Introduction: Navigating the Global Market for vertical cnc wood router

In an increasingly competitive global marketplace, sourcing the right vertical CNC wood router can pose significant challenges for international B2B buyers. With diverse applications ranging from furniture production to intricate woodwork, the stakes are high for businesses in regions such as Africa, South America, the Middle East, and Europe, including Saudi Arabia and Brazil. Selecting the appropriate CNC machine not only affects operational efficiency but also impacts product quality, cost-effectiveness, and ultimately, customer satisfaction.

This comprehensive guide serves as an essential resource for understanding the nuances of vertical CNC wood routers. It covers a wide range of topics, including various types of machines, their applications across industries, and critical considerations for supplier vetting. Additionally, it delves into cost factors, maintenance requirements, and the latest technological advancements, providing buyers with a holistic view of the market landscape.

By equipping decision-makers with actionable insights and best practices, this guide empowers B2B buyers to make informed purchasing decisions that align with their operational goals. Whether you’re a startup looking to invest in your first machine or an established manufacturer seeking to upgrade your capabilities, navigating the complexities of the vertical CNC wood router market has never been more straightforward. Embrace the opportunity to enhance your production processes and elevate your business’s competitive edge.

Understanding vertical cnc wood router Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Vertical CNC Router | Basic functionality, suitable for standard cutting and engraving | Furniture manufacturing, cabinetry, signage | Pros: Cost-effective, easy to use. Cons: Limited advanced features. |

| High-Speed Vertical CNC Router | Enhanced speed and precision, often equipped with advanced software | High-volume production, intricate designs | Pros: Increased productivity, excellent precision. Cons: Higher upfront cost. |

| Multi-Head Vertical CNC Router | Multiple spindles for simultaneous operations, versatile | Complex pattern making, 3D sculpting | Pros: Versatile applications, efficient for large projects. Cons: More complex setup and maintenance. |

| Vertical Machining Center | Integrated drilling and milling capabilities, compact design | Custom furniture, cabinetry, and detailed work | Pros: Space-efficient, high versatility. Cons: May require skilled operators. |

| Entry-Level Vertical CNC Router | Affordable, user-friendly, ideal for small businesses | Small-scale furniture making, prototypes | Pros: Low cost, accessible for beginners. Cons: Limited capabilities for larger projects. |

What Are the Characteristics of Standard Vertical CNC Routers?

Standard vertical CNC routers are designed for fundamental wood processing tasks such as cutting, engraving, and drilling. These machines are typically more affordable, making them an attractive option for small to medium-sized enterprises. Their straightforward operation is ideal for businesses that require reliable performance without the need for extensive features. However, buyers should consider that while they are cost-effective, they may lack the advanced functionalities needed for more complex projects.

How Do High-Speed Vertical CNC Routers Enhance Production?

High-speed vertical CNC routers are engineered for enhanced speed and precision, making them suitable for high-volume production environments. These machines often come equipped with advanced software that allows for intricate designs and faster cycle times. B2B buyers seeking to increase productivity and maintain high-quality output will find these routers beneficial. However, the higher upfront investment may be a concern for budget-conscious companies.

What Makes Multi-Head Vertical CNC Routers Versatile?

Multi-head vertical CNC routers feature multiple spindles that enable simultaneous operations, allowing for greater versatility in applications. These machines are particularly effective for complex pattern-making and 3D sculpting, catering to industries such as furniture design and advertising. While they provide significant efficiency advantages for large projects, buyers must consider the complexity of setup and maintenance, which may require specialized knowledge.

Why Choose a Vertical Machining Center?

Vertical machining centers combine drilling and milling capabilities in a compact design, making them ideal for custom furniture and cabinetry. Their space-efficient layout allows businesses to maximize production areas while maintaining versatility in operations. However, the requirement for skilled operators to manage these machines can be a barrier for some businesses, particularly smaller ones lacking technical expertise.

What Are the Benefits of Entry-Level Vertical CNC Routers?

Entry-level vertical CNC routers are designed for affordability and ease of use, making them perfect for small businesses and startups. They are suitable for basic furniture making and prototyping, allowing new entrants to the market to develop their skills without significant financial risk. However, these machines often come with limited capabilities, which could hinder growth for businesses that expand into more complex projects.

Key Industrial Applications of vertical cnc wood router

| Industry/Sector | Specific Application of vertical cnc wood router | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Precision cutting and engraving of furniture components | Enhanced design flexibility and reduced waste | Machine size, tooling options, and software compatibility |

| Interior Design | Customization of cabinetry and decorative elements | Unique offerings that cater to specific client needs | Material handling capabilities and clamping systems |

| Signage and Advertising | Production of intricate signage and promotional displays | High-quality, detailed outputs that attract customers | Speed, precision, and the ability to work with diverse materials |

| Construction and Carpentry | Fabrication of structural wood components and fixtures | Improved accuracy and efficiency in production | Machine durability, support for large workpieces, and service availability |

| Arts and Crafts | Creation of bespoke art pieces and 3D sculptures | Opportunities for artistic expression and market differentiation | Versatility in material types and ease of use |

How is Vertical CNC Wood Router Used in Furniture Manufacturing?

