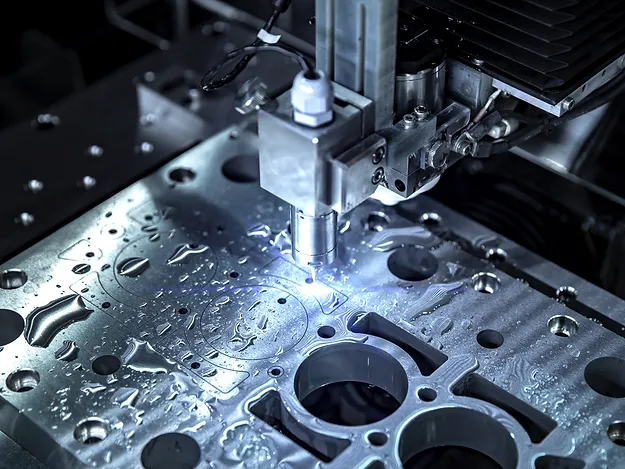

Precision Water Jet Cutting Services at Honyo Prototype

Honyo Prototype delivers advanced CNC water jet cutting services as a core component of our comprehensive precision manufacturing solutions. This cold-cutting process eliminates thermal distortion and heat-affected zones, making it ideal for processing sensitive materials like composites, titanium, glass, and advanced alloys where traditional thermal methods are unsuitable. Our high-pressure abrasive water jet systems achieve exceptional accuracy and edge quality across complex geometries, supporting demanding prototyping and low-volume production requirements without compromising material integrity.

Our water jet capabilities are fully integrated within Honyo’s broader CNC machining ecosystem, which includes multi-axis milling, turning, and laser cutting. This integration ensures seamless workflow for projects requiring hybrid manufacturing approaches. Engineers benefit from a single-source solution where water jet cutting for initial blanking or intricate profiling can be efficiently combined with secondary CNC operations, reducing lead times and supply chain complexity. We maintain strict process control to consistently achieve tolerances down to ±0.1 mm, supporting critical applications across aerospace, medical device development, and energy sectors.

Key technical parameters for our water jet cutting service are summarized below for immediate reference:

| Parameter | Capability Range | Notes |

|---|---|---|

| Max Thickness | Up to 200 mm (8″) | Varies by material hardness |

| Typical Tolerance | ±0.1 mm (0.004″) | Achievable on most materials |

| Common Materials | Metals, Composites, Stone, Glass, Plastics | Full material compatibility list available |

Accelerate your prototyping timeline with Honyo Prototype’s Online Instant Quote system. Upload your DXF, DWG, or STEP file directly to our platform for a detailed, no-obligation cost estimate within minutes—no manual RFQ submission required. This digital workflow provides immediate visibility into manufacturability feedback and pricing for water jet cutting and associated CNC services, empowering faster design validation and procurement decisions. Experience the precision and efficiency of integrated CNC manufacturing backed by responsive engineering support.

Technical Capabilities

Waterjet Cutting Service – Technical Specifications

Honyo Prototype offers high-precision waterjet cutting services optimized for complex geometries and tight-tolerance components across a range of engineering materials. Our advanced 3-axis, 4-axis, and 5-axis waterjet systems deliver accurate, burr-free cuts without heat-affected zones, making them ideal for sensitive materials and critical applications.

The following table outlines the technical capabilities and material performance:

| Parameter | Specification |

|---|---|

| Cutting Method | High-pressure abrasive waterjet (typically 55,000–90,000 psi) |

| Axis Configuration | 3-axis (X, Y, Z), 4-axis (with rotational A-axis), 5-axis (A and B/C rotations) |

| Positioning Accuracy | ±0.005 in (±0.13 mm) |

| Repeatability | ±0.003 in (±0.08 mm) |

| Typical Tolerance | ±0.005 in (±0.13 mm); tight-tolerance applications down to ±0.002 in (±0.05 mm) |

| Kerf Width | 0.030–0.050 in (0.76–1.27 mm), depending on nozzle and abrasive |

| Edge Quality | Smooth, no thermal distortion, minimal taper (adjustable via taper compensation) |

| Maximum Cutting Thickness | Up to 6 in (152 mm) for steel; up to 8 in (203 mm) for softer materials |

| Materials Supported | Aluminum, Steel (mild, stainless, tool), ABS, Nylon, composites, plastics, titanium, brass, copper |

| Aluminum Performance | Excellent edge quality; no oxidation or warping; ideal for aerospace parts |

| Steel Performance | High precision on mild and stainless; no HAZ; suitable for tooling and fixtures |

| ABS Performance | Clean, smooth cuts; no melting; excellent for prototyping and enclosures |

| Nylon Performance | Burr-free cuts; maintains material integrity; ideal for wear-resistant parts |

| Lead Time | 3–7 days depending on complexity and volume |

| CAD/CAM Integration | Compatible with DXF, DWG, STEP, IGES; full CAM programming for multi-axis paths |

