Guide Contents

Project Insight: Unique Sheet Metal

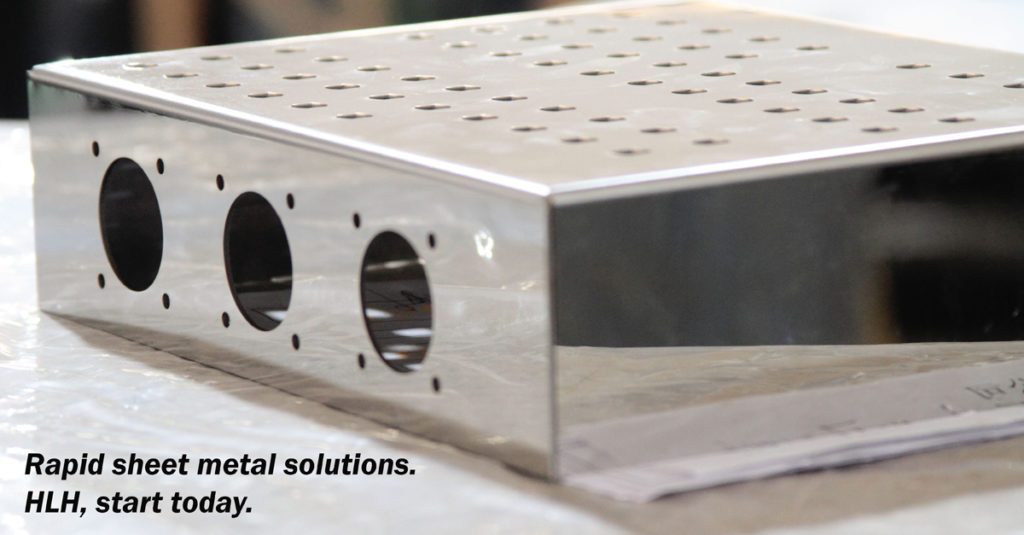

Manufacturing Insight: Unique Sheet Metal Solutions for Accelerated Product Development

In today’s fast-paced hardware innovation landscape, speed and precision aren’t just advantages—they’re non-negotiable. At Honyo Prototype, we’ve reimagined sheet metal fabrication through a digital-first approach, enabling startups and engineers to transform concepts into reality faster than ever.

The Challenges of Custom Sheet Metal Prototyping

Engineering and setup costs often exceed 50% of total project expenses in small batches, stifling rapid iteration.

Manual quoting processes cause 5–10 day delays before production even begins.

Design flaws discovered late in production lead to costly rework and timeline overruns.

