Introduction: Navigating the Global Market for used woodworking cnc

In today’s competitive woodworking industry, sourcing used woodworking CNC machines presents both opportunities and challenges for international B2B buyers. As manufacturers from Africa, South America, the Middle East, and Europe seek to enhance productivity while managing costs, the need for reliable and efficient CNC equipment becomes paramount. This guide offers a comprehensive overview of the used woodworking CNC market, addressing the complexities of sourcing, evaluating machine types, understanding their applications, and navigating supplier vetting processes.

With a focus on practical insights, this resource will delve into the various types of CNC routers and their specific applications in woodworking, from cabinetry to intricate furniture design. It will also outline crucial factors affecting pricing, helping buyers make informed financial decisions. By equipping buyers with actionable knowledge about machine specifications, maintenance considerations, and market trends, this guide empowers stakeholders to optimize their purchasing strategies.

Whether you are a small business owner in Germany looking to expand your production capabilities or a large manufacturer in Brazil seeking cost-effective solutions, this guide is tailored to meet your needs. It highlights best practices for sourcing used woodworking CNC machines, ensuring that you can confidently navigate the global market and secure the right equipment for your operational requirements.

Understanding used woodworking cnc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Routers | Computer-controlled, high precision cutting, often with ATC (Automatic Tool Change) | Cabinetry, furniture making, signage | Pros: High precision, versatile. Cons: Initial investment can be high. |

| CNC Lathes | Rotating workpiece, ideal for cylindrical shapes and details | Spindle turning, furniture legs, wooden bowls | Pros: Excellent for round shapes. Cons: Limited to cylindrical work. |

| CNC Machining Centers | Multi-axis capabilities, complex part production, often includes tool changers | Aerospace, automotive components | Pros: Highly versatile, can handle complex shapes. Cons: Requires skilled operators. |

| CNC Plasma Cutters | Utilizes plasma to cut through metal and other materials | Metal fabrication, custom signage | Pros: Fast cutting speed, suitable for thick materials. Cons: Limited to conductive materials. |

| CNC Laser Cutters | Uses laser technology for precision cutting and engraving | Detailed artwork, signage, intricate designs | Pros: High precision, minimal material wastage. Cons: Slower cutting speed for thicker materials. |

What Are the Key Characteristics of CNC Routers in Woodworking?

CNC routers are versatile machines known for their precision and ability to execute complex designs. They are widely used in cabinetry and furniture making, where intricate shapes and detailed cuts are essential. When considering a CNC router, buyers should evaluate the machine’s specifications, such as spindle power and table size, to ensure it meets their production needs. Additionally, the availability of features like automatic tool changers can significantly enhance productivity.

How Do CNC Lathes Serve the Woodworking Industry?

CNC lathes are specialized for turning operations, making them ideal for producing cylindrical wooden components like furniture legs and decorative pieces. These machines rotate the workpiece against a stationary cutting tool, allowing for high accuracy and smooth finishes. Buyers should consider the lathe’s maximum diameter and length capabilities, as well as its spindle speed, to match their production requirements. While CNC lathes are excellent for specific applications, they may not be suitable for flat or intricate designs.

What Advantages Do CNC Machining Centers Offer for Complex Part Production?

CNC machining centers are advanced machines capable of performing multiple operations, including milling, drilling, and tapping, all within a single setup. This versatility makes them invaluable in industries such as aerospace and automotive, where precision and complexity are paramount. When purchasing, buyers should assess the machine’s axis capabilities and tooling options to ensure it can handle the desired applications. However, the complexity of these machines often necessitates skilled operators, which can be a consideration for businesses.

In What Situations Are CNC Plasma Cutters Most Beneficial?

CNC plasma cutters are designed for cutting metal and other conductive materials using high-velocity plasma. They are commonly used in metal fabrication and custom signage production. These machines are favored for their speed and efficiency when working with thicker materials. Buyers should consider the thickness of the materials they intend to cut and the required cutting speed when selecting a plasma cutter. While they excel in metal applications, they are not suitable for non-conductive materials.

How Do CNC Laser Cutters Enhance Precision in Woodworking?

CNC laser cutters utilize focused laser beams to cut and engrave materials with extreme precision. They are particularly effective for detailed artwork, signage, and intricate wood designs. When evaluating laser cutters, buyers should focus on the laser power and cutting speed, as these factors influence the thickness and type of materials that can be processed. While laser cutters provide high accuracy and minimal waste, they may have slower cutting speeds for thicker materials, which could impact production timelines.

Key Industrial Applications of used woodworking cnc

| Industry/Sector | Specific Application of used woodworking cnc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Custom furniture components production | High precision cuts reduce material waste and labor costs. | Look for machines with reliable software compatibility and support. |

| Cabinetry Production | Cabinet doors and intricate designs fabrication | Enhanced design capabilities allow for unique offerings. | Ensure the machine can handle the specific materials used in cabinetry. |

| Architectural Millwork | Custom moldings and architectural features creation | Ability to produce detailed designs that meet client specifications. | Assess the machine’s tooling options for diverse applications. |

| Sign Making | Production of intricate signage and displays | Increases production speed and accuracy for competitive pricing. | Verify the machine’s versatility for different materials and sizes. |

| Musical Instrument Manufacturing | Crafting of precise wood components for instruments | Consistency in quality leads to superior sound and performance. | Focus on machines with fine-tuning capabilities for delicate work. |

How is Used Woodworking CNC Applied in Furniture Manufacturing?

