Contents

Manufacturing Insight: Types Of Metal Castings

Understanding Metal Forming Processes and Honyo’s Precision Sheet Metal Expertise

While metal casting remains a vital process for creating complex, near-net-shape components from molten material, many industrial applications achieve superior speed, cost efficiency, and dimensional precision through modern sheet metal fabrication. At Honyo Prototype, we specialize in advanced sheet metal solutions—leveraging CNC punching, laser cutting, precision bending, and robotic welding—to transform flat metal stock into high-integrity enclosures, brackets, chassis, and structural assemblies. Unlike casting, which involves significant lead times for mold creation and material solidification, our sheet metal capabilities deliver rapid iteration, tighter tolerances, and reduced waste for low-to-medium volume production runs.

Honyo Prototype excels in bridging design intent with manufacturability, offering end-to-end sheet metal fabrication services from prototyping to full-scale production. Our ISO 9001-certified facility utilizes state-of-the-art machinery and rigorous quality control to ensure components meet exact specifications across aluminum, steel, stainless steel, and specialty alloys. For engineering teams seeking accelerated development cycles, our Online Instant Quote platform provides real-time pricing and manufacturability feedback within minutes—eliminating procurement delays and empowering faster project validation. Partner with Honyo to convert your sheet metal designs into precision-engineered reality, backed by technical consultation and on-time delivery.

Technical Capabilities

Honyo Prototype provides advanced manufacturing solutions across multiple metal and plastic fabrication processes. Below are the technical specifications related to laser cutting, bending, and welding for common materials used in metal castings and associated fabrication. While ABS and Nylon are not metals and therefore not used in metal casting, they are included for comparative context in fabrication processes where applicable.

| Process | Material | Thickness Range | Tolerance (Typical) | Surface Finish (Ra) | Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum | 0.5 mm – 25 mm | ±0.1 mm | 3.2 – 6.3 µm | High precision cutting; reflective material requires proper laser setup |

| Laser Cutting | Steel (Mild/Carbon) | 0.5 mm – 30 mm | ±0.1 mm | 3.2 – 6.3 µm | Ideal for clean, burr-free edges; nitrogen or oxygen assist options |

| Laser Cutting | ABS | 1 mm – 10 mm | ±0.2 mm | 6.3 – 12.5 µm | Not applicable for metal casting; limited to plastic fabrication |

| Laser Cutting | Nylon | 1 mm – 12 mm | ±0.2 mm | 6.3 – 12.5 µm | Poor laser absorption; not recommended; CNC preferred |

| Bending | Aluminum | 0.8 mm – 12 mm | ±0.2° angular | As received | Excellent formability; minimum bend radius = 1× thickness |

| Bending | Steel (Mild/Carbon) | 0.8 mm – 20 mm | ±0.5° angular | As received | High springback; requires overbending; tooling wear considerations |

| Bending | ABS | 1 mm – 6 mm | ±1.0° angular | As received | Limited ductility; prone to cracking; not used in structural casting |

| Bending | Nylon | 1 mm – 8 mm | ±1.0° angular | As received | Good flexibility but requires preheating for bending |

| Welding | Aluminum | 2 mm – 20 mm | ±0.5 mm | 6.3 – 12.5 µm | Requires TIG or MIG with argon shielding; high thermal conductivity |

| Welding | Steel (Mild/Carbon) | 1.5 mm – 40 mm | ±0.5 mm | 6.3 – 12.5 µm | Suitable for MIG, TIG, or arc welding; post-weld grinding often needed |

| Welding | ABS | Not applicable | N/A | N/A | Joined via adhesive or ultrasonic welding; not fusion weldable |

| Welding | Nylon | Not applicable | N/A | N/A | Compatible with hot plate or vibration welding; not suitable for arc |

Notes:

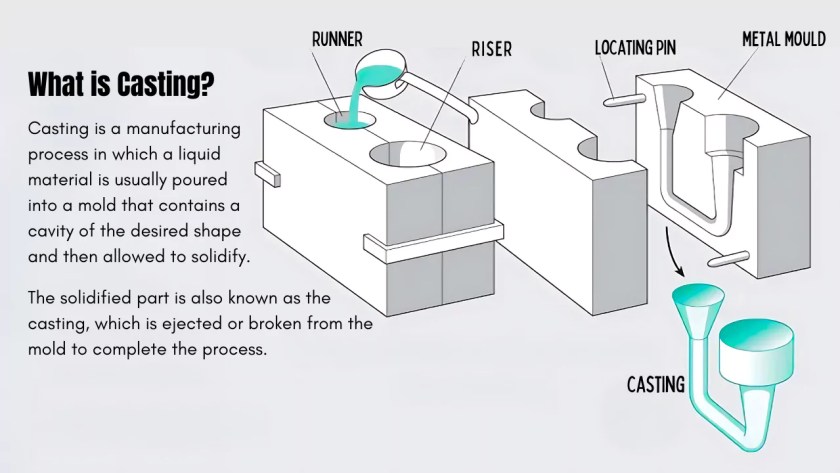

Metal casting typically involves pouring molten metal (e.g., aluminum or steel alloys) into molds. Post-casting, components may undergo laser cutting, bending, or welding for finishing or integration.

ABS and Nylon are thermoplastics used in prototyping and non-structural applications. They are not cast using metal casting techniques but may be machined or formed separately.

Honyo Prototype ensures tight tolerances and high repeatability across all processes, with material-specific parameter optimization for quality output.

From CAD to Part: The Process

Honyo Prototype Metal Casting Process Overview

