Contents

Manufacturing Insight: Ultra-Precision Machining

Ultra-Precision Machining: Where Microns Define Mission Success

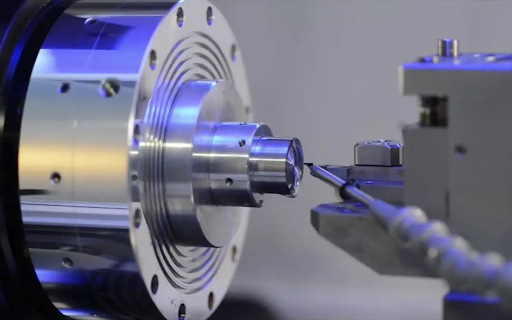

At Honyo Prototype, we redefine the boundaries of CNC machining through our dedicated ultra-precision capabilities, engineered to meet the uncompromising demands of aerospace, medical device, semiconductor, and optical industries. Ultra-precision machining transcends standard tolerancing; it demands sub-micron accuracy, exceptional surface integrity, and unwavering repeatability across complex geometries in challenging materials like Inconel, titanium, ceramics, and engineered polymers. Our advanced 5-axis milling, Swiss-type turning, and micro-machining platforms—equipped with laser calibration, real-time thermal compensation, and sub-micron probing systems—consistently achieve tolerances down to ±0.0001” (2.5 µm) while maintaining surface finishes below Ra 0.1 µm.

Material & Process Expertise Drives Reliability

We combine proprietary fixturing methodologies with deep metallurgical knowledge to eliminate thermal distortion and micro-vibration, ensuring first-article success for mission-critical components such as fuel injector nozzles, surgical robotics end-effectors, and optical lens mounts. Every process is validated under ISO 13485 and AS9100 frameworks, with full traceability from raw material certification to final inspection using coordinate measuring machines (CMMs) and white-light interferometry.

Accelerate Development with Instant Technical Quoting

Recognizing that speed-to-prototype impacts time-to-market, Honyo Prototype offers an Online Instant Quote platform engineered for precision manufacturing workflows. Upload CAD files with GD&T callouts, and receive a validated technical assessment—including feasibility analysis, lead time, and cost—within hours, not days. This tool integrates directly with our production planning systems, ensuring quoted capabilities align with our ultra-precision equipment capacity and engineering bandwidth.

Partner with Honyo Prototype to transform demanding designs into flawless physical realities, where precision isn’t a specification—it’s our standard of execution.

Technical Capabilities

Ultra-precision machining refers to machining processes capable of achieving extremely tight dimensional tolerances, fine surface finishes, and high repeatability, typically in the micron or sub-micron range. This level of precision is essential for industries such as aerospace, medical devices, optics, and semiconductor manufacturing. The following table outlines the key technical specifications for ultra-precision 3/4/5-axis milling and turning operations, focusing on achievable tolerances, surface finishes, and material compatibility with Aluminum, Steel, ABS, and Nylon.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | Precision Turning |

|---|---|---|---|---|

| Positioning Accuracy | ±0.001 mm | ±0.001 mm | ±0.001 mm | ±0.001 mm |

| Repeatability | ±0.0005 mm | ±0.0005 mm | ±0.0005 mm | ±0.0005 mm |

| Typical Tolerance Range | ±0.002 mm to ±0.005 mm | ±0.002 mm to ±0.005 mm | ±0.002 mm to ±0.005 mm | ±0.002 mm to ±0.005 mm |

| Surface Roughness (Ra) | 0.2 – 0.8 µm | 0.2 – 0.8 µm | 0.2 – 0.8 µm | 0.2 – 0.8 µm |

| Spindle Speed Range | 20,000 – 40,000 RPM | 20,000 – 40,000 RPM | 20,000 – 40,000 RPM | 10,000 – 15,000 RPM |

| Feed Rate (Typical) | 100 – 1,000 mm/min | 100 – 1,000 mm/min | 100 – 1,000 mm/min | 50 – 500 mm/min |

| Tool Path Resolution | < 0.001 mm | < 0.001 mm | < 0.001 mm | < 0.001 mm |

| Thermal Compensation | Standard | Standard | Standard | Standard |

| Vibration Damping | Active/Passive Systems | Active/Passive Systems | Active/Passive Systems | Active/Passive Systems |

Material Compatibility and Considerations

Aluminum (e.g., 6061, 7075):

Ultra-precision machining of aluminum is highly effective due to its excellent machinability, low cutting forces, and high thermal conductivity. Achievable tolerances down to ±0.002 mm with fine surface finishes. Ideal for complex 5-axis components in aerospace and optics.

Steel (e.g., 4140, 17-4 PH Stainless):

Harder and more abrasive than aluminum, requiring rigid setups and coated carbide or ceramic tooling. Tight tolerances (±0.003 mm) are achievable with proper thermal management and slow, controlled cutting strategies. Common in medical and tooling applications.