In the furniture manufacturing industry, used woodworking CNC machines are employed to produce custom components with precision. These machines can cut, shape, and finish wood pieces to exact specifications, which significantly reduces material waste and labor costs. For international buyers, especially from regions like Africa and South America, sourcing machines that offer reliable software support and compatibility with local materials is crucial. Additionally, manufacturers should consider the machine’s ability to handle various wood types and thicknesses to cater to diverse customer needs.

What Role Does Used CNC Play in Cabinetry Production?

Used woodworking CNC routers are integral to cabinetry production, where they are utilized to fabricate cabinet doors and intricate designs. The precision of CNC technology allows for unique designs that can elevate a brand’s market position. Buyers from Europe, particularly Germany, should prioritize machines that can accommodate the specific types of wood and finishes prevalent in their markets. Furthermore, ensuring that the CNC machine can handle the required dimensions and weights of cabinetry components is vital for efficiency.

How is Used Woodworking CNC Beneficial for Architectural Millwork?

In architectural millwork, used woodworking CNC machines are essential for creating custom moldings and detailed architectural features. These machines allow for a high level of detail that meets specific client requirements, enhancing the aesthetic appeal of buildings. Buyers from the Middle East, where architectural demands are often intricate, should look for machines with diverse tooling options to accommodate various design needs. The ability to produce consistent quality in complex designs is a key consideration for sourcing.

How Does Used CNC Enhance Sign Making?

The sign-making industry leverages used woodworking CNC machines to produce intricate signage and displays. These machines increase production speed while maintaining high accuracy, allowing businesses to offer competitive pricing. International buyers, particularly from emerging markets, should ensure that the CNC machines they source can handle various materials, including plastics and composites, alongside wood. Versatility in size and design capabilities will also aid in meeting diverse customer demands.

What is the Impact of Used CNC in Musical Instrument Manufacturing?

In the musical instrument manufacturing sector, used woodworking CNC machines are crucial for crafting precise wood components that affect sound quality. Consistency in production leads to superior instruments that meet high-performance standards. Buyers, especially from regions with a rich musical heritage, should focus on machines that offer fine-tuning capabilities and can handle delicate wood types. Understanding the specific requirements for sound quality and craftsmanship is essential when sourcing CNC equipment in this niche market.

3 Common User Pain Points for ‘used woodworking cnc’ & Their Solutions

Scenario 1: Difficulty in Assessing Machine Condition Before Purchase

The Problem: When purchasing used woodworking CNC machines, B2B buyers often struggle to accurately assess the condition of the equipment. This can lead to significant financial losses if they acquire a machine that is not operationally sound or requires extensive repairs. Buyers may face challenges such as hidden defects, outdated technology, or insufficient maintenance history that are not disclosed by the seller. This uncertainty can create anxiety, as the investment is substantial, and any post-purchase issues can disrupt production schedules.

The Solution: To mitigate these risks, buyers should conduct thorough due diligence before making a purchase. This includes requesting detailed maintenance records and service history from the seller. It is advisable to arrange for an independent inspection by a qualified technician who specializes in CNC machinery. This expert can evaluate the machine’s condition, including its mechanical components, software capabilities, and overall performance metrics. Additionally, potential buyers should seek to understand the specific applications for which the machine was previously used, ensuring it aligns with their operational needs. By following these steps, buyers can make informed decisions, reducing the likelihood of costly surprises post-purchase.

Scenario 2: Incompatibility with Existing Software and Tools

The Problem: Another common pain point for buyers of used woodworking CNC machines is the potential incompatibility with existing software systems and tooling. Many businesses rely on specific CAD/CAM software for design and manufacturing processes, and older CNC machines may not support these applications. This can result in inefficient workflows, increased downtime, and the need for additional investments in new software or upgrades, which can strain budgets and resources.

The Solution: Buyers should prioritize compatibility when sourcing used CNC machines. Before finalizing a purchase, they should confirm that the machine’s control system and software are compatible with their current setup. This can involve researching the machine’s specifications and reaching out to the manufacturer for compatibility information. Additionally, businesses can consider investing in training for their staff on the new system or seek machines that come with updated software packages. Establishing a clear understanding of the software landscape will not only streamline integration but also enhance overall productivity.

Scenario 3: Limited Availability of Replacement Parts

The Problem: B2B buyers often face challenges related to the availability of replacement parts for used woodworking CNC machines. Older models may have limited support from manufacturers, making it difficult to source essential components when repairs are needed. This can lead to extended machine downtime, impacting production schedules and overall operational efficiency. The inability to quickly replace worn or broken parts can also lead to increased maintenance costs and frustration for the maintenance teams.

The Solution: To address this issue, buyers should consider the long-term availability of parts when selecting a used CNC machine. Before purchase, they should research the manufacturer’s support policies and the availability of spare parts for the specific model. It is beneficial to choose machines from reputable brands known for their ongoing support and part availability. Additionally, buyers can develop relationships with third-party suppliers who specialize in aftermarket parts for older models. By taking these proactive steps, businesses can ensure they have access to the necessary components, minimizing downtime and maintaining production efficiency.

