Contents

Manufacturing Insight: Up And Down Milling Machine

Clarifying Milling Strategies and Honyo Prototype’s Precision CNC Capabilities

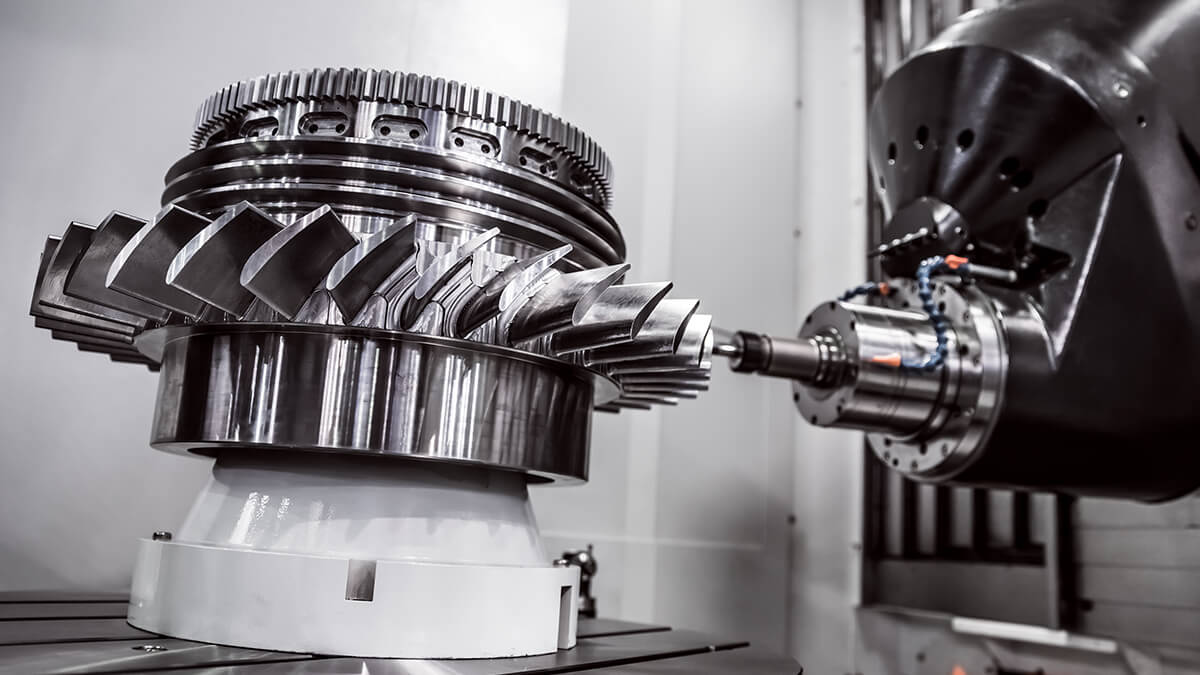

It is important to clarify that the terms “up milling” and “down milling” refer to distinct cutting strategies—conventional milling (up milling) and climb milling (down milling)—rather than separate machine types. Both techniques are executed on modern CNC milling centers, where precise control over spindle direction, feed rate, and toolpath geometry determines the optimal approach for a given application. At Honyo Prototype, our advanced 3-, 4-, and 5-axis CNC machining centers leverage these strategies with engineering rigor to deliver exceptional part accuracy, surface finish, and material integrity across aluminum, steel, titanium, and engineering plastics.

Our manufacturing process begins with strategic analysis: conventional milling mitigates chatter in interrupted cuts or thin-walled features, while climb milling maximizes tool life and surface quality in continuous contouring. This expertise ensures your prototypes and low-volume production parts meet stringent GD&T requirements without compromising efficiency. Every job benefits from our in-house metrology lab, real-time process monitoring, and engineer-to-engineer collaboration to resolve manufacturability challenges early.

For immediate project assessment, Honyo Prototype’s Online Instant Quote platform provides transparent, geometry-driven pricing within hours—not days. Simply upload your STEP or IGES file to receive a detailed manufacturability analysis, lead time estimate, and competitive quote, empowering faster decision-making for your next development cycle.