In the furniture manufacturing sector, vertical CNC wood routers are essential for precision cutting, engraving, and shaping of various components like tabletops, chair parts, and cabinetry. These machines allow manufacturers to create intricate designs with minimal waste, significantly enhancing design flexibility. For international buyers, especially from regions such as Africa and South America, sourcing routers that accommodate diverse wood types and offer robust software for design customization is crucial. Additionally, ensuring the machine can handle large workpieces is vital for maximizing efficiency.

What Role Does Vertical CNC Wood Router Play in Interior Design?

Interior designers leverage vertical CNC wood routers to customize cabinetry and decorative elements, enabling them to meet specific client demands. The ability to produce unique designs enhances a business’s portfolio, attracting more clientele. Buyers from the Middle East and Europe should consider routers that provide advanced clamping systems and material handling capabilities to ensure smooth operations. Furthermore, the ability to work with various materials, including MDF and solid wood, is vital for achieving high-quality finishes.

How is Vertical CNC Wood Router Beneficial for Signage and Advertising?

In the signage and advertising industry, vertical CNC wood routers are utilized to produce detailed signage and promotional displays. The precision of these machines ensures high-quality outputs that can effectively attract customers. International buyers should prioritize sourcing routers that can handle a variety of materials, including acrylic and wood, while also providing high-speed operations for timely project completion. Understanding the machine’s capabilities for intricate designs will also play a significant role in meeting client specifications.

What Advantages Does Vertical CNC Wood Router Offer in Construction and Carpentry?

Vertical CNC wood routers are increasingly used in construction and carpentry for fabricating structural wood components and fixtures. The accuracy and efficiency provided by these machines lead to significant time savings and reduced material waste. For buyers in regions like Europe and the Middle East, it is essential to consider the durability of the machine and its ability to support larger workpieces. Additionally, access to reliable after-sales support and service is critical to maintaining operational efficiency.

How Do Arts and Crafts Benefit from Vertical CNC Wood Routers?

Artists and craftsmen utilize vertical CNC wood routers to create bespoke art pieces and intricate 3D sculptures. The versatility of these machines allows for the use of various materials, fostering creativity and innovation. Buyers from Africa and South America should focus on sourcing machines that are user-friendly and capable of executing complex designs efficiently. Moreover, having the ability to easily switch between different tooling options can enhance the creative process and lead to unique offerings in the arts and crafts market.

3 Common User Pain Points for ‘vertical cnc wood router’ & Their Solutions

Scenario 1: Difficulty in Precision Machining for Complex Designs

The Problem:

B2B buyers often encounter challenges when it comes to achieving high precision in machining complex wood designs using vertical CNC routers. This is especially true for businesses that require intricate patterns, such as in furniture or custom cabinetry. Inadequate precision can lead to increased waste, higher costs, and unsatisfied customers, ultimately affecting profitability and brand reputation. The issue may stem from inadequate machine capabilities, poor software integration, or insufficient operator training.

The Solution:

To address precision challenges, buyers should prioritize vertical CNC routers that offer advanced features such as high-resolution servo motors and robust control systems. Selecting machines with user-friendly software that supports CAD/CAM integration can significantly enhance design accuracy. Moreover, investing in operator training programs is crucial. Ensuring that staff are well-trained in both the machinery and software will facilitate optimal performance and minimize errors. Buyers should also consider a machine’s capacity for customization, allowing them to adapt the equipment to specific project requirements. Regular maintenance and calibration of the CNC router are essential practices that should not be overlooked to maintain precision over time.

Scenario 2: Inefficient Production Processes Leading to Increased Costs

The Problem:

Many B2B buyers find that their vertical CNC wood routers are not optimizing production processes effectively, leading to longer cycle times and increased operational costs. Inefficiencies can arise from various factors, including outdated machinery, inadequate tooling, or poor workflow management. For companies looking to scale, these inefficiencies can be detrimental to competitiveness, particularly in markets where speed and cost-effectiveness are critical.

The Solution:

To streamline production processes, companies should assess their current setup and identify bottlenecks. Investing in vertical CNC routers with features such as automatic tool changers and multi-spindle configurations can significantly reduce cycle times. Additionally, integrating a robust workflow management system can help in planning and optimizing production schedules. It is also beneficial to evaluate the entire production line and consider upgrades or modifications to machines that complement the CNC router, such as automated material handling systems. Collaborating with suppliers who offer comprehensive support and training can further enhance efficiency, ensuring that operators are well-versed in the best practices for using the machinery.

Scenario 3: Challenges in Material Handling and Workpiece Clamping

The Problem:

Material handling and workpiece clamping pose significant challenges for B2B buyers using vertical CNC wood routers. Improper clamping can lead to vibrations during machining, resulting in poor quality finishes and inaccuracies. Additionally, manual clamping processes are time-consuming and can slow down production. This challenge is particularly pronounced for businesses that handle a variety of materials and sizes, as inconsistent clamping solutions can lead to increased setup times and machining errors.

The Solution:

To enhance material handling and clamping efficiency, buyers should consider vertical CNC routers equipped with advanced vacuum clamping systems. These systems provide a secure hold on various materials without the need for physical clamps, thus reducing setup time and improving machining accuracy. Furthermore, investing in routers that offer automated clamping adjustments can accommodate different workpiece sizes, allowing for quick transitions between projects. Implementing a systematic approach to material handling, such as using jigs or fixtures designed for specific applications, can also streamline workflows. Finally, regular training on best practices for clamping and handling materials will empower operators to maximize the capabilities of their vertical CNC routers, resulting in higher quality outputs and improved operational efficiency.