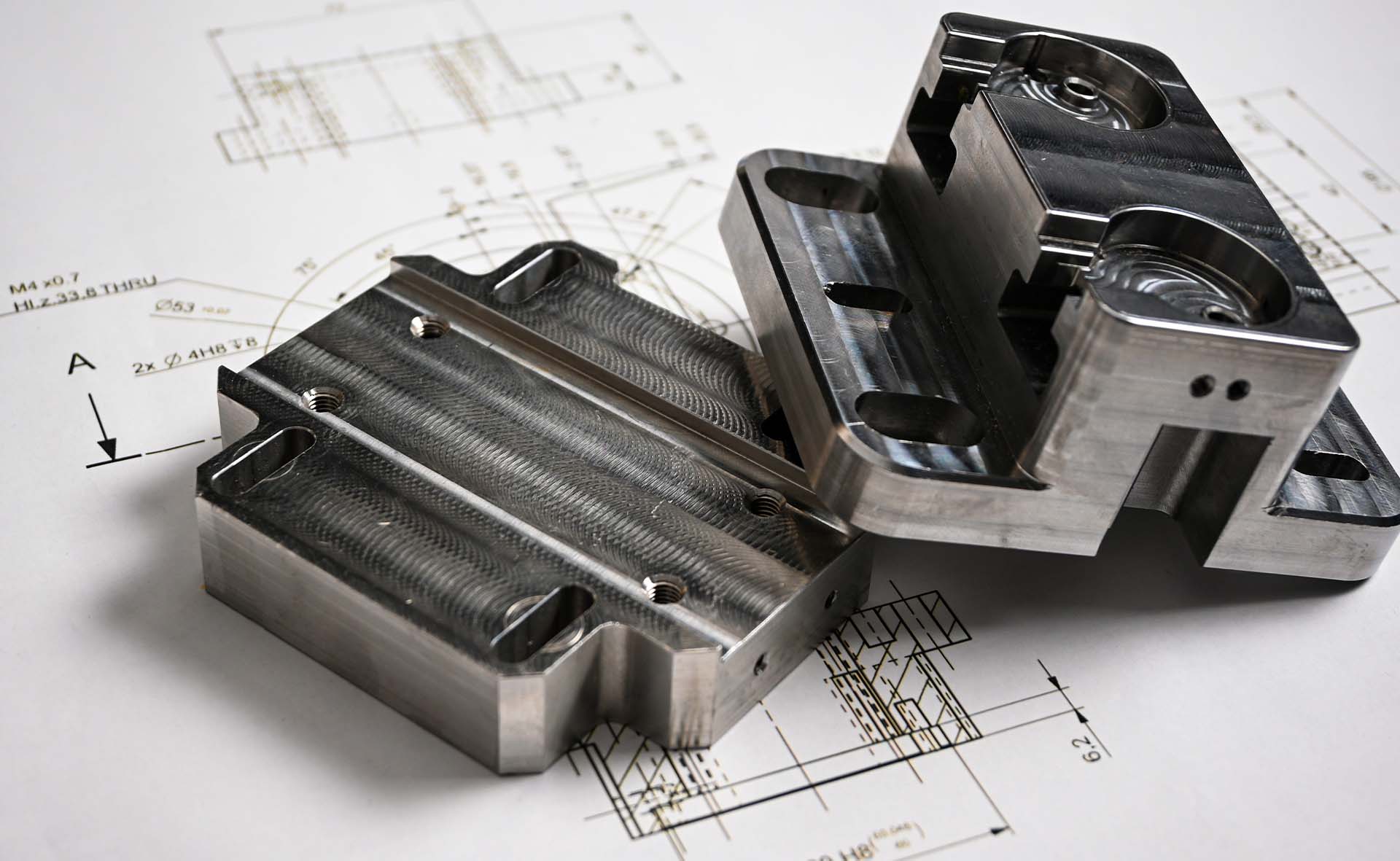

Honyo’s Digital-First Approach to Precision Manufacturing

Online Instant Quote: AI-driven pricing in seconds—no hidden fees, no waiting.

AI-Powered DFM Analysis: Real-time design feedback to eliminate manufacturing errors before production.

72-Hour Prototype Turnaround: From digital file to physical part—accelerating your time-to-market.