Material & Process Capabilities Summary

| Parameter | Specification |

|———————|———————————————–|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling centers |

| Max Work Envelope | 1000 x 600 x 500 mm |

| Tolerances | ±0.005 mm standard; ±0.001 mm precision |

| Lead Time | As fast as 3 business days for prototypes |

| Supported Formats | STEP, IGES, Parasolid, native CAD files |

Partner with Honyo Prototype to transform complex designs into precision-machined reality, backed by decades of aerospace and medical-grade manufacturing discipline. Initiate your project today through our Online Instant Quote system for responsive, engineering-led support.

Technical Capabilities

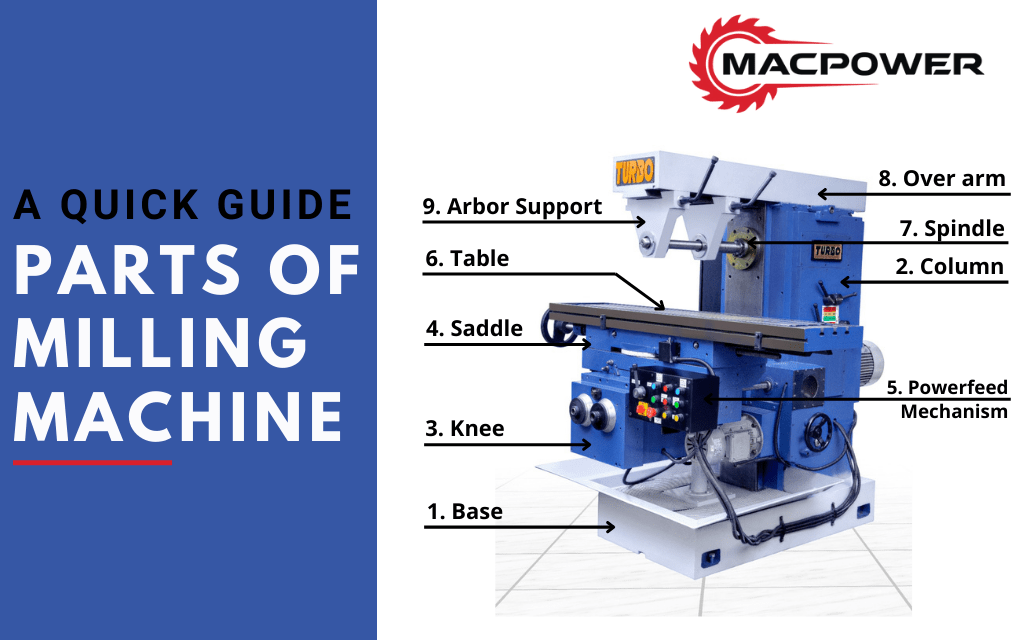

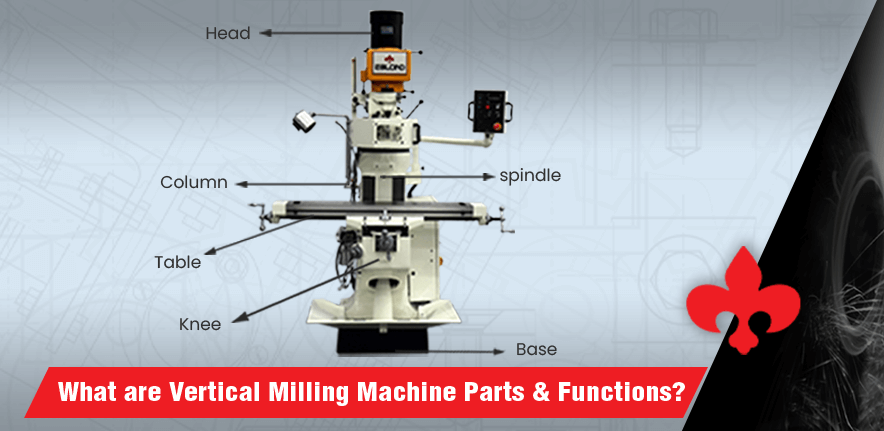

Honyo Prototype delivers high-precision machining solutions using advanced 3, 4, and 5-axis milling machines integrated with turning capabilities for complex, tight-tolerance components. These multi-axis CNC machining centers combine milling and turning operations to achieve superior accuracy, surface finish, and geometric complexity across a range of engineering materials including aluminum, steel, ABS, and nylon.

