Introduction: Navigating the Global Market for used wood cnc

In today’s competitive landscape, sourcing used wood CNC machines presents unique challenges for B2B buyers. From understanding the intricacies of machine specifications to navigating the complexities of international shipping and customs, the process can often feel overwhelming. This guide addresses these challenges head-on, providing a comprehensive overview of the used wood CNC market. It covers various types of CNC routers, their applications in woodworking, and essential considerations for supplier vetting and cost analysis.

As a B2B buyer from regions such as Africa, South America, the Middle East, or Europe—including countries like Saudi Arabia and Nigeria—you face specific hurdles that require tailored solutions. This guide empowers you with the knowledge needed to make informed purchasing decisions. You’ll find insights into the latest market trends, detailed breakdowns of machine capabilities, and practical tips for evaluating suppliers to ensure you invest wisely.

By equipping yourself with the right information, you can confidently navigate the global market for used wood CNC machines, maximizing your investment and enhancing your production capabilities. Whether you’re looking to expand your operations or optimize existing workflows, this resource serves as a vital tool in your strategic planning.

Understanding used wood cnc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Router | Computer-controlled cutting, various sizes, ATC | Cabinetry, furniture, signage, custom parts | Pros: High precision, versatile; Cons: Higher initial cost, requires training. |

| CNC Machining Center | Multi-functional, can perform drilling and milling | Aerospace, automotive, large-scale production | Pros: High efficiency, multi-tasking; Cons: Larger footprint, may require more maintenance. |

| CNC Laser Cutter | Uses laser technology for cutting and engraving | Sign making, intricate designs, prototyping | Pros: Excellent detail, minimal material waste; Cons: Limited to certain materials, higher operating costs. |

| CNC Plasma Cutter | Utilizes plasma for cutting metals and thick materials | Metal fabrication, art, industrial applications | Pros: Fast cutting speeds, effective for thick materials; Cons: Less precise than laser cutting, requires ventilation. |

| CNC Waterjet Cutter | Uses high-pressure water for cutting | Aerospace, automotive, stone cutting | Pros: Versatile, can cut various materials; Cons: Slower than other methods, higher operational costs. |

What are the characteristics of CNC Routers for B2B buyers?

CNC routers are among the most popular types of used wood CNC machines due to their versatility and precision. They can handle various materials, including wood, plastics, and composites, making them ideal for industries such as cabinetry and furniture manufacturing. A key feature is the Automatic Tool Change (ATC) capability, which enhances productivity by allowing for quick tool swaps. B2B buyers should consider the size of the working area, the power of the spindle, and the machine’s compatibility with existing software systems.

How do CNC Machining Centers differ in functionality?

CNC machining centers are designed for more complex operations beyond simple cutting, including drilling and milling. These machines are equipped with multiple axes, allowing them to perform intricate tasks in a single setup. They are particularly beneficial in industries like aerospace and automotive, where precision and efficiency are paramount. When purchasing, buyers should evaluate the machine’s versatility, tooling options, and the type of materials it can process, as these factors directly impact production capabilities.

What advantages do CNC Laser Cutters offer for specific applications?

CNC laser cutters are renowned for their ability to create intricate designs and precise cuts, making them ideal for applications in signage and prototyping. They operate using laser technology, which offers a clean cut with minimal kerf and material waste. However, their use is limited to certain materials, such as thin metals, plastics, and wood. Buyers should assess the laser power, cutting speed, and the maximum thickness of materials that can be processed, as these attributes determine the machine’s effectiveness for specific projects.

What are the key considerations for CNC Plasma Cutters in industrial settings?

CNC plasma cutters are primarily used for cutting metals, making them suitable for industries like metal fabrication and industrial applications. They operate at high speeds and can cut through thick materials efficiently. However, they may not provide the same level of precision as laser cutters. Buyers should consider the machine’s cutting speed, the thickness of materials it can handle, and the required ventilation systems due to the fumes produced during cutting.

How do CNC Waterjet Cutters stand out in material versatility?

CNC waterjet cutters utilize high-pressure water jets to cut through various materials, including metal, glass, and stone. Their versatility makes them suitable for diverse applications, from aerospace components to artistic endeavors. While they are slower than other cutting methods, they do not produce heat-affected zones, preserving the integrity of the material. B2B buyers should evaluate the machine’s cutting speed, material compatibility, and maintenance requirements to ensure it meets their operational needs.

Key Industrial Applications of used wood cnc

| Industry/Sector | Specific Application of used wood cnc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Custom furniture design and production | High precision and efficiency in creating intricate designs | Machine condition, software compatibility, and tooling |

| Cabinetry and Millwork | Cabinet making and custom cabinetry solutions | Streamlined production processes and reduced material waste | Size specifications, vacuum hold-down systems, and power requirements |

| Signage and Display | Production of signage and promotional displays | Enhanced design capabilities and rapid prototyping | Material compatibility, cutting speed, and software integration |

| Musical Instruments | Crafting of wooden instruments like guitars | Consistent quality and precision in intricate designs | Specific tooling for different wood types and acoustic properties |

| Architectural Modeling | Creation of detailed architectural models | Improved visualization and client presentations | Precision specifications, size limitations, and software compatibility |

How is Used Wood CNC Revolutionizing Furniture Manufacturing?

In the furniture manufacturing sector, used wood CNC machines are employed for custom furniture design and production. These machines facilitate high precision cutting and shaping, allowing manufacturers to create intricate designs that are not feasible with traditional methods. The automation reduces labor costs and increases production speed, addressing common issues such as design inconsistencies and material wastage. For international buyers, particularly in regions like Africa and South America, sourcing machines that can handle diverse wood types and have robust after-sales support is crucial.

