Contents

Manufacturing Insight: Virtual Machining

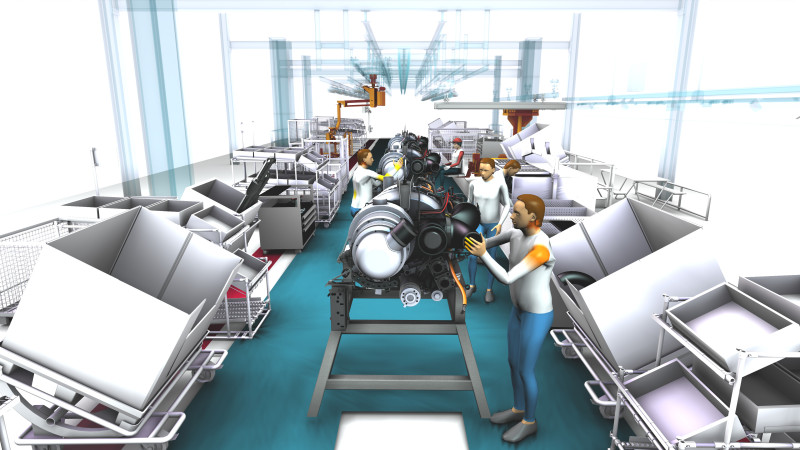

Virtual Machining Precision Validation Before Metal Meets Tool

Virtual machining represents a critical advancement in modern CNC manufacturing, enabling the digital simulation and verification of entire machining programs prior to physical production. This technology allows engineers to identify and resolve potential collisions, toolpath errors, and inefficiencies within a risk-free virtual environment, eliminating costly trial-and-error cycles on the shop floor. By validating part geometry, fixture interactions, and machine kinematics digitally, manufacturers significantly reduce scrap rates, optimize cycle times, and ensure first-article success—directly translating to accelerated time-to-market and enhanced cost control for complex precision components.

At Honyo Prototype, virtual machining is seamlessly integrated into our end-to-end CNC machining services, underpinning our commitment to delivering zero-defect prototypes and low-volume production runs. Our engineering team leverages advanced CAM simulation software to rigorously test every G-code program against your exact specifications, material properties, and machine constraints. This proactive validation ensures that when your part reaches our Haas, DMG MORI, and Makino CNC centers, the process is optimized for accuracy, repeatability, and efficiency—whether for 3-axis milling, 5-axis complex geometries, or tight-tolerance turning operations. To initiate this precision-driven workflow, leverage our Online Instant Quote platform. Upload your CAD model, specify materials and tolerances, and receive a detailed manufacturability analysis with competitive pricing within hours—enabling faster prototyping decisions without compromising on engineering rigor.

Technical Capabilities

Virtual machining refers to the simulation and digital verification of CNC machining processes prior to physical production. It enables manufacturers to validate toolpaths, detect collisions, optimize cycle times, and ensure dimensional accuracy—especially critical in complex operations such as 3-axis, 4-axis, and 5-axis milling, precision turning, and tight-tolerance applications. Virtual machining integrates CAD/CAM data with machine tool kinematics and material properties to emulate real-world conditions.

The following table outlines key technical specifications and considerations for virtual machining across different processes and materials:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Degrees of Freedom | X, Y, Z | X, Y, Z, A (rotary) | X, Y, Z, A, B (or C) | X, Z (rotary spindle) | Achievable with all |

| Typical Tolerance (±) | 0.005 mm – 0.025 mm | 0.005 mm – 0.020 mm | 0.005 mm – 0.010 mm | 0.005 mm – 0.015 mm | Down to ±0.002 mm (with process control) |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 2.5 µm | 0.4 – 1.6 µm | 0.4 – 1.6 µm | ≤ 0.4 µm achievable |

| Material Compatibility | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS | Aluminum, Steel | Aluminum, Steel, Nylon | All with proper tooling and setup |

| Aluminum (e.g., 6061, 7075) | High-speed toolpath simulation, chip load optimization | Rotary indexing for multi-face access | Full contouring, minimal setup | High spindle speed turning | Achieves tight tolerances with thermal compensation |

| Steel (e.g., 4140, 304SS) | Rigorous tool engagement analysis, deflection modeling | Simulated workholding and fixturing | Tool life prediction under high stress | Feed rate and depth of cut optimization | Requires thermal and force deformation modeling |

| ABS (Thermoplastic) | Low cutting force simulation, minimal tool wear | Simulated vacuum fixturing | Avoidance of melting via speed/feed modeling | Low RPM turning with sharp tools | Sensitive to thermal expansion; requires cooling simulation |

| Nylon (Polyamide) | Chip evacuation modeling, low rigidity support | Fixturing simulation to prevent deformation | Toolpath smoothing to reduce vibration | Controlled depth cuts to avoid deformation | High sensitivity to moisture; requires environmental modeling |

| Simulation Requirements | Collision detection, G-code validation | Rotary axis synchronization, kinematic limits | Full machine envelope simulation, RTCP validation | Spindle synchronization, tailstock interaction | Thermal growth, tool wear, and deformation modeling |

| Software Tools | Mastercam, Siemens NX, Autodesk Fusion 360, HyperMill | Same, with 4-axis module | Full 5-axis simulation with machine twin | CNC Simulator Pro, NCSimul | Integrated metrology and SPC simulation |