Strategic Material Selection Guide for used woodworking cnc

When selecting materials for used woodworking CNC machines, it’s essential to consider various factors that influence performance, durability, and cost-effectiveness. Here, we analyze four common materials used in CNC woodworking applications: aluminum, steel, plastics, and composite materials. Each material has unique properties and implications for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum in CNC Applications?

Aluminum is a lightweight metal known for its excellent machinability and corrosion resistance. Its thermal conductivity allows for efficient heat dissipation during machining processes, which is crucial for maintaining tool longevity. Aluminum typically has a temperature rating of around 200°C, making it suitable for various woodworking applications.

Pros and Cons of Using Aluminum:

– Pros: Lightweight, resistant to rust and corrosion, and easy to machine. It offers good strength-to-weight ratio, making it ideal for intricate designs.

– Cons: Relatively higher cost compared to some other materials and can be prone to scratching and denting.

Impact on Application:

Aluminum is compatible with a wide range of woodworking applications, particularly in cabinetry and furniture making, where aesthetic appeal is vital.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN for aluminum grades. In regions like Europe and the Middle East, preferences may lean towards specific alloys for enhanced performance.

How Does Steel Compare as a Material for CNC Woodworking?

Steel is renowned for its strength and durability. It can withstand high pressures and temperatures, making it suitable for heavy-duty applications. The corrosion resistance of steel can vary based on the type (e.g., stainless steel vs. carbon steel), with stainless steel offering superior protection.

Pros and Cons of Using Steel:

– Pros: High strength, excellent wear resistance, and longevity. Steel components can handle heavy loads and high-speed operations.

– Cons: Heavier than aluminum, which can affect machine dynamics. It may require additional treatments (e.g., coating) to enhance corrosion resistance.

Impact on Application:

Steel is often used in structural components of CNC machines and can be beneficial for applications requiring high precision and strength, such as industrial woodworking.

Considerations for International Buyers:

International buyers should be aware of the varying standards for steel grades and treatments across regions. Compliance with local regulations regarding environmental impact and safety is also crucial.

What Role Do Plastics Play in CNC Woodworking?

Plastics, such as acrylic and polycarbonate, are increasingly used in CNC applications due to their versatility and ease of machining. They offer good chemical resistance and can be molded into complex shapes, making them suitable for decorative elements.

Pros and Cons of Using Plastics:

– Pros: Lightweight, cost-effective, and available in various colors and finishes. They are easy to shape and cut, making them suitable for prototyping.

– Cons: Lower mechanical strength compared to metals and can be susceptible to scratching and UV degradation.

Impact on Application:

Plastics are commonly used for signage, display cases, and decorative components in woodworking projects.

Considerations for International Buyers:

Buyers should consider the environmental regulations regarding plastic usage in their regions, especially in Europe, where sustainability is increasingly prioritized.

How Do Composite Materials Enhance CNC Woodworking Applications?

Composite materials, such as MDF (Medium Density Fiberboard) and plywood, are popular in woodworking due to their strength and stability. They are engineered to provide uniform density and are less prone to warping compared to solid wood.

Pros and Cons of Using Composite Materials:

– Pros: Cost-effective, stable, and available in large sheets, making them ideal for mass production. They can be easily machined and finished.

– Cons: May have lower durability compared to solid wood and can emit VOCs (volatile organic compounds) if not properly treated.

Impact on Application:

Composites are widely used in furniture making, cabinetry, and interior applications where aesthetic and structural integrity are essential.

Considerations for International Buyers:

It’s important for buyers to check compliance with local standards for VOC emissions and to consider the sustainability of the sourced materials.

Summary Table of Material Selection for Used Woodworking CNC

| Material | Typical Use Case for used woodworking cnc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Cabinetry, furniture components | Lightweight and corrosion-resistant | Higher cost, prone to scratches | Medium |

| Steel | Structural components, heavy-duty parts | High strength and durability | Heavier, may require coatings | High |

| Plastics | Decorative elements, signage | Cost-effective and versatile | Lower strength, UV degradation | Low |

| Composite | Furniture, cabinetry | Stable and easy to machine | Lower durability, VOC emissions | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, aiding in informed decision-making for their CNC woodworking needs.

In-depth Look: Manufacturing Processes and Quality Assurance for used woodworking cnc

What Are the Main Stages of Manufacturing Used Woodworking CNC Machines?

The manufacturing process for used woodworking CNC machines typically involves several critical stages: material preparation, forming, assembly, and finishing.

Material Preparation

In this initial stage, raw materials such as metal, plastics, and electronics are sourced. Manufacturers often select high-grade steel for structural components to ensure durability and precision. This stage may involve cutting, bending, and shaping materials into manageable sizes for further processing.

Forming

Once materials are prepared, forming techniques come into play. This includes machining processes such as milling, turning, and laser cutting to create the machine’s components. CNC machines are often fabricated using computer-aided design (CAD) and computer-aided manufacturing (CAM) software to ensure precise dimensions and tolerances. This technology is crucial for creating parts that will fit together seamlessly during assembly.

Assembly

The assembly stage involves integrating various components into a complete CNC machine. This may include installing the control systems, motors, and cutting tools. Skilled technicians perform this step, ensuring that all parts are correctly aligned and functional. It is common for manufacturers to implement modular designs that facilitate easier repairs and upgrades in the future.