What Role Does Used Wood CNC Play in Cabinetry and Millwork?

In cabinetry and millwork, used wood CNC routers are integral for crafting custom cabinetry solutions. They optimize production processes by enabling precise cuts and minimizing waste, which is vital in maintaining profitability. The ability to program complex designs directly into the machine ensures consistency across multiple units. Buyers, especially from the Middle East and Europe, should focus on machines with adequate hold-down systems and sufficient power to handle various cabinetry materials, ensuring efficient operation.

How is Used Wood CNC Enhancing Signage and Display Production?

The signage and display industry benefits significantly from used wood CNC machines by enabling the rapid production of custom signs and promotional displays. These machines enhance design capabilities, allowing for intricate carvings and shapes that attract consumer attention. The rapid prototyping feature also aids in quick market testing of new designs. For B2B buyers in regions like Saudi Arabia and Nigeria, it is essential to consider the machine’s cutting speed and material compatibility to meet diverse market demands.

In What Ways is Used Wood CNC Beneficial for Musical Instrument Crafting?

Used wood CNC routers are crucial in the crafting of wooden musical instruments, such as guitars. They provide consistent quality and precision, which are essential for producing instruments with intricate designs and specific acoustic properties. The ability to work with different wood types allows manufacturers to cater to various market preferences. Buyers should ensure that the sourced machines come with specific tooling designed for musical instrument production, especially when sourcing from international markets.

How is Used Wood CNC Transforming Architectural Modeling?

In architectural modeling, used wood CNC machines are utilized to create detailed models that enhance visualization for clients. These machines allow architects to produce accurate representations of their designs, improving client presentations and facilitating better feedback. The precision offered by CNC technology reduces the likelihood of errors during model creation. Buyers in Europe and the Middle East should prioritize sourcing machines that can accommodate large sizes and have compatibility with architectural design software to streamline their workflow.

3 Common User Pain Points for ‘used wood cnc’ & Their Solutions

Scenario 1: Navigating Quality Concerns with Used Wood CNC Machines

The Problem:

B2B buyers often face significant anxiety when purchasing used wood CNC machines due to concerns about quality and functionality. This is especially true for businesses in emerging markets like Nigeria or Saudi Arabia, where the availability of reliable machinery can be limited. Buyers worry about hidden defects, outdated technology, and the potential for costly repairs shortly after the purchase. The fear of investing substantial capital only to receive a machine that underperforms or fails to meet production standards is a daunting challenge.

The Solution:

To mitigate quality concerns, buyers should adopt a comprehensive evaluation strategy before finalizing a purchase. Start by sourcing machinery from reputable dealers who provide detailed histories of their equipment, including maintenance records and previous usage. Request a physical inspection or, if possible, a demonstration of the machine in operation. This allows buyers to assess the machine’s performance firsthand.

Additionally, consider purchasing from sellers who offer warranties or guarantees. A warranty can provide peace of mind and a safeguard against unforeseen issues. Finally, establish a clear communication line with the seller regarding the machine’s condition and any repairs made prior to sale. This thorough approach helps ensure that the used CNC machine will meet operational expectations and minimizes the risk of unexpected problems.

Scenario 2: Understanding Compatibility with Existing Systems

The Problem:

Another common pain point for B2B buyers of used wood CNC machines is ensuring compatibility with existing systems and software. Many businesses, particularly those in Europe and South America, invest heavily in specific software ecosystems for their operations. When acquiring a used CNC machine, there’s often uncertainty about whether it will integrate smoothly with current design and production workflows. This can lead to operational disruptions and increased training costs if the new machine operates on different protocols or requires different software.

The Solution:

To address compatibility issues, buyers should conduct a thorough analysis of their existing systems before making a purchase. This includes identifying the software and hardware specifications currently in use. When evaluating a used CNC machine, inquire specifically about its compatibility with your existing software. Request detailed technical specifications and documentation from the seller to assess this compatibility.

Furthermore, consider involving your IT and production teams in the decision-making process. Their insights can help identify potential integration challenges early on. If compatibility is uncertain, look for machines that can be upgraded or retrofitted with compatible technology. Many used CNC machines can be modified to work with newer software, which may provide a long-term solution without the need for a complete system overhaul.

Scenario 3: Managing Post-Purchase Support and Maintenance

The Problem:

After acquiring a used wood CNC machine, many buyers find themselves unprepared for the ongoing support and maintenance needs of the equipment. This is particularly true for international buyers in regions with limited access to technical expertise and parts, such as certain countries in Africa and the Middle East. Without adequate support, businesses may struggle to maintain production efficiency, leading to costly downtimes and decreased profitability.

The Solution:

To effectively manage post-purchase support, buyers should prioritize establishing a robust maintenance plan at the time of purchase. Research local technicians or service providers who specialize in CNC machine maintenance. Building a relationship with a local expert can facilitate quicker responses to any issues that arise.

Additionally, consider investing in a service contract with the seller if available. This can provide access to professional support and parts for a specified period. Buyers should also prioritize training for their operators on the specific used CNC machine to ensure they can troubleshoot minor issues independently. This knowledge transfer is crucial in regions where immediate technical support may not be readily available.

By anticipating these support and maintenance needs and proactively addressing them, businesses can enhance the longevity and performance of their used wood CNC machines, ensuring a better return on investment.

Strategic Material Selection Guide for used wood cnc

What Are the Key Materials Used in CNC Woodworking Machines?