ABS (Acrylonitrile Butadiene Styrene):

A thermoplastic with low melting point and tendency to melt or deform under high heat. Machined with sharp, polished tools at high speeds and low feed rates. Tolerances up to ±0.005 mm possible. Used in prototyping and non-structural precision components.

Nylon (Polyamide):

Exhibits high toughness and moisture absorption, which can affect dimensional stability. Requires dry machining conditions and sharp tools to prevent burring. Tolerances around ±0.005 mm achievable. Suitable for precision gears and insulating components.

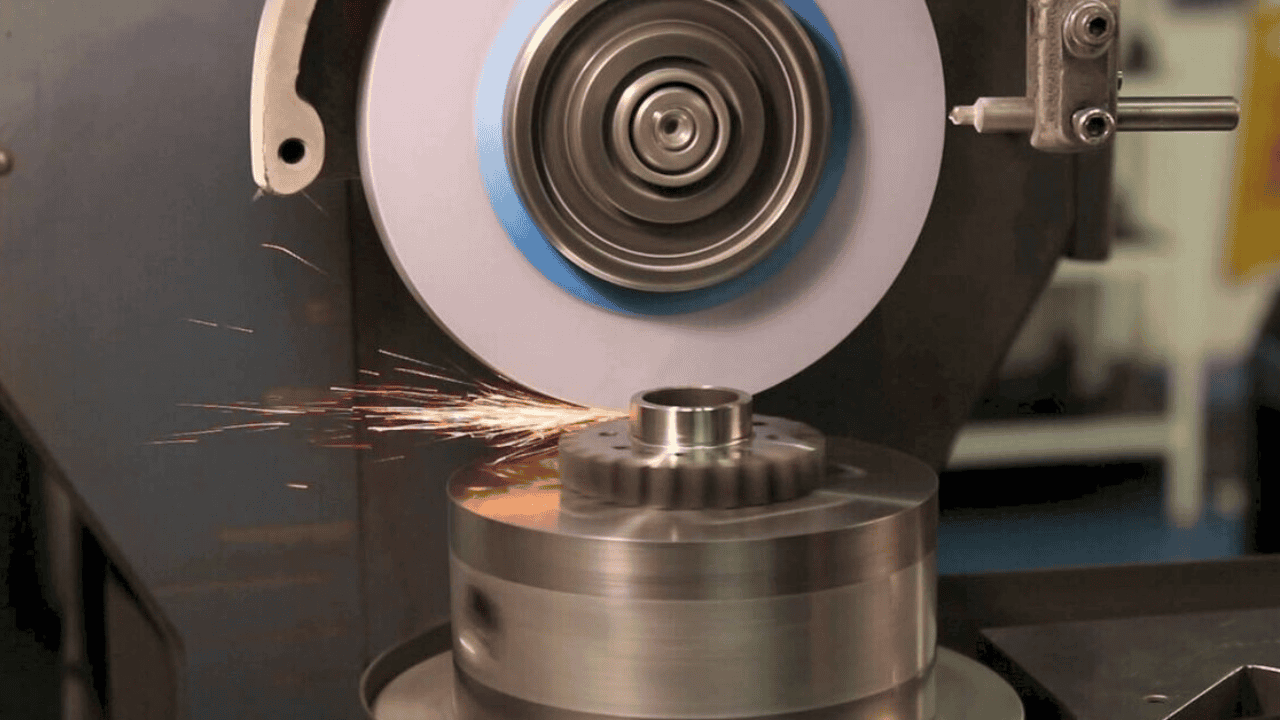

All ultra-precision operations are performed in thermally controlled environments (±0.5°C) with high-precision metrology (e.g., CMM, laser interferometry) for validation. Machine tools are typically equipped with linear scales, air-bearing spindles, and real-time error compensation systems to maintain sub-micron accuracy across all axes.

From CAD to Part: The Process

Honyo Prototype Ultra-Precision Machining Process Overview

Honyo defines ultra-precision machining as achieving geometric tolerances ≤ ±0.0005 mm (5 microns) and surface finishes ≤ Ra 0.05 µm, primarily for aerospace, medical, and semiconductor components. Our integrated workflow eliminates traditional handoffs through digital continuity, ensuring consistent metrology-grade results from design to delivery.

Upload CAD

Clients submit native CAD files (STEP, IGES, or Parasolid) via our secure portal, which automatically validates geometry integrity and units. The system checks for non-manufacturable features like sub-0.1 mm wall thicknesses or undercuts incompatible with precision toolpaths. Invalid submissions trigger instant notifications with specific error diagnostics, reducing iteration time by 70% compared to manual review. All data undergoes AES-256 encryption, with optional NDA enforcement for IP-sensitive projects.