Finishing

Finishing processes enhance the machine’s appearance and durability. This may involve painting, powder coating, or applying protective coatings to resist wear and corrosion. Additionally, this stage often includes the installation of safety features, such as emergency stops and safety guards, complying with international safety standards.

How Is Quality Assurance Implemented in Used Woodworking CNC Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process, particularly for used woodworking CNC machines. Manufacturers adhere to various international standards to ensure that their products meet quality expectations.

International Standards

A significant standard relevant to the manufacturing of CNC machines is ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has established processes for continuous improvement and customer satisfaction. Additionally, CE marking is essential for machines sold in the European market, ensuring compliance with health, safety, and environmental protection standards.

Industry-Specific Standards

In industries such as woodworking, compliance with specific standards like API (American Petroleum Institute) may also be relevant, especially for machines used in specialized applications. These certifications help B2B buyers confirm that the machines meet rigorous industry requirements.

What Are the Key Quality Control Checkpoints in CNC Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that each machine meets the required specifications.

Incoming Quality Control (IQC)

At the beginning of the manufacturing process, incoming materials are inspected for quality and compliance with specifications. This includes checking the physical and chemical properties of metals and components.

In-Process Quality Control (IPQC)

During the manufacturing stages, in-process inspections are conducted. This involves monitoring the machining processes to ensure that tolerances are maintained and that no defects occur. Technicians may use tools such as calipers and gauges to perform these checks.

Final Quality Control (FQC)

The final inspection occurs after assembly and finishing. This step involves testing the complete machine to ensure it operates as intended. Common tests include functional tests, safety checks, and performance assessments. Any discrepancies found during this phase must be rectified before the machine is shipped.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should adopt a proactive approach to verify the quality control practices of their suppliers. Here are several methods:

Audits

Conducting audits of a supplier’s manufacturing facilities is one of the most effective ways to assess quality control processes. Buyers can evaluate the supplier’s adherence to international standards and their internal QC measures.

Quality Reports

Requesting detailed quality reports from suppliers can provide insights into their manufacturing processes and QC results. These reports should outline inspection results, compliance with standards, and any corrective actions taken.

Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can perform inspections and audits, providing unbiased evaluations of the supplier’s QC practices.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate several quality control nuances when sourcing used woodworking CNC machines.

Understanding Regional Standards

Different regions may have specific standards and regulations that must be met. For example, European buyers need to ensure compliance with CE marking, while buyers in Africa or South America may have different local standards. Familiarizing oneself with these regulations is crucial to avoid potential compliance issues.

Cultural and Language Barriers

Cultural differences can affect communication and understanding of quality expectations. Buyers should ensure that they have clear agreements and documentation in place to mitigate misunderstandings related to quality specifications.

Sourcing from Reputable Suppliers

It is vital to source from suppliers with a proven track record in quality assurance. Researching suppliers’ history, customer reviews, and previous audits can help buyers make informed decisions. Buyers should prioritize suppliers who demonstrate transparency in their processes and are willing to provide detailed quality documentation.

In conclusion, understanding the manufacturing processes and quality assurance measures in place for used woodworking CNC machines is essential for B2B buyers. By being informed about these aspects, buyers can ensure they are investing in high-quality equipment that meets their operational needs and international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘used woodworking cnc’

When sourcing used woodworking CNC machines, a structured approach is essential to ensure you make informed decisions. This checklist serves as a practical guide for B2B buyers, helping you navigate the complexities of acquiring high-quality used equipment tailored to your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider factors such as the type of materials you’ll be processing, the size and complexity of your projects, and the desired precision levels.

– Key Specifications: Look for details like spindle speed, table size, and the number of axes.

– Compatibility: Ensure the machine can integrate with your existing systems and software.

Step 2: Research Market Prices

Understanding the market value of used woodworking CNC machines is crucial for negotiating effectively. Research various platforms and listings to get a sense of the price range for the models you are interested in.

– Price Benchmarks: Compare prices from multiple suppliers, factoring in the machine’s condition, age, and included features.

– Hidden Costs: Be aware of additional expenses such as shipping, installation, and potential repairs.

Step 3: Evaluate Potential Suppliers

Thorough vetting of suppliers is critical before finalizing any purchase. Request company profiles, case studies, and references from other buyers within your industry or region.

– Supplier Reputation: Investigate their track record for reliability and customer service.

– Certifications: Look for certifications that demonstrate adherence to industry standards.

Step 4: Inspect the Equipment

Before committing to a purchase, arrange for a comprehensive inspection of the equipment. This step helps you assess the machine’s physical and operational condition.

– Operational Testing: If possible, run the machine to evaluate its performance and check for any irregularities.

– Wear and Tear: Look for signs of significant wear, such as rust, damaged components, or unusual noises during operation.

Step 5: Negotiate Terms and Conditions

Once you are satisfied with the inspection, proceed to negotiate the terms of sale. Clear communication about payment terms, warranties, and return policies is essential for a smooth transaction.

– Warranty Options: Inquire about any warranties or guarantees that come with the equipment.

– Payment Flexibility: Discuss payment terms that suit both parties, such as deposits or installment plans.

Step 6: Plan for Installation and Training

After securing your used CNC machine, ensure you have a plan for installation and training your team. Proper setup and understanding of the equipment are vital for maximizing productivity.

– Professional Installation: Consider hiring experts for installation to avoid complications.

– Training Programs: Invest in training for your operators to ensure they can effectively use the machine and maintain its longevity.