When selecting materials for used wood CNC routers, understanding the properties and implications of various materials is crucial for optimizing performance and ensuring compatibility with specific applications. Below are analyses of four common materials used in CNC woodworking machines, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Aluminum

Key Properties:

Aluminum is lightweight yet strong, with excellent corrosion resistance and thermal conductivity. It can withstand moderate temperatures and is non-magnetic, making it suitable for various CNC applications.

Pros & Cons:

The primary advantage of aluminum is its durability and ease of machining, which allows for precise cuts and shapes. However, it can be more expensive than other materials, and its lower tensile strength compared to steel may limit its use in heavy-duty applications.

Impact on Application:

Aluminum is ideal for components that require precision and a lightweight design, such as frames and supports in CNC routers. Its compatibility with various cutting tools and techniques enhances its utility in woodworking.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM B221 for aluminum extrusions. Understanding local sourcing options can also help mitigate costs, especially in regions like Africa and South America, where import tariffs may apply.

2. Steel

Key Properties:

Steel is known for its high tensile strength and durability. It can withstand high pressures and temperatures, making it suitable for heavy-duty CNC applications.

Pros & Cons:

The key advantage of steel is its robustness, which allows it to handle demanding workloads without deforming. However, it is heavier than aluminum and can be prone to corrosion unless treated, which may increase maintenance costs.

Impact on Application:

Steel is often used in the construction of CNC router frames and bases, providing stability during operation. Its strength is essential for applications requiring high precision and load-bearing capabilities.

Considerations for International Buyers:

Buyers should be aware of the various grades of steel available and their corresponding standards, such as ASTM A36. In regions with high humidity, like parts of the Middle East, corrosion-resistant coatings may be necessary.

3. Composite Materials

Key Properties:

Composite materials, often made from a combination of wood fibers and plastics, offer a balance of strength and weight. They are resistant to moisture and can be engineered for specific performance characteristics.

Pros & Cons:

The main advantage of composites is their versatility and lower weight, which can enhance machine efficiency. However, they may not be as durable as metals and can be more complex to manufacture, leading to higher costs.

Impact on Application:

Composites are suitable for applications requiring intricate designs and shapes, such as decorative woodworking. Their compatibility with various CNC tools makes them a popular choice in modern woodworking.

Considerations for International Buyers:

B2B buyers should check for compliance with environmental standards, especially in Europe, where regulations on material sourcing and sustainability are stringent. Understanding local preferences for eco-friendly materials can also influence purchasing decisions.

4. High-Density Polyethylene (HDPE)

Key Properties:

HDPE is a strong, lightweight plastic known for its chemical resistance and durability. It performs well under a wide range of temperatures and is non-toxic, making it safe for various applications.

Pros & Cons:

The key advantage of HDPE is its resistance to moisture and chemicals, which makes it ideal for environments where wood may be exposed to liquids. However, it may not withstand high temperatures as well as metals, limiting its use in high-heat applications.

Impact on Application:

HDPE is often used in CNC applications for parts that require chemical resistance, such as jigs and fixtures. Its lightweight nature can improve machine speed and efficiency.

Considerations for International Buyers:

Buyers should ensure compliance with international standards like ASTM D638 for plastics. Additionally, understanding local regulations regarding plastic use and disposal is essential, particularly in regions with strict environmental laws.

Summary Table

| Material | Typical Use Case for used wood cnc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frames and supports | Lightweight and corrosion-resistant | Higher cost compared to other metals | Medium |

| Steel | Heavy-duty frames and bases | High strength and durability | Prone to corrosion | High |

| Composite Materials | Intricate designs and shapes | Versatile and lightweight | Less durable than metals | Medium |

| High-Density Polyethylene | Jigs and fixtures | Chemical and moisture resistant | Limited high-temperature performance | Low |

This strategic material selection guide provides insights into the various materials used in CNC woodworking applications, helping international B2B buyers make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for used wood cnc

What Are the Key Stages in the Manufacturing Process of Used Wood CNC Machines?

The manufacturing process of used wood CNC machines encompasses several critical stages, each of which plays a vital role in ensuring the machine’s functionality and durability. Understanding these stages can help B2B buyers make informed decisions when sourcing equipment.

Material Preparation: What Materials Are Commonly Used?

The first step in manufacturing used wood CNC machines involves the selection and preparation of materials. Typically, high-quality metals such as steel and aluminum are used for the machine frame, while specific plastics and composites may be employed for components such as the control panels and housing. The materials undergo rigorous quality checks to ensure they meet the necessary specifications for strength and durability.

Once materials are selected, they are cut and shaped using various techniques, including laser cutting, water jet cutting, or traditional machining methods. This stage is crucial as it lays the foundation for the structural integrity of the CNC machine.

Forming: How Are CNC Components Shaped?

In the forming stage, the prepared materials are shaped into specific components. This may involve processes like bending, stamping, or forging, depending on the part being produced. For instance, the machine’s base may be welded from steel plates, while internal components like gears or pulleys might be machined to precise tolerances.

Advanced manufacturing techniques, such as computer numerical control (CNC) machining, are used to ensure high accuracy and repeatability. This precision is particularly important for parts that will directly affect the machine’s operational capabilities, such as the spindle or tool changer.

Assembly: What Is Involved in the Assembly Process?

The assembly stage is where all the individual components come together to form a complete CNC machine. This process typically involves several sub-assemblies, including the frame, motion systems, electronics, and control systems. Skilled technicians perform this assembly, often following detailed engineering drawings and specifications.