This service is particularly suited for clients requiring high-accuracy fabrication of prototypes and low-volume production parts where thermal cutting methods are unsuitable. Multi-axis capability allows for beveled edges, complex contours, and angled features in a single setup, reducing secondary operations.

From CAD to Part: The Process

Honyo Prototype Water Cutting Service Process Overview

Honyo Prototype delivers precision waterjet cutting services through a streamlined digital workflow designed for engineering efficiency and rapid turnaround. Our process integrates AI-driven analysis with expert engineering validation to ensure manufacturability and cost-effectiveness from initial design to final delivery.

CAD Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, DXF, or DWG formats) via our secure customer portal. The system automatically validates file integrity, extracts critical geometry data including material type, thickness, and feature complexity, and performs preliminary nesting optimization. All uploaded designs are processed under strict NDA compliance with ISO 27001-certified data security protocols.

AI-Powered Quoting Engine

Uploaded designs enter our proprietary AI quoting system, trained on 12,000+ historical waterjet production datasets. The AI analyzes material utilization, cutting path length, machine time, and secondary operations to generate an instant preliminary quote with cost breakdown. Key parameters evaluated include material grade compatibility (metals, composites, ceramics), thickness range (0.5mm to 200mm), and tolerance requirements (±0.1mm standard). This AI output undergoes immediate human review by our applications engineering team to validate assumptions and adjust for contextual factors like material availability or geometric constraints.

Engineering DFM Analysis

Every project proceeds to mandatory Design for Manufacturability (DFM) review by Honyo’s certified manufacturing engineers. During this phase, we identify and resolve potential production issues including inadequate kerf compensation, fragile feature geometry, or suboptimal nesting layouts. Clients receive a formal DFM report within 4 business hours detailing actionable recommendations such as suggested minimum feature sizes, lead-in/lead-out optimization, or material-specific adjustments. This step typically reduces post-production rework by 65% based on client feedback metrics.

Production Execution

Approved designs move to production on our OMAX 60120 Intelli-MAX series waterjet systems operating at 60,000 PSI. All cuts utilize garnet abrasive with precision-controlled taper compensation. Real-time process monitoring tracks critical parameters including pressure consistency, nozzle wear, and dimensional accuracy through integrated CMM verification at defined intervals. Complex geometries benefit from our dynamic tilting head technology to maintain perpendicularity across varying material thicknesses. Production batches include first-article inspection reports with full traceability to raw material certifications.

Quality-Controlled Delivery

Finished parts undergo final inspection per AS9102 aerospace standards or client-specified protocols, including deburring verification and surface finish validation. Parts are packaged in anti-static, humidity-controlled containers with custom foam cradling for fragile components. Standard lead time from DFM approval to shipment is 3-5 business days for simple geometries, with expedited 24-hour options available. All shipments include digital quality documentation accessible via our client portal, with global logistics managed through DHL and FedEx with real-time tracking.

Production Timeline Expectations

| Project Complexity | DFM Completion | Standard Lead Time | Expedited Option |

|——————–|—————-|——————-|——————|

| Simple 2D Profiles | <4 hours | 3 business days | 24 hours |

| Complex 3D Contours| 8 hours | 5 business days | 48 hours |

| Multi-Layer Assemblies | 12 hours | 7 business days | 72 hours |

This integrated workflow ensures clients receive production-ready parts with minimized design iterations while maintaining rigorous quality standards for aerospace, medical, and industrial applications. Honyo’s process eliminates traditional quoting bottlenecks through validated AI-human collaboration, providing transparent cost and timeline predictability from the initial CAD submission.

Start Your Project

Looking for precision water cutting services? Contact Susan Leo at [email protected] to discuss your project requirements. With our advanced waterjet cutting technology and manufacturing expertise, we deliver clean, accurate cuts for a wide range of materials. Our production facility is located in Shenzhen, ensuring efficient turnaround and high-quality output for both prototypes and production runs. Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.