Contents

Manufacturing Insight: Unique Sheet Metal

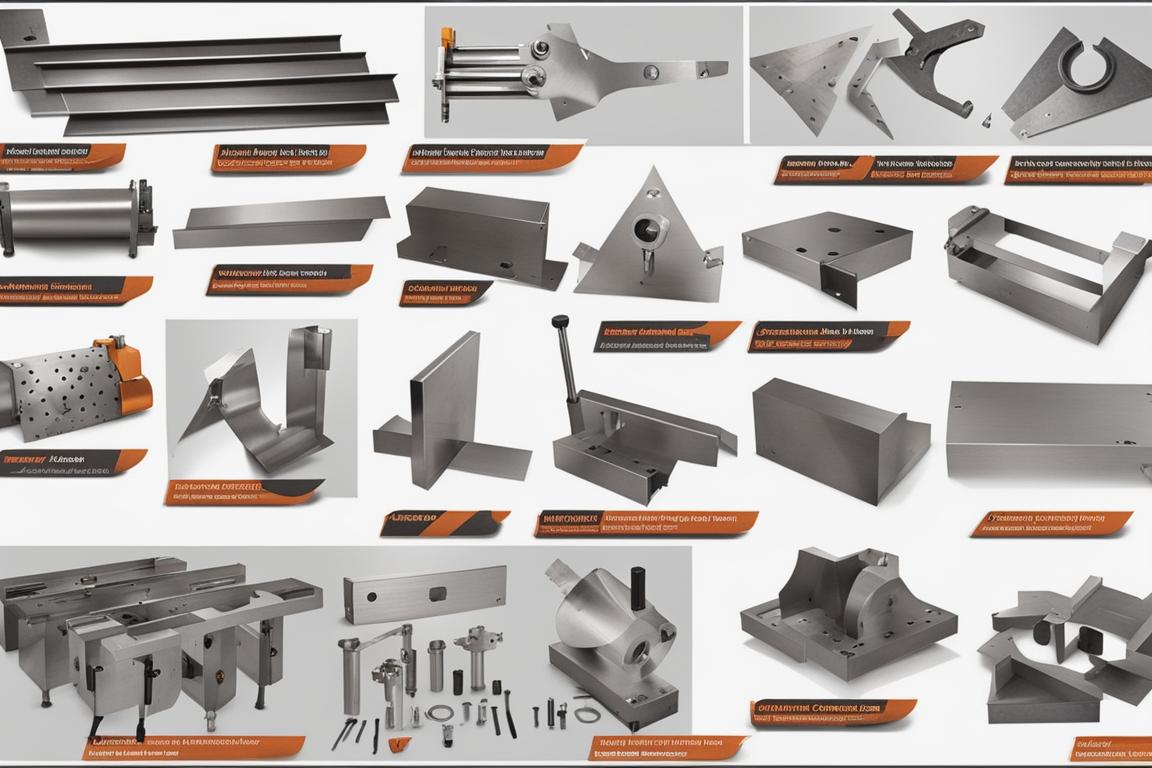

Elevate Your Prototyping and Low-Volume Production with Precision Sheet Metal Fabrication

At Honyo Prototype, we recognize that standard sheet metal solutions often fall short when engineering demands unique geometries, tight tolerances, or rapid iteration. Our Sheet Metal Fabrication services are engineered specifically for B2B clients who require complex, custom metal components without the delays of traditional manufacturing procurement. We excel in transforming intricate designs—from laser-cut enclosures and formed brackets to multi-stage welded assemblies—using advanced CNC punching, bending, and laser cutting technologies capable of holding sub-0.1mm tolerances across materials including 304/316 stainless steel, 5052/6061 aluminum, and cold-rolled steel.

What sets Honyo apart is our commitment to accelerating your development cycle. Unlike conventional vendors requiring manual RFQ reviews, our proprietary Online Instant Quote platform delivers binding pricing and lead times in under 60 seconds. Simply upload your STEP or DXF file, specify material and finish requirements, and receive immediate transparency on cost and manufacturability—eliminating days of back-and-forth communication. This seamless integration of engineering expertise and digital efficiency ensures your unique sheet metal components move from concept to certified hardware faster, with zero compromise on quality or technical support.

Partner with Honyo Prototype to resolve your most demanding fabrication challenges with precision, speed, and unwavering reliability. Your next breakthrough component is only a quote away.

Technical Capabilities

Technical Specifications for Unique Sheet Metal Fabrication

The term “unique sheet metal” refers to custom-engineered sheet metal components that require precision processing through laser cutting, bending, and welding. These parts often involve complex geometries, tight tolerances, and multi-material integration. Below are the technical specifications for key fabrication processes with emphasis on compatible materials including Aluminum, Steel, ABS, and Nylon.

