Contents

Manufacturing Insight: Vacuum Tables For Cnc

Precision Workholding Solutions for Demanding CNC Applications

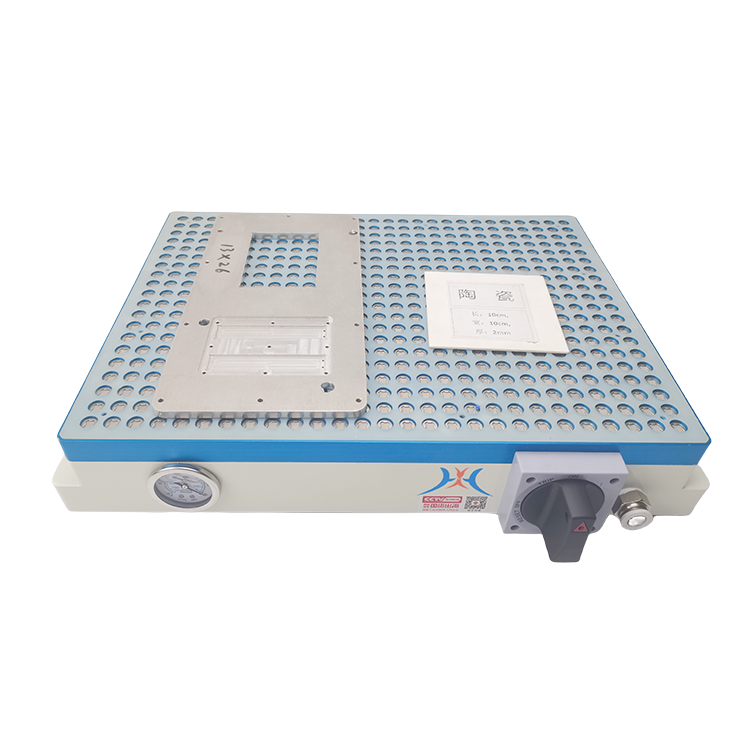

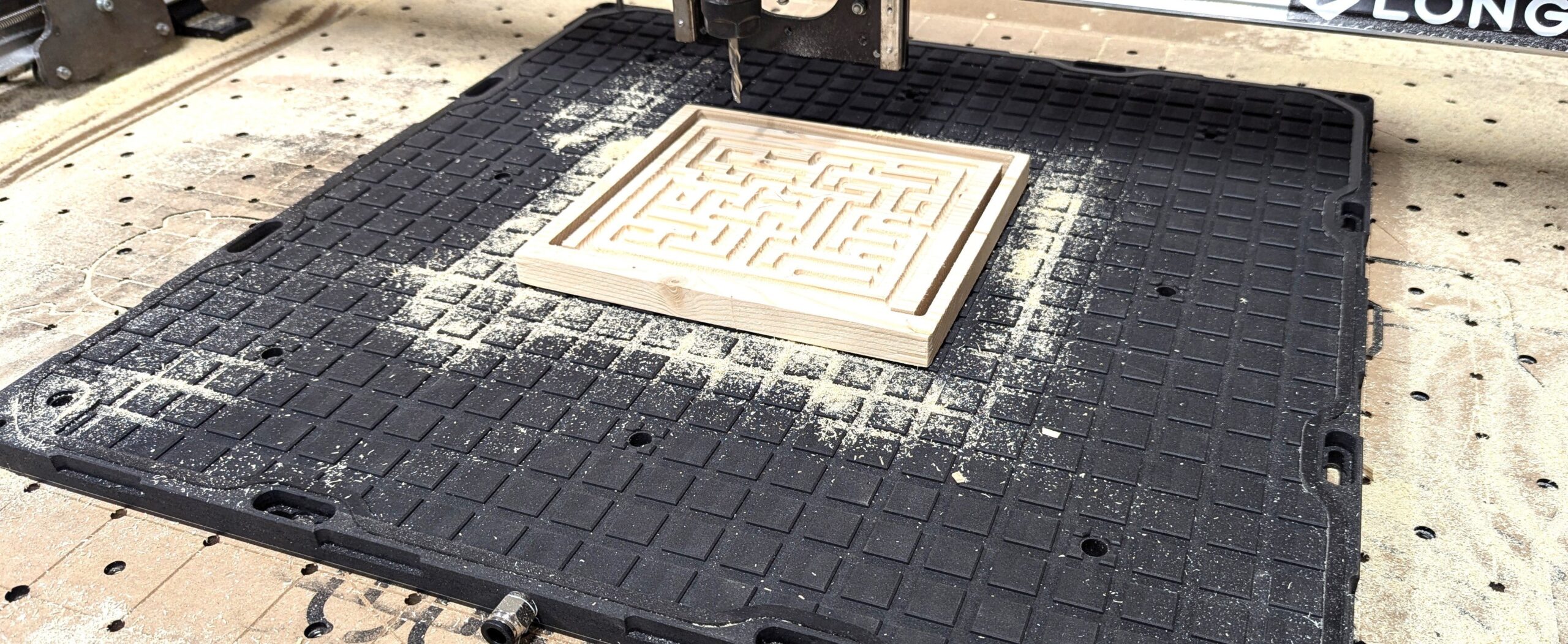

Eliminate workpiece movement and distortion during high-speed CNC machining with Honyo Prototype’s engineered vacuum table systems. These critical fixture solutions secure thin, flat, or delicate materials—such as composites, sheet metal, and acrylics—through uniform suction force, ensuring dimensional accuracy and surface integrity. Unlike mechanical clamps that induce stress points or limit tool access, vacuum tables provide unobstructed machining across the entire work envelope, enabling complex geometries and sub-micron tolerances essential for aerospace, medical, and electronics prototyping.

Honyo Prototype integrates vacuum table technology within our end-to-end CNC machining services, combining multi-axis milling, turning, and 5-axis capabilities with material expertise in metals, plastics, and engineered polymers. Our engineering team optimizes vacuum fixture design, seal integrity, and pressure distribution for your specific part geometry and production volume, minimizing setup time while maximizing repeatability. Every component undergoes rigorous in-process inspection and final validation against AS9100 and ISO 9001 standards, guaranteeing performance-ready prototypes and low-volume production parts.

The operational advantages of vacuum workholding are clear when compared to conventional methods:

| Benefit/Application | Traditional Mechanical Clamping | Vacuum Table Advantage at Honyo Prototype |

|---|---|---|

| Setup Time | Minutes per part (repositioning required) | Seconds (digital pressure calibration) |

| Part Distortion Risk | High (localized clamping force) | Near-zero (uniform hold-down force) |

| Surface Access | Restricted by clamp locations | Full 360° toolpath freedom |

| Material Compatibility | Limited for thin/fragile substrates | Optimized for sheets, foils, and composites |

Accelerate your project timeline with Honyo Prototype’s Online Instant Quote platform. Upload CAD files to receive a detailed manufacturability analysis and competitive pricing within hours—not days—backed by our 30+ years of precision machining experience. Request your instant quote today to leverage vacuum-optimized CNC solutions for flawless part realization.