During assembly, components undergo alignment checks to ensure that they meet the required tolerances. Proper alignment is essential for the machine’s performance, affecting cutting accuracy and overall efficiency.

Finishing: What Are the Final Touches Before Quality Control?

Once assembled, the CNC machine undergoes a finishing process, which may include surface treatments such as painting, anodizing, or powder coating. These treatments not only enhance the machine’s aesthetics but also protect it from corrosion and wear.

This stage may also involve the installation of additional features like dust collection systems or improved cooling mechanisms, which can enhance the machine’s operational efficiency. After finishing, the machine is typically cleaned and prepared for the quality control phase.

How Is Quality Assurance Conducted for Used Wood CNC Machines?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the machines meet international standards and customer expectations. For B2B buyers, understanding the QA process can provide confidence in the reliability of their purchased equipment.

What International Standards Are Relevant for Quality Control?

International standards such as ISO 9001 are fundamental in guiding manufacturers in establishing an effective quality management system. This standard emphasizes customer satisfaction, continuous improvement, and process efficiency. Additionally, industry-specific certifications like CE marking (for compliance with European health, safety, and environmental protection standards) or API standards (for oil and gas equipment) may also apply.

These certifications not only indicate compliance with industry benchmarks but also enhance the machine’s credibility in international markets, making them crucial for buyers from regions like Africa, South America, the Middle East, and Europe.

What Are the Key Quality Control Checkpoints?

Quality control typically involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint assesses raw materials and components for compliance with specifications before production begins.

- In-Process Quality Control (IPQC): During the manufacturing process, various checks are conducted to ensure that the components meet the required tolerances. This could include dimensional checks and functional tests.

- Final Quality Control (FQC): Once the machine is fully assembled, it undergoes extensive testing to verify its performance. This includes operational tests, safety checks, and final inspections to ensure that all components function as intended.

What Common Testing Methods Are Used?

Common testing methods for CNC machines include performance tests, where the machine is operated under various conditions to assess its capabilities. Vibration analysis and thermal imaging may also be employed to identify potential issues that could affect performance or longevity.

Additionally, electrical safety tests ensure that all electrical components comply with safety regulations. For international buyers, understanding these testing methods can provide insights into the machine’s reliability and safety standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers need to be proactive in verifying the quality control measures employed by suppliers. Here are several actionable strategies:

What Steps Can Be Taken to Conduct Supplier Audits?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control processes. Buyers can request to visit the manufacturing facility, observe the production line, and review the quality management systems in place. This firsthand evaluation can reveal the supplier’s commitment to quality.

What Documentation Should Buyers Request?

Buyers should request detailed quality assurance documentation, including quality control reports, certifications, and compliance records. These documents provide a comprehensive overview of the manufacturer’s adherence to international standards and internal quality protocols.

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct inspections at various stages of production, providing unbiased assessments of quality and compliance. This is particularly beneficial for international transactions, where trust in the supplier may be limited.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers must navigate additional complexities when it comes to quality control. Different countries may have varying standards and regulations, which can affect the certification process. For instance, buyers from Africa may face unique challenges in terms of logistics and compliance with local regulations.

Understanding these nuances and being prepared to address them can significantly enhance the purchasing experience. Engaging local experts or consultants who are familiar with both the source and destination markets can also facilitate smoother transactions.

Conclusion

In summary, the manufacturing processes and quality assurance measures for used wood CNC machines are comprehensive and essential for ensuring reliability and performance. By understanding these processes, B2B buyers can make informed decisions, ensuring they source equipment that meets their operational needs while adhering to international standards. Proper due diligence in assessing supplier quality control can lead to successful and sustainable business relationships in a competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘used wood cnc’

Introduction

Navigating the procurement of used CNC wood routers can be a complex process, especially for international B2B buyers. This guide aims to simplify the sourcing journey by providing a step-by-step checklist to ensure you make informed and strategic decisions. By following these steps, you can effectively assess suppliers and select the right machinery that meets your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to outline your specific technical requirements. Determine the size, power, and features of the CNC wood router that align with your production goals.

– Considerations include:

– Maximum workpiece dimensions and weight.

– Required spindle speed and motor power.

– Additional features such as tool changers or vacuum systems.

Step 2: Research Market Trends and Prices

Understanding current market trends and pricing for used CNC routers is vital for making a competitive purchase. Analyze recent sales data and industry reports to gauge the average prices for various models.

– Focus on:

– Historical price trends for specific brands and models.

– Availability of similar machines within your budget range.

– Seasonal fluctuations that might affect pricing.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request comprehensive company profiles, including their experience in the industry and customer testimonials.

– Key actions:

– Ask for case studies demonstrating their successful sales of similar machinery.

– Verify their reputation through third-party review sites and industry forums.

Step 4: Inspect the Machinery

Once you identify potential suppliers, arrange for an inspection of the used CNC wood router. This step is crucial to assess the machine’s condition and functionality firsthand.

– What to check:

– Look for signs of wear and tear or any modifications that might affect performance.

– Test the machine’s operational capabilities and any included accessories or attachments.

Step 5: Verify Compliance and Certifications

Ensure that the equipment complies with local safety and operational standards. This verification protects your investment and ensures that the machinery can be legally operated in your region.

– Important documents to review:

– Certificates of compliance with international standards (e.g., CE marking for Europe).

– Maintenance records that indicate proper servicing and care.

Step 6: Negotiate Terms and Conditions

Once you’re satisfied with the machine and supplier, negotiate the terms of sale. This includes pricing, delivery schedules, and warranty provisions to protect your investment.

