Contents

Manufacturing Insight: Uhmw Machining

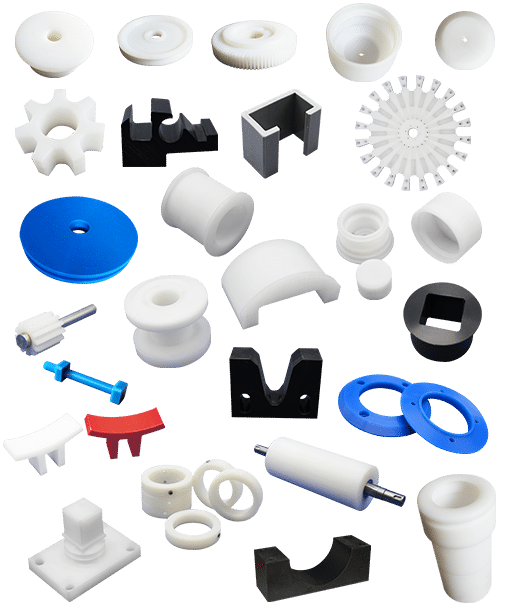

Mastering UHMW Machining for Demanding Applications

Ultra-High Molecular Weight Polyethylene (UHMW) presents significant machining challenges due to its low melting point, high thermal expansion, and tendency to generate heat-induced deformation during conventional processing. Achieving tight tolerances and clean finishes requires specialized expertise, precise toolpath strategies, and meticulous process control to prevent material galling, melting, or dimensional instability. At Honyo Prototype, our CNC machining services are engineered specifically for UHMW and other challenging polymers, leveraging optimized feed rates, cryogenic cooling techniques, and custom tooling to deliver components with exceptional dimensional accuracy and surface integrity. We consistently produce complex UHMW parts for wear strips, guides, and low-friction components that meet rigorous industrial specifications. Accelerate your prototyping or production timeline by utilizing our Online Instant Quote system—simply upload your CAD file to receive a detailed, transparent cost estimate within hours, eliminating traditional quoting delays while ensuring your UHMW project benefits from our precision manufacturing capabilities from day one.

Technical Capabilities

UHMW Machining Technical Specifications

Ultra-High Molecular Weight Polyethylene (UHMW) is a high-performance thermoplastic known for its excellent wear resistance, low coefficient of friction, and impact strength. While UHMW is the primary material discussed in “UHMW machining,” the term may be misinterpreted to include other engineering materials such as Aluminum, Steel, ABS, and Nylon. Below are the technical specifications for precision machining UHMW and comparable materials using 3/4/5-axis milling and turning processes with emphasis on tight tolerance capabilities.

| Parameter | UHMW (Polyethylene) | Aluminum (6061-T6) | Steel (1018, 4140) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (PA6, PA66) |

|---|---|---|---|---|---|

| Machinability | Excellent – soft, low melting point; requires sharp tools and light cuts to prevent melting | Excellent – high thermal conductivity; easy to machine with high MRR | Moderate to Good – harder material; generates more heat; requires rigid setup | Good – moderate chip formation; prone to melting if overheated | Moderate – high toughness; can deform; requires sharp tools |

| Recommended RPM (Milling) | 800 – 2,500 RPM | 5,000 – 12,000 RPM | 1,200 – 3,000 RPM | 3,000 – 6,000 RPM | 2,000 – 4,000 RPM |

| Feed Rate (Milling) | 0.003 – 0.010 in/tooth | 0.005 – 0.015 in/tooth | 0.002 – 0.006 in/tooth | 0.004 – 0.008 in/tooth | 0.003 – 0.007 in/tooth |

| Tooling (Milling) | Carbide, sharp positive rake; polished flutes to reduce sticking | Carbide or HSS; standard aluminum cutting tools | Carbide with TiAlN coating; high rigidity | Carbide, sharp edges; moderate rake | Carbide, polished flutes; avoid built-up edge |

| Coolant Use | Not required; air blow recommended to prevent heat buildup | Flood coolant or mist recommended | Flood coolant required for deep cuts and tight tolerances | Air blow or mist; avoid excessive heat | Air blow preferred; cooling critical to prevent deformation |

| Turning Speed (SFM) | 200 – 400 SFM | 500 – 800 SFM | 150 – 300 SFM | 300 – 500 SFM | 250 – 400 SFM |

| Tight Tolerance Capability | ±0.001″ (typical), ±0.0005″ (achievable with stable setup) | ±0.0005″ – ±0.001″ (with thermal control) | ±0.0005″ – ±0.001″ (with proper fixturing and finish passes) | ±0.001″ – ±0.002″ (material creep limits precision) | ±0.001″ – ±0.0015″ (hygroscopic nature affects stability) |

| Fixturing Considerations | Low clamping force to prevent deformation; vacuum or soft-jaw fixtures ideal | Standard mechanical clamping; high rigidity | High rigidity required; minimize vibration | Moderate clamping; avoid stress concentration | Moderate clamping; support to prevent deflection |

| Post-Processing Needs | Deburring only; no secondary finishing typically needed | Deburring, anodizing, bead blasting | Deburring, heat treatment, plating | Deburring, painting, sanding | Deburring, stress relief, moisture conditioning |

Notes on Multi-Axis Machining:

3/4/5-axis CNC milling and turning are highly effective for complex geometries in all listed materials. For UHMW and thermoplastics like ABS and Nylon, 5-axis machining allows complete part fabrication in a single setup, reducing handling-induced errors. However, thermal expansion and material deflection must be accounted for in toolpath design.