Step 7: Monitor Performance Post-Purchase

After the installation, continuously monitor the machine’s performance to ensure it meets your operational needs. Regular maintenance and timely upgrades can prolong the machine’s life and enhance productivity.

– Maintenance Schedule: Establish a routine for inspections and maintenance.

– Performance Metrics: Set benchmarks to measure the machine’s efficiency and output quality.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing used woodworking CNC machines, ensuring they make informed decisions that align with their business objectives.

Comprehensive Cost and Pricing Analysis for used woodworking cnc Sourcing

What Are the Key Cost Components for Sourcing Used Woodworking CNC Machines?

When evaluating the cost structure of used woodworking CNC machines, several critical components must be taken into account. These include:

-

Materials: The type and quality of materials used in the machine’s construction significantly affect the cost. For instance, machines made with high-grade steel and precision components will typically command higher prices than those constructed from lower-quality materials.

-

Labor: The costs associated with labor encompass both assembly and maintenance. If a machine has been well-maintained, it may incur lower labor costs in the long run, making it a more attractive option for buyers.

-

Manufacturing Overhead: This includes indirect costs related to the production of the CNC machines, such as utilities, rent, and administrative expenses. Understanding these costs can provide insight into the overall pricing strategy of suppliers.

-

Tooling: The condition and quality of tooling included with the CNC machine can influence the price. Buyers should consider whether they need to invest in additional tooling after purchase.

-

Quality Control (QC): Machines that have undergone rigorous quality control measures often come with higher price tags. Certifications and warranties can also affect the pricing, providing assurance of reliability.

-

Logistics: Shipping and handling costs can vary widely based on the machine’s size and weight, as well as the distance from the supplier. International buyers must consider customs duties and taxes as additional costs.

-

Margin: Suppliers will typically add a margin to cover their costs and achieve profitability. Understanding the margin can help buyers gauge the fairness of the offered price.

How Do Price Influencers Affect the Cost of Used Woodworking CNC Machines?

Several factors can influence the pricing of used woodworking CNC machines:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Buyers should negotiate for better pricing when ordering multiple machines.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality: The overall quality and type of materials used in the CNC machine will directly impact pricing. Higher quality often equates to a higher price, but it can also mean lower maintenance costs.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is essential for calculating total costs. Buyers should clarify these terms to avoid hidden fees.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Used Woodworking CNC Machines?

To maximize cost-efficiency and ensure a favorable purchasing experience, buyers should consider the following strategies:

-

Negotiation: Don’t hesitate to negotiate prices and terms. Many suppliers expect some level of negotiation, especially for used equipment.

-

Total Cost of Ownership (TCO): Evaluate the long-term costs associated with operating and maintaining the CNC machine. A lower initial purchase price may lead to higher operational costs if the machine is not durable or efficient.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, and the Middle East should be aware of additional costs such as import duties, taxes, and potential currency fluctuations. Understanding these factors can provide a clearer picture of the total investment required.

-

Disclaimer on Indicative Prices: Prices for used woodworking CNC machines can vary significantly based on condition, specifications, and market demand. Always seek current quotes and verify the details before making a purchase decision.

By considering these factors and strategies, international B2B buyers can make informed decisions that align with their operational needs and budget constraints, ultimately leading to successful sourcing of used woodworking CNC machines.

Alternatives Analysis: Comparing used woodworking cnc With Other Solutions

Exploring Alternatives to Used Woodworking CNC Machines

In the woodworking industry, precision and efficiency are paramount. While used woodworking CNC machines offer advanced capabilities for cutting and shaping wood, various alternative solutions can also meet the needs of manufacturers. Understanding these alternatives is essential for B2B buyers to make informed decisions that align with their operational requirements and budget constraints.

Comparison Table

| Comparison Aspect | Used Woodworking CNC | Manual Woodworking Tools | Laser Cutting Machines |

|---|---|---|---|

| Performance | High precision and speed | Lower precision, slower pace | High precision, intricate cuts |

| Cost | Moderate to high initial cost | Low initial cost | High initial cost |

| Ease of Implementation | Requires skilled operators | Easy to use, less training needed | Requires specialized training |

| Maintenance | Regular maintenance needed | Minimal maintenance | Moderate maintenance |

| Best Use Case | Large-scale production | Small batches, artisanal work | Complex designs, engraving |

Detailed Breakdown of Alternatives

Manual Woodworking Tools

Manual woodworking tools, such as saws, chisels, and planes, are traditional options for woodworkers. They are generally low-cost and easy to acquire, making them accessible for small businesses and artisans. The ease of use allows for quick adjustments and personalization in woodworking projects. However, the performance in terms of speed and precision is significantly lower compared to CNC machines. Manual tools are best suited for small-scale projects or artisanal craftsmanship, where intricate details and unique designs are prioritized over production speed.

Laser Cutting Machines

Laser cutting machines represent a modern technology that offers high precision and the ability to create intricate designs with minimal material waste. They excel in applications requiring detailed engraving and cutting of various materials, including wood, acrylic, and metal. However, the initial investment can be quite high, making it a less viable option for smaller companies. Additionally, laser machines require specialized training for operators, which can add to operational costs. These machines are ideal for businesses focused on detailed, custom work where precision is critical.