| Parameter | Laser Cutting | Bending | Welding |

|---|---|---|---|

| Material Compatibility | Aluminum (5052, 6061), Steel (Mild, Stainless 304/316), ABS (limited), Nylon (limited) | Aluminum, Steel (Mild, Stainless) — ABS and Nylon not suitable for bending | Aluminum (TIG/MIG), Steel (MIG/Stick/TIG) — ABS and Nylon not weldable via traditional methods |

| Thickness Range | 0.5 mm – 12 mm (Aluminum & Steel); ABS/Nylon: up to 6 mm (with CO₂ laser) | 0.8 mm – 6 mm (Aluminum & Steel); excludes thermoplastics | 1.0 mm – 10 mm (Aluminum & Steel); thermoplastics require specialty joining |

| Tolerance | ±0.1 mm (precision cut with fiber laser) | ±0.2° angular tolerance; ±0.1 mm linear bend placement | ±0.5 mm positional tolerance; post-weld distortion ≤ 0.5 mm per 100 mm |

| Edge Quality | Burr-free edges with minimal heat-affected zone (HAZ) | Smooth, crack-free bends with controlled grain direction | Smooth, spatter-controlled weld beads; post-clean acceptable |

| Process Notes | Fiber laser preferred for metals; CO₂ laser used for thicker non-metals | Requires tool-specific punch/die sets; minimum bend radius = 1× material thickness | Gas shielding (Ar for Al, CO₂/Mixed for Steel); fixturing critical |

| Surface Finish | Matte finish; optional deburring or passivation for corrosion resistance | Can retain mill finish; anodizing/painting post-forming | Requires grinding/polishing; post-weld coating often applied |

| Joining Alternatives for ABS/Nylon | Cut via CO₂ laser; no post-laser welding | Not applicable — thermoforming preferred for shaping | Ultrasonic welding, solvent bonding, or mechanical fasteners required |

Notes:

Aluminum and Steel are primary materials for full-process fabrication (cut, bend, weld).

ABS and Nylon are thermoplastics typically not classified as sheet metal but may be included in hybrid assemblies. They are process-limited: laser cutting possible with CO₂ systems, but bending and traditional welding are not feasible.

For mixed-material designs, mechanical fastening or adhesive bonding is recommended to integrate thermoplastics with metal components.

From CAD to Part: The Process

Honyo Prototype Unique Sheet Metal Manufacturing Process

Honyo Prototype specializes in low-volume, high-complexity sheet metal fabrication where conventional quoting systems fail. Our “unique sheet metal” designation applies to parts featuring extreme geometries, tight tolerances, unconventional materials, or integrated secondary processes. The end-to-end workflow is engineered for precision and speed without sacrificing manufacturability.

CAD Upload

Customers submit native 3D CAD files (STEP, IPT, SLDPRT) via our secure portal. Unlike generic platforms, our system immediately parses geometric complexity, material specifications, and critical features such as micro-perforations, deep draws exceeding 3x material thickness, or compound bends below 0.5mm radii. File validation checks for non-manifold edges and ensures tolerance callouts align with ASME Y14.5 standards before progression.

AI-Powered Quoting Engine

Uploaded CAD data feeds our proprietary AI quoting system, trained on 12,000+ historical builds. The engine dynamically calculates costs by analyzing:

Material utilization efficiency considering laser kerf and nest collision risks

Secondary operation sequencing (e.g., welding before or after anodizing)

Geometric complexity penalties for features like embedded threads in thin-gauge aluminum

Real-time material market fluctuations for exotics (e.g., Inconel 625, beryllium copper)

Quotes include granular cost breakdowns and highlight high-risk features requiring DFM intervention, typically generated within 90 minutes.

Engineer-Led DFM Analysis

All unique parts undergo mandatory DFM review by senior sheet metal engineers. This phase identifies and resolves non-manufacturable features through collaborative iteration. Critical focus areas include:

| Feature Type | Common Issue | Honyo Resolution Path |

|---|---|---|

| Bend Geometry | Interference in multi-bend sequences | Redesign bend order or add relief cuts |

| Thin Features | Buckling in <0.8mm sections | Recommend stiffening ribs or material upgrade |

| Tight Tolerances | ±0.05mm on formed edges | Propose post-form CNC milling step |

| Material Constraints | Springback in high-strength alloys | Adjust bend allowance via FEA simulation |

Engineers provide annotated 3D models with actionable suggestions, maintaining design intent while ensuring producibility. Approval requires explicit sign-off from both Honyo and the customer.

Precision Production

Approved designs move to our dedicated unique-parts cell featuring:

Hybrid laser-turret systems (Amada LC-3015 with 6kW fiber laser + 36-station turret) for mixed-technology optimization

In-process CMM validation at critical stages (e.g., after primary forming, pre-finishing)

Material traceability via barcode tracking from coil to shipment

Environmental controls for sensitive finishes (e.g., humidity-stable anodizing for aerospace alloys)

All welds undergo 100% visual inspection with AWS D17.1 compliance documentation; critical structural welds receive ultrasonic testing.

Certified Delivery

Final inspection packages include:

First-article inspection report (FAIR) with 32-point dimensional verification

Material test certificates (MTRs) with full chemical and mechanical properties

Process validation records for secondary operations (e.g., torque values for captive nuts)

Packaging engineered for part geometry (e.g., custom foam cradles for warped assemblies)

Shipments include serialized tracking with real-time logistics updates and meet ITAR/EAR compliance requirements where applicable. Average lead time from DFM approval to delivery is 12–18 business days, contingent on feature complexity.

This integrated process ensures technically challenging sheet metal components achieve first-pass yield rates exceeding 92% while maintaining full traceability from digital model to certified physical part.

Start Your Project

Discover precision-engineered unique sheet metal solutions crafted for demanding applications. At Honyo Prototype, we specialize in custom sheet metal fabrication with tight tolerances, complex geometries, and rapid turnaround—backed by our state-of-the-art facility in Shenzhen.

Partner with us for prototyping and low-volume production that meets aerospace, medical, and industrial equipment standards.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.