Introduction: Navigating the Global Market for wash plate removal tool

In today’s competitive landscape, sourcing effective wash plate removal tools is essential for businesses engaged in appliance repair and maintenance. One of the primary challenges faced by B2B buyers across regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Saudi Arabia—is identifying reliable tools that can efficiently tackle the complexities of appliance servicing. This guide addresses these challenges head-on, offering an in-depth exploration of various types of wash plate removal tools, their applications, and best practices for use.

The comprehensive scope of this guide includes critical insights into supplier vetting processes, cost considerations, and market trends, enabling international buyers to make informed purchasing decisions. By understanding the nuances of different tools and their functionalities, businesses can streamline their operations, reduce downtime, and enhance customer satisfaction. Furthermore, the guide provides actionable advice on assessing supplier reliability and product quality, ensuring that your investment yields maximum returns.

As the global market for appliance servicing continues to evolve, having access to the right information and resources is paramount. This guide empowers B2B buyers by equipping them with the knowledge needed to navigate the complexities of sourcing wash plate removal tools effectively, ultimately facilitating smoother operations and greater success in their respective markets.

Understanding wash plate removal tool Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Wash Plate Puller | Hand-operated tool with a lever mechanism | Small appliance repair shops | Pros: Cost-effective; Cons: Labor-intensive, requires skill. |

| Air Wedge Removal Tool | Inflatable bags that create space for removal | Appliance maintenance services | Pros: Minimal risk of damage; Cons: Requires precision use. |

| Universal Socket Tool | Adjustable socket compatible with various sizes | Appliance manufacturers | Pros: Versatile for different models; Cons: May not fit all. |

| Torque Wrench | Precision tool for applying specific torque levels | Industrial appliance repairs | Pros: Ensures proper installation; Cons: Higher investment. |

| Specialty Wash Plate Tool | Designed specifically for certain brands/models | Authorized service centers | Pros: Tailored for specific applications; Cons: Limited use. |

What are the characteristics of a Manual Wash Plate Puller?

Manual wash plate pullers are designed for straightforward, hands-on removal of wash plates. They typically feature a lever mechanism that provides leverage to dislodge stuck components. These tools are ideal for small appliance repair shops where budget constraints are a concern. However, they require a certain skill level to operate effectively, making them less suitable for inexperienced technicians.

How does an Air Wedge Removal Tool work in appliance maintenance?

Air wedge removal tools utilize inflatable bags that fit into tight spaces around the wash plate. By inflating the bags, technicians can create a gap, which allows for easier removal without damaging the appliance. This tool is particularly beneficial for appliance maintenance services that prioritize damage-free interventions. The precision required for effective use may pose a challenge for some technicians, but the benefits often outweigh the drawbacks.

Why choose a Universal Socket Tool for wash plate removal?

Universal socket tools are adjustable and can accommodate various sizes of nuts and bolts, making them a versatile choice for appliance manufacturers and repair businesses. Their adaptability allows technicians to work on different models without needing multiple tools. However, while they offer flexibility, these tools may not fit every specific application, potentially leading to inefficiencies in some cases.

What advantages does a Torque Wrench provide in the removal process?

Torque wrenches are essential for ensuring that components are removed and reinstalled with the correct torque specifications. This precision is crucial in industrial appliance repairs, where improper torque can lead to future issues. Although torque wrenches represent a higher investment, their ability to prevent costly mistakes makes them a valuable addition to any repair toolkit.

How do Specialty Wash Plate Tools enhance service efficiency?

Specialty wash plate tools are crafted for specific brands or models, allowing for highly efficient and effective removal processes. These tools are predominantly used by authorized service centers where brand loyalty and service quality are paramount. While they offer excellent performance for designated applications, their limited versatility can restrict their usefulness in broader repair contexts.

Key Industrial Applications of wash plate removal tool

| Industry/Sector | Specific Application of wash plate removal tool | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Appliance Repair Services | Used to safely remove wash plates in washing machines for maintenance | Reduces downtime, enhances service efficiency | Quality, durability, and compatibility with various washing machine brands |

| Manufacturing | Assists in the assembly and disassembly of washing machines on production lines | Streamlines production processes, reduces labor costs | Tool specifications must meet industrial standards and ergonomic design |

| Rental Equipment Providers | Facilitates quick repairs of washing machines in rental units | Minimizes equipment downtime, improves customer satisfaction | Availability of replacement parts and tool versatility for different models |

| Home Appliance Retailers | Essential for in-store demonstrations of appliance repairs | Enhances customer trust and service offerings | Tools should be easy to use and demonstrate effectiveness for customer engagement |

| Industrial Cleaning Services | Aids in maintenance of large-scale washing equipment | Ensures operational efficiency and longevity of equipment | Sourcing tools that can withstand heavy use and provide reliable performance |

How is the Wash Plate Removal Tool Used in Appliance Repair Services?