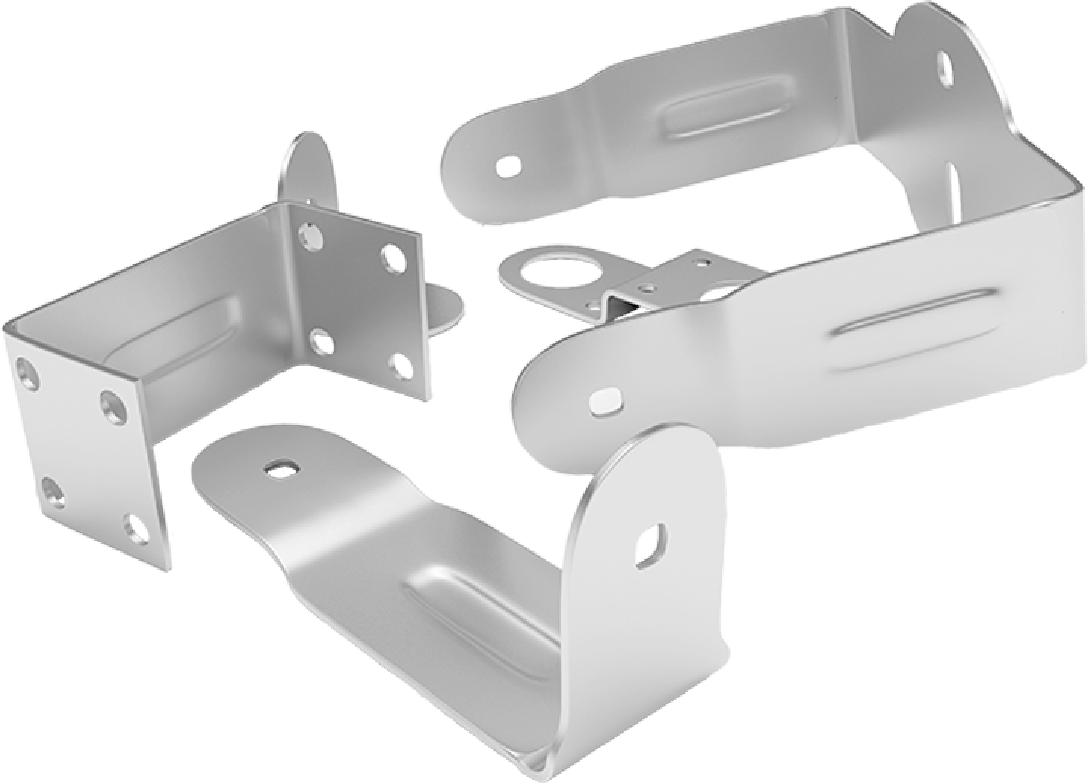

Optimizing Cost and Quality for Enclosures, Brackets, and Chassis

Integrated, automated processes reduce lead times by 40% compared to traditional manufacturers.

Precision laser cutting (±0.1mm) and bending ensure tight tolerances for complex geometries.

Smart material nesting and standardized processes cut costs without compromising on custom designs.

At Honyo Prototype, we don’t just fabricate sheet metal—we engineer solutions that power your innovation. Let’s build the future, faster.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities for Unique Sheet Metal