– Considerations include:

– Payment terms that suit your financial situation.

– Warranty coverage for repairs or replacements.

– Delivery logistics, including shipping and installation support.

Step 7: Finalize the Purchase Agreement

After negotiations, ensure that all agreements are documented in a formal purchase contract. This contract should clearly outline all terms, including payment, delivery, and post-purchase support.

– Essential elements:

– Detailed specifications of the CNC router.

– Clear timelines for delivery and installation.

– Contact information for support and service inquiries.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing used CNC wood routers with confidence, ensuring they make informed, strategic purchases that meet their operational needs.

Comprehensive Cost and Pricing Analysis for used wood cnc Sourcing

What Are the Key Cost Components in Sourcing Used Wood CNC Machines?

When evaluating the cost structure for used wood CNC machines, several components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The quality and type of materials used in CNC machines significantly affect pricing. Machines with higher-grade components may command a premium but offer better durability and performance.

-

Labor: Labor costs are associated with the refurbishment and maintenance of used CNC machines. Skilled technicians are often required to ensure that machines are in optimal working condition, which can add to the total cost.

-

Manufacturing Overhead: This includes expenses related to utilities, facility costs, and other indirect expenses incurred during the refurbishment process.

-

Tooling: The condition and availability of tooling (like bits and fixtures) can influence pricing. Machines sold with additional tooling may represent better value.

-

Quality Control: Rigorous QC processes ensure that the machines meet operational standards. Suppliers may pass these costs onto buyers, impacting the final price.

-

Logistics: Transportation and handling costs are significant, especially for international buyers. The distance from the supplier to the buyer’s location can substantially influence total costs.

-

Margin: The supplier’s margin varies widely based on market conditions and competition. Understanding this margin can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of Used Wood CNC Machines?

Several factors can influence the pricing of used wood CNC machines, particularly for international buyers.

-

Volume/MOQ: Suppliers may offer discounts for bulk purchases. Understanding minimum order quantities (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Unique specifications or customizations can lead to higher costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials and Quality Certifications: Machines with certifications (e.g., ISO) or made from high-quality materials generally cost more. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their service quality and guarantees.

-

Incoterms: The choice of Incoterms can significantly impact total costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for calculating the final price.

What Buyer Tips Can Help Negotiate Better Prices for Used Wood CNC Machines?

International B2B buyers can leverage several strategies to enhance cost efficiency when sourcing used wood CNC machines:

-

Negotiation Skills: Engaging in open discussions about pricing can yield significant savings. Buyers should research market prices and be prepared to negotiate based on their findings.

-

Total Cost of Ownership (TCO): Beyond the initial purchase price, buyers should consider TCO, which includes maintenance, operational costs, and potential downtime. A slightly higher upfront cost may be justified if the machine offers lower operational costs.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, and the Middle East should be aware of currency fluctuations and import duties, as these can significantly affect the final price. It’s advisable to factor these elements into the budgeting process.

-

Seek Multiple Quotes: Obtaining quotes from several suppliers can provide leverage in negotiations and help buyers identify the best deals.

-

Inspect Before Purchase: If possible, inspecting the machine before finalizing the purchase can prevent costly surprises. Buyers should request detailed photographs and documentation to assess the machine’s condition.

Disclaimer on Indicative Prices

Prices for used wood CNC machines can vary significantly based on the factors outlined above. The information provided serves as a guideline, and buyers are encouraged to conduct thorough due diligence and consult multiple sources before making purchasing decisions.

Alternatives Analysis: Comparing used wood cnc With Other Solutions

Exploring Alternatives to Used Wood CNC Solutions

When considering machinery for woodworking, it’s essential to evaluate various alternatives to used wood CNC routers. Each option offers unique advantages and challenges, allowing businesses to select the best fit based on their operational needs and budget constraints. Below, we compare used wood CNC routers against two viable alternatives: manual woodworking machines and laser cutting technology.

Comparison Table

| Comparison Aspect | Used Wood CNC | Manual Woodworking Machines | Laser Cutting Technology |

|---|---|---|---|

| Performance | High precision and efficiency | Varies; typically lower precision | Extremely high precision; fast |

| Cost | Moderate initial investment | Generally lower initial cost | High initial investment; ongoing material costs |

| Ease of Implementation | Requires skilled operators | Easier for beginners; less training needed | Requires technical training for operation |

| Maintenance | Regular maintenance needed | Low maintenance; simpler mechanics | High maintenance; sensitive components |

| Best Use Case | Large-scale production, intricate designs | Custom, artisanal projects | Highly detailed cuts and engravings |

What Are the Benefits and Drawbacks of Manual Woodworking Machines?

Manual woodworking machines, such as table saws, jointers, and routers, are traditional tools that allow for hands-on craftsmanship. Their primary advantage lies in their lower cost and ease of use. These machines are ideal for smaller operations or businesses focused on custom, artisanal projects where intricate details can be crafted by hand. However, they lack the precision and efficiency of CNC routers, making them less suitable for large-scale production. Additionally, manual methods can lead to increased labor costs as more skilled craftsmen are needed to achieve quality results.

How Does Laser Cutting Technology Compare to Used Wood CNC Routers?

Laser cutting technology employs focused light beams to cut or engrave materials with exceptional precision. This method is particularly advantageous for intricate designs, offering clean cuts and the ability to work with various materials beyond wood, such as acrylic and metal. However, the initial investment for laser cutting machines can be significantly higher than that for used wood CNC routers. Additionally, while laser cutters require less physical effort, they demand technical expertise to operate and maintain, which may present a barrier for some businesses. Despite these drawbacks, the speed and precision of laser cutting can make it a compelling option for specific applications.