In appliance repair services, the wash plate removal tool is essential for technicians tasked with maintaining and servicing washing machines. The tool allows for the efficient removal of wash plates, which can become stuck due to residue buildup or wear. By facilitating this process, businesses can reduce downtime and enhance service efficiency, leading to higher customer satisfaction. International buyers should prioritize tools that are compatible with a wide range of washing machine brands to accommodate diverse clientele.

What Role Does the Wash Plate Removal Tool Play in Manufacturing?

In manufacturing environments, particularly in the assembly of washing machines, the wash plate removal tool is used to streamline the disassembly and assembly processes. This efficiency can significantly reduce labor costs and enhance production timelines. For manufacturers in regions like Africa and South America, sourcing tools that meet industrial standards and ergonomic design is crucial for maintaining a productive workforce and ensuring worker safety.

How Can Rental Equipment Providers Benefit from This Tool?

For rental equipment providers, the wash plate removal tool is vital for conducting quick repairs on washing machines in rental units. The ability to swiftly address maintenance issues minimizes equipment downtime, ensuring that rental services remain reliable and customer satisfaction remains high. Buyers in the Middle East and Europe should consider the versatility of the tool to accommodate various washing machine models, as this can significantly streamline their operations.

Why is This Tool Important for Home Appliance Retailers?

Home appliance retailers can utilize the wash plate removal tool for in-store demonstrations, showcasing their commitment to customer service and technical support. By effectively demonstrating how to address common appliance issues, retailers enhance customer trust and promote their service offerings. Retailers should look for tools that are user-friendly and effective, as these attributes can greatly influence customer engagement and satisfaction.

What Advantages Does the Wash Plate Removal Tool Offer to Industrial Cleaning Services?

In industrial cleaning services, the wash plate removal tool is critical for maintaining large-scale washing equipment. Regular maintenance ensures that machines operate efficiently, which is essential for service providers aiming to deliver high-quality cleaning results. When sourcing tools, companies should focus on durability and reliability to withstand heavy usage, especially in demanding environments typical in many industries across Africa and the Middle East.

3 Common User Pain Points for ‘wash plate removal tool’ & Their Solutions

Scenario 1: Difficulty in Removing Stuck Wash Plates in Heavy-Duty Appliances

The Problem: B2B buyers in the appliance repair sector often encounter challenges with removing stuck wash plates, especially in heavy-duty machines. These plates can become lodged due to wear, corrosion, or the buildup of grime. When attempting to remove them without the right tools, technicians risk damaging the appliance or injuring themselves, leading to increased repair times and costs. This situation is particularly prevalent in regions where older models are still in use, and replacement parts may not be readily available.

The Solution: To effectively address this issue, B2B buyers should invest in specialized wash plate removal tools designed for heavy-duty applications. These tools often include air wedges or prying tools that provide the necessary leverage without causing damage. For optimal results, technicians should first assess the specific model of the appliance to ensure compatibility with the tool. Additionally, utilizing penetrating oil can help loosen the wash plate before attempting removal. By stocking a range of removal tools and training technicians on their proper use, companies can significantly reduce the time spent on repairs and improve overall service efficiency.

Scenario 2: Inadequate Tool Specifications Leading to Ineffective Repairs

The Problem: Many B2B buyers face the challenge of selecting the right wash plate removal tool due to insufficient specifications or unclear product descriptions. This often results in purchasing tools that are either incompatible or ineffective for their specific appliance models, leading to frustration among technicians and potential delays in service. The lack of standardization in tool design across different brands further complicates this issue, especially for international buyers who may not have easy access to local supplier insights.

The Solution: To mitigate this pain point, buyers should prioritize sourcing tools from reputable manufacturers that provide comprehensive specifications and compatibility information. Establishing a strong relationship with suppliers who understand the nuances of various appliance models can also enhance the selection process. It is advisable to request detailed product datasheets and user guides before making a purchase. Furthermore, buyers could consider implementing a standardized tool inventory system within their operations, ensuring that technicians have access to the correct tools for each job. This proactive approach will minimize errors and streamline the repair process.

Scenario 3: Limited Training and Knowledge on Tool Usage

The Problem: A significant pain point for B2B buyers is the lack of training and knowledge regarding the proper use of wash plate removal tools among their technicians. Many technicians may not be familiar with the best practices for using these tools, leading to ineffective removal attempts and potential damage to the appliances. This lack of expertise can result in increased operational costs and diminished customer satisfaction, especially in competitive markets where service quality is paramount.

The Solution: To address this challenge, B2B buyers should invest in comprehensive training programs focused on the effective use of wash plate removal tools. This training can include hands-on workshops, instructional videos, and detailed manuals that demonstrate best practices. Collaborating with tool manufacturers to provide specialized training sessions can also ensure that technicians are well-equipped to handle various appliance models. Additionally, creating a feedback loop where technicians can share their experiences and tips can foster a culture of continuous improvement. By enhancing the skill set of their workforce, companies can improve service quality and customer satisfaction while reducing the risk of costly mistakes.