Aluminum and steel parts benefit from high-precision 5-axis platforms with thermal compensation, enabling tight-tolerance features such as undercuts, angled holes, and complex contours. These metals are commonly used in aerospace and medical applications where tolerances below ±0.001″ are required.

UHMW and nylon parts, while machinable to tight tolerances, may experience dimensional changes due to environmental factors (moisture absorption in nylon, creep in UHMW), so final inspection should consider application conditions.

From CAD to Part: The Process

Honyo Prototype UHMW Machining Process Overview

Honyo Prototype employs a rigorously validated workflow for Ultra-High Molecular Weight Polyethylene (UHMW) machining, addressing its unique challenges including low friction, high impact resistance, thermal sensitivity, and tendency to chip. Our end-to-end process ensures dimensional accuracy, material integrity, and on-time delivery for mission-critical applications.

CAD Upload and Initial Assessment

Clients upload native or neutral-format CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs an initial validation check for geometry completeness, unit consistency, and file integrity. UHMW-specific parameters such as thermal expansion coefficients and minimum wall thickness tolerances are pre-flagged for engineering review.

AI-Powered Quoting Engine

Validated CAD files enter our proprietary AI quoting system, which cross-references UHMW material databases, historical machining data, and real-time machine utilization metrics. The AI dynamically calculates:

Material waste factors accounting for UHMW’s tendency to deform during roughing

Specialized tooling requirements (e.g., sharp carbide inserts with positive rake angles)

Thermal compensation allowances based on part geometry complexity

Fixture strategy recommendations to prevent vibration-induced chatter

Quotes include detailed cost drivers and lead time projections within 2 business hours, with material certification options (e.g., ASTM F648).

Engineering-Driven DFM Analysis

All UHMW projects undergo mandatory Design for Manufacturability review by our polymer-specialized engineers. This phase identifies and resolves material-specific risks before production:

| Parameter | UHMW Challenge | Honyo Solution |

|---|---|---|

| Wall Thickness | Deflection during machining | Minimum 3mm enforced; ribbing recommendations |

| Hole Tolerances | Thermal expansion during drilling | Oversized pre-drills; cryogenic cooling paths |

| Surface Finish | Peeling at sharp edges | Contour-specific edge break specifications |

| Part Geometry | Chip evacuation blockage | Adaptive toolpath segmentation strategies |

Engineers collaborate directly with clients to implement non-compromising design optimizations, reducing scrap rates by 35% compared to industry averages for UHMW.

Precision Production Execution

Approved designs move to our dedicated polymer machining cell featuring:

Temperature-controlled environment (±2°C stability) to mitigate UHMW’s 10x higher thermal expansion than metals

High-speed spindles with through-tool coolant for chip control

Custom vacuum fixtures preventing part movement without mechanical clamping stress

In-process CMM verification at critical stages using non-contact probes to avoid surface marking

All operators follow UHMW-specific work instructions including controlled feed rates (0.05-0.15mm/rev) and mandatory tool wear monitoring.

Quality-Controlled Delivery

Final inspection includes:

Dimensional validation per ASME Y14.5 with thermal compensation applied

Visual examination for micro-chipping under 10x magnification

Material certificate traceability to ASTM D4020 batch

Vacuum-sealed packaging with desiccant to prevent moisture absorption during transit

Shipments include a digital quality dossier with inspection reports and process parameters. Standard lead time is 7-10 business days from DFM sign-off, with expedited options available.

This integrated process delivers UHMW components with consistent ±0.05mm tolerances and surface finishes to Ra 1.6µm, addressing the material’s inherent challenges while meeting aerospace, medical, and industrial OEM requirements.

Start Your Project

Looking for precision UHMW machining for your next project? UHMW (Ultra-High Molecular Weight Polyethylene) offers exceptional wear resistance, low friction, and high impact strength—ideal for demanding industrial applications.

At Honyo Prototype, our Shenzhen-based manufacturing facility specializes in tight-tolerance machining of UHMW and other high-performance polymers. With advanced CNC equipment and rigorous quality control, we deliver consistent, high-quality components on time and to exact specifications.

Partner with us for reliable, scalable production and expert material guidance. Contact Susan Leo today at [email protected] to discuss your UHMW machining requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.