Contents

Manufacturing Insight: Uv Resistant Plastics

Precision UV Resistant Plastic Components Through Advanced CNC Machining

Exposure to ultraviolet radiation presents a significant challenge for plastic components in outdoor, aerospace, automotive, and medical applications, often leading to embrittlement, discoloration, and critical dimensional instability. At Honyo Prototype, we specialize in machining high-performance UV resistant plastics—including ASA, acrylic (PMMA), polycarbonate blends, and specialty polyolefins—engineered to withstand prolonged solar exposure without compromising structural integrity or functional precision. Our CNC machining processes are rigorously optimized for these sensitive materials, ensuring exacting tolerances, superior surface finishes, and long-term reliability even under harsh environmental conditions.

Unlike injection molding or 3D printing, CNC machining eliminates internal stresses and material inconsistencies inherent in other fabrication methods, making it the preferred solution for mission-critical UV-exposed prototypes and low-volume production parts. Our multi-axis milling and turning capabilities maintain micron-level accuracy across complex geometries, while our material science expertise ensures optimal feed rates, tool selection, and thermal management to prevent UV stabilizer degradation during fabrication. This results in components that retain mechanical properties, optical clarity, and aesthetic consistency throughout their operational lifespan.

Accelerate your development cycle with Honyo Prototype’s Online Instant Quote platform. Upload your CAD file to receive a detailed manufacturability analysis and competitive pricing for UV resistant plastic machining within hours—not days. Our engineering team collaborates directly with clients to select the ideal material grade and machining strategy, ensuring your design meets stringent environmental durability requirements from prototype to production. Partner with us for technically validated solutions where performance under sunlight is non-negotiable.

Technical Capabilities

UV resistant plastics are engineered to withstand prolonged exposure to ultraviolet radiation without significant degradation in mechanical properties, color stability, or surface finish. These materials are critical in outdoor applications where long-term environmental exposure is expected. When machining UV resistant plastics—especially in high-precision 3-axis, 4-axis, and 5-axis milling or turning operations—material stability, thermal behavior, and dimensional consistency are key considerations. Tight tolerance requirements (±0.005 mm to ±0.025 mm typical) demand optimized toolpaths, low residual stress materials, and appropriate fixturing.

While metals like aluminum and steel are inherently UV stable, they are not plastics. However, they are often used in conjunction with UV resistant plastics for hybrid assemblies or tooling. Below is a comparison of relevant materials in the context of precision machining:

| Material | UV Resistance | Machinability (Milling/Turning) | Typical Tolerance (± mm) | Thermal Stability | Notes for Precision Machining |

|---|---|---|---|---|---|

| ABS (UV stabilized) | Moderate to Good | Excellent – low tool wear, smooth finish | 0.025 – 0.050 | Moderate – prone to creep | Ideal for prototypes; use sharp tools to minimize burring; avoid excessive heat buildup |

| Nylon (UV stabilized, e.g., Nylon 6 or 12 with additives) | Good | Good – slightly abrasive, requires sharp carbide tools | 0.012 – 0.025 | Low – hygroscopic and thermally expansive | Pre-dry material before machining; allow for post-machining dimensional stabilization |

| Polycarbonate (UV coated/stabilized) | Very Good | Fair – prone to stress cracking | 0.025 | Moderate – high CTE | Use non-aromatic coolants; minimize clamping pressure to avoid micro-cracking |

| Acrylic (PMMA, UV resistant grade) | Excellent | Very Good – brittle, chip control critical | 0.012 – 0.025 | Low – sensitive to thermal shock | High-speed machining with polished tools recommended; avoid vibration |

| Aluminum (e.g., 6061-T6, 7075-T6) | Excellent (inorganic) | Excellent – high precision achievable | 0.005 – 0.012 | Very High | Often used for molds or structural components; compatible with high-speed 5-axis milling |

| Steel (e.g., 4140, 17-4 PH) | Excellent (inorganic) | Good to Very Good – higher tool wear | 0.005 – 0.025 | Very High | Used in tooling or high-strength applications; requires rigid setups and proper cooling |

Note: For UV resistant plastic components requiring tight tolerances, post-machining environmental stabilization (temperature and humidity conditioning) is often necessary—especially for hygroscopic materials like nylon. In multi-axis operations, tool engagement and thermal management are critical to maintain dimensional accuracy and surface quality.

From CAD to Part: The Process

Honyo Prototype UV Resistant Plastics Manufacturing Process

Honyo Prototype delivers precision-engineered UV resistant plastic components through a rigorously controlled workflow designed to ensure material integrity and performance under prolonged solar exposure. Our process begins with CAD file submission and culminates in certified delivery, integrating advanced material science with manufacturing expertise.

Upload CAD

Clients initiate the process by uploading detailed 3D CAD models via our secure portal. For UV resistant applications, we specifically require material specifications or environmental exposure conditions (e.g., ISO 4892-2 weathering requirements, outdoor marine use). This enables our system to pre-qualify material options such as ASA, PMMA, or UV-stabilized polycarbonate grades. Incomplete environmental data triggers an automated request for clarification to prevent downstream mismatches.

AI Quote Generation

Our proprietary AI engine analyzes the CAD geometry, material requirements, and UV resistance criteria against a database of 200+ validated polymer formulations. The algorithm calculates part complexity, identifies high-risk features for UV degradation (e.g., thin walls <0.8mm, sharp corners), and cross-references real-time resin pricing from certified suppliers like SABIC and Covestro. Quotes include material lot traceability and UV stability test data, with human engineering oversight applied to all submissions exceeding 50,000 lux exposure thresholds. Typical turnaround is under 90 minutes.