Strategic Material Selection Guide for vertical cnc wood router

What Are the Key Materials Used in Vertical CNC Wood Routers?

When selecting materials for vertical CNC wood routers, understanding the properties, advantages, and limitations of each material is crucial for optimizing performance and suitability for specific applications. Here, we analyze four common materials used in vertical CNC wood routers: solid wood, MDF (Medium Density Fiberboard), plywood, and aluminum.

How Does Solid Wood Perform in Vertical CNC Wood Routers?

Solid wood is a classic choice for CNC machining due to its natural beauty and structural integrity. Key properties include high strength-to-weight ratio and excellent durability under various conditions. However, solid wood can be susceptible to warping and requires careful handling to maintain its integrity.

Pros: Solid wood offers unmatched aesthetics and durability, making it ideal for high-end furniture and cabinetry. Its natural variations can enhance the final product’s appeal.

Cons: The cost of solid wood can be high, and its machining can be complex due to variations in density and grain direction. Additionally, it may require more maintenance and finishing processes.

For international buyers, compliance with local regulations regarding sustainable sourcing is essential, particularly in regions like Europe where stringent standards exist.

What Are the Benefits of Using MDF in CNC Wood Routing?

MDF is a popular engineered wood product made from wood fibers, wax, and resin, providing a smooth surface for machining. Its properties include uniform density and excellent machinability, making it a favored choice for intricate designs.

Pros: MDF is cost-effective and allows for precise cuts and engravings, making it suitable for detailed applications like furniture fronts and decorative items.

Cons: It is less durable than solid wood and can be prone to moisture damage, which may limit its use in humid environments. Additionally, MDF can produce harmful dust during machining, necessitating proper ventilation and dust collection systems.

International buyers should ensure that MDF products comply with emission standards such as E1 or E0, especially in regions like Europe and the Middle East.

How Does Plywood Compare for Vertical CNC Wood Router Applications?

Plywood consists of multiple layers of wood veneer glued together, providing strength and stability. It is resistant to warping and cracking, making it suitable for various applications, including cabinetry and structural components.

Pros: Plywood is versatile and can be manufactured in various grades to suit different applications. It is often more affordable than solid wood and offers good durability.

Cons: The quality of plywood can vary significantly based on the manufacturing process and the type of wood used. Lower-grade plywood may have voids or inconsistencies that can affect machining quality.

For B2B buyers, understanding the grading system and ensuring compliance with standards like ASTM can help in selecting the right plywood for specific applications.

Why Is Aluminum Used in Vertical CNC Wood Routers?

Aluminum is increasingly used in CNC machining due to its lightweight and corrosion-resistant properties. It can be machined to high tolerances, making it suitable for components that require precision.

Pros: Aluminum is durable, lightweight, and resistant to environmental factors, making it ideal for outdoor applications. Its machinability allows for intricate designs and quick production times.

Cons: The cost of aluminum can be higher than wood-based materials, and it may require specialized tooling for effective machining. Additionally, it can be prone to scratching and denting.

For buyers in regions like Saudi Arabia and Brazil, understanding local supply chains and availability of aluminum grades that meet international standards is crucial for ensuring quality.

Summary Table of Material Selection for Vertical CNC Wood Routers

| Material | Typical Use Case for vertical cnc wood router | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Solid Wood | High-end furniture, cabinetry | Aesthetic appeal and durability | High cost and complex machining | High |

| MDF | Furniture fronts, decorative items | Cost-effective and precise machining | Prone to moisture damage and harmful dust | Low |

| Plywood | Cabinetry, structural components | Versatile and durable | Quality can vary, affecting machining quality | Medium |

| Aluminum | Precision components, outdoor applications | Lightweight and corrosion-resistant | Higher cost and specialized tooling required | High |

This strategic material selection guide provides a comprehensive overview of the materials commonly used in vertical CNC wood routers, helping international B2B buyers make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for vertical cnc wood router

What Are the Main Stages in the Manufacturing Process of Vertical CNC Wood Routers?

The manufacturing process of vertical CNC wood routers involves several critical stages, each essential for ensuring the final product’s performance, durability, and precision.

-

Material Preparation: This initial stage involves sourcing high-quality materials, such as aluminum extrusions, steel frames, and high-grade electronic components. Suppliers often provide certification for the materials, ensuring compliance with international standards. The materials are then inspected for defects and categorized according to their specifications.

-

Forming: The forming stage includes cutting, bending, and machining the raw materials into components. Advanced techniques such as CNC machining, laser cutting, and water jet cutting are employed to achieve high precision. Computer Numerical Control (CNC) technology allows for intricate designs and reduces human error. This step often involves the use of specialized tools and machines to ensure that parts meet the exact dimensions required for assembly.

-

Assembly: During assembly, the prepared components are brought together to form the vertical CNC wood router. This stage may involve manual labor and robotic assistance, depending on the complexity of the machine. Assembly is typically performed in a clean environment to minimize contamination and defects. Key components like the spindle, control unit, and vacuum systems are integrated, and the entire machine is calibrated for optimal performance.

-

Finishing: The final stage of manufacturing involves surface treatments, painting, and protective coatings to enhance durability and aesthetic appeal. Quality checks are performed to ensure that all components are correctly aligned and functioning before the machine is packaged for shipment. This stage may also include software installation and testing to ensure that the CNC machine operates according to specifications.