Conclusion: Choosing the Right Solution for Your Woodworking Needs

Selecting the appropriate solution for woodworking needs involves evaluating specific business requirements, including production volume, budget, and desired precision. Used woodworking CNC machines are excellent for high-volume production with consistent quality. In contrast, manual tools may be preferable for smaller operations focused on craftsmanship, while laser cutting machines are ideal for intricate designs and versatility across materials. By carefully assessing these alternatives, B2B buyers can determine the best fit for their operations, ensuring efficiency and profitability in their woodworking endeavors.

Essential Technical Properties and Trade Terminology for used woodworking cnc

When considering the purchase of used woodworking CNC machines, it is crucial to understand key technical properties and industry terminology that can significantly impact decision-making. This guide will outline essential specifications and common trade terms to enhance your purchasing process.

What Are the Key Technical Properties of Used Woodworking CNC Machines?

-

Material Grade

The material grade of a CNC router refers to the quality and type of materials used in its construction. Common materials include steel and aluminum, which impact durability and performance. A higher material grade typically indicates a more robust machine, essential for heavy-duty operations. For B2B buyers, understanding material grade helps assess the machine’s longevity and suitability for specific projects. -

Tolerance

Tolerance measures the allowable deviation from a specified dimension in the machining process. Precision is vital in woodworking, as tighter tolerances lead to better fitting components and a higher quality of finish. In a B2B context, knowing the tolerance levels can help buyers ensure that the machine meets their production standards, reducing waste and rework costs. -

Spindle Speed (RPM)

The spindle speed indicates how fast the cutting tool rotates, typically measured in revolutions per minute (RPM). Different materials require different spindle speeds for optimal cutting efficiency. For instance, hardwoods may require lower speeds compared to softer woods. Understanding spindle speed allows buyers to choose a machine that aligns with their production needs and material types. -

Table Size

The table size of a CNC router defines the maximum dimensions of the workpiece it can accommodate. A larger table size allows for more extensive projects but may require more space. For businesses looking to scale operations, selecting the right table size is critical for maximizing productivity and ensuring versatility in handling various projects. -

Axis Configuration

CNC routers can come in different axis configurations, such as 3-axis, 4-axis, or 5-axis. The number of axes determines the complexity of cuts the machine can achieve. For example, a 5-axis machine can create intricate designs and shapes that a 3-axis machine cannot. Understanding axis configurations is essential for businesses that require advanced machining capabilities. -

Vacuum System

The vacuum system is crucial for holding the workpiece securely during machining. A robust vacuum system minimizes movement and improves precision. In the B2B landscape, knowing the specifications of the vacuum system can inform buyers about the machine’s capability to handle different material sizes and types effectively.

What Are Common Trade Terms Used in the CNC Woodworking Industry?

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of CNC machines, knowing the OEM can help buyers understand the quality and reliability of the equipment, as established brands often provide better support and replacement parts. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to assess their purchasing needs and budget constraints. It can also influence negotiation strategies and supplier selection. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting a detailed quotation for specific products or services. This term is critical for buyers looking to compare prices and terms across different suppliers, ensuring they get the best value. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and liabilities in cross-border transactions, reducing risks associated with international trade. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is vital for planning production schedules and managing inventory effectively. For B2B buyers, shorter lead times can improve responsiveness to market demands. -

Refurbished

Refurbished indicates that a used machine has been restored to working condition, often with new parts or upgrades. Buyers should be cautious and verify the extent of refurbishment to ensure the machine meets their operational needs.

By familiarizing yourself with these critical properties and terms, you can make informed decisions when purchasing used woodworking CNC machines, ensuring that your investment aligns with your business goals and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the used woodworking cnc Sector

What Are the Current Market Dynamics and Key Trends in the Used Woodworking CNC Sector?

The global used woodworking CNC market is experiencing significant growth, driven by the increasing demand for precision and automation in woodworking applications. Key trends include the rise of digitalization and Industry 4.0, which are enhancing operational efficiencies and enabling real-time monitoring of machinery. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these technological advancements is crucial for making informed purchasing decisions.

Another notable trend is the shift towards multi-functionality in CNC machines, allowing businesses to optimize their production lines. Machines that can perform various tasks—from cutting to engraving—are becoming more sought after, as they reduce the need for multiple machines and lower operational costs. Additionally, the growing emphasis on customization in woodworking projects is pushing manufacturers to invest in versatile CNC solutions.

International buyers are also increasingly prioritizing suppliers that offer comprehensive after-sales support, including maintenance services and training, to ensure smooth operations. Moreover, the fluctuating costs of raw materials and the need for quick turnaround times are making it essential for businesses to source used CNC machinery that can provide immediate ROI.

How Important Is Sustainability and Ethical Sourcing in the Used Woodworking CNC Market?

Sustainability is a critical consideration for B2B buyers in the used woodworking CNC sector. The environmental impact of manufacturing processes, including waste generation and energy consumption, has prompted companies to seek eco-friendly solutions. By sourcing used machinery, businesses can significantly reduce their carbon footprint, as these machines require less energy to operate compared to newer models.

Ethical sourcing practices are also gaining traction. Buyers are encouraged to engage with suppliers who adhere to sustainable practices and offer ‘green’ certifications for their equipment. These certifications often indicate that the machinery meets certain environmental standards, contributing to responsible production and sourcing efforts.