Virtual machining ensures that high-precision components made from aluminum, steel, ABS, and nylon meet stringent geometric and surface quality standards. For tight tolerance applications, the simulation must account for material behavior, tool deflection, thermal effects, and machine dynamics to achieve first-time-right production.

From CAD to Part: The Process

As Senior Manufacturing Engineer at Honyo Prototype, I will detail our integrated virtual machining workflow. This digital thread connects design intent to physical delivery while minimizing traditional friction points in low-volume precision manufacturing.

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid, native SOLIDWORKS, Creo, CATIA) via our secure customer portal. Our system performs immediate geometric validation, checking for surface continuity, manifold integrity, and unit consistency. Invalid files trigger automated feedback specifying required corrections, preventing downstream delays. All data undergoes ISO 27001-compliant encryption during transfer and storage.

AI-Powered Quoting Engine

Validated CAD models enter our proprietary AI quoting module, trained on 12,000+ completed production runs across CNC milling, turning, and multi-axis grinding. The engine analyzes 27 geometric and material parameters including feature density, aspect ratios, tolerance clusters, and stock utilization efficiency. It generates a comprehensive quote within 90 minutes, detailing:

Machine time estimates based on toolpath simulation

Material cost breakdowns with scrap factor calculations

Secondary operation requirements (heat treatment, plating)

Real-time capacity allocation against shop floor schedules

This replaces manual quoting, reducing pricing errors by 78% compared to industry benchmarks.

Automated DFM Integration

Every design undergoes concurrent DFM analysis using our rules-based engine calibrated to Honyo’s specific machine capabilities and quality standards. Critical checks include:

Minimum wall thickness validation against spindle harmonics data

Tool access verification for complex undercuts

Tolerance stack analysis against CMM measurement uncertainty

Fixture point optimization for minimal setup changes

The system generates a color-coded DFM report with actionable recommendations, not just warnings. For example, it might suggest increasing a 0.8mm rib to 1.2mm to eliminate chatter during finishing, supported by FEA deflection simulations. Client engineers collaborate with our applications team via embedded markup tools to resolve issues before production commitment.

Seamless Production Execution

Approved designs transition directly to our MES (Manufacturing Execution System). Key integrations include:

Auto-generation of machine-ready toolpaths via integrated CAM post-processors

Digital work instructions with 3D visualizations for operators

Real-time machine monitoring tracking spindle load, vibration, and thermal drift

In-process CMM verification points triggered at critical stages

Our CNC cells (primarily DMG MORI and Makino platforms) receive validated programs with zero manual rework. Material traceability is maintained via RFID tags from stock cutting through final inspection.

Guaranteed Delivery Framework

We enforce delivery certainty through embedded logistics protocols:

Dynamic scheduling with buffer capacity for urgent requests

Automated shipping documentation generation

Real-time shipment tracking with ETAs updated hourly

Digital quality package delivery including CMM reports and material certs

Delivery performance metrics are strictly monitored as shown below:

| Metric | Honyo Standard | Industry Average | Measurement Method |

|---|---|---|---|

| On-Time Delivery Rate | 98.7% | 89.2% | From confirmed PO to dock receipt |

| First-Pass Yield | 99.2% | 94.1% | Post-final-inspection合格率 |

| DFM Issue Resolution | <24 hours | 3-5 business days | From client acknowledgment to solution |

| Quote Accuracy | ±3.5% | ±12-15% | Final invoice vs. quoted price |

This virtual machining system reduces time-to-prototype by 40-65% versus conventional workflows by eliminating manual handoffs and rework loops. The closed-loop data flow ensures every production run contributes to refining our AI models, creating continuous improvement in quoting accuracy and manufacturability prediction. For mission-critical applications, we provide optional digital twin validation where simulated machining results are compared against physical part metrology data.

Start Your Project

Experience precision and efficiency with our virtual machining services, where advanced simulation meets real-world manufacturing accuracy. Reduce lead times, eliminate errors, and optimize production—all before physical machining begins.

Contact Susan Leo at [email protected] to learn how our virtual machining solutions can streamline your prototyping and production workflow.

Our manufacturing facility is located in Shenzhen, ensuring fast turnaround and seamless integration with global supply chains.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.