What Quality Assurance Practices Are Essential for Vertical CNC Wood Routers?

Quality assurance (QA) is crucial in the manufacturing of vertical CNC wood routers, ensuring that each unit meets industry standards and customer expectations. Here are the key components of a robust QA process:

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, which outlines the requirements for a quality management system. This certification ensures that companies consistently provide products that meet customer and regulatory requirements. In addition to ISO, other certifications such as CE (Conformité Européenne) signify compliance with health, safety, and environmental protection standards applicable to the European market.

-

Quality Control Checkpoints: The QA process typically includes several checkpoints:

– Incoming Quality Control (IQC): Materials and components are inspected upon arrival to ensure they meet the required specifications.

– In-Process Quality Control (IPQC): During manufacturing, various tests and inspections are conducted to monitor the production process and identify any issues early.

– Final Quality Control (FQC): Once assembly is complete, the entire machine undergoes a comprehensive inspection and testing phase to verify functionality and performance. -

Testing Methods: Common testing methods for vertical CNC wood routers include functional testing, where machines are operated to ensure they meet performance specifications, and durability testing, which assesses the machine’s ability to withstand extended use. Vibration analysis, thermal imaging, and precision measurements are also employed to ensure quality.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to invest in vertical CNC wood routers should take proactive steps to verify the quality control practices of their suppliers. Here are actionable strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality assurance practices, and overall operational standards of potential suppliers. This can include reviewing documentation related to compliance with international standards and quality certifications.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports, including records of inspections, tests conducted, and outcomes. These documents provide insight into the supplier’s commitment to maintaining high standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control measures. This can be particularly beneficial for international buyers who may not have the resources for direct audits.

-

Understanding Certification Nuances: Different regions have varying requirements for quality certifications. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with local standards and ensure that their suppliers are compliant with both international and regional regulations.

What Are the Benefits of a Rigorous Quality Assurance Process for B2B Buyers?

Investing in vertical CNC wood routers from manufacturers with robust quality assurance processes offers several advantages:

-

Consistency in Performance: A well-implemented QA process ensures that each machine produced meets the same high standards, leading to consistent performance across all units.

-

Reduced Downtime and Maintenance: Quality machines are less prone to breakdowns, which translates to lower maintenance costs and reduced downtime in production.

-

Enhanced Customer Satisfaction: By sourcing from suppliers committed to quality, buyers can ensure that they receive reliable products that meet their specific needs, ultimately leading to greater customer satisfaction in their own businesses.

-

Long-Term Cost Savings: While the initial investment may be higher with quality-focused manufacturers, the long-term savings from reduced maintenance, increased efficiency, and fewer replacements can be significant.

In conclusion, understanding the manufacturing processes and quality assurance practices of vertical CNC wood routers is essential for B2B buyers. By focusing on these elements, businesses can make informed purchasing decisions that contribute to their operational efficiency and product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vertical cnc wood router’

Introduction

This sourcing guide provides a practical checklist for B2B buyers looking to procure a vertical CNC wood router. As the demand for precision woodworking increases, selecting the right equipment becomes vital to ensuring efficiency, quality, and return on investment. This guide outlines essential steps to navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications required for your projects. Consider factors such as the size of the workpieces, types of materials to be processed (e.g., solid wood, MDF, plywood), and desired features like multi-spindle capabilities or advanced clamping systems. Defining these parameters will help you narrow down options and ensure the machine aligns with your production needs.

Step 2: Research Reputable Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the industry. Look for companies that specialize in vertical CNC wood routers and have established credibility through positive customer reviews and testimonials. Utilize platforms like industry trade shows, online forums, and professional networks to gather insights on potential suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This evaluation helps ensure the supplier has the expertise and resources necessary to meet your requirements. Pay attention to their after-sales support and warranty offerings, as these can significantly affect your long-term satisfaction.

Step 4: Verify Certifications and Compliance

Ensure that the suppliers you are considering meet international quality standards and certifications. Look for compliance with ISO standards or specific safety regulations relevant to your region. Certifications not only indicate product reliability but also demonstrate the supplier’s commitment to quality and customer satisfaction.

Step 5: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that outline the costs associated with each machine. This should include pricing for additional features, installation costs, and any ongoing maintenance agreements. Comparing these quotations will give you a clear picture of the total investment required and help you make an informed decision.

Step 6: Assess Delivery and Installation Services

Evaluate the delivery and installation services offered by the suppliers. Confirm the timeline for delivery and whether they provide on-site installation support. A reliable supplier should also offer training sessions for your staff to ensure smooth operation of the CNC machine, which can save time and reduce errors in the long run.

Step 7: Consider Long-Term Support and Maintenance

Finally, inquire about the long-term support options available from the supplier. This includes warranty terms, availability of spare parts, and access to technical support. Establishing a good relationship with a supplier who provides robust support can be invaluable, especially as your production needs evolve or when technical issues arise.

By following this checklist, you can make informed decisions that will enhance your woodworking capabilities and contribute to your business’s success.

Comprehensive Cost and Pricing Analysis for vertical cnc wood router Sourcing

What Are the Key Cost Components of Vertical CNC Wood Routers?

When sourcing vertical CNC wood routers, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of materials can vary significantly based on the quality and type of components used, such as the frame, motors, and electronic controls. High-grade materials increase durability and performance, but they also raise the initial investment.

