Contents

Manufacturing Insight: Uv Blocking Plastic Sheet

Honyo Prototype delivers precision-engineered solutions for demanding industrial applications, including critical protection against ultraviolet radiation. While we specialize exclusively in sheet metal fabrication—not plastic sheet production—our expertise directly supports UV-sensitive systems requiring robust metal enclosures. Many clients integrate UV-blocking plastic components into equipment housings where our fabricated aluminum, stainless steel, or coated carbon steel enclosures provide essential structural integrity, EMI shielding, and environmental sealing. This metal-plastic synergy ensures complete protection for optics, medical devices, and outdoor electronics exposed to solar degradation.

Our end-to-end sheet metal capabilities cover laser cutting, CNC bending, welding, and finishing to exact specifications, enabling seamless integration with UV-filtering materials. Whether you require custom chassis, protective shrouds, or precision frames for UV-critical assemblies, Honyo ensures dimensional accuracy and material compatibility. Accelerate your project timeline with our Online Instant Quote system—submit CAD files or technical drawings to receive detailed manufacturing feedback and pricing within minutes, eliminating traditional quotation delays. Partner with us to transform UV protection requirements into field-ready metal solutions backed by rigorous quality control.

Technical Capabilities

UV Blocking Plastic Sheet – Technical Specifications for Laser Cutting, Bending, and Welding

