Guide Contents

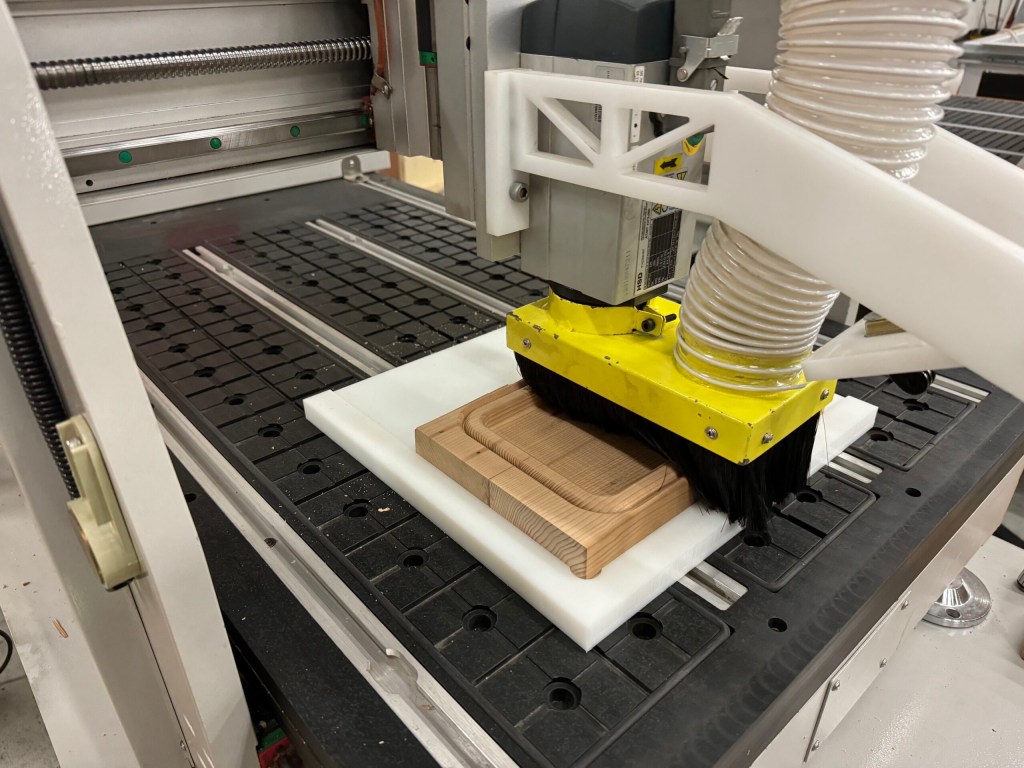

Project Insight: Vacuum Pump Cnc Table

Precision Meets Speed: The Critical Role of Vacuum Table CNC Machining in Product Development

In today’s hyper-competitive product development landscape, the difference between a viable prototype and a market-ready solution often hinges on precision and speed. Vacuum table CNC machining has become indispensable for hardware startups and engineers, providing the stability and flexibility required to produce complex, high-tolerance parts without compromising on turnaround time. At Honyo Prototype, we leverage this technology to transform your designs into reality—faster, smarter, and with unmatched accuracy.

Why Vacuum Table CNC is Essential for High-Precision Prototyping

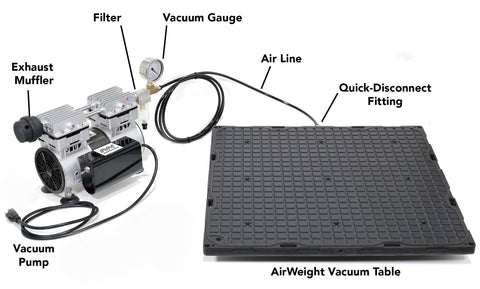

Zero-Vibration Stability: Industrial-grade vacuum systems eliminate part movement during high-speed machining, ensuring consistent surface finishes and tight tolerances (±0.01mm) critical for functional prototypes in medical, aerospace, and IoT applications.

Full Geometric Access: Unlike mechanical clamps that obstruct tool paths, vacuum tables secure parts without physical fixtures—enabling seamless 5-axis machining of intricate geometries in a single setup.

Material Preservation: Delicate materials like carbon fiber composites, thin-walled aluminum, or acrylics remain intact under uniform vacuum pressure—avoiding deformation that would compromise dimensional accuracy.

Honyo Prototype: Your End-to-End Digital Manufacturing Partner

Online Instant Quote: Upload your CAD file and receive an accurate, real-time quote within 60 seconds—no manual estimates, no delays. Our AI-driven platform instantly analyzes design complexity, material requirements, and tolerances for transparent pricing.

AI-Powered Process Optimization: Our proprietary algorithms automatically configure vacuum table setups and optimize toolpaths for maximum precision and efficiency. Every step is engineered to reduce lead times without sacrificing quality.

48-Hour Prototype Delivery: From design validation to production-ready parts, we accelerate your innovation cycle with industry-leading turnaround times. Get functional prototypes in days, not weeks—so you can iterate faster and launch sooner.