-

Labor: Labor costs encompass the wages of skilled workers involved in the assembly and testing of the CNC machines. In regions with higher labor costs, such as Europe, this can significantly impact pricing.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and depreciation of manufacturing equipment. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive pricing.

-

Tooling: Specific tooling required for customization or advanced features can add to the cost. Buyers should assess whether the included tooling meets their operational needs or if additional investments are necessary.

-

Quality Control: Ensuring that machines meet certain standards incurs additional costs. A rigorous QC process guarantees performance and reliability, which is particularly important for buyers in industries with strict quality requirements.

-

Logistics: Shipping and handling costs can vary based on the machine’s weight and size, as well as the shipping distance. For international buyers, understanding Incoterms is essential to determine who bears the logistics costs.

-

Margin: Suppliers typically include a profit margin that can vary based on competition and market demand. High-end models may carry a higher margin due to advanced features and better materials.

What Influences the Pricing of Vertical CNC Wood Routers?

Several factors can influence the pricing of vertical CNC wood routers:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to discounts. Buyers should consider their production needs and negotiate terms that benefit both parties.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Material Quality and Certifications: Machines made from high-quality materials or those with certifications (e.g., ISO) may be priced higher but offer better longevity and performance.

-

Supplier Reputation and Reliability: Established suppliers with a proven track record may charge more due to their reliability and customer service. It’s essential to balance cost with the quality of service.

-

Incoterms: Understanding Incoterms helps buyers determine shipping responsibilities and costs, impacting the total landed cost of the equipment.

How Can Buyers Optimize Costs and Negotiate Effectively?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, optimizing costs while ensuring quality is vital. Here are some tips:

-

Negotiate Smartly: Leverage your purchasing volume and long-term relationship potential to negotiate better pricing and terms. Don’t hesitate to ask for discounts on bulk orders or favorable payment terms.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term operational costs, including maintenance, energy consumption, and potential downtime. Machines with higher initial costs may offer lower TCO through efficiency and reliability.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to factors like tariffs, local demand, and currency fluctuations. Understanding these nuances can help in making informed purchasing decisions.

-

Request Detailed Quotations: Ensure that suppliers provide comprehensive quotes that outline all components, including shipping and handling, to avoid hidden costs.

-

Evaluate Multiple Suppliers: Comparing offers from different suppliers can provide leverage in negotiations and help identify the best value proposition.

Conclusion

The sourcing of vertical CNC wood routers involves a complex interplay of costs and pricing factors. By understanding these components and leveraging negotiation strategies, international B2B buyers can optimize their investments while ensuring they receive quality machinery that meets their operational needs. Always remember to request indicative prices and remain aware of market fluctuations that can impact final costs.

Alternatives Analysis: Comparing vertical cnc wood router With Other Solutions

Exploring Alternatives to Vertical CNC Wood Routers for Wood Processing

In the competitive landscape of wood processing, the vertical CNC wood router stands out as an efficient solution. However, there are several alternative technologies that can achieve similar results. Understanding these alternatives helps B2B buyers make informed decisions based on their specific operational needs and budget constraints.

| Comparison Aspect | Vertical CNC Wood Router | Multi-Head CNC Wood Router | Horizontal CNC Router |

|---|---|---|---|

| Performance | High precision with multi-directional machining capabilities, ideal for complex designs. | Versatile with horizontal and vertical spindles for diverse applications, including 3D work. | Excellent for large sheet materials, but limited in vertical operations and complex cuts. |

| Cost | Typically ranges from $10,000 to $50,000 depending on features and size. | More economical, often starting around $4,500, with potential for higher configurations. | Generally ranges from $8,000 to $30,000, depending on size and capabilities. |

| Ease of Implementation | Requires skilled operators and setup can be complex due to software needs. | User-friendly with intuitive controls; easier for operators to adapt to. | Straightforward setup but may require additional tools for complex tasks. |

| Maintenance | Regular maintenance required for precision and longevity; parts can be costly. | Moderate maintenance with lower costs; often more robust with fewer issues. | Low maintenance but may need adjustments for precision over time. |

| Best Use Case | Ideal for custom furniture, cabinetry, and detailed engraving. | Suitable for furniture decoration, signage, and 3D artistic work. | Best for cutting large panels or sheet materials in bulk. |

Detailed Breakdown of Alternatives

Multi-Head CNC Wood Router

The multi-head CNC wood router is a flexible solution that allows for both horizontal and vertical operations. Its ability to handle various materials and perform intricate designs makes it ideal for businesses focused on furniture and signage. The cost-effectiveness and user-friendly interface facilitate easier adoption for companies with less experienced staff. However, it may not offer the same level of precision as a vertical CNC wood router for highly detailed tasks.

Horizontal CNC Router

Horizontal CNC routers are designed primarily for cutting large sheets of wood and other materials. They excel in high-volume production environments where speed is critical. The straightforward design allows for easier maintenance and operation, making them an attractive option for companies that prioritize efficiency over intricate details. However, their limited vertical capabilities may restrict their application in more complex woodworking tasks, making them less versatile than vertical CNC routers.

Conclusion: Choosing the Right Wood Processing Solution

When selecting a wood processing solution, B2B buyers must consider their specific needs, including the complexity of the projects, budget constraints, and the skill level of the operators. Vertical CNC wood routers offer unmatched precision for detailed work, while alternatives like multi-head and horizontal CNC routers provide flexibility and cost savings for various applications. By carefully evaluating these aspects, businesses can invest in the most suitable technology that aligns with their operational goals and enhances their productivity.