DFM Analysis

Design for Manufacturability (DFM) is where UV performance is critically validated. Our engineers conduct a dual-phase review:

First, structural analysis checks wall uniformity, rib design, and draft angles to prevent stress concentrators that accelerate UV-induced cracking.

Second, material-specific adjustments are implemented, such as increasing wall thickness by 15% for transparent PMMA parts exceeding 2mm depth to maintain optical clarity after 5,000-hour QUV testing. Clients receive a DFM report highlighting UV risk mitigations, including recommended stabilizer packages (e.g., HALS additives at 0.3–0.5% concentration) and secondary operations like plasma coating for enhanced resistance.

Production Execution

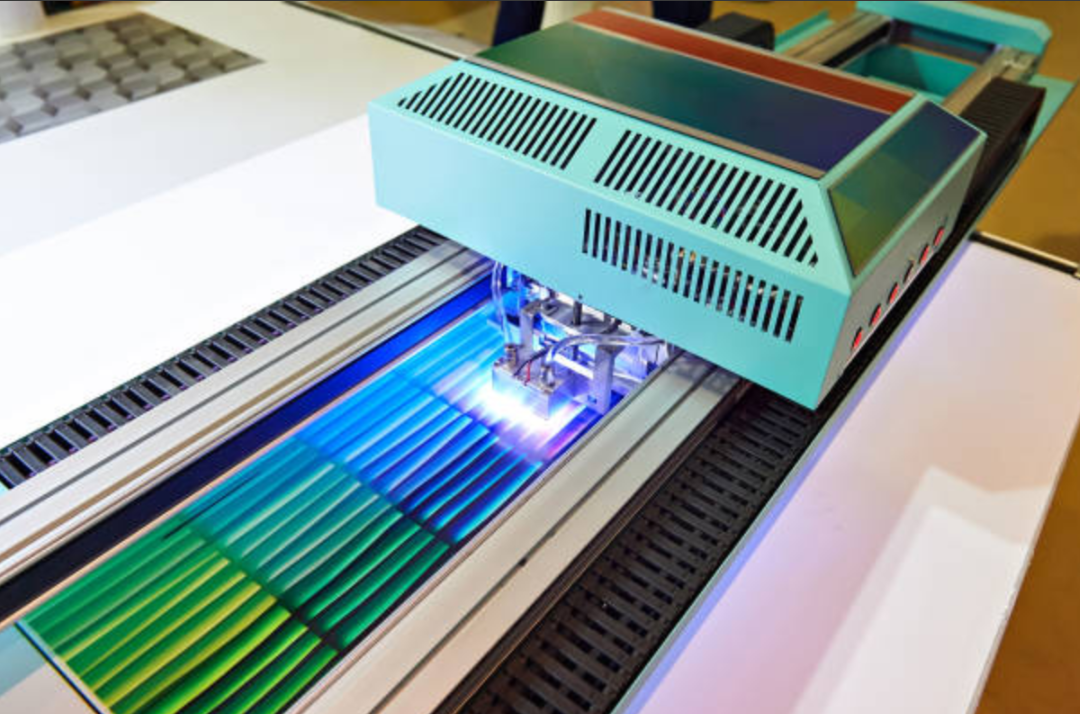

UV resistant production follows strict protocols:

Material drying occurs at 80°C for 4+ hours in desiccant dryers to prevent hydrolysis that compromises UV stabilizers. Injection molding uses nitrogen-purged barrels to minimize thermal oxidation, with melt temperatures controlled within ±5°C of resin specifications. In-process validation includes real-time FTIR spectroscopy to confirm stabilizer distribution homogeneity. All parts undergo accelerated weathering per ASTM G154 within 24 hours of molding, with spectral irradiance logs documented for client review. Critical dimensions are verified via CMM before secondary operations like metallization or bonding.

Delivery and Certification

Final parts ship in UV-blocking opaque containers with humidity indicators. Each shipment includes:

Material Certificates with lot-specific UV resistance data (e.g., ΔE color shift <2.0 after 3,000 hours)

Weathering test reports against ISO 4892-3 or client-specified cycles

Traceability documentation linking to resin manufacturer’s stabilization data

Standard delivery is 7–10 days post-DFM approval, with expedited options for time-sensitive outdoor applications. All UV resistant components carry Honyo’s 24-month performance guarantee against premature degradation under specified environmental conditions.

Material Performance Reference

| Material | Typical UV Resistance (QUV-B, 60°C) | Max Continuous Outdoor Use | Key Applications |

|———-|———————————–|—————————-|—————–|

| ASA | 3,000–5,000 hours | 5–7 years | Automotive trim, outdoor enclosures |

| UV-PC | 1,500–2,500 hours | 3–5 years | Lighting lenses, medical housings |

| PMMA | 8,000–10,000 hours | 10+ years | Signage, solar panel covers |

| PBT+UV | 2,000–3,000 hours | 4–6 years | Electrical connectors, agricultural fittings |

This integrated approach ensures UV resistant plastics meet stringent functional and longevity requirements while maintaining cost efficiency. We collaborate with clients during DFM to optimize designs for both manufacturability and environmental resilience, reducing total project risk.

Start Your Project

Looking for high-performance UV resistant plastics for your next project? Honyo Prototype offers durable, precision-engineered plastic solutions designed to withstand prolonged exposure to sunlight and harsh environmental conditions. Ideal for outdoor applications in automotive, aerospace, consumer electronics, and industrial equipment.

Our manufacturing facility in Shenzhen ensures fast turnaround, strict quality control, and cost-effective production for prototypes and low-volume runs.

Contact Susan Leo today at [email protected] to discuss your UV resistant material requirements and get expert guidance on the best polymer selection for your application.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.