With Susan Leo’s visionary leadership, Honyo Prototype combines cutting-edge technology with human expertise to turn your concepts into reality. Partner with us to build what’s next—faster, smarter, and with uncompromising precision.

Honyo Capabilities & Technology

Precision CNC Machining for Vacuum Table Components

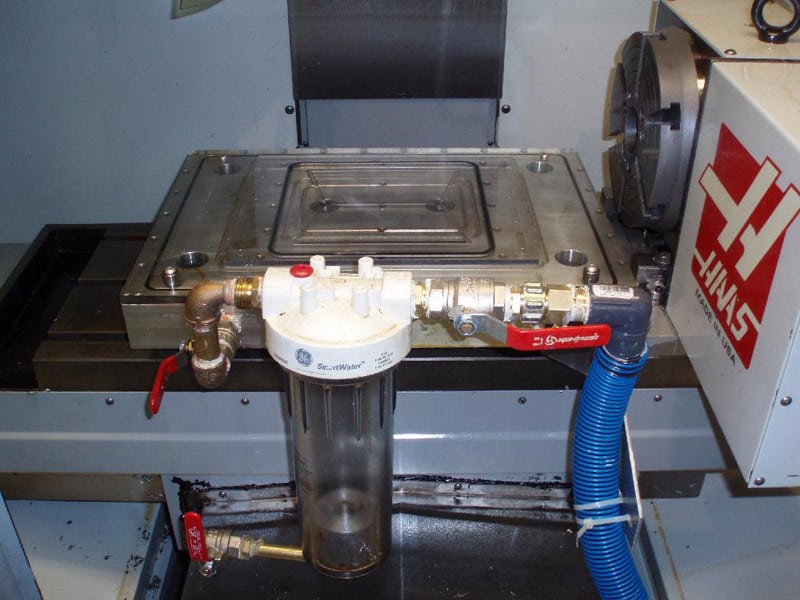

Advanced Multi-Axis Machining for Vacuum Integrity

3/4/5-axis precision machining for complex vacuum channel geometries, ensuring even pressure distribution and optimal airflow control.

Tight tolerances of +/-0.01mm guarantee perfect sealing surfaces, eliminating leaks and maximizing vacuum efficiency.

Surface finish optimization tailored for minimal air leakage, critical for high-performance vacuum systems.

Scalable Production from Prototype to Volume

Single-unit prototypes to 10,000+ production runs – seamlessly scale from proof-of-concept to mass production without compromising quality.

Rapid iteration support for hardware startups, enabling quick design refinements and functional testing.

Flexible scheduling to align with your project timeline, whether you need urgent prototypes or long-term production runs.

ISO-Certified Quality Assurance

ISO 9001 certified processes with full material traceability and compliance documentation for aerospace, medical, and industrial applications.

In-process and final inspection using CMM (Coordinate Measuring Machines) and optical metrology for zero-defect outcomes.

Rigorous QC protocols validated through statistical process control (SPC) to ensure consistency across every batch.

Smart Service Experience

AI-Powered Instant Quote: Get real-time pricing, manufacturability feedback, and design recommendations in seconds via our digital platform.

3-5 Day Prototype Turnaround: Accelerate time-to-market with industry-leading lead times for functional testing and validation.

Dedicated Engineering Support: Collaborate with our specialists to optimize designs for vacuum integrity, cost efficiency, and performance.

“Precision isn’t just a metric – it’s the foundation of reliable vacuum systems. At Honyo, we engineer components that perform under pressure, every time.”

– Susan Leo, Founder

Materials & Surface Finishes

Precision Material Selection for Vacuum Pump CNC Tables

Optimized Material Options

Selecting the right material ensures rigidity, thermal stability, and vacuum seal integrity—critical for precision CNC table performance. Honyo Prototype’s material expertise ensures your design meets functional and cost targets:

Aluminum 6061:

Best for: General-purpose vacuum tables requiring lightweight, corrosion-resistant, and easily machinable properties.

Why choose it? Balances strength, machinability, and cost. Anodizing enhances surface durability and vacuum seal consistency.

Honyo Advantage: ±0.01mm flatness tolerance ensures perfect sealing across the entire table surface.

Aluminum 7075:

Best for: High-load or aerospace-grade applications where strength-to-weight ratio is critical.

Why choose it? Superior tensile strength vs. 6061, though requires advanced machining expertise. Ideal for industrial-grade vacuum tables.

Honyo Advantage: Precision 5-axis machining minimizes distortion during high-stress operations.

Stainless Steel 304/316:

Best for: Harsh environments (e.g., chemical exposure, medical, or outdoor use).

Why choose it? Exceptional corrosion resistance and thermal stability. 316 adds molybdenum for saltwater/acid resistance.

Honyo Advantage: Passivation treatment eliminates surface contaminants to maintain vacuum integrity.

Brass:

Best for: Specialized components requiring electrical conductivity or non-magnetic properties.

Why choose it? Ideal for custom vacuum manifold parts or sensor housings—though not typically used for the main table structure.