Essential Technical Properties and Trade Terminology for vertical cnc wood router

What Are the Key Technical Properties of a Vertical CNC Wood Router?

Understanding the critical specifications of a vertical CNC wood router is essential for B2B buyers, particularly those looking to make informed purchasing decisions. Here are some pivotal technical properties to consider:

-

Work Area Dimensions

The work area dimensions indicate the maximum size of the material that can be processed. For instance, a common size is 1300mm x 2500mm (approximately 4′ x 8′). This specification is crucial for businesses that handle large panels or furniture components, as it directly affects production capabilities and workflow efficiency. -

Spindle Power

Spindle power, often measured in kilowatts (kW), determines the cutting and engraving capability of the router. A typical spindle power ranges from 3.5kW to 6kW, which influences the machine’s ability to work with various materials, including solid wood, MDF, and plastics. Higher spindle power can translate to faster processing speeds and the ability to handle denser materials, which is important for productivity and operational costs. -

Precision and Tolerance

Tolerance levels indicate how closely the machining process can adhere to specified dimensions, usually measured in millimeters. A tolerance of ±0.01mm is common in high-quality CNC routers. This property is vital for industries requiring high precision, such as furniture manufacturing and cabinetry, where even minor discrepancies can lead to product rejections and increased costs. -

Control System

The type of control system used (e.g., Mach3, CAMPUS V7) influences the machine’s ease of use and programming capabilities. A user-friendly control system enables operators to efficiently program complex tasks and reduces training time. For B2B buyers, the choice of control system can affect labor costs and machine utilization. -

Material Compatibility

Different CNC routers are designed to work with specific materials, such as wood, plastics, and metals. Understanding the material compatibility ensures that the selected machine meets the specific needs of the business, which can help in avoiding costly mistakes and ensuring versatility in production. -

Clamping System

The clamping system, often vacuum-based or mechanical, is critical for securing materials during processing. A reliable clamping system minimizes the risk of movement, leading to higher accuracy and better finish quality. For businesses, this can reduce waste and improve overall product quality.

Which Trade Terms Should B2B Buyers Know When Purchasing a Vertical CNC Wood Router?

Familiarity with industry-specific terminology can significantly enhance communication and negotiation processes. Here are some essential trade terms relevant to vertical CNC wood routers:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and assess product quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, especially for businesses that may not require large quantities. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific goods or services. It is an essential step in procurement, allowing buyers to compare prices and terms from multiple vendors. -

Incoterms (International Commercial Terms)

These are a set of predefined international rules that clarify the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms helps businesses understand shipping costs, risks, and delivery timelines. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times helps businesses plan their production schedules and manage customer expectations effectively. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and its longevity. Knowing the warranty terms is essential for risk management and can influence purchasing decisions, particularly for high-value equipment.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring they select the right vertical CNC wood router to meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the vertical cnc wood router Sector

What are the Current Market Dynamics and Key Trends in the Vertical CNC Wood Router Sector?

The global vertical CNC wood router market is experiencing robust growth, driven by increasing demand for precision machining in furniture and cabinetry manufacturing. Key trends include the adoption of automation and advanced software solutions, which are enhancing production efficiency and precision. Technologies such as automatic suction cup positioning and integrated software for hole recognition are becoming standard, enabling manufacturers to reduce cycle times and improve output quality. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should note that these advancements allow for greater customization and flexibility in production processes, catering to diverse market needs.

Moreover, the rise of Industry 4.0 is leading to a greater emphasis on data analytics and IoT connectivity, allowing manufacturers to monitor and optimize their operations in real-time. As global supply chains evolve, sourcing vertical CNC wood routers with integrated smart technology can provide businesses with a competitive edge. Buyers should also consider the geographical advantages of sourcing from regions with established manufacturing capabilities, such as Europe and Asia, to ensure reliable supply and support.

How is Sustainability and Ethical Sourcing Impacting the Vertical CNC Wood Router Industry?

Sustainability is increasingly becoming a focal point for B2B buyers in the vertical CNC wood router market. The environmental impact of manufacturing processes is under scrutiny, with an emphasis on reducing waste and energy consumption. Buyers should prioritize suppliers that demonstrate a commitment to sustainability through responsible sourcing practices and the use of environmentally friendly materials. Certifications such as FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) are critical indicators of ethical sourcing.

The shift toward sustainable production is not only beneficial for the environment but also aligns with consumer preferences for eco-friendly products. By sourcing vertical CNC wood routers that utilize ‘green’ materials and processes, businesses can enhance their brand reputation and appeal to a broader customer base. Furthermore, investing in energy-efficient machinery can lead to long-term cost savings, making it an attractive proposition for B2B buyers.

What is the Historical Context of Vertical CNC Wood Routers and Their Evolution?

The vertical CNC wood router has evolved significantly since its inception, transitioning from manual operations to highly automated systems that enhance precision and efficiency. Initially, the market was dominated by traditional woodworking techniques, but the advent of computer numerical control (CNC) technology in the late 20th century revolutionized the industry. Early CNC machines were limited in functionality and required skilled operators, but advancements in software and hardware have led to the development of user-friendly interfaces and versatile machines capable of handling complex tasks.

