Contents

Manufacturing Insight: Vacuum Pump Cnc Table

Precision Vacuum Table Manufacturing for Demanding CNC Applications

Honyo Prototype delivers mission-critical vacuum pump CNC tables engineered for uncompromising flatness, thermal stability, and repeatable holding force in high-precision machining environments. These specialized fixtures are fundamental to aerospace, semiconductor, and optical component production where even micron-level workpiece displacement can compromise part integrity. Our tables integrate seamlessly with multi-axis CNC systems, utilizing advanced channel geometries and proprietary sealing surfaces to maintain vacuum integrity under aggressive milling, grinding, or EDM operations.

Leveraging our ISO 9001-certified CNC machining capabilities—including 5-axis milling, high-speed aluminum alloy fabrication, and sub-micron tolerance grinding—Honyo transforms complex vacuum table designs into production-ready solutions. We machine all critical sealing surfaces to ≤0.0002″ (5µm) flatness across dimensions up to 48″ x 96″, utilizing stress-relieved 6061-T6 and 7075 aluminum alloys with anodized or hardcoat finishes for extended service life. Every table undergoes rigorous vacuum decay testing and CMM validation to ensure consistent performance in vacuum levels down to 10⁻³ Torr.

Accelerate your fixture procurement cycle with Honyo’s Online Instant Quote platform. Upload CAD files for vacuum table components—including plenums, manifold blocks, or custom sealing inserts—and receive manufacturability feedback with formal pricing in under 2 hours. Our system automatically evaluates geometric complexity, material utilization, and secondary process requirements to provide accurate, no-commitment quotations for prototypes through low-volume production runs. Streamline your workflow by visiting Honyo Prototype’s Online Instant Quote portal today.