Strategic Material Selection Guide for wash plate removal tool

When selecting materials for a wash plate removal tool, it is essential to consider various factors that influence performance, durability, and overall cost. Below is an analysis of four common materials used in the manufacturing of these tools, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Steel for Wash Plate Removal Tools?

Steel is a widely used material for wash plate removal tools due to its excellent strength and durability. It typically has a high tensile strength, allowing it to withstand significant force without deforming. Steel tools can handle high temperatures and pressures, making them suitable for heavy-duty applications.

Pros: Steel tools are highly durable and can last a long time under normal operating conditions. They are also relatively cost-effective compared to other materials.

Cons: Steel is susceptible to corrosion if not properly treated, which can limit its lifespan in humid or wet environments. Additionally, manufacturing processes may involve complex machining, which can increase production costs.

Impact on Application: Steel tools perform well with various media, including water and detergents, but may not be suitable for corrosive chemicals without proper coatings.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that the steel used meets local standards for corrosion resistance, especially in coastal areas. Compliance with ASTM standards can be a selling point.

How Does Aluminum Compare as a Material for Wash Plate Removal Tools?

Aluminum is another popular choice for wash plate removal tools due to its lightweight nature and resistance to corrosion. It has a lower tensile strength than steel but compensates with a high strength-to-weight ratio, making it easier to handle.

Pros: The primary advantage of aluminum is its corrosion resistance, which extends the tool’s lifespan in humid or wet environments. It is also easier to machine, which can lower manufacturing costs.

Cons: While aluminum is lighter, it is not as strong as steel, which may limit its use in heavy-duty applications. Additionally, it can be more expensive than steel, depending on market fluctuations.

Impact on Application: Aluminum tools are suitable for use with water and mild detergents but may not withstand harsh chemicals without degrading.

Considerations for International Buyers: Buyers in Europe may prefer aluminum for its lightweight properties, especially for portable tools. Compliance with EU regulations on material safety can enhance marketability.

What Are the Benefits of Composite Materials for Wash Plate Removal Tools?

Composite materials, such as fiberglass or carbon fiber, are increasingly being used for wash plate removal tools due to their unique properties. These materials offer high strength while remaining lightweight and resistant to corrosion.

Pros: Composites are highly resistant to chemicals and environmental factors, making them ideal for various applications. They also provide excellent durability and can be designed for specific ergonomic needs.

Cons: The primary drawback is the higher manufacturing cost associated with composite materials. Additionally, they may require specialized manufacturing processes, which can complicate production.

Impact on Application: Composite tools can be used with a wide range of media, including aggressive chemicals, without risk of degradation.

Considerations for International Buyers: Buyers from South America and Africa may find composites appealing due to their durability in diverse climates. Understanding local standards for composites, such as JIS in Japan, can be crucial for compliance.

How Does Plastic Fit into the Material Selection for Wash Plate Removal Tools?

Plastic materials, such as high-density polyethylene (HDPE) or polypropylene, are often used for wash plate removal tools due to their lightweight and corrosion-resistant properties.

Pros: Plastic tools are generally less expensive to produce and can be molded into complex shapes, which can enhance functionality. They are also resistant to many chemicals, making them versatile.

Cons: The main limitation of plastic is its lower strength compared to metals, which can lead to breakage under excessive force. They may also have lower temperature resistance.

Impact on Application: Plastic tools are suitable for use with water and mild detergents but may not be appropriate for high-stress applications or extreme temperatures.

Considerations for International Buyers: Buyers in regions like Saudi Arabia should consider the local climate’s effect on plastic durability. Compliance with international standards for plastic materials can also boost product acceptance.

Summary Table of Material Selection for Wash Plate Removal Tools

| Material | Typical Use Case for wash plate removal tool | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications | High durability and strength | Susceptible to corrosion | Medium |

| Aluminum | Lightweight, portable tools | Corrosion resistance | Lower strength than steel | Medium |

| Composite | Chemical-resistant applications | High strength-to-weight ratio | Higher manufacturing costs | High |

| Plastic | General-purpose, low-stress applications | Lightweight and cost-effective | Lower strength and temperature limits | Low |

This analysis provides a comprehensive overview of material options for wash plate removal tools, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for wash plate removal tool

What Are the Main Stages of Manufacturing a Wash Plate Removal Tool?

The manufacturing process for a wash plate removal tool involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a pivotal role in ensuring the final product is durable, efficient, and meets the specific needs of B2B buyers.

How Is Material Prepared for the Wash Plate Removal Tool?

Material preparation begins with the selection of high-quality raw materials, typically steel or aluminum, known for their strength and resistance to wear and corrosion. The selected materials undergo a series of processes, including cutting and shaping, to prepare them for forming. This stage often involves the use of Computer Numerical Control (CNC) machines, which enhance precision and reduce human error, ensuring that the components are cut to the exact specifications required for optimal functionality.

What Forming Techniques Are Commonly Used?

In the forming stage, techniques such as stamping, forging, or machining are utilized to create the tool’s body and functional components. Stamping involves pressing the material into a die, producing consistent shapes rapidly. Forging, on the other hand, entails shaping the metal through compressive forces, resulting in a stronger and more resilient product. Machining may also be employed for fine-tuning, where precision drilling and milling create intricate features necessary for the tool’s operation.