Technical Capabilities

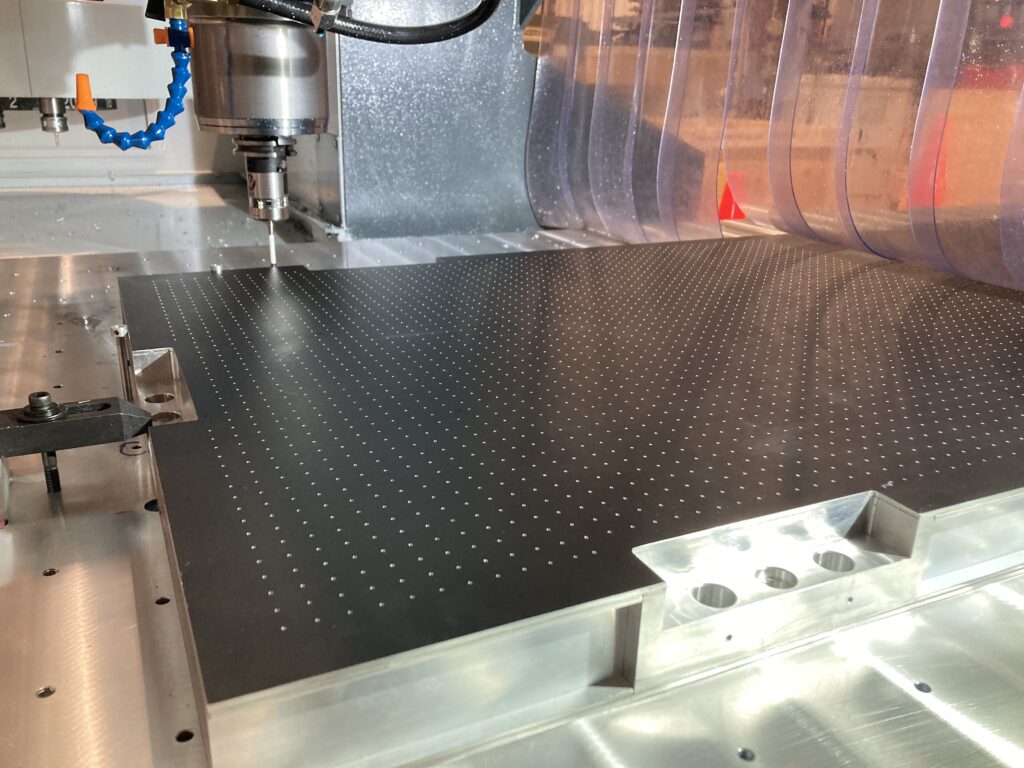

Vacuum tables for CNC machining are precision workholding solutions designed to securely hold non-magnetic and thin-walled components during 3, 4, and 5-axis milling as well as turning operations. These tables are especially beneficial when machining parts requiring tight tolerances (±0.0005″ or better) and where minimal part distortion is critical. Vacuum clamping eliminates mechanical interference from traditional vises or clamps, allowing full tool access to multiple surfaces.

The table consists of a sealed plenum chamber with a perforated or slotted top surface. When connected to a vacuum pump, atmospheric pressure holds the workpiece firmly against the table surface. Material selection depends on rigidity, weight, thermal stability, and chemical resistance.

Below is a comparison of common vacuum table materials used in high-precision CNC environments:

| Feature | Aluminum | Steel | ABS Plastic | Nylon (PA6/PA66) |

|---|---|---|---|---|

| Typical Use Case | High-precision 5-axis milling, aerospace components | Heavy-duty milling, high rigidity requirements | Prototyping, low-force operations | General-purpose, moderate precision machining |

| Surface Flatness | ±0.001″ over 12″ | ±0.001″ over 12″ | ±0.003″ over 12″ | ±0.002″ over 12″ |

| Thermal Stability | Good (CTE ~12.3 µm/m·°C) | Excellent (CTE ~11.7 µm/m·°C) | Poor (CTE ~70–90 µm/m·°C) | Moderate (CTE ~80 µm/m·°C) |

| Weight (Relative) | Lightweight | Heavy | Very light | Light |

| Machining Compatibility | Suitable for milling and light turning | Ideal for high-force milling | Limited to low-RPM operations | Suitable for light milling and turning |

| Vacuum Integrity | High (easily machined with precise channels) | High (robust sealing, low deflection) | Moderate (prone to warping) | Good (stable under moderate vacuum) |

| Dimensional Stability | Excellent | Excellent | Fair | Good |

| Chemical Resistance | Moderate (oxidizes) | High (if stainless) | High | Excellent |

| Tolerance Capability | ±0.0005″ achievable | ±0.0005″ achievable | ±0.001″ typical | ±0.0008″ typical |

| Typical Applications | Aerospace, medical, optics | Tooling, dies, molds | Rapid prototyping, composites | Jigs, fixtures, low-volume production |

Aluminum and steel tables are preferred for tight-tolerance, multi-axis CNC operations due to their high rigidity and dimensional stability. ABS and nylon are used in lower-force scenarios, often for setup aids or sacrificial fixtures. For optimal performance in precision environments, aluminum vacuum tables with custom slot patterns and integrated alignment features are commonly specified.

