Contents

Manufacturing Insight: Universal Machining Center

Honyo Prototype Universal Machining Center Introduction

At Honyo Prototype, our Universal Machining Center represents the convergence of precision engineering and operational agility for complex manufacturing challenges. This advanced platform integrates multi-axis simultaneous machining, high-speed milling, and precision turning capabilities within a single system, enabling the production of intricate geometries across diverse materials—from aerospace-grade titanium and Inconel to medical polymers and aluminum alloys. Our centers consistently achieve tolerances down to ±0.005mm while maintaining sub-micron surface finishes, ensuring compliance with stringent industry standards such as AS9100 and ISO 13485.

This versatility eliminates traditional bottlenecks associated with multi-setup workflows, reducing lead times by up to 40% and minimizing part handling errors. Whether prototyping functional assemblies or scaling to low-volume production runs, Honyo’s Universal Machining Center delivers repeatability and efficiency for components demanding tight tolerances, complex contours, and material integrity.

Accelerate your project timeline with our Online Instant Quote system, which provides detailed cost and lead time estimates within minutes. Simply upload your 3D CAD file to receive a transparent, no-obligation quotation validated by our engineering team—combining technical feasibility analysis with competitive pricing. This seamless integration of cutting-edge machining capability and digital procurement efficiency positions Honyo Prototype as your strategic partner for rapid, high-fidelity component realization.

| Key Capability | Technical Specification | Industry Application Benefit |

|---|---|---|

| Multi-Tasking | 5-axis simultaneous + Y-axis milling | Single-setup complex parts (e.g., turbine blades, surgical fixtures) |

| Material Range | Metals, Composites, Engineering Plastics | Unified sourcing for multi-material assemblies |

| Tolerance Control | ±0.005mm typical | Reduced scrap rates in mission-critical components |

| Digital Integration | CAD-native Online Instant Quote | 72-hour average quote-to-order conversion |