In addition, there is a growing market for machinery that utilizes eco-friendly materials or processes. Buyers should look for CNC machines that support the use of sustainable wood products or those that are designed to minimize waste during operations. By prioritizing sustainability and ethical sourcing, businesses can enhance their brand reputation and appeal to environmentally-conscious consumers.

What Is the Evolution of the Used Woodworking CNC Sector?

The evolution of the used woodworking CNC sector is marked by significant technological advancements that have transformed traditional woodworking practices. Initially, woodworking relied heavily on manual tools and techniques, which limited precision and efficiency. The introduction of CNC technology revolutionized the industry, enabling automated and highly accurate machining processes.

As CNC technology matured, so did the market for used machines. Early adopters began to upgrade their equipment, creating a thriving secondary market. This evolution has been characterized by increasing sophistication in machine capabilities, including the integration of software that allows for complex designs and real-time data analytics.

Today, the used woodworking CNC market serves a diverse range of industries, from furniture manufacturing to custom cabinetry. This diversification highlights the importance of understanding historical trends and technological advancements for B2B buyers looking to make strategic investments in used CNC machinery. Understanding the sector’s evolution not only informs purchasing decisions but also helps businesses anticipate future trends and innovations in woodworking technology.

Frequently Asked Questions (FAQs) for B2B Buyers of used woodworking cnc

-

How can I assess the quality of used woodworking CNC machines?

To evaluate the quality of used woodworking CNC machines, start by requesting detailed specifications and maintenance records from the seller. Look for signs of wear and tear, such as rust, unusual noises, or irregular movements during demonstrations. It’s also beneficial to review any available user feedback and ratings for the specific model. If possible, arrange for a third-party inspection to verify the machine’s operational condition and performance capabilities before finalizing your purchase. -

What are the key factors to consider when selecting a used woodworking CNC router?

When selecting a used woodworking CNC router, consider factors such as the machine’s age, operational history, and brand reputation. Evaluate the technical specifications, including spindle speed, working area, and compatibility with your desired materials. Additionally, consider the availability of spare parts and service support for the brand in your region, as this can significantly affect your long-term operational efficiency and maintenance costs. -

What are the common payment terms for purchasing used woodworking CNC machines?

Payment terms for used woodworking CNC machines can vary widely depending on the seller and the buyer’s location. Typically, you might encounter options such as upfront payment, bank transfers, or installment plans. It is crucial to clarify these terms in advance and ensure that they align with your cash flow capabilities. Additionally, consider using secure payment methods or escrow services to protect your investment during the transaction. -

How do I verify the legitimacy of a supplier when sourcing used CNC machinery internationally?

To verify a supplier’s legitimacy when sourcing used CNC machinery, conduct thorough research including checking their business credentials, reviews, and ratings on trade platforms. Request references from previous customers and verify their operational history. Engaging in direct communication and asking for video demonstrations can also provide insight into their business practices. If possible, visit the supplier’s facility or engage a local representative to conduct an on-site inspection. -

What are the typical lead times for shipping used woodworking CNC machines internationally?

Lead times for shipping used woodworking CNC machines internationally can vary based on the machine’s location, shipping method, and customs clearance processes. Generally, you can expect lead times to range from two to six weeks. To ensure timely delivery, confirm shipping schedules and any potential delays with your supplier. It’s also advisable to factor in additional time for customs clearance and local transportation to your facility. -

Can I customize used woodworking CNC machines to fit my specific production needs?

Yes, many used woodworking CNC machines can be customized to meet specific production needs. Customization options may include software upgrades, tool changes, or modifications to the machine’s hardware. When considering a used machine, discuss your requirements with the supplier, and inquire about the feasibility of modifications. It’s essential to ensure that any changes do not compromise the machine’s warranty or operational integrity. -

What should I include in a quality assurance plan for used CNC machinery?

A quality assurance plan for used CNC machinery should include regular maintenance schedules, performance benchmarks, and operational checks to ensure the equipment meets your production standards. Document inspection protocols for incoming materials and finished products, along with a feedback loop for continuous improvement. In addition, training for operators on proper usage and maintenance can help extend the machine’s lifespan and enhance productivity. -

What are the advantages of purchasing used woodworking CNC machines over new ones?

Purchasing used woodworking CNC machines offers several advantages, including significant cost savings compared to new models. Used machines often come with established operational histories, allowing you to assess their reliability and performance. Additionally, many used machines have been upgraded or refurbished, providing modern features at a lower price point. This makes them an attractive option for businesses looking to expand production without substantial capital investment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Used Woodworking Cnc Manufacturers & Suppliers List

1. CNC Machines – Used Industrial Routers

Domain: cncmachines.com

Registered: 1997 (28 years)

Introduction: Used Industrial CNC Routers available at CNCMachines.com. Key brands include Multicam, Laguna, Industrial CNC, Avid, ShopSabre, C.R. Onsrud, and Vision. Various models include LAGUNA SMARTSHOP M, INDUSTRIAL CNC ARTISAN 408, BIESSE ROVER K FT1531, AVID PRO 60120, and more. Specifications include sizes such as 60″x120″x10.5″, 48″x96″x12″, and 49.5″x98.75″. Options available include vacuum systems, d…