How Can B2B Buyers Decide on the Right Solution?

Choosing the right woodworking solution requires careful consideration of various factors, including budget, production volume, and desired precision. For businesses aiming for large-scale production with intricate designs, used wood CNC routers present a balanced solution with high efficiency and precision. Conversely, for smaller operations focused on custom craftsmanship, manual woodworking machines offer flexibility and lower costs. Meanwhile, laser cutting technology stands out for its precision and versatility but comes at a higher price point. Ultimately, B2B buyers should evaluate their specific needs, available resources, and long-term goals to determine the best fit for their woodworking operations.

Essential Technical Properties and Trade Terminology for used wood cnc

What Are the Essential Technical Properties of Used Wood CNC Machines?

When considering the purchase of used wood CNC machines, understanding their technical properties is vital for making informed decisions. Below are critical specifications that B2B buyers should be familiar with:

-

Material Grade

The material grade of a CNC machine determines its durability and capability to process various types of wood. Common materials include steel and aluminum for the frame, which affect the machine’s stability during operation. A higher material grade often translates to a longer lifespan and better performance, making it essential for companies looking to optimize production efficiency. -

Tolerance

Tolerance refers to the allowable deviation from a specified dimension in the machining process. It is crucial for ensuring that parts fit together correctly, especially in industries like cabinetry and furniture making. A tighter tolerance usually results in higher production costs but can significantly enhance the quality of the final product, making it a key consideration for quality-focused businesses. -

Spindle Speed (RPM)

The spindle speed, measured in revolutions per minute (RPM), indicates how fast the cutting tool rotates. Different materials require different spindle speeds for optimal cutting performance. Higher RPMs are generally better for softer woods, while lower speeds are often necessary for harder materials. Understanding spindle speed helps buyers select a machine that meets their specific production needs. -

Table Size

The table size of a CNC router dictates the dimensions of materials that can be processed. Standard sizes vary, and selecting the appropriate table size is crucial for accommodating your typical workpiece dimensions. A larger table allows for more versatility but may also increase the machine’s footprint and cost. -

Axis Configuration

CNC routers come with various axis configurations, typically ranging from 3-axis to 5-axis machines. The number of axes affects the complexity of cuts that can be achieved. For intricate designs and detailed work, a multi-axis machine is preferable, while simpler tasks may only require a 3-axis setup. -

Vacuum System

A robust vacuum system is essential for holding materials securely during machining. This feature is particularly important when working with large sheets of wood, as it minimizes movement and enhances precision. Buyers should consider the efficiency and capacity of the vacuum system to ensure it meets their production requirements.

What Are Common Trade Terms in the Used Wood CNC Industry?

Familiarity with industry terminology can greatly enhance communication and negotiation between buyers and sellers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products or components that are sold under another company’s brand name. Understanding whether a used CNC machine is from an OEM can help assess its reliability and support options. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. In the context of used CNC machines, this term may apply to additional components or accessories. Knowing the MOQ can help buyers manage inventory and budget effectively. -

RFQ (Request for Quotation)

An RFQ is a formal document soliciting price quotes from suppliers. For buyers interested in used wood CNC machines, submitting an RFQ can streamline the procurement process, ensuring that they receive competitive pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that outline the responsibilities of buyers and sellers in shipping and delivery. Familiarity with these terms helps buyers understand shipping costs, risks, and obligations associated with their purchase. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For used CNC machines, understanding the lead time is crucial for planning production schedules and ensuring timely delivery of equipment. -

Refurbished

A refurbished CNC machine has been restored to a condition that meets certain performance standards. Buyers should inquire about the refurbishment process, as it can significantly affect the machine’s reliability and lifespan.

By grasping these essential technical properties and trade terms, B2B buyers can navigate the used wood CNC market more effectively, ensuring that they make informed purchasing decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the used wood cnc Sector

What Are the Current Market Dynamics and Key Trends in the Used Wood CNC Sector?

The global market for used wood CNC machines is experiencing significant growth, driven by factors such as rising demand for precision manufacturing, increased automation in woodworking, and the need for cost-effective production solutions. B2B buyers from regions like Africa, South America, the Middle East, and Europe, particularly in countries like Saudi Arabia and Nigeria, are increasingly seeking affordable options to enhance their production capabilities without incurring the high costs associated with new machinery.

Emerging trends highlight a shift towards digitalization and integration of advanced technologies, such as IoT-enabled CNC machines that provide real-time monitoring and predictive maintenance capabilities. This shift not only enhances operational efficiency but also reduces downtime, making it a compelling proposition for manufacturers in developing markets. Additionally, the rise of online marketplaces for used machinery is facilitating easier access to global suppliers, enabling buyers to compare models and prices efficiently.

Another key trend is the growing preference for versatile machines that can handle various materials beyond wood, such as composites and plastics. This adaptability allows manufacturers to diversify their offerings and cater to a broader range of clients, a crucial factor in competitive markets. As these dynamics unfold, international buyers must stay informed about technological advancements and shifting consumer preferences to make informed sourcing decisions.

How Does Sustainability and Ethical Sourcing Impact the Used Wood CNC Market?

Sustainability is becoming increasingly important for businesses operating in the used wood CNC sector. The environmental impact of manufacturing processes, including waste generation and energy consumption, has prompted companies to seek eco-friendly alternatives. This shift is particularly relevant for B2B buyers in regions where regulatory frameworks are evolving to prioritize sustainable practices.