How Are Components Assembled?

The assembly stage combines all the manufactured parts into the final product. This may include attaching handles, securing locking mechanisms, or integrating pneumatic components for air wedges. Assembly is usually performed in a clean environment to minimize contamination and ensure that the tool functions correctly. Automated assembly lines may be used for larger production runs, while manual assembly is more common for custom or smaller batches.

What Finishing Processes Are Implemented?

Finishing processes enhance the tool’s appearance and durability. Techniques such as anodizing, powder coating, or plating are applied to protect against rust and wear. These processes not only improve the aesthetic appeal of the tool but also increase its lifespan, making it a more valuable investment for B2B buyers.

How Is Quality Assurance Implemented in the Manufacturing of Wash Plate Removal Tools?

Quality assurance (QA) is crucial in the manufacturing of wash plate removal tools, ensuring that each tool meets industry standards and customer expectations. This process involves adherence to international standards such as ISO 9001, which outlines a framework for quality management systems.

What Are the Relevant International Standards for Quality Control?

ISO 9001 certification signifies that a manufacturer has implemented a robust quality management system, focusing on continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) or API (American Petroleum Institute) can enhance credibility and assure buyers of compliance with health, safety, and environmental regulations.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint examines the raw materials for defects or deviations from specifications before they are used in production.

-

In-Process Quality Control (IPQC): This involves monitoring the manufacturing process itself, ensuring that each stage adheres to quality standards and that any deviations are corrected in real-time.

-

Final Quality Control (FQC): The final inspection occurs before the product is packaged and shipped. This step includes functional testing and visual inspections to confirm that the tools meet all specifications and performance criteria.

What Common Testing Methods Are Used for Wash Plate Removal Tools?

Testing methods play a critical role in validating the quality and performance of wash plate removal tools. Common methods include:

-

Functional Testing: Ensures that the tool operates as intended under various conditions.

-

Durability Testing: Assesses the tool’s performance over extended use, simulating real-world conditions to identify potential failure points.

-

Safety Testing: Evaluates the tool for any safety hazards, ensuring compliance with safety regulations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are several methods to ensure that the tools meet their expectations:

-

Supplier Audits: Conducting audits can provide insights into a supplier’s manufacturing processes, quality control practices, and adherence to international standards. This can be done in person or through third-party services.

-

Quality Reports: Requesting detailed quality reports from suppliers can help assess their quality management systems and the results of their testing procedures.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the product quality before shipment. These inspections can identify defects or deviations from specifications.

What Are the QC and Certification Nuances for International Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is essential, especially when sourcing from manufacturers in diverse regions such as Africa, South America, the Middle East, and Europe. Some key considerations include:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should familiarize themselves with local standards to ensure compliance.

-

Cultural Considerations: Understanding cultural differences in business practices can aid in building strong supplier relationships, which is critical for ensuring consistent quality.

-

Language Barriers: Effective communication is vital. Buyers should ensure that all specifications and quality expectations are clearly documented and understood by all parties involved.

By considering these factors, international buyers can make informed decisions, ensuring they procure high-quality wash plate removal tools that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wash plate removal tool’

Introduction

In the realm of appliance maintenance and repair, sourcing the right tools is critical for operational efficiency. This guide offers a practical checklist for B2B buyers looking to procure a wash plate removal tool. Whether you are in Africa, South America, the Middle East, or Europe, following these steps will help ensure that you select the most suitable tool for your needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of any procurement process. Identify the types of washers your business services and the specific models that require wash plate removal. This will help narrow down the tool’s design, size, and compatibility, ensuring that it meets your operational requirements.

- Consider the brands: Different brands may have unique designs that require specific tools.

- Assess the frequency of use: Determine if you need a heavy-duty tool for frequent use or a simpler option for occasional repairs.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers who specialize in wash plate removal tools. Look for manufacturers or distributors with a strong presence in your target markets.

- Check online directories: Websites like Alibaba or ThomasNet can provide a list of manufacturers.

- Attend industry trade shows: These events are excellent for networking and discovering new suppliers.

Step 3: Evaluate Supplier Certifications

Before proceeding with a purchase, it’s crucial to verify the certifications of potential suppliers. Certifications ensure that the tools meet international standards for safety and performance.

- ISO certifications: Look for suppliers with ISO 9001 certification, which indicates a commitment to quality management.

- Local regulations: Ensure compliance with any regional standards that may apply in your market.

Step 4: Request Samples

Before finalizing your order, request samples of the wash plate removal tools. Testing the tools firsthand can provide insights into their usability and durability.

- Assess material quality: Ensure the tool is made from high-grade materials that will withstand repeated use.

- Evaluate ergonomics: A well-designed tool can significantly enhance efficiency and comfort during use.

Step 5: Compare Pricing and Terms

Collect quotes from multiple suppliers and compare their pricing structures. Be sure to consider not only the cost of the tools but also shipping, customs duties, and potential bulk discounts.