PEEK (Polyether Ether Ketone):

Best for: Extreme temperature or chemical exposure scenarios (e.g., semiconductor manufacturing).

Why choose it? High heat resistance and low outgassing—perfect for cleanroom or vacuum-chamber applications.

Honyo Advantage: Precision CNC machining of high-performance polymers ensures dimensional stability at ±0.01mm.

Surface Finishes for Maximum Performance

Surface quality directly impacts vacuum seal reliability and longevity. Honyo’s finishes are engineered for zero leakage and long-term durability:

Anodizing (Type II/III):

Ideal for: Aluminum tables in industrial or outdoor settings.

Why it works: Creates a hard, non-porous surface that resists wear and corrosion while maintaining vacuum seal integrity. Matte or colored options available.

Mirror Polishing:

Ideal for: High-precision applications (e.g., semiconductor, medical devices).

Why it works: Eliminates micro-scratches to ensure flawless sealing—critical for vacuum tables handling delicate components.

Passivation (Stainless Steel):

Ideal for: Corrosion-prone environments.

Why it works: Removes free iron from the surface, enhancing rust resistance without altering dimensions or adding coatings.

Powder Coating:

Not recommended for vacuum sealing surfaces—but ideal for structural frames needing color or extra protection.

How to Choose: Key Considerations

Partner with Honyo’s AI-driven platform to eliminate guesswork and optimize your design:

Application Environment:

Harsh chemicals? → Stainless Steel 316 or PEEK.

General manufacturing? → Aluminum 6061 with anodizing.

Load & Precision Needs:

High-stress loads? → Aluminum 7075 or steel.

Ultra-precision prototypes? → Mirror-polished aluminum for ±0.01mm flatness.

Cost vs. Performance:

Aluminum 6061 delivers the best ROI for 90% of vacuum table applications—combine with Honyo’s fast-turnaround machining to accelerate time-to-market.

Vacuum Seal Integrity:

Avoid porous finishes (e.g., standard paint). Opt for anodized, polished, or passivated surfaces to ensure leak-free performance.

Why Partner with Honyo Prototype?

We turn material complexity into simplicity with innovative, end-to-end solutions:

Online Instant Quote:

Get real-time pricing and material recommendations in seconds—no back-and-forth emails. Our AI platform analyzes your specs to suggest the optimal material/finish combo.

AI-Powered Design Support:

Our engineers use simulation tools to validate vacuum seal performance before machining—reducing prototyping cycles by 40%.

Fast Turnaround:

3–5 days for prototypes, 7–10 days for production runs. With ±0.01mm tolerances and ISO-certified processes, we deliver precision parts when you need them.

“At Honyo, we don’t just machine parts—we engineer solutions. Whether you’re building a DIY vacuum table or a high-end industrial system, our expertise ensures every detail meets your performance goals.”

— Susan Leo, Founder

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we’ve redefined precision manufacturing with a seamless, AI-driven workflow that transforms your design into high-accuracy parts—faster and more transparent than ever before. Here’s how:

1. Upload CAD File

Drag-and-drop your design files (STEP, STL, IGES, etc.) into our intuitive platform. No technical expertise required—our system handles the rest.

2. Get Instant Quote (AI Engine)

Receive real-time pricing within seconds. Our AI-powered platform analyzes complexity, materials, and tolerances for instant, transparent quotes—no hidden fees or delays.

3. DFM Analysis

Automated Design for Manufacturability checks identify potential issues and suggest optimizations. Receive actionable insights to refine your design for cost, speed, and precision before production begins.

4. Production & Delivery

Precision CNC machining with integrated vacuum table fixturing ensures ±0.01mm tolerances for complex geometries. Track your order in real-time with delivery in as little as 3 days—engineered for speed and reliability.

Start Your Project with Honyo

Start Your Project with Honyo: Precision CNC Machining Engineered for Vacuum Table Applications

Precision Machining, Guaranteed

3/4/5-Axis CNC Machining: Handle complex geometries and intricate details with seamless multi-axis precision.

±0.01mm Tolerances: Vacuum table fixturing eliminates vibration and movement, ensuring unmatched stability for critical aerospace, medical, and industrial components.

Functional Prototypes to End-Use Parts: From concept to production-ready parts—designed for real-world performance.

Streamlined Process, Faster Results

AI-Powered Instant Quote: Get accurate pricing in minutes via our digital platform—no lengthy back-and-forth.

3–5 Day Prototype Turnaround: Accelerate your timeline with rapid prototyping; 1–2 weeks for production runs.

Real-Time Project Tracking: Monitor progress from design to delivery with transparent, cloud-based collaboration tools.

Partner with Susan Leo & the Honyo Team

Direct Facility Access: Collaborate in person at our Shenzhen/Dongguan manufacturing hubs for design reviews and quality validation.

Expert-Led Support: Leverage 15+ years of precision machining expertise from our founder and engineering team.

Ready to Begin?

Email: [email protected]

Phone: +86 139 2843 8620

Let’s build the future—precision-engineered, on your timeline.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.