Precision Technology Suite

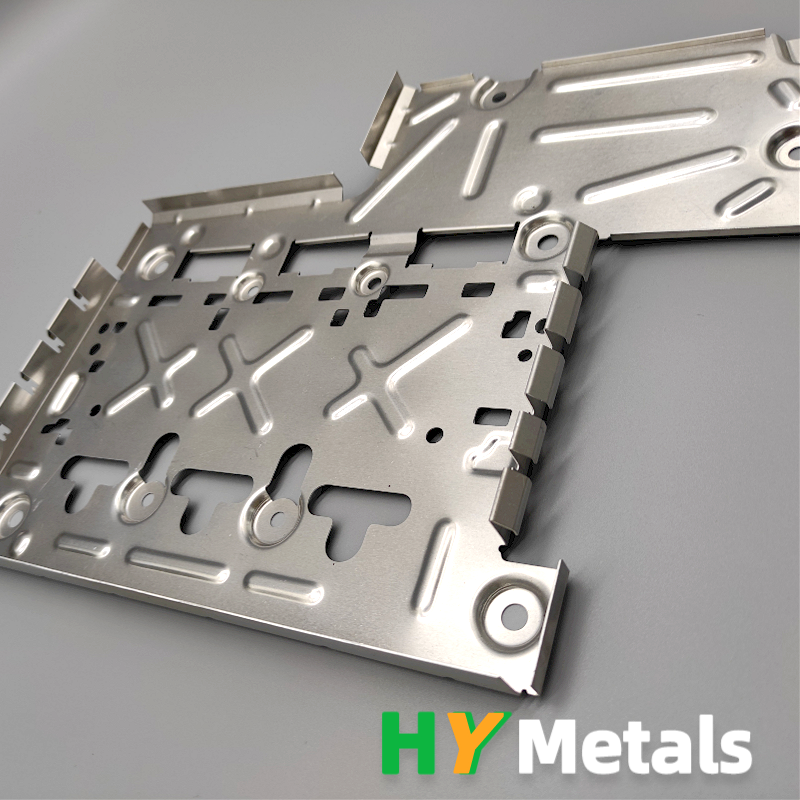

Laser Cutting: ±0.1mm precision for complex geometries; handles materials 0.5–25mm thick with minimal heat distortion. Ideal for intricate enclosure panels and bracket components.

Precision Bending: Multi-axis press brakes with real-time angle monitoring; achieves tight tolerances (±0.5°) for complex chassis structures without secondary operations.

Robotic Welding: TIG/MIG automation ensures consistent, high-strength joints; perfect for structural enclosures requiring minimal post-weld finishing.

Eco-Friendly Powder Coating: 15+ standard colors + custom RAL matching; durable, corrosion-resistant finishes with 100% material recovery.

Scalable Production Capacity

Seamlessly scale from single prototypes to 10,000+ units—no retooling costs or MOQs. Our flexible production lines adapt instantly to your project’s volume needs.

Dedicated production slots for startups: Priority handling for early-stage projects with rapid feedback loops.

ISO-Certified Quality Assurance

ISO 9001:2015 certified processes with full traceability from raw material to finished part.

In-process inspections at every stage (cutting, bending, welding, coating) with 100% dimensional verification using CMM and optical scanners.

Digital-First Service Model

Online Instant Quote: Upload your CAD file for real-time pricing in seconds—no manual quotes, no hidden fees. AI analyzes geometry, material, and finish to deliver transparent cost breakdowns.

AI-Powered Design Optimization: Proprietary DFM engine identifies cost-saving opportunities—like standard material thicknesses, simplified bends, and efficient nesting—reducing material waste by up to 20% and eliminating engineering revisions.

Fast Turnaround Guaranteed: Prototypes in 3–5 business days; production orders in 1–2 weeks. Integrated in-house processes eliminate third-party dependencies for faster delivery.

Materials & Surface Finishes

Material Options & Finishes

Strategic Material Selection for Every Application

Aluminum (6061-T6, 5052, 7075)

Why choose it: Lightweight, corrosion-resistant, and ideal for enclosures, brackets, and heat sinks.

Cost tip: Standard grades reduce lead times and costs—avoid exotic alloys unless necessary.

Honyo Advantage: Our AI platform instantly identifies the optimal grade for your design, eliminating unnecessary material costs.

Steel (304 Stainless, 1018 Carbon, Galvanized)

Why choose it: High strength-to-weight ratio, cost-effective for structural components like chassis and frames.

Cost tip: Use galvanized steel for outdoor applications to avoid extra coating costs.

Honyo Advantage: Real-time market data integration ensures stable pricing, even during steel price fluctuations.

Copper & Brass

Why choose it: Superior electrical and thermal conductivity. Perfect for EMI shielding, connectors, and heat exchangers.

Cost tip: Standard copper alloys (C110) minimize custom processing fees.

Honyo Advantage: Specialized handling protocols ensure precision without premium costs.

Precision Surface Finishes for Enhanced Performance

Anodizing (Type II/III)

Best for: Aluminum enclosures needing color options and wear resistance. 20+ color choices with matte or glossy finishes.

Honyo Edge: Automated color matching with AI-driven process optimization for consistent results.

Powder Coating

Best for: Brackets and chassis requiring durable, scratch-resistant finishes. 200+ RAL colors available.

Honyo Edge: Eco-friendly process with same-day turnaround—no VOC emissions, faster curing times.

Polishing & Electroplating

Best for: High-end aesthetics (e.g., medical devices, premium enclosures). Mirror finishes or nickel/chrome plating for conductivity.

Honyo Edge: In-house plating lines reduce lead time by 40% vs. outsourcing.