Below are the technical specifications for our up and down (simultaneous multi-axis) milling and turning systems:

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis Simultaneous Milling with Live Tooling Turning (Mill-Turn Center) |

| Axis Configuration | X, Y, Z linear axes with A (rotary table) and B (tilting spindle) rotational axes |

| Spindle Speed | Up to 24,000 RPM (high-speed for aluminum and plastics), configurable for steel |

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Tolerance Range | ±0.005 mm (standard), down to ±0.002 mm for critical features |

| Tool Changer Capacity | 30–60 tools (automatic tool changer with ATC) |

| Maximum Work Envelope (XYZ) | 800 mm × 600 mm × 500 mm (configurable based on machine model) |

| Rotary Table Range (A-axis) | Continuous 360° rotation |

| Spindle Tilt (B-axis) | ±110° tilt capability for complex 5-axis tool paths |

| Control System | Siemens SINUMERIK 840D or Fanuc 31i-B5 for high-precision motion control |

| Rapid Traverse Rate | 60 m/min (X/Y/Z), 36 m/min (rotary axes) |

| Material Compatibility | Aluminum (6061, 7075), Steel (4140, 1018, Stainless 304/316), ABS, Nylon (PA6, PA66) |

| Surface Finish (Typical) | Ra 0.8 µm (milled), Ra 1.6 µm (turned), polishable to Ra 0.4 µm |

| Coolant System | High-pressure through-spindle coolant (for steel/aluminum), air cooling (for ABS/nylon) |

| In-Process Probing | Available with Renishaw touch probes for automated setup and inspection |

| Applications | Aerospace components, medical devices, automotive molds, precision housings |

These mill-turn centers support both up milling (conventional milling) and down milling (climb milling) strategies, selected automatically based on geometry and material to optimize tool life, surface quality, and dimensional stability. The integration of 4th and 5th axes enables single-setup machining of complex geometries, minimizing cumulative tolerances and ensuring high repeatability across production runs.

From CAD to Part: The Process

Honyo Prototype specializes in rapid manufacturing services including CNC milling, not the production of milling machines themselves. Our process applies to customer part fabrication using advanced equipment such as up/down milling configurations. Below is the precise workflow for customer part production:

Upload CAD

Customers submit 3D CAD files (STEP, IGES, or native formats) via our secure portal. The system validates file integrity and extracts critical geometric data. For milling projects, this stage identifies features requiring climb milling (down milling) or conventional milling (up milling) based on wall geometry, material, and tolerance requirements.

AI Quote

Our proprietary AI engine analyzes the CAD model against real-time machine capacity, material costs, and process parameters. It automatically determines optimal toolpaths, including milling direction strategy. The AI evaluates whether climb milling (reducing tool deflection on thin walls) or conventional milling (for cast surfaces) is appropriate, generating a quote with lead time and cost within 2 hours. Material waste and fixture requirements are factored into the calculation.

DFM Analysis

Engineers perform a formal Design for Manufacturability review within 24 hours. For CNC milling projects, this includes specific validation of milling direction feasibility. Key checks include:

| DFM Check Category | Milling-Specific Parameters | Action if Non-Compliant |

|---|---|---|

| Geometry Validation | Wall thickness vs. tool diameter, internal corner radii | Recommend design modification or specialized tooling |

| Tolerance Assessment | Surface finish requirements vs. climb/conventional capability | Adjust process parameters or suggest alternative finishing |

| Material Considerations | Workpiece hardness vs. recommended milling direction | Switch between up/down milling strategy in CAM plan |

This stage confirms whether the design can leverage climb milling for precision features or requires conventional milling for stability, with documented recommendations.

Production

Approved parts enter our CNC workflow. For milling operations:

Up milling (conventional) is applied for initial roughing of cast/forged stock to manage variable material engagement.

Down milling (climb) is used for final finishing passes on milled surfaces to achieve ±0.005mm tolerances and superior surface finishes.

All milling occurs on HAAS VF-2SSYT vertical machining centers with Renishaw probing for in-process verification. Toolpath simulations are validated against DFM recommendations before machining begins.

Delivery

Completed parts undergo first-article inspection using CMM and optical comparators. Dimensional reports matching AS9102 standards are provided. Parts ship via DHL/FedEx with real-time tracking. Typical lead time from CAD upload to delivery is 5-7 business days for milled components, with expedited options available. All deliverables include process documentation specifying critical milling directions applied during production.

Start Your Project

For inquiries about the up and down milling machine, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring efficient production and quality control for your prototyping and machining needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.