Ethical sourcing is essential in this context. Buyers should ensure that their suppliers adhere to responsible sourcing practices, particularly regarding the materials used in CNC machines. The use of certified ‘green’ materials, such as sustainably sourced wood and recycled components, is gaining traction. Such certifications not only enhance the credibility of suppliers but also align with the growing consumer demand for environmentally responsible products.

Furthermore, integrating sustainability into the supply chain can lead to cost savings and improved brand reputation. B2B buyers are encouraged to engage with suppliers who prioritize sustainability and can provide transparent information about their sourcing practices, thus fostering a more ethical and environmentally friendly marketplace.

What Is the Brief Evolution and History of CNC Technology Relevant to B2B Buyers?

CNC technology has its roots in the early 1950s when it was first developed for the aerospace industry. Over the decades, it has evolved from simple, manually programmed machines to highly sophisticated systems capable of executing complex tasks with unparalleled precision. The introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) software in the 1980s further revolutionized the industry, allowing for greater automation and efficiency in woodworking.

In the context of used wood CNC machines, this evolution has led to a vast array of options available to B2B buyers. As businesses increasingly look to upgrade their capabilities, the market for used CNC machinery has flourished, providing opportunities for cost-effective investments. Understanding the historical context of CNC technology can help buyers appreciate the advancements that have shaped the current landscape, ensuring they make informed decisions when sourcing equipment.

Conclusion

Navigating the used wood CNC sector requires a keen understanding of market dynamics, sustainability considerations, and the historical context of CNC technology. By staying abreast of these factors, international B2B buyers can make informed decisions that not only enhance their operational capabilities but also align with broader environmental and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of used wood cnc

1. How do I ensure the quality of used wood CNC machines before purchasing?

To ensure quality, start by requesting detailed documentation on the machine’s history, including maintenance records and previous usage. Consider conducting a physical inspection or hiring a third-party expert to assess the condition. Pay attention to key features such as spindle performance, software compatibility, and the overall mechanical integrity. Additionally, inquire about warranties or guarantees offered by the seller, as these can provide added assurance regarding the machine’s reliability.

2. What is the best type of used wood CNC router for small-scale furniture production?

For small-scale furniture production, a versatile CNC router with a working area of around 4×8 feet is often ideal. Models like the Laguna SmartShop or AXYZ Pacer series offer robust capabilities for intricate cuts and designs while maintaining cost-effectiveness. Look for features such as automatic tool changers (ATC) and vacuum hold-down systems to enhance efficiency and precision. It’s also beneficial to choose a machine with a strong support network for software and parts.

3. What are the common payment terms for purchasing used wood CNC machines internationally?

Payment terms can vary widely among suppliers, but common practices include upfront payments, deposits, or payment upon delivery. Many suppliers accept letters of credit, which can provide additional security for both parties. Ensure to discuss and agree on payment terms before finalizing the transaction. It’s advisable to use secure payment platforms or methods that offer buyer protection, especially for international transactions.

4. How do I vet suppliers of used wood CNC machines?

Vetting suppliers involves several steps: First, check their reputation through online reviews and testimonials from previous customers. Request references and reach out to them for feedback. Verify the supplier’s business credentials and ensure they comply with local regulations. Additionally, assess their customer service responsiveness and willingness to provide detailed machine information. Attending industry trade shows or exhibitions can also help you connect with reputable suppliers.

5. Can I customize a used wood CNC machine to fit my specific needs?

Yes, many used CNC machines can be customized or retrofitted to meet specific operational requirements. This may include adding new software, upgrading components like spindles or tool changers, or modifying the machine’s working area. When considering customization, consult with the supplier or a CNC specialist to ensure that the modifications are feasible and cost-effective. Be aware of the potential impact on warranties and support.

6. What is the minimum order quantity (MOQ) for used wood CNC equipment?

The MOQ for used CNC machines can vary significantly based on the supplier and the type of machine. Some suppliers may offer individual machines, while others might require a minimum order of multiple units, especially for bulk purchases. It’s essential to clarify the MOQ with the supplier before proceeding, as this can affect your overall investment and operational planning.

7. What logistics considerations should I keep in mind when importing used wood CNC machines?

When importing used CNC machines, consider shipping costs, customs duties, and import regulations specific to your country. Ensure that the supplier provides proper documentation for customs clearance, including invoices and certificates of origin. It’s advisable to work with a logistics partner experienced in heavy machinery to facilitate transportation and installation. Plan for potential delays in shipping and customs processing.

8. How can I ensure proper training for my team on a used wood CNC machine?

To ensure effective training, inquire if the supplier offers training programs or resources for the specific model you are purchasing. Many suppliers provide operational manuals, video tutorials, or on-site training as part of the sale. Consider scheduling hands-on training sessions for your team, which can significantly enhance their proficiency with the machine. Additionally, online forums and user groups can be valuable resources for ongoing support and knowledge sharing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Used Wood Cnc Manufacturers & Suppliers List

1. Multicam – SMARTSHOP M

Domain: cncmachines.com

Registered: 1997 (28 years)

Introduction: Used Industrial CNC Routers available at CNCMachines.com. Key brands include Multicam, Laguna, Industrial CNC, Avid, ShopSabre, C.R. Onsrud, and Vision. Models include LAGUNA SMARTSHOP M, INDUSTRIAL CNC ARTISAN 408, BIESSE ROVER K FT1531, AVID PRO 60120, LAGUNA SMARTSHOP 2, VISION VR48, and more. Specifications include various sizes and features such as vacuum systems, dust collectors, probes, and…