- Inquire about warranties: A good warranty can protect your investment in case of defects or issues.

- Check payment terms: Ensure that the payment options align with your financial processes.

Step 6: Read Reviews and Testimonials

Investigate the experiences of other buyers by reading reviews and testimonials. This can provide invaluable insights into the supplier’s reliability and the quality of their products.

- Industry forums and groups: Engage with communities on platforms like LinkedIn to gather feedback.

- Request case studies: Ask suppliers for examples of how their tools have benefitted similar businesses.

Step 7: Finalize Your Purchase

After completing all previous steps and feeling confident in your choice, proceed to finalize your purchase. Ensure that all agreements are documented and clarify delivery timelines and post-purchase support.

- Establish a communication channel: Maintain open lines of communication with the supplier for any future needs or support.

- Plan for inventory management: Consider how you will store and manage the tools upon arrival to ensure they remain in optimal condition.

By following this checklist, B2B buyers can streamline the sourcing process for wash plate removal tools, ensuring they select high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for wash plate removal tool Sourcing

What Are the Key Cost Components in Sourcing a Wash Plate Removal Tool?

When sourcing a wash plate removal tool, understanding the cost structure is crucial for effective budgeting and financial planning. The primary components of cost include:

-

Materials: The choice of materials significantly impacts the price. High-quality steel or composite materials provide durability but may raise costs. Sourcing local materials can reduce shipping costs, especially for international buyers.

-

Labor: Labor costs vary by region. In developing markets such as Africa and South America, labor might be less expensive, which can influence overall pricing. However, skilled labor may come at a premium, especially for tools requiring precise manufacturing.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, rent, and equipment maintenance. Manufacturers in regions with lower overhead costs can offer more competitive pricing.

-

Tooling: Specialized tooling for producing wash plate removal tools can be a significant upfront investment. Buyers should inquire about tooling costs as they can impact the final price, especially for custom orders.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and performance. While this adds to the cost, it is essential for maintaining brand reputation and avoiding costly returns.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and the buyer’s destination. Buyers should consider Incoterms that define responsibilities for shipping costs and risks.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding the typical margins within the industry can aid in negotiations.

How Do Price Influencers Affect the Cost of Wash Plate Removal Tools?

Several factors influence the pricing of wash plate removal tools, which can significantly affect a buyer’s purchasing decision:

-

Volume/MOQ: Bulk purchases typically lead to lower per-unit costs. Buyers should assess their needs and consider ordering in larger quantities to benefit from economies of scale.

-

Specifications and Customization: Custom designs or additional features can increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials and Quality Certifications: Tools made from higher-grade materials or those with quality certifications (e.g., ISO standards) will generally command higher prices. Buyers should weigh the benefits of quality against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a history of quality and service may charge more, but they often provide better assurance of product performance.

-

Incoterms: Understanding shipping terms is vital for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly alter the total cost of ownership.

What Are Effective Buyer Tips for Negotiating Wash Plate Removal Tool Prices?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings:

-

Leverage Total Cost of Ownership (TCO): Consider all costs associated with the tool, including maintenance, shipping, and potential downtime. A higher upfront cost may be justified if the tool offers better longevity or performance.

-

Negotiate Based on Market Conditions: Understanding local market conditions and supplier capabilities can provide leverage in negotiations. Keep abreast of industry trends to make informed decisions.

-

Request Multiple Quotes: Don’t settle for the first offer. Collecting quotes from multiple suppliers can reveal competitive pricing and provide negotiating power.

-

Establish Long-Term Relationships: Building a rapport with suppliers can lead to better pricing and preferential treatment in future transactions. Consider discussing potential future orders to negotiate a better deal.

-

Be Mindful of Currency Fluctuations: For international transactions, currency exchange rates can impact overall costs. Consider locking in prices or negotiating in a stable currency to mitigate risks.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and subject to change based on market conditions, material availability, and supplier pricing strategies. Buyers should conduct thorough research and obtain updated quotes before making purchasing decisions.

Alternatives Analysis: Comparing wash plate removal tool With Other Solutions

When it comes to removing wash plates from washing machines, various solutions exist beyond the dedicated wash plate removal tool. Each option has its own strengths and weaknesses, which can significantly impact efficiency and cost-effectiveness for B2B buyers. This analysis will compare the wash plate removal tool with two alternative methods: the use of air wedges and DIY methods involving screwdrivers and prying techniques.

| Comparison Aspect | Wash Plate Removal Tool | Air Wedges | DIY Methods (Screwdrivers) |

|---|---|---|---|

| Performance | High efficiency, minimizes damage | Moderate efficiency, may require multiple attempts | Variable efficiency, risk of damage |

| Cost | Moderate investment | Low cost, typically under $30 | Minimal cost, tools often already owned |

| Ease of Implementation | User-friendly, designed specifically for the task | Requires some skill to position correctly | Requires basic DIY skills and knowledge |

| Maintenance | Low, as it’s a one-time tool | Low, but may need replacement if damaged | None, as no special tools are used |

| Best Use Case | Frequent maintenance needs or professional settings | Casual or infrequent use, ideal for small workshops | One-time repairs or casual users |

How Do Air Wedges Compare to the Wash Plate Removal Tool?