2. Vevor – S4040 CNC Router Machine

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Cnc Woodworking Machine, Machine Type: 3 Axis Router Machine, 4 Axis Router Machine, 5 Axis Router Machine, Mini CNC Router Machine, Engraver Machine, Metal Engraving Machine, Best Selling Products: Vevor S4040 CNC Router Machine 300W 3 Axis Wood Engraving Milling Machine (ZAR 5,300.17), RATTM Motor 1610PRO-MJ Mini Router Machine Kit (ZAR 634.44), SainSmart Genmitsu 5.5w Blue Laser Head Module Ki…

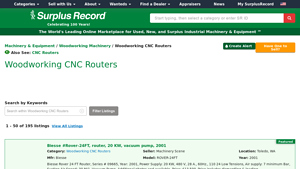

3. Weeke – CNC Woodworking Routers

Domain: surplusrecord.com

Registered: 1995 (30 years)

Introduction: Used CNC Woodworking Routers For Sale | Surplus Record

Manufacturers:

– Weeke (18)

– Biesse (15)

– Homag (13)

– Onsrud (13)

– Komo (10)

– Morbidelli (9)

– Thermwood (8)

– Scm (7)

– Cam-Wood (6)

– Holz-Her (6)

– Multicam (6)

– Scmi (6)

– Baileigh (5)

– Cosmec (5)

– Felder (5)

– Busellato (4)

– Camaster (4)

– Giben (3)

– Axyz (2)

– Grizzly (2)

– Heian (2)

– Ima (2)

– Laguna (2)

– Newcnc (2)

– Ander…

4. Andi – Stratos CNC Router

Domain: exfactory.com

Registered: 1995 (30 years)

Introduction: This company, Andi – Stratos CNC Router, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Machineseeker – Used CNC Wood

Domain: machineseeker.com

Registered: 1999 (26 years)

Introduction: Used CNC Wood for sale on Machineseeker.com – many listings online now. Key details include:

– Categories: Woodworking machinery, Metal working machinery, Commercial vehicles, Waste management & recycling equipment, Industrial automation technology, etc.

– Manufacturers: Mercedes-Benz, SCM, WEINIG, HOMAG, WINTER, BIESSE, Mazak, Renault, Holzkraft, Iveco, HOLZ-HER, Gildemeister, MAN, Deckel Maho,…

6. CNC Exchange – Pre-Owned CNC Machines

Domain: cncexchange.com

Registered: 2000 (25 years)

Introduction: CNC Exchange specializes in buying and selling high-quality, pre-owned CNC machines including Vertical Machining Centers, Horizontal Machining Centers, Lathes and Turning Centers, Automatics and Screw Machines, Swiss Type Lathes, Grinders and EDM (Electrical Discharge Machines), Gear, Broach, and Finishing Equipment, Routers and Woodworking Fabrication, and other equipment. They offer services suc…

7. KD Capital – Used CNC Routers

Domain: kdcapital.com

Registered: 2003 (22 years)

Introduction: Used CNC Routers for Sale – KD Capital Equipment offers a variety of used CNC routers, with 104 models available. The routers are suitable for cutting materials such as wood, metal, glass, foam, and plastics. They enhance automation and precision, improving shop quality and productivity. Common applications include producing door carvings, decorations, panels, sign boards, frames, moldings, musica…

8. BIESSE – NEW SKIPPER 100 L

Domain: ferwoodgroup.com

Registered: 2017 (8 years)

Introduction: Used CNC Routers and CNC Machine Centres for Wood available in the USA. Key products include: 1. BIESSE NEW SKIPPER 100 L – Availability: in stock 2. BIESSE ROVER A 3.30 K1 – Availability: in stock 3. WEEKE BHX 055 – Availability: in stock 4. HOMAG BAZ 322/40/K – Availability: in stock 5. BIESSE ROVER A 3.30 – Availability: in stock 6. MASTERWOOD PROJECT 4005 L – Availability: immediate 7. BREMA E…

9. Revelation Machinery – Used CNC Machines

Domain: revelationmachinery.com

Registered: 2016 (9 years)

Introduction: Used CNC Machines for Sale, including CNC Lathes, Vertical Machining Centers, Horizontal Machining Centers, Mills, EDM, Gear Machinery, Grinders, Gun Drills, Routers, and more. Featured brands include Haas, Doosan, and Hurco. Inventory includes multi-axis lathes, Swiss-type lathes, vertical turret lathes, engine lathes, boring mills, CNC/manual knee mills, gantry/bridge mills, and various other CN…

Strategic Sourcing Conclusion and Outlook for used woodworking cnc

In the competitive landscape of woodworking, the strategic sourcing of used CNC machinery presents significant advantages for international buyers. Understanding the unique needs of your market—whether in Africa, South America, the Middle East, or Europe—is essential to maximizing value from your investment. Used CNC routers, such as those from reputable brands like Biesse and Anderson, offer not only cost savings but also the ability to leverage advanced technology for precision cutting and shaping.

By focusing on reliable suppliers and conducting thorough inspections of machinery, businesses can mitigate risks associated with purchasing used equipment. The availability of various models and configurations allows buyers to choose machinery that aligns perfectly with their operational requirements, enhancing productivity and reducing lead times.

Looking ahead, the demand for used woodworking CNC equipment is expected to grow, driven by an increasing emphasis on sustainability and cost-effectiveness. International buyers are encouraged to seize this opportunity—invest in high-quality used machinery that can elevate your production capabilities and adapt to evolving market demands. Embrace strategic sourcing today to position your business for future success.