2. Vevor – S4040 CNC Router Machine 300W

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: CNC Woodworking Routers for sale on eBay include various types such as 3 Axis Router Machines, 4 Axis Router Machines, Mini CNC Routers, and Engraver Machines. Key products listed are: 1. Vevor S4040 CNC Router Machine 300W 3 Axis Wood Engraving Milling Machine – $296.99 (New) 2. Rockler Corner Radius Routing Templates – $28.95 (New), $15.00 (Used) 3. RATTM Motor 1610PRO-MJ Mini Router Machine Kit…

3. Andi – Stratos CNC Router

Domain: exfactory.com

Registered: 1995 (30 years)

Introduction: This company, Andi – Stratos CNC Router, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

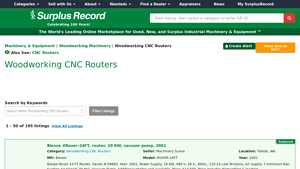

4. CNC Woodworking Routers – Key Manufacturers

Domain: surplusrecord.com

Registered: 1995 (30 years)

Introduction: Used CNC Woodworking Routers For Sale | Surplus Record

Key Product Details:

1. **Manufacturers:**

– Weeke (18)

– Biesse (15)

– Homag (13)

– Onsrud (13)

– Komo (10)

– Morbidelli (9)

– Thermwood (8)

– Scm (7)

– Cam-Wood (6)

– Holz-Her (6)

– Multicam (6)

– Scmi (6)

– Baileigh (5)

– Cosmec (5)

– Felder (5)

– Busellato (4)

– Camaster (4)

– Giben (…

5. CaMaster – CNC Wood Router

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, CaMaster – CNC Wood Router, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. CNC Routers – Used Equipment for Sale

Domain: kdcapital.com

Registered: 2003 (22 years)

Introduction: Used CNC Routers for Sale – KD Capital Equipment offers a variety of used CNC routers, updated daily. The product categories include brands such as AXYZ, AccTek, Anderson, Baileigh, Biesse, CAMaster, CMS, CR Onsrud, DeMichele Group, Denver, Edge-Sweets, Elumatec, FOM, Felder, Gerber, Haas, Hensel Burkhardt, Holz-Her, Homag, Komo, Laguna, Legacy, Motionmaster, Multicam, NewCNC, OZ Machine, Quintax,…

7. Machineseeker – Used CNC Wood

Domain: machineseeker.com

Registered: 1999 (26 years)

Introduction: Used CNC Wood for sale on Machineseeker.com. Key product details include:

– Categories: Woodworking machinery, Metal working machinery, Commercial vehicles, Waste management & recycling equipment, Industrial automation technology, etc.

– Manufacturers: Mercedes-Benz, SCM, WEINIG, HOMAG, WINTER, BIESSE, Mazak, Renault, Holzkraft, HOLZ-HER, etc.

– Condition: New, Ex-display machine, Used, Defecti…

8. Revelation Machinery – CNC Routers

Domain: revelationmachinery.com

Registered: 2016 (9 years)

Introduction: CNC routers are machines that cut various materials including steel, glass, wood, plastics, foam, and stone. They can perform functions such as punching, grooving, milling, and engraving. These computer-controlled machines are similar to milling machines, using programs to control tool paths, commonly in G-code, Heidenhain, or Mazak programming languages. CNC routers have a rotating tool/cutter co…

9. Ibid Machinery – Weeke Optimat Vertical CNC Machine

Domain: ibidmachinery.com

Registered: 2020 (5 years)

Introduction: [{‘name’: ‘2016 Weeke Optimat Vertical CNC Machine’, ‘location’: ‘Pennsylvania’, ‘regular_price’: ‘$188,000.00 USD’, ‘sale_price’: ‘$130,000.00 USD’, ‘availability’: ‘In stock’}, {‘name’: ‘2020 Gannomat Index 280 Trend CNC Drill and Dowel’, ‘location’: ‘Illinois’, ‘regular_price’: ‘$93,000.00 USD’, ‘sale_price’: ‘$75,000.00 USD’, ‘availability’: ‘In stock’}, {‘name’: ‘2021 Morbidelli UX 200 CNC Dr…

10. X Carve Pro – CNC Machine for Woodworking

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: All inclusive CNC for beginner with a price limit of $8-10K for woodworking. Intended for making cutting boards, inlays, bowls, and furniture templates. Desired bed size: 4′ x 2′ or 4′ x 4′. Preference for a pro model that comes mostly assembled. Considering options like X Carve Pro and Onefinity. Recommendations include Shapeoko 5 Pro and Stepcraft M1400 with automatic tool changer for commercial…

Strategic Sourcing Conclusion and Outlook for used wood cnc

The market for used wood CNC machines presents significant opportunities for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. By strategically sourcing these machines, businesses can enhance their production capabilities while managing costs effectively. Key takeaways include the importance of evaluating machine condition, understanding the specific needs of your operations, and leveraging the diverse range of models available, from brands like Biesse and AXYZ to Haas and Laguna.

Investing in used CNC routers not only provides access to advanced technology but also supports sustainability by extending the lifecycle of manufacturing equipment. As companies worldwide prioritize efficiency and innovation, now is the time to capitalize on these opportunities.

Looking ahead, B2B buyers should be proactive in exploring partnerships with reliable suppliers and considering the evolving needs of their markets. By doing so, you can ensure that your operations remain competitive in a rapidly changing landscape. Embrace the potential of used wood CNC machinery and position your business for future success. Start your sourcing journey today to unlock the benefits of quality machinery at competitive prices.