Air wedges are inflatable bags that can create a gap between the wash plate and the agitator. They are particularly useful in situations where space is tight, allowing for adjustments without much disassembly. The advantages of air wedges include their low cost and versatility, as they can also be used for other appliance adjustments. However, they require a certain level of skill to position properly, and achieving the desired lift may take multiple attempts. Additionally, there is a risk of damaging the wash plate if not used carefully.

What Are the Pros and Cons of DIY Methods for Wash Plate Removal?

DIY methods often involve using common household tools like screwdrivers to pry up the wash plate. This approach can be highly cost-effective since it utilizes tools that many users already have. However, the efficiency of this method can vary widely based on the user’s skill level and the specific model of the washing machine. There is also a significant risk of damaging the wash plate or the surrounding components, which can lead to additional repair costs. This method is best suited for one-time repairs or for users who are comfortable with basic mechanical tasks.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right tool or method for wash plate removal hinges on several factors, including frequency of use, budget constraints, and the skill level of the personnel involved. For businesses that perform regular maintenance or repairs on washing machines, investing in a dedicated wash plate removal tool can save time and reduce the risk of damage. Conversely, air wedges may be suitable for smaller operations or infrequent tasks, while DIY methods can serve budget-conscious buyers who are comfortable with hands-on repairs. By assessing these aspects, B2B buyers can make informed decisions that align with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for wash plate removal tool

What Are the Key Technical Properties of a Wash Plate Removal Tool?

When sourcing a wash plate removal tool, several technical specifications are crucial for ensuring efficiency and durability in various applications. Below are some essential properties to consider:

1. Material Grade

The material grade of a wash plate removal tool typically refers to the type of metal or alloy used in its construction, such as stainless steel or high-carbon steel. High-grade materials provide better strength, corrosion resistance, and longevity. This is particularly important in industrial settings where tools are subjected to wear and tear, as a durable tool minimizes replacement costs and downtime.

2. Tolerance Levels

Tolerance levels indicate the permissible limits of variation in the tool’s dimensions. For a wash plate removal tool, precise tolerances are essential to ensure a snug fit and effective operation. Inaccurate tolerances can lead to inefficient tool performance, potential damage to components, and increased maintenance costs. B2B buyers should prioritize tools with tight tolerances to ensure compatibility with various washer models.

3. Ergonomic Design

An ergonomic design enhances user comfort and reduces fatigue during extended use. Features such as cushioned grips and optimized handle shapes allow for better control and leverage, which is particularly beneficial when removing stubborn wash plates. Investing in ergonomically designed tools can improve productivity and worker satisfaction, leading to lower injury rates.

4. Weight and Portability

The weight of the removal tool can significantly affect its ease of use, especially in tight spaces. A lightweight tool can enhance maneuverability and reduce the physical strain on technicians. For B2B buyers, selecting portable tools can facilitate easier transportation and storage, making them ideal for service professionals who work in various locations.

5. Finish and Coating

The finish and coating of the tool can impact its performance and durability. Tools with a corrosion-resistant coating can withstand exposure to moisture and chemicals, which is crucial in environments where they may encounter water or cleaning agents. A high-quality finish also contributes to the tool’s aesthetic appeal, which can be a consideration for companies focused on brand image.

What Trade Terminology Should B2B Buyers Understand for Wash Plate Removal Tools?

Understanding industry-specific terminology is vital for effective communication and negotiation in B2B transactions. Here are some common terms relevant to the purchase of wash plate removal tools:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or tools that are used in the manufacturing of a final product. When sourcing a wash plate removal tool, knowing whether a tool is OEM can ensure compatibility with specific washer brands and models, thereby reducing the risk of operational issues.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory levels and cash flow. Suppliers often set MOQs based on production costs, and being aware of these can help businesses negotiate better purchasing terms.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products. This process is crucial for B2B buyers looking to compare prices and terms from different suppliers. A well-structured RFQ can lead to better deals and informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers to clarify shipping responsibilities, risk management, and costs associated with the delivery of wash plate removal tools.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. It is a critical factor for B2B buyers to consider, as longer lead times can impact project timelines and operational efficiency. Knowing a supplier’s lead times can help businesses plan their inventory and maintenance schedules more effectively.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing wash plate removal tools, ensuring they select the right products for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the wash plate removal tool Sector

What Are the Current Market Dynamics and Key Trends Influencing the Wash Plate Removal Tool Sector?

The wash plate removal tool sector is experiencing notable growth driven by several global factors. Increasing demand for home appliances, particularly washing machines, is prompting the need for efficient maintenance tools. Emerging markets in Africa, South America, the Middle East, and Europe are witnessing a surge in appliance ownership, thereby amplifying the demand for tools that facilitate repairs and maintenance. This trend is compounded by a growing consumer preference for DIY solutions, leading to a rise in sales of specialized tools like wash plate removal devices.