Technical Capabilities

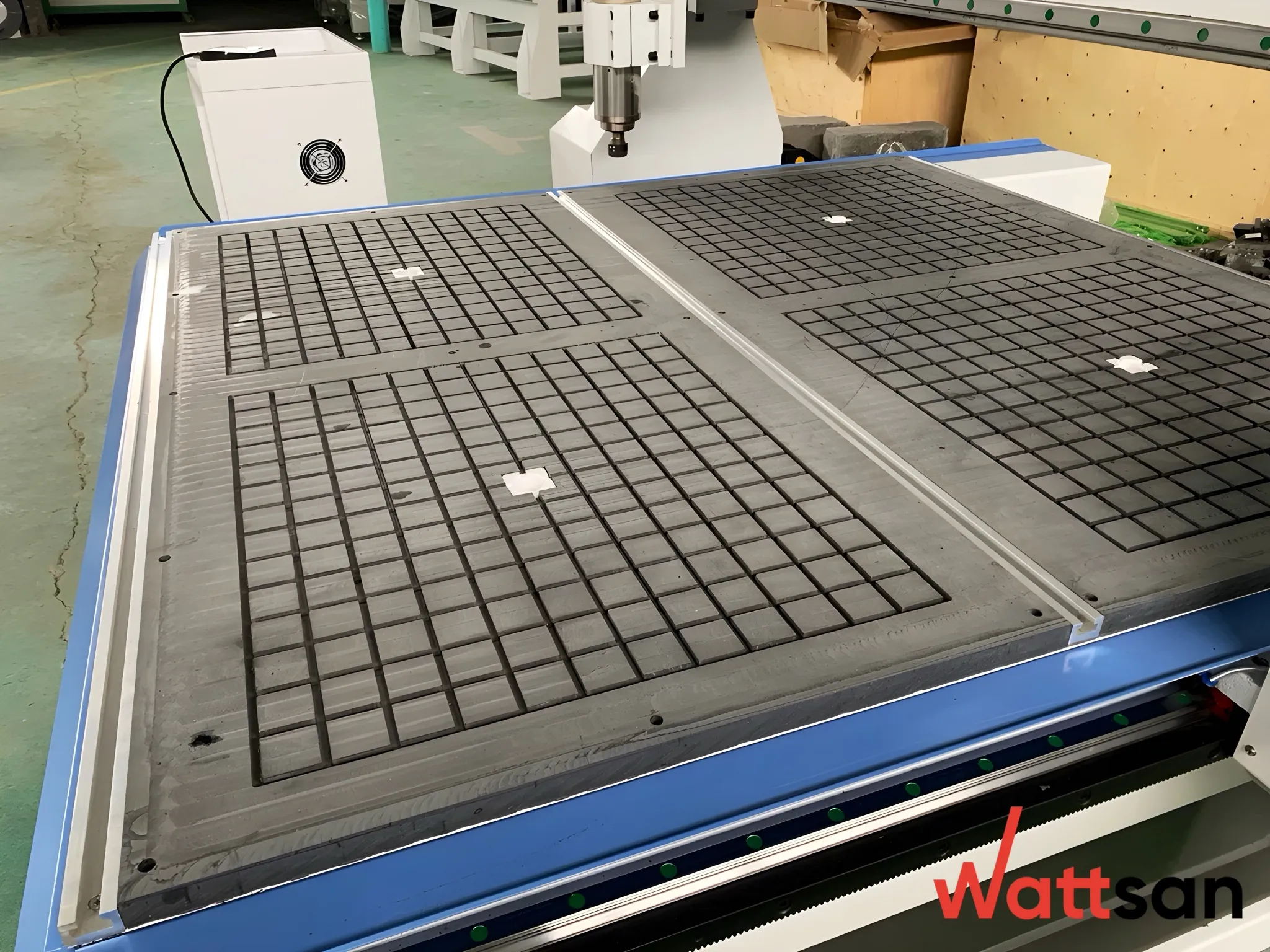

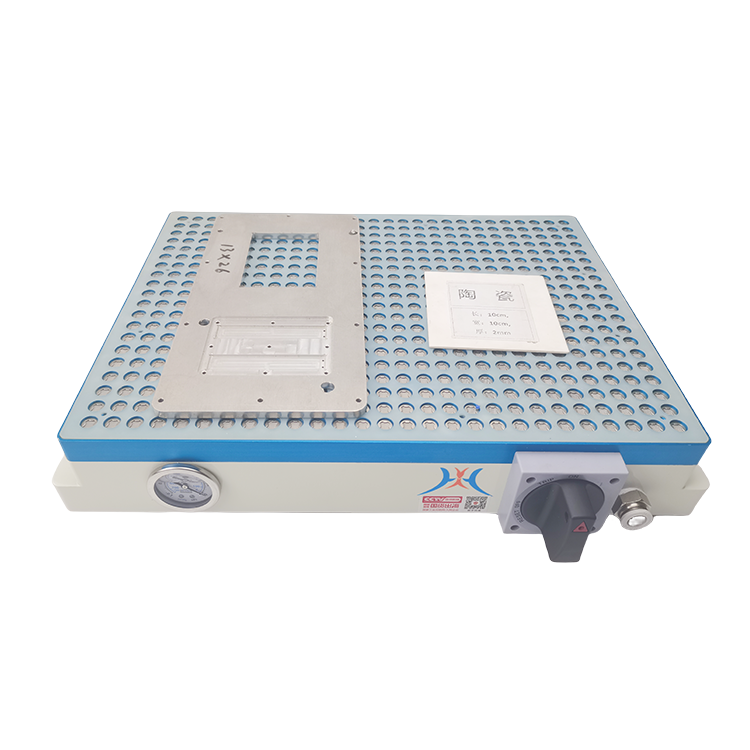

Vacuum pump CNC tables are specialized workholding solutions designed to securely hold flat or slightly contoured workpieces during high-precision machining operations. These tables are particularly effective in 3-axis, 4-axis, and 5-axis milling applications where consistent clamping force and unobstructed tool access are critical. They utilize a network of internal channels connected to a vacuum pump to generate suction across the table surface, minimizing part deformation and enabling tight tolerance machining.

The table is typically constructed from high-strength cast aluminum or steel for rigidity and thermal stability, with a precision-machined surface finish to ensure an effective seal. Sealing gaskets or sacrificial top plates (often made from ABS or nylon) may be used to isolate zones or protect the base table. These materials also allow for localized vacuum zones tailored to the workpiece footprint, improving efficiency and holding force.

Below is a summary of technical specifications relevant to vacuum pump CNC tables used in precision milling and turning applications:

| Parameter | Specification / Details |

|---|---|

| Table Material | Cast aluminum (e.g., 6061-T6) or hardened steel (e.g., 1045) for structural rigidity |

| Surface Finish | Ground or precision-milled to ≤ 0.001″ flatness tolerance over 12” x 12” area |

| Vacuum Source | External rotary vane or diaphragm vacuum pump (adjustable pressure: 15–28 inHg) |

| Holding Force | 12–20 psi average (dependent on surface seal and material thickness) |

| Port Pattern | Grid of Ø6–10 mm blind holes with internal channels; 1” to 2” spacing |

| Seal Materials | Nitrile rubber gaskets; optional sacrificial top layers in ABS or nylon |

| Compatible Machining Axes | 3-axis, 4-axis (indexing/continuous), 5-axis (full simultaneous) |

| Typical Workpiece Materials | Aluminum (6061, 7075), steel (1018, 4140), ABS, nylon (PA6, PA12) |

| Max Workpiece Thickness | 0.1” to 2” (dependent on vacuum penetration and material rigidity) |

| Tolerance Capability | ±0.0005” (12.7 µm) achievable with stable fixturing and thermal control |

| Applications | High-speed milling, precision contouring, thin-plate machining, prototype fabrication |

| Integration Compatibility | Designed for FANUC, Siemens, Heidenhain, and Mach4/3 control systems |