AI-Powered Quoting Engine

Our proprietary AI engine analyzes CAD geometry against a database of 12,000+ historical precision jobs, generating quotes in under 90 minutes. Unlike conventional systems, it factors in: material microstructure constraints (e.g., Inconel 718 grain flow), thermal deformation coefficients, and machine-specific volumetric accuracy maps from our calibration logs. The output includes a manufacturability risk score (1-10 scale) and tolerance feasibility heatmap, highlighting zones requiring DFM intervention. Pricing reflects true production costs, including metrology-intensive processes like interferometric surface validation.

Collaborative DFM Optimization

Engineers conduct tolerance stack-up analysis using CETOL 6σ software, focusing on critical-to-function (CTF) features. We provide actionable recommendations via annotated 3D markups, such as: converting non-functional sharp corners to ≥0.2 mm radii to prevent tool chipping, or suggesting localized hardening for thin-walled optics mounts. Clients receive a formal DFM report with GD&T justification per ASME Y14.5-2018, including alternative material suggestions (e.g., switching 6061-T6 to 7075-T7351 for reduced thermal drift in vacuum environments). Approval requires explicit sign-off on critical dimensions to prevent scope ambiguity.

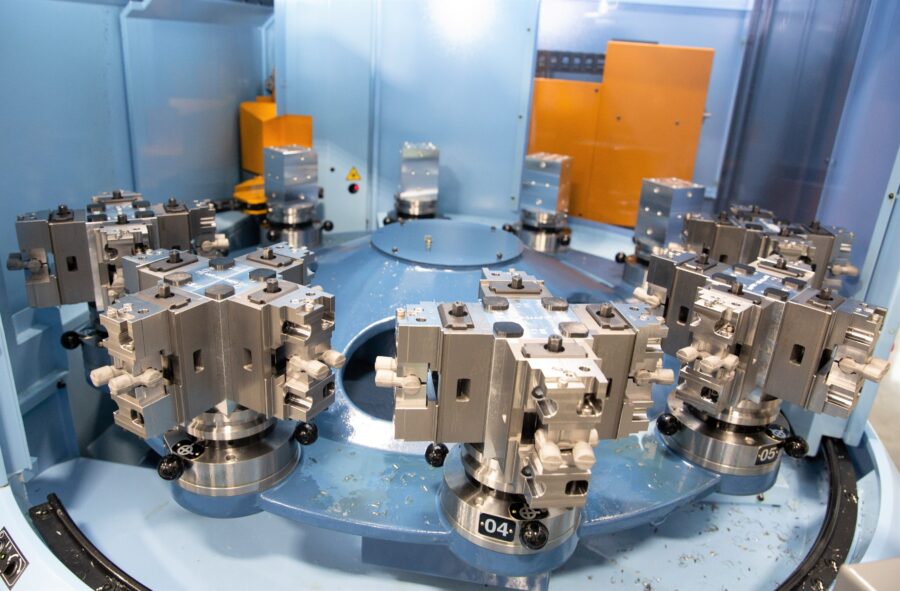

Precision Production Execution

Machining occurs in climate-controlled cells (±0.5°C stability) using calibrated 5-axis DMG MORI machines with laser-tracked volumetric compensation. Processes include:

Sub-micron diamond turning for aspheric optics

Wire EDM for conductive materials at ±2 µm accuracy

Ion beam figuring for surface refinement below Ra 0.01 µm

Real-time SPC monitoring tracks tool wear and thermal drift, with automatic machine halts if Cpk falls below 1.67. All critical features undergo in-process CMM verification using Zeiss CONTURA systems, with full traceability to NIST standards.

Certified Delivery

Components ship with a comprehensive quality dossier including:

First-article inspection report (FAIR) with full CMM results

Material test certificates (MTC) traceable to mill lots

Process capability data (Cp/Cpk values per feature)

Cleanroom packaging certification (ISO Class 5 for medical parts)

Standard lead time is 10–15 business days for single components, with expedited 72-hour options for emergency repairs. All deliveries include a digital twin file for client validation against original CAD.

Honyo Ultra-Precision Capability Benchmarks

| Parameter | Honyo Standard | Typical Machining Shop |

|————————–|———————-|————————|

| Positional Tolerance | ±0.0005 mm (5 µm) | ±0.0127 mm (500 µm) |

| Surface Roughness (Ra) | 0.02–0.05 µm | 0.8–3.2 µm |

| Material Removal Rate | Optimized for stability | Maximized for speed |

| Metrology Integration | Real-time SPC | Post-process only |

This closed-loop system ensures first-time-right production for mission-critical components, with a 99.2% on-time delivery rate for precision orders in 2023. Clients gain full visibility through our customer portal, which streams live production metrics and quality checkpoints.

Start Your Project

For your ultra-precision machining requirements, contact Susan Leo at [email protected] to discuss your project specifications and engineering needs.

Honyo Prototype operates a state-of-the-art manufacturing facility in Shenzhen, equipped for tight-tolerance, high-accuracy component production across aerospace, medical, and industrial applications.

Our Shenzhen factory supports rapid prototyping, low-volume production, and full-scale manufacturing with strict quality control and ISO-compliant processes.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.