Technologically, the sector is embracing innovations such as ergonomic designs and multifunctional tools that enhance usability and efficiency. For B2B buyers, particularly in regions like Nigeria and Saudi Arabia, sourcing trends are shifting towards suppliers that offer both quality and affordability. The rise of e-commerce platforms has also changed the landscape, allowing buyers to access a wider range of products and suppliers without geographical limitations. Furthermore, the integration of digital technologies in inventory management and supply chain logistics is streamlining procurement processes, making it easier for international buyers to source the right tools quickly and cost-effectively.

How Is Sustainability and Ethical Sourcing Impacting the Wash Plate Removal Tool Market?

Sustainability is becoming an increasingly critical consideration in the wash plate removal tool sector. As global awareness of environmental issues rises, B2B buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices. The environmental impact of manufacturing processes, including waste management and energy consumption, is under scrutiny. Buyers are encouraged to seek out tools made from recyclable materials or those that have been certified as environmentally friendly.

Ethical sourcing is equally important, particularly for international buyers concerned about labor practices in the supply chain. Ensuring that suppliers adhere to fair labor standards and responsible sourcing can enhance a company’s reputation and appeal to eco-conscious consumers. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability. By incorporating these considerations into their procurement processes, B2B buyers not only contribute to a healthier planet but also align their businesses with the growing trend of corporate social responsibility.

What Is the Brief History of Wash Plate Removal Tools and Their Evolution?

The evolution of wash plate removal tools can be traced back to the increasing complexity of home appliances. Initially, basic tools were utilized for simple maintenance tasks; however, as washing machines evolved, so did the need for specialized tools. Early wash plate removal tools were rudimentary, often requiring brute force and risking damage to the appliance. Over the years, innovations have led to the development of more sophisticated tools designed specifically for ease of use and efficiency.

Today’s wash plate removal tools often feature ergonomic designs, allowing technicians and DIY enthusiasts alike to execute repairs without damaging components. The integration of materials that enhance durability and functionality has also transformed the market. As the sector continues to grow, the focus will likely remain on developing tools that simplify maintenance tasks while promoting sustainability and ethical sourcing practices.

Frequently Asked Questions (FAQs) for B2B Buyers of wash plate removal tool

-

How do I effectively remove a stuck wash plate?

To remove a stuck wash plate, utilize a combination of prying techniques and lubricants. Insert a flathead screwdriver into the designated holes on the plate and gently pry upwards. Applying a penetrating oil can help loosen any rust or debris. If necessary, using air wedges can provide additional leverage without damaging the plate. Always ensure that you’re prepared to replace the wash plate if it gets damaged during removal. -

What is the best tool for removing a wash plate?

The ideal tool for removing a wash plate is a specialized wash plate removal tool designed to fit various models. These tools provide the leverage needed without risking damage to the appliance. Alternatively, a set of sturdy screwdrivers and air wedges can be effective for DIY solutions. When sourcing tools, ensure they are compatible with the specific make and model of the washer for optimal results. -

What are the key factors to consider when sourcing wash plate removal tools internationally?

When sourcing wash plate removal tools from international suppliers, consider factors such as product quality, compliance with local standards, and supplier reliability. It’s essential to review certifications and past customer feedback. Additionally, assess the supplier’s shipping capabilities, lead times, and their ability to handle customs clearance in your region to ensure a smooth procurement process. -

What are the minimum order quantities (MOQs) for wash plate removal tools?

Minimum order quantities (MOQs) for wash plate removal tools can vary widely among suppliers. Typically, MOQs range from 50 to 500 units, depending on the manufacturer and the tool’s complexity. It’s advisable to discuss your needs with potential suppliers, as some may offer flexibility for first-time orders or smaller businesses. Always clarify the MOQ before finalizing any agreements. -

What payment terms should I negotiate when purchasing wash plate removal tools?

When negotiating payment terms, consider options such as net 30, net 60, or even letter of credit for larger orders. Ensure that the terms align with your cash flow and inventory management needs. Additionally, inquire about any discounts for early payment or bulk purchases. Establishing clear payment terms helps avoid misunderstandings and builds a stronger relationship with the supplier. -

How can I ensure quality assurance for wash plate removal tools?

To ensure quality assurance, request certifications and compliance documentation from suppliers. Consider conducting factory audits or quality checks before shipment, especially for large orders. It may also be beneficial to ask for samples to evaluate the tool’s performance and durability. Establishing a clear quality control process can mitigate risks and ensure that the tools meet your standards. -

What logistics considerations should I keep in mind when importing tools?

When importing wash plate removal tools, logistics considerations include shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with your country’s import laws to streamline the process. Additionally, factor in shipping costs and potential delays, especially during peak seasons. Ensure that all necessary documentation, such as invoices and certificates of origin, is prepared to avoid customs complications. -

How do I vet suppliers for wash plate removal tools?