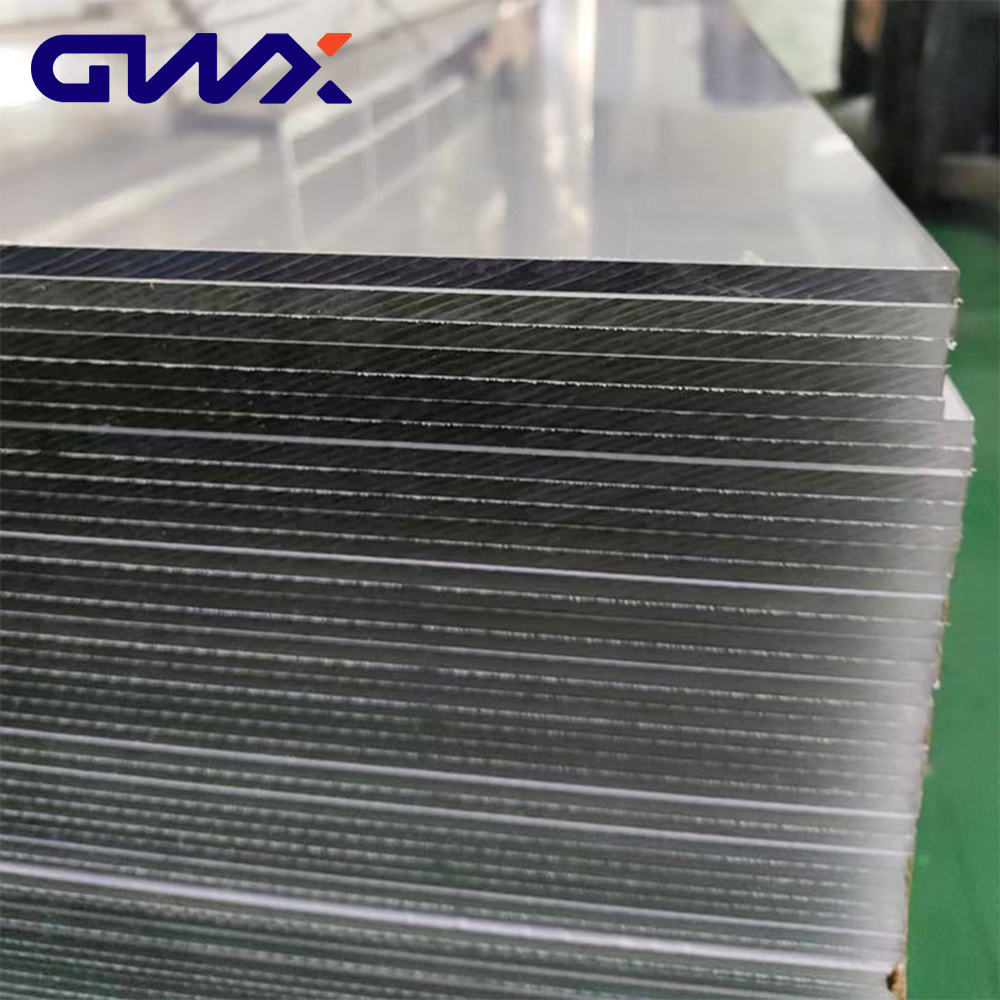

The following table outlines the technical characteristics and compatibility of UV blocking plastic sheets when processed using laser cutting, bending, and welding techniques. For comparison, common alternative materials—aluminum, steel, ABS, and nylon—are also included. UV blocking plastic sheets are typically manufactured from modified acrylic (PMMA), polycarbonate (PC), or PET with UV stabilizers, designed to absorb or reflect ultraviolet radiation while maintaining optical clarity and mechanical integrity.

| Material | Form / Type | Laser Cutting Compatibility | Bending Characteristics | Welding Method & Compatibility | Thermal Resistance (°C) | Optical Clarity | Notes |

|---|---|---|---|---|---|---|---|

| UV Blocking Plastic (PMMA based) | 1–10 mm sheet, optically clear with UV inhibitor | Excellent – clean cuts with CO₂ lasers; minimal charring | Good – can be cold or heat bent with proper tooling; springback negligible | Not weldable via traditional methods; solvent or adhesive bonding recommended | 80–90 | High | Prone to cracking under high stress; sensitive to certain solvents |

| UV Blocking Plastic (PC based) | 1–12 mm sheet, high impact with UV protection | Good – CO₂ laser cutting possible; requires controlled settings to minimize melting | Excellent – high ductility allows tight-radius bending with heat | Limited – can be ultrasonically or vibration welded; adhesive bonding preferred | 115–135 | High (initially), may yellow over time without UV layer | Higher cost; excellent impact resistance |

| Aluminum (e.g., 5052, 6061) | 0.5–6 mm sheet | Excellent – fiber lasers effective; high reflectivity requires protective measures | Excellent – high formability, low springback, CNC press braking common | Excellent – TIG, MIG, or laser welding suitable | 400–600 | Opaque | High thermal conductivity; not applicable for transparent UV shielding |

| Steel (e.g., mild steel, 304 SS) | 0.8–10 mm sheet | Good – fiber lasers standard; slower than aluminum | Moderate – requires high force; springback must be compensated | Excellent – MIG, TIG, spot welding standard | 400–800 (varies by alloy) | Opaque | Prone to oxidation; heavier than plastics and aluminum |

| ABS (UV stabilized) | 1–10 mm sheet | Good – CO₂ laser cuts cleanly; slight edge melting possible | Good – thermoforming and heat bending effective | Good – ultrasonic, hot plate, or solvent welding | 80–105 | Low to medium (translucent options) | Susceptible to UV degradation unless stabilized; lower rigidity than PC |

| Nylon (e.g., PA6, PA66) | 2–15 mm sheet | Poor – high laser absorption causes burning; not recommended | Moderate – requires preheating; prone to warping | Good – hot gas or ultrasonic welding effective | 150–180 | Low (semi-opaque) | High moisture absorption; excellent wear resistance |

Notes on UV Blocking Plastic Processing:

Laser Cutting: CO₂ lasers (wavelength ~10.6 μm) are ideal for UV-stabilized plastics due to high absorption. Parameters must be optimized to avoid edge melting (especially in polycarbonate).

Bending: Heat bending is typically performed using strip heaters or oven-based systems. UV blocking sheets retain formability similar to their base resin but may require controlled cooling to prevent stress cracking.

Welding: Traditional thermal welding (e.g., hot plate) is feasible for thick UV-stabilized sheets. However, most applications use adhesive bonding (e.g., acrylic-compatible structural adhesives) to maintain UV seal integrity and optical performance.

UV blocking plastic sheets are best suited for enclosures, protective glazing, and outdoor displays where optical performance and UV protection are critical. Material selection should balance process compatibility, environmental exposure, and mechanical demands.