Today, vertical CNC wood routers are integral to modern woodworking operations, enabling manufacturers to produce intricate designs with minimal waste and maximum efficiency. This evolution reflects broader trends in manufacturing, where technology continues to reshape processes and create opportunities for innovation. As the market continues to develop, B2B buyers must remain informed about technological advancements and their implications for sourcing and production strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of vertical cnc wood router

-

How do I choose the right vertical CNC wood router for my business needs?

Choosing the right vertical CNC wood router involves assessing your specific production requirements, such as material types, desired applications, and production volume. Consider key specifications like work area size, spindle power, and automation features. Evaluate the machine’s versatility for tasks like cutting, engraving, and drilling, as well as its compatibility with your existing software systems. It’s also crucial to analyze the after-sales support, warranty, and maintenance services offered by the supplier to ensure long-term operational efficiency. -

What are the advantages of vertical CNC wood routers compared to horizontal models?

Vertical CNC wood routers provide several advantages, including a smaller footprint, which is beneficial for limited workspace. They often allow for easier access to the workpiece for setup and adjustments. Furthermore, vertical machines can handle a variety of applications, including 3D engraving, making them versatile for different woodworking projects. Their design also typically allows for more precise machining of parts, leading to higher-quality finishes in furniture and cabinetry production. -

What customization options are available for vertical CNC wood routers?

Many manufacturers offer customization options to tailor vertical CNC wood routers to specific business needs. Customizations can include adjustments to the work area size, spindle configurations, and additional features such as multi-head setups for enhanced productivity. Software can also be customized to integrate with existing systems, improving workflow efficiency. Discuss your specific requirements with potential suppliers to explore available configurations that align with your production goals. -

What is the typical lead time for ordering a vertical CNC wood router?

Lead times for ordering vertical CNC wood routers can vary significantly based on the manufacturer, model, and customization requirements. Generally, standard models can be delivered within 4 to 8 weeks, while customized machines may take longer, potentially up to 12 weeks or more. It is advisable to confirm lead times with the supplier and consider factors such as shipping logistics, customs clearance, and installation services when planning your purchase. -

What are the minimum order quantities (MOQ) for vertical CNC wood routers?

Minimum order quantities (MOQ) for vertical CNC wood routers typically depend on the supplier and the specific machine model. Some manufacturers may offer machines as single units, while others may require orders of multiple units to secure better pricing or availability. Always clarify MOQ policies with suppliers, especially if you’re considering bulk purchases or are part of a larger production plan. This will help you align your budget and inventory needs accordingly. -

What payment terms are commonly offered by suppliers of vertical CNC wood routers?

Payment terms for vertical CNC wood routers can vary by supplier and may include options such as upfront payments, deposits, and financing arrangements. Common practices include a 30% deposit upon order confirmation, with the remaining balance due before shipment or delivery. International buyers should inquire about payment methods accepted, such as bank transfers, credit cards, or letters of credit, and ensure that they comply with any local regulations or currency exchange considerations. -

How can I vet suppliers of vertical CNC wood routers for quality and reliability?

To vet suppliers effectively, start by researching their market reputation through customer reviews and testimonials. Assess their industry experience and the range of products offered. Request references from previous clients and verify their after-sales support and warranty policies. Additionally, consider visiting their manufacturing facility if possible, or attending trade shows to see the equipment in action. This due diligence will help ensure you partner with a reliable supplier who meets your quality standards. -

What are the logistics considerations when importing vertical CNC wood routers?

When importing vertical CNC wood routers, logistics considerations include shipping methods, customs regulations, and delivery timelines. Evaluate whether to use air freight for faster delivery or sea freight for cost-effectiveness. Familiarize yourself with import duties, taxes, and required documentation, such as bills of lading and customs declarations. It’s advisable to work with experienced freight forwarders to navigate these complexities and ensure that your machinery arrives safely and on schedule.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Vertical Cnc Wood Router Manufacturers & Suppliers List

1. Holz-Her – EVOLUTION Series CNC Machining Centers

Domain: m.holzherusa.com

Registered: 2010 (15 years)

Introduction: EVOLUTION Series CNC Machining Centers: Vertical CNC machines for wood processing with entry-level pricing. Models include EVOLUTION 7402, EVOLUTION 7405 4mat, and EVOLUTION 7405 Connect. Features include:

– Unique machining options for solid wood and panels, including curved parts and MDF furniture fronts.

– Vacuum-based clamping system (patent pending) with software-controlled suction cup positi…