To vet suppliers, start by researching their reputation through reviews and ratings on trade platforms. Look for suppliers with a proven track record in manufacturing quality tools. Request references from previous clients and assess their responsiveness during the inquiry process. If possible, visit the supplier’s facility or engage in video calls to evaluate their operations. Establishing trust through thorough vetting can lead to successful long-term partnerships.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Wash Plate Removal Tool Manufacturers & Suppliers List

1. Whirlpool – WTW8127LC1 Washer Replacement Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Whirlpool Washer model WTW8127LC1; requires removal of the wash plate for replacement; involves a bolt in the center; agitator base is removable; suggested tools include ratchet straps, an alan wrench, and a hammer drill with a 7/16″ socket.

2. Whirlpool – WTW8127LW0 Top Load Washer

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: Whirlpool Washer Model: WTW8127LW0; Type: Top Load; Age: Less than 1 year; Features: 2 in 1 removal agitator; Issue: Coins stuck underneath wash plate; Removal Instructions: Squeeze handle on top portion of agitator, rotate counter-clockwise, pull up, pry up vanity cap with small flat head screwdriver to access agitator bolt; Warranty: Still under warranty, opening may void warranty.

3. Facebook – Pry Bar Technique

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Pry Bar Technique, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

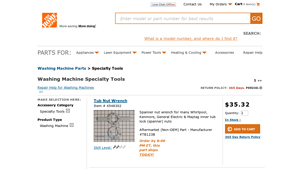

4. Tub Nut Wrench – Aftermarket Spanner Tool

Domain: appliancerepair.homedepot.com

Registered: 1992 (33 years)

Introduction: [{‘name’: ‘Tub Nut Wrench’, ‘item_number’: ‘4548302’, ‘description’: ‘Spanner nut wrench for many Whirlpool, Kenmore, General Electric & Maytag inner tub lock (spanner) nuts’, ‘type’: ‘Aftermarket (Non-OEM)’, ‘manufacturer_part_number’: ‘TB123B’, ‘price’: ‘$35.32’, ‘availability’: ‘In Stock’}, {‘name’: ‘Spring Removal Tool’, ‘item_number’: ‘4993766’, ‘description’: ‘Removal tool for outer boot sea…

5. H and B – Plastic Bucket 5 Gallon

Domain: myhandb.bb

Introduction: H and B Plastic Bucket 5 gallon – BBD 16.99

Window Sash UIPVC IMP 36in x 50in – BBD 359.98

Paraquat Herbicide 24% 1lt – BBD 21.49

Makita Cut-Off Chop Saw 14 in (LW1401) – BBD 549.99

Craftsman Mower With Bag 21in 150cc (4.25HP) (7026052) – BBD 1,491.99

Wheelbarrow Solid Wheel Steel Handle Red 6cu – BBD 169.99

S-Trap Toilet with Push Button (AC2108) – BBD 299.99

Knotty Pine Door 6-Panel 36in x 80in …

6. Ocean State Job Lot – Diverse Product Range

Domain: oceanstatejoblot.com

Registered: 1998 (27 years)

Introduction: Ocean State Job Lot offers a wide range of products across various categories including:

– Lawn & Garden: Seed starters, outdoor furniture, garden tools, watering supplies, and outdoor decor.

– Outdoor Recreation: Bicycles, camping gear, water sports equipment, and outdoor toys.

– Kitchen & Dining: Cookware, small kitchen appliances, dinnerware, and kitchen storage.

– Grocery: Snacks, organic food…

7. Repco – Aftermarket Car Parts

Domain: repco.co.nz

Introduction: Repco New Zealand offers a wide range of aftermarket car parts and accessories including: Braking components (brake pads, rotors, calipers), Climate Control parts (compressors, condensers), Driveline parts (drive shafts, clutches), Electrical parts (alternators, ignition modules), Engine parts (gaskets, oil pumps), Filtration products (air filters, oil filters), Fuel system components (fuel pumps,…

Strategic Sourcing Conclusion and Outlook for wash plate removal tool

In conclusion, the strategic sourcing of wash plate removal tools is essential for optimizing maintenance operations in the appliance repair industry. As the demand for efficient and effective appliance repair services continues to grow, sourcing high-quality tools can significantly enhance service delivery and customer satisfaction. B2B buyers should focus on partnerships with reliable suppliers that offer innovative solutions, such as air wedges and specialized removal kits, which not only expedite the repair process but also minimize the risk of damage to appliances.

Furthermore, understanding the regional nuances of the markets in Africa, South America, the Middle East, and Europe can provide a competitive edge. By leveraging local knowledge and aligning with suppliers who understand the specific needs of these markets, businesses can enhance their operational efficiency and service quality.

As we look to the future, it is crucial for international B2B buyers to prioritize strategic sourcing to stay ahead in a competitive landscape. Investing in the right tools and partnerships will ensure that your business remains agile and responsive to evolving customer needs. Explore your options today to secure a reliable supply chain that supports your growth objectives in the appliance repair sector.