How Honyo’s AI Platform Eliminates Cost Surprises

✨ Online Instant Quote: Upload your CAD file, get a real-time price with material/finish recommendations in seconds—no engineering delays.

🤖 AI Design Optimization: Our algorithms flag potential cost drivers (e.g., sharp bends, non-standard holes) and suggest design tweaks to cut costs by up to 25%.

⚡ Fast Turnaround Guarantee: From quote to delivery in 3-5 days for prototypes—critical for hardware startups scaling quickly.

Pro Tip: For startups, leverage Honyo’s AI-driven platform to iterate designs before production—saving up to 30% in engineering costs while ensuring manufacturability.

Ready to optimize your project?

Get Your Instant Quote in 60 seconds—no engineers, no delays, just precision.

From Quote to Part: Our Process

How It Works: From CAD to Part in Record Time

Transforming complexity into simplicity with AI-driven precision

1. Upload Your CAD File

Accepts all standard formats (STEP, STL, DXF, IGES, SolidWorks, etc.)

Zero manual conversion—our system processes files instantly

Enterprise-grade security with 24/7 cloud access and encrypted transfers

2. Get Instant AI-Powered Quote

Real-time pricing in under 10 seconds—no waiting for manual quotes

Fully transparent cost breakdown: materials, processes, quantities, and shipping

No hidden engineering fees—AI automates DFM checks, eliminating traditional design consultation costs

3. Automated DFM Analysis & Optimization

AI scans for manufacturability risks (e.g., bend radii, hole placement, tolerances)

Smart suggestions to reduce material waste, simplify bends, and standardize features

Immediate cost-saving recommendations—no redesign delays or extra charges

4. Precision Production & Lightning-Fast Delivery

Fully in-house workflow: laser cutting → bending → welding → powder coating

Shenzhen-based manufacturing hub enables 3–5 day prototype turnaround

Real-time production tracking via customer portal + ISO-certified quality checks at every stage

From upload to delivery, Honyo’s AI-driven platform transforms your CAD files into precision parts faster, smarter, and more affordably—whether you’re prototyping enclosures, brackets, or chassis. Focus on innovation; we handle the rest.

Start Your Project with Honyo

Start Your Project with Honyo

Precision, Speed, and Unmatched Value for Hardware Innovation

At Honyo Prototype, we’ve redefined sheet metal fabrication for hardware startups and engineering teams. Our AI-driven platform eliminates traditional manufacturing bottlenecks—delivering high-quality enclosures, brackets, and chassis with zero engineering overhead, instant pricing, and industry-leading speed.

AI-Powered Cost Optimization

Automated DFMA analysis: Real-time design validation to eliminate waste, reduce assembly steps, and cut costs by 30–50% vs. traditional vendors.

No engineering fees: Our system handles design-for-manufacturability checks—so you avoid costly NRE charges for small batches.

Live market intelligence: Dynamic pricing adjusts for material fluctuations (e.g., steel trends $1,000–$1,500/ton) to lock in competitive rates.

Instant Quotes in 60 Seconds

Upload your CAD file → Get a transparent, itemized quote instantly—no manual estimates or delays.

See exact costs for materials, processes (laser cutting, bending, welding), and finishes (powder coating) upfront.

Optimize designs before production with AI-driven suggestions for nesting efficiency and standard material use.

3x Faster Turnaround

Prototype in 3–5 days, production in 7–10 days (vs. industry average 14–21 days).

Integrated smart manufacturing cells for seamless laser cutting → bending → welding → powder coating—all under one roof.

Dedicated Shenzhen/Dongguan facilities with 24/7 capacity for urgent requests—no supply chain delays.

Let’s Build Smarter Together

Founder Susan Leo and our engineering team are ready to optimize your project from concept to delivery.

Contact us today:

[email protected] | +86 139 2843 8620

Visit our facilities: Shenzhen/Dongguan, China—see innovation in action.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.