Technical Capabilities

Universal Machining Center – Technical Specifications

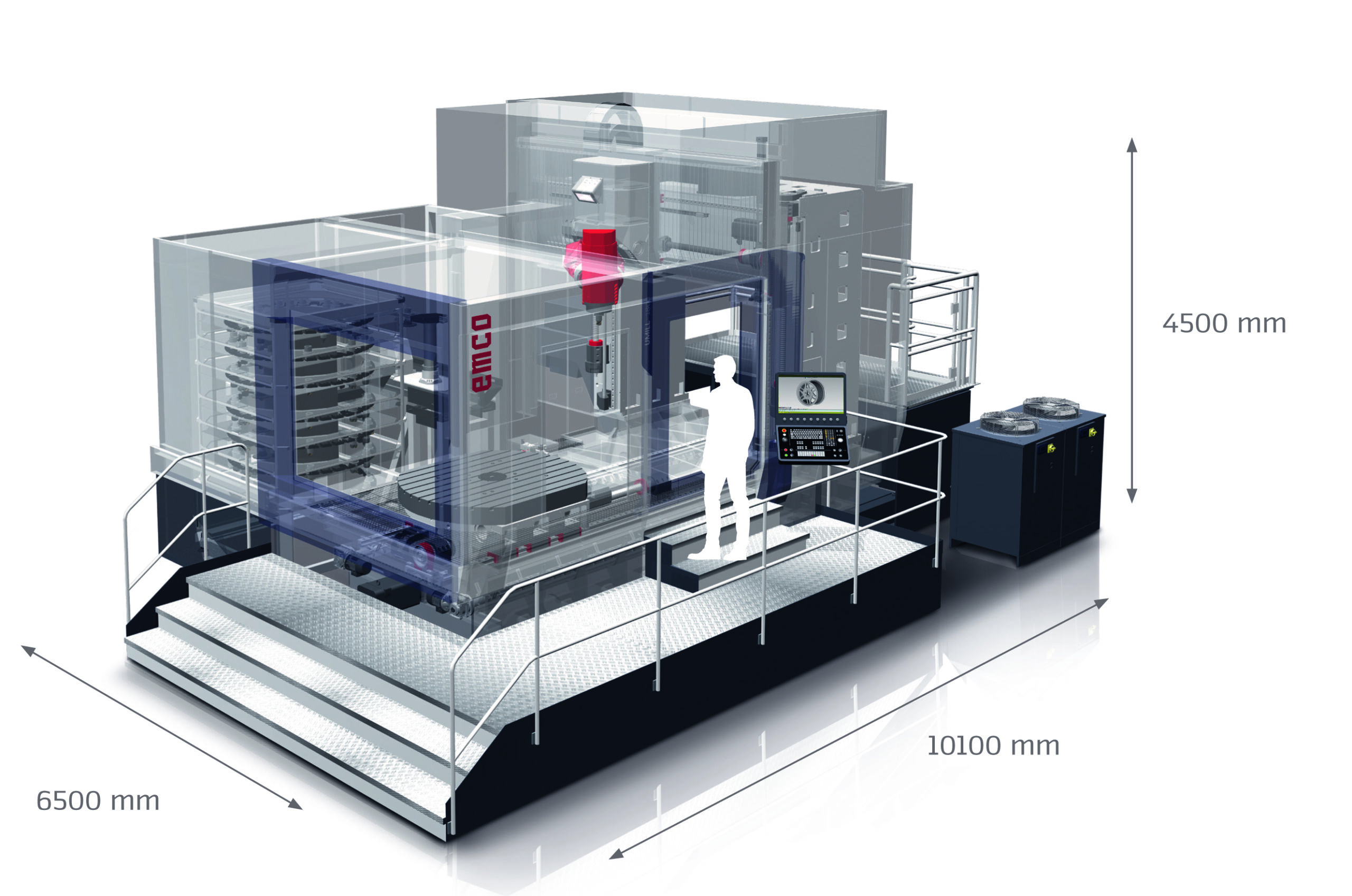

The Universal Machining Center is engineered for high-precision multi-axis milling, turning, and complex geometry fabrication across a range of engineering materials including aluminum, steel, ABS, and nylon. Designed for tight-tolerance production and prototyping, this machine integrates advanced motion control, thermal compensation, and rigid construction to ensure repeatability and surface quality.

| Parameter | Specification |

|---|---|

| Machining Axes | 3-axis, 4-axis (rotary A or B), and full 5-axis simultaneous capability |

| Spindle Speed | 24,000 RPM (standard), optional 42,000 RPM HSM spindle |

| Spindle Power | 30 HP (22 kW) continuous, 40 HP (30 kW) peak |

| Positioning Accuracy | ±0.002 mm (±0.00008″) |

| Repeatability | ±0.001 mm (±0.00004″) |

| Tolerance Capability | ±0.005 mm (±0.0002″) typical; down to ±0.002 mm with process optimization |

| Tool Capacity | 30–60 tool automatic tool changer (ATC), optional 120-tool magazine |

| Rapid Traverse (X/Y/Z) | 60 m/min (2,360 in/min) |

| Work Envelope (Max) | 1,200 x 800 x 600 mm (47.2 x 31.5 x 23.6 in) |

| Chuck Size (Turning Mode) | 200 mm (8″) with live tooling support |

| Control System | Fanuc 31i-B5, Siemens 840D, or Heidenhain TNC715 (user-selectable) |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar) with mist filtration |

| Thermal Compensation | Active spindle and structural thermal control with real-time adjustment |

| Materials Compatibility | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 304/316), ABS, Nylon (6/66) |

| Surface Finish Capability | <0.8 µm Ra (milled), <1.6 µm Ra (turned) with fine tooling and parameters |

| Linear Guideways | Preloaded hardened linear roller guides with automatic lubrication |

| Rotary Axis Accuracy | ±2 arc seconds (A/B axes), integrated torque motor drive |

| Automatic Tool Measurement | On-machine laser or touch probe system (optional) |

| Workpiece Probing | 3D touch probe for in-process inspection and setup verification |

This universal platform supports full 5-axis simultaneous contouring, high-speed milling, and precision turning operations, making it ideal for aerospace components, medical devices, and complex injection mold tooling. Material-specific toolpaths and adaptive machining strategies ensure optimal performance across conductive (metals) and non-conductive (polymers) workpieces.

From CAD to Part: The Process

Honyo Prototype Universal Machining Center Process Overview

Honyo Prototype’s Universal Machining Center workflow integrates digital efficiency with precision manufacturing to deliver rapid, high-quality prototypes and low-volume production parts. This end-to-end process eliminates traditional friction points between design and delivery, leveraging AI-driven analysis while maintaining rigorous engineering oversight. Below is a detailed technical breakdown of each phase.