From CAD to Part: The Process

Honyo Prototype UV Blocking Plastic Sheet Manufacturing Process

Our end-to-end workflow for UV blocking plastic sheet production begins with precise digital input and concludes with validated delivery, ensuring optimal performance for applications requiring solar radiation resistance. The process integrates advanced automation with expert engineering oversight to mitigate risks like photodegradation and optical distortion.

Upload CAD

Clients submit detailed CAD files specifying critical parameters: sheet dimensions, UV cutoff wavelength (e.g., 380nm blocking), optical clarity requirements, and substrate material (e.g., PMMA, PC, or specialty copolymers). Our secure portal validates file integrity and auto-extracts geometric data, tolerances, and layer specifications. For UV-sensitive applications, we explicitly flag requirements for UV stabilizer concentration and spectral transmission data in the submission metadata.

AI Quote Generation

Proprietary AI analyzes the CAD geometry, material specifications, and UV performance criteria against live databases of resin supplier data, machine capabilities, and historical production metrics. The system generates a detailed quote within 2 business hours, including: material cost breakdown (accounting for UV additive premiums), processing constraints (e.g., maximum sheet size per extrusion line), and spectral validation testing fees. Critical UV-specific variables like transmission curves per ISO 9050 are pre-validated against material options.

DFM Analysis

Senior engineers conduct a formal Design for Manufacturability review focused on UV performance integrity. Key checks include: verifying uniform additive dispersion feasibility, assessing thermal stability during processing to prevent stabilizer degradation, confirming edge sealing methods to inhibit UV ingress at joints, and validating optical distortion risks under accelerated aging simulations. Clients receive a formal DFM report with actionable recommendations—such as adjusting wall thickness to maintain UV cutoff thresholds—before tooling commencement.

Production

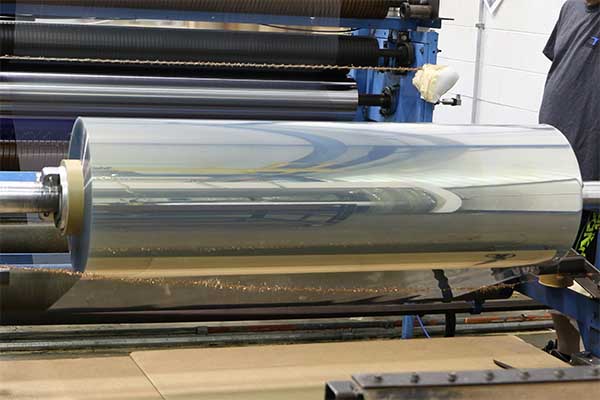

Manufacturing occurs in climate-controlled cleanrooms with real-time process monitoring. UV blocking sheets undergo: precision extrusion with proprietary additive masterbatches, inline spectrophotometric validation at 10nm intervals (250–800nm range), and automated edge polishing to eliminate microfractures that compromise UV resistance. Every batch includes third-party certified test coupons per ASTM D1003 and ISO 489, with full traceability to raw material lot numbers.

Delivery

Finished sheets are packaged in UV-opaque, humidity-controlled containers with desiccants. Delivery includes: the product, a material test report showing spectral transmittance graphs, batch-specific UV degradation curves from QUV accelerated testing, and a certificate of conformance. Standard lead time is 12 business days from DFM approval; expedited options are available.

Delivery Timeline Summary

| Stage | Standard Timeline | Expedited Timeline |

|—————————|——————-|——————–|

| CAD to Quote | ≤2 business days | ≤4 business hours |

| DFM Approval | ≤3 business days | ≤1 business day |

| Production | 7 business days | 4 business days |

| Validation & Packaging | 2 business days | 1 business day |

| Total | 12 business days | 6 business days |

This integrated approach ensures UV blocking sheets consistently achieve >99% UVA/UVB rejection while maintaining mechanical and optical properties per client specifications. All process stages adhere to ISO 9001:2015 protocols with full digital traceability.

Start Your Project

Looking for high-performance UV blocking plastic sheets for your next project? Ensure superior protection against ultraviolet radiation with precision-engineered sheets manufactured at our Shenzhen facility. Trusted for optical clarity, durability, and consistent UV filtration.

Contact Susan Leo today at [email protected] to request samples, technical specifications, or custom quoting. Let Honyo Prototype deliver reliable material solutions tailored to your application needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.