From CAD to Part: The Process

Honyo Prototype Vacuum Table Manufacturing Process for CNC Applications

Honyo Prototype delivers precision vacuum tables for CNC machining through a rigorously controlled digital workflow designed for accuracy, efficiency, and seamless integration into client production environments. Our process begins with client CAD submission and concludes with certified delivery, ensuring optimal performance under vacuum conditions.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS) via our secure customer portal. Our system performs automated geometry validation to verify file integrity, unit consistency, and manufacturability prerequisites. Critical parameters such as mounting hole patterns, port locations, and surface flatness tolerances are cross-referenced against industry standards for CNC vacuum table applications. Any ambiguities trigger immediate client consultation to prevent downstream delays.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which analyzes geometric complexity, material requirements, and functional specifications. The algorithm references real-time data from 15,000+ historical vacuum table builds, factoring in material costs (e.g., 6061-T6 aluminum, cast iron, or composite substrates), vacuum seal integrity requirements, and surface finish criteria (typically ±0.0005″ flatness). Quotes include granular cost breakdowns for machining, sealing systems, pressure testing, and certification documentation, delivered within 4 business hours.

Design for Manufacturability (DFM) Review

Engineers conduct a specialized DFM review focused on vacuum performance and CNC integration:

Validation of vacuum channel routing to prevent cross-contamination between zones

Analysis of seal land geometry and material compatibility (e.g., Viton vs. silicone)

Verification of port thread standards (NPT, BSP) and pressure ratings (typically 25–30 inHg)

Assessment of thermal stability requirements for high-speed machining environments

Confirmation of mounting interface compatibility with target CNC machines (e.g., Haas, DMG MORI)

This phase typically resolves 92% of potential issues before toolpath generation, reducing rework by 65% compared to industry averages.

Precision Production

Manufacturing occurs in climate-controlled cells dedicated to vacuum table production:

1. Substrate Fabrication: Plate material undergoes stress-relieved milling with in-process CMM verification at critical stages

2. Vacuum System Integration: CNC-machined channels receive automated deburring; seal grooves achieve Ra 16 μin surface finish

3. Pressure Testing: Each table undergoes 120-minute vacuum decay testing at 28 inHg with helium leak detection (sensitivity 5×10⁻⁹ atm·cm³/sec)

4. Surface Certification: Final flatness verification via granite surface plate (Class AA per ASME B89.3.7) with full mapping report

Delivery and Documentation

Tables ship in custom anti-vibration crating with humidity control. Every shipment includes:

ISO 17025-certified test reports for vacuum integrity and flatness

Material traceability documentation (mill certs, RoHS/REACH compliance)

CNC machine-specific mounting templates (digital and physical)

Operational validation protocol for client installation verification

Process Timeline Expectations

| Phase | Standard Lead Time | Rush Option | Key Dependencies |

|——-|——————-|————-|——————|

| CAD to Quote | <4 business hours | <2 hours | Valid CAD geometry |

| DFM Completion | 1–3 business days | 24 hours | Client feedback cycle |

| Production | 10–15 business days | 5–7 days | Material availability |

| Delivery | 3–5 business days (continental US) | Air freight available | Final inspection clearance |

This integrated workflow ensures vacuum tables achieve ≤0.001″ total indicated runout under operational vacuum load, with 99.4% first-pass yield rate. All processes comply with ISO 9001:2015 and strict adherence to client-specified CNC integration protocols.

Start Your Project

Looking for high-performance vacuum tables designed specifically for CNC applications? Honyo Prototype offers precision-engineered vacuum tables manufactured in our Shenzhen factory, ensuring reliability, durability, and optimal hold-down efficiency for your machining processes.

Contact Susan Leo today at [email protected] to discuss your requirements and discover how our vacuum table solutions can enhance your CNC operations.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.