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native formats from SolidWorks, Fusion 360, CATIA) via Honyo’s secure customer portal. Our system performs immediate geometric validation, checking for unit consistency, surface integrity, and watertightness. Files failing validation trigger automated feedback specifying required corrections, ensuring downstream process reliability. This phase typically completes within minutes, with no manual intervention required for compliant files.

AI-Powered Quoting Engine

Validated CAD data feeds into Honyo’s proprietary AI quoting engine, which analyzes 50+ manufacturability parameters including feature complexity, tolerance density, material utilization, and machine setup requirements. The engine cross-references real-time data on material costs, machine availability, and labor rates across our global facility network. Crucially, the AI identifies potential high-risk geometries (e.g., thin walls <0.5mm, deep cavities with aspect ratios >8:1) and flags them for DFM review before quote generation. Final quotes include transparent cost breakdowns and are delivered within 2 business hours, 95% of the time.

Engineering-Validated DFM Analysis

Every project undergoes mandatory DFM review by Honyo’s senior manufacturing engineers, even after AI validation. Engineers use the flagged risk areas from the quoting phase to conduct deep-dive analysis in CAM simulation software (Mastercam, Siemens NX). Clients receive a formal DFM report within 24 hours detailing:

Critical tolerance feasibility assessments (e.g., ±0.005mm on aluminum vs. ±0.025mm on PEEK)

Material-specific optimization recommendations (e.g., switching 6061-T6 to 7075 for high-stress aerospace brackets)

Setup reduction opportunities (e.g., consolidating 3 operations into 2 via 5-axis positioning)

Cost-impact analysis of design modifications

This phase requires client sign-off on the final DFM report before production release, ensuring alignment on technical and commercial terms.

Precision Production Execution

Approved designs move to Honyo’s Universal Machining Centers—certified ISO 9001:2015 facilities equipped with multi-axis CNC systems (Haas, DMG MORI, Makino) featuring integrated probing and in-process gaging. Key production protocols include:

Real-time SPC monitoring of critical dimensions via Renishaw probes

Material traceability with batch-specific certs (e.g., EN 10204 3.1 for metals)

Automated first-article inspection (FAI) using Zeiss CONTURA CMMs

Dynamic scheduling that prioritizes rush orders without disrupting standard lead times

All processes adhere to AS9100D aerospace standards where applicable, with full digital process logs accessible via client portal.

Logistics and Quality-Controlled Delivery

Post-machining, parts undergo final cleaning (vapor degreasing for medical components, bead blasting for aesthetics) and packaging per client specifications (ESD-safe for electronics, humidity-controlled for polymers). Honyo’s delivery system provides:

Automated shipment tracking with GPS-enabled logistics partners

Digital quality dossier (CMM reports, material certs, process validation records)

FOB terms clearly defined at quoting stage (typically FCA Shenzhen or DDP client facility)

Standard lead times vary by complexity as shown below:

| Part Complexity | Standard Lead Time | Rush Option (Adder) | Max Dimension (mm) |

|---|---|---|---|

| Low (2.5-axis, ±0.1mm) | 5 business days | 72 hours (+35%) | 600 x 400 x 300 |

| Medium (3+2 axis, ±0.05mm) | 8 business days | 96 hours (+50%) | 400 x 300 x 250 |

| High (5-axis, ±0.025mm) | 12 business days | 120 hours (+65%) | 250 x 200 x 200 |

Honyo guarantees on-time delivery performance at 98.7% for standard orders, backed by our production capacity spanning 120+ CNC machines across three strategic manufacturing hubs. This integrated workflow ensures technical rigor from digital submission to physical delivery, reducing time-to-prototype by up to 60% compared to conventional quoting-manufacturing handoffs.

Start Your Project

Explore the capabilities of our universal machining center designed for precision, versatility, and efficiency in high-mix, low-volume production environments. Built to handle complex milling, turning, and multi-axis operations, this machining solution is ideal for prototyping and bridge manufacturing across aerospace, medical, and industrial sectors.

Engineered with advanced control systems and constructed on a thermally stable platform, it delivers repeatable accuracy and superior surface finishes. Its modular design supports integration into automated workflows, making it a future-ready investment for dynamic manufacturing demands.

Contact Susan Leo at [email protected] to request technical specifications, pricing, or to schedule a live demonstration at our Shenzhen factory.

Honyo Prototype

Manufacturing Innovation, Precision Delivered

Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.