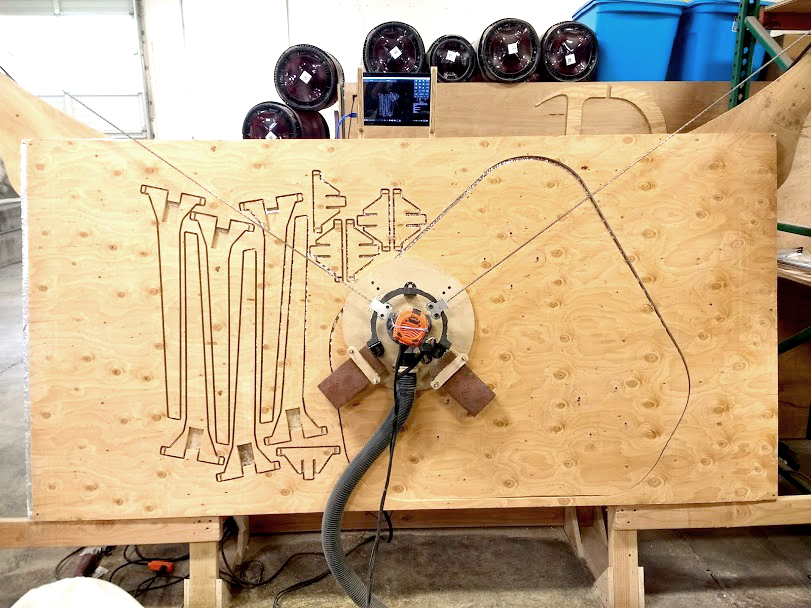

2. CNC Solutions – Vertical Router for Architects

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Vertical CNC router design for architects in a small office space in Barcelona. Dimensions: 2500 x 1250 x 100mm (height·width·depth) with a reduced machine volume of around 3 x 2 x 0.5m (h·w·d). Materials include aluminium tubes, rectangular and square profiles, and 3cm thick laminated pine boards for rigidity. Additional materials: acrylic for sides and hinged door. Budget: less than €4,000 each….

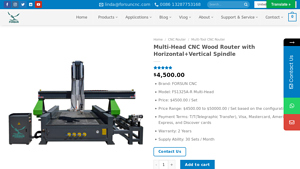

3. FORSUN CNC – Multi-Head CNC Wood Router

Domain: forsuncnc.com

Registered: 2020 (5 years)

Introduction: { “Product Name”: “Multi-Head CNC Wood Router with Horizontal+Vertical Spindle”, “Brand”: “FORSUN CNC”, “Model”: “FS1325A-R”, “Price”: “$4500.00”, “Price Range”: “$4500.00 to $50000.00”, “Payment Terms”: [“T/T”, “Visa”, “Mastercard”, “American Express”, “Discover”], “Warranty”: “2 Years”, “Supply Ability”: “30 Sets / Month”, “Work Area”: “1300mm x 2500mm x 200mm”, “Packing Size”: “3200mm x 2200mm …

4. Shaper – Shaper Origin

Domain: shapertools.com

Registered: 2015 (10 years)

Introduction: {“name”: “Shaper Origin”, “price”: “$2,899.00”, “shipping”: “free shipping”, “description”: “A handheld CNC router designed for woodworkers, combining the form factor of a traditional router with the precision of a high-end CNC machine.”, “features”: {“cutting_technology”: “Handheld CNC routing”, “auto_correction”: “Auto corrects within a 1/2” range”, “design_compatibility”: “Works with almost any…

5. Maslow – Large Format CNC Routing

Domain: maslowcnc.com

Registered: 2016 (9 years)

Introduction: Maslow 4 Large format CNC routing made accessible. The goal is to make large format CNC routing accessible for everyone to bring big human scale things from the digital world into the physical world.

6. HOMAG – DRILLTEQ V-200

Domain: homag.com

Registered: 2000 (25 years)

Introduction: Vertical CNC Processing Center DRILLTEQ V-200 is a flexible all-rounder for processing in just 5 m². It is suitable for drilling, trimming, and grooving, making it ideal for just-in-time production for trade businesses and custom production in large companies. There are 3 configurations available:

– Package 1: 8 vertical drilling spindles, 4 horizontal in X-direction, 2 horizontal in Y-direction,…

7. Hendrick – CNC Routers

Domain: hendrickmanufacturing.com

Registered: 2007 (18 years)

Introduction: Hendrick CNC Routers include 3-axis and 5-axis machines designed for heavy-duty production. The 3-axis CNC routers feature:

– HHD Series: Powerful router with 24/7 uptime, up to 16 tools, capable of cutting corrugated, aluminum, plastic, and wood at high speeds with accuracy.

– HSR Series: High-speed CNC router built for durability, capable of routing wood, plastic, aluminum, and corrugated mater…

8. Northwood – Multi-Head CNC Routers

Domain: northwoodmachine.com

Registered: 2003 (22 years)

Introduction: Northwood Multi-Head CNC Routers and Machining Centers are 3-Axis TA CNC Machining Centers that typically start with a single tooling plate and one spindle unit. Spindles can range up to 24HP liquid-cooled and commonly feature four or more on a single tooling plate. The machines can accommodate multiple tooling plates for dual-processing, allowing simultaneous machining on separate tables for diff…

Strategic Sourcing Conclusion and Outlook for vertical cnc wood router

As businesses navigate the evolving landscape of woodworking technology, the strategic sourcing of vertical CNC wood routers emerges as a pivotal factor for competitive advantage. Key takeaways for international B2B buyers include the importance of selecting machines that enhance efficiency, precision, and versatility. The EVOLUTION series, for instance, showcases innovative features such as automatic suction cup positioning and a user-friendly interface, which can significantly reduce cycle times and improve production quality.

Investing in robust CNC solutions not only streamlines operations but also opens avenues for customization and scalability, catering to diverse market needs across Africa, South America, the Middle East, and Europe. As demand for high-quality wood products continues to rise, leveraging advanced machining technology will be crucial for businesses aiming to meet customer expectations and thrive in a competitive market.

Looking ahead, it is essential for buyers to engage with reputable suppliers and explore the latest advancements in CNC technology. By prioritizing strategic sourcing, businesses can position themselves to capitalize on emerging trends and drive sustainable growth in the woodworking sector. Take the next step in enhancing your operations by assessing your CNC needs today.