This configuration supports tight-tolerance machining by minimizing part movement and distortion, especially critical when working with thin or non-ferrous materials like aluminum and plastics such as ABS and nylon. The absence of mechanical clamps enhances toolpath accessibility in multi-axis operations, improving setup efficiency and repeatability.

From CAD to Part: The Process

Honyo Prototype delivers precision vacuum workholding solutions including CNC vacuum tables through a rigorously defined engineering-to-delivery workflow. Our process ensures technical feasibility, manufacturability, and on-time delivery for these critical workholding components which require exacting flatness tolerances and vacuum integrity.

Upload CAD

Clients initiate the process by uploading detailed 3D CAD models of the vacuum table assembly via our secure customer portal. We require STEP or native format files with all critical features including vacuum channel geometry, port locations, sealing surfaces, and material specifications. For vacuum tables, we specifically verify inclusion of gasket groove dimensions, vacuum port thread types, and surface finish annotations for the workholding plane.

AI-Powered Preliminary Quote

Our proprietary AI engine analyzes the CAD geometry against real-time machine capability databases, material costs, and historical production data. Within 2 hours, clients receive a technical quotation detailing material options (typically aluminum 6061-T6 or cast iron), vacuum performance metrics (expected clamping force per square inch), flatness tolerances achievable (typically ±0.0005″ over 12″ span), and a preliminary lead time. The AI flags potential issues such as insufficient wall thickness around vacuum channels or unmanufacturable undercuts.

Engineering-Driven DFM Analysis

All vacuum table projects undergo mandatory Design for Manufacturing review by our senior manufacturing engineering team. This phase focuses on vacuum-specific critical parameters:

| DFM Consideration | Vacuum Table Specific Requirement | Honyo Standard |

|---|---|---|

| Material Selection | Thermal stability during machining | 6061-T6 stress-relieved per AMS 4027 |

| Channel Geometry | Avoid sharp internal corners causing vacuum dead zones | Minimum 0.030″ radius on all channel intersections |

| Surface Flatness | Workholding plane critical for seal integrity | 0.0002″ per 6″ with precision ground finish |

| Port Configuration | Thread compatibility with client’s pump system | Standard NPT or metric threads with depth verification |

| Leak Testing | Hermetic seal validation | 10^-5 atm cc/sec helium leak test post-machining |

The engineering team collaborates with the client to resolve conflicts between design intent and manufacturing realities, providing annotated CAD markups and alternative solutions when necessary. This phase typically completes within 72 business hours.

Precision Production

Approved designs enter our climate-controlled production floor where vacuum tables undergo specialized processing:

Multi-axis CNC machining centers execute complex vacuum channel networks using tapered end mills to ensure consistent channel depth

In-process CMM verification at critical stages including post-roughing channel inspection and final flatness validation

Dedicated vacuum testing stations with calibrated flow meters verify suction distribution across the entire work surface

All sealing surfaces receive final precision grinding to achieve Ra 8 μin finish

Assembly includes installation of proprietary filter assemblies at vacuum ports to prevent chip ingress

Certified Delivery

Each vacuum table ships with comprehensive documentation including:

Final inspection report with flatness map and vacuum performance data

Material certification and heat treat documentation

Helium leak test certificate

Operational guidelines for maintenance and pump compatibility

Traceable serial number linked to production batch records

Typical delivery timelines range from 10-15 business days for standard aluminum vacuum tables after DFM approval. Expedited services with 72-hour machining slots are available for urgent requirements. All shipments include real-time logistics tracking with temperature and shock monitoring during transit to ensure dimensional stability.

Start Your Project

For high-performance vacuum pump CNC tables designed to meet precision manufacturing demands, contact Susan Leo at [email protected]. Our advanced solutions are engineered for reliability and efficiency, supporting a wide range of industrial applications.

Manufactured at our state-of-the-art facility in Shenzhen, we ensure strict quality control and fast production turnaround. Reach out today to discuss your project requirements and discover how our vacuum pump CNC tables can enhance your workflow.

Contact:

Susan Leo

Email: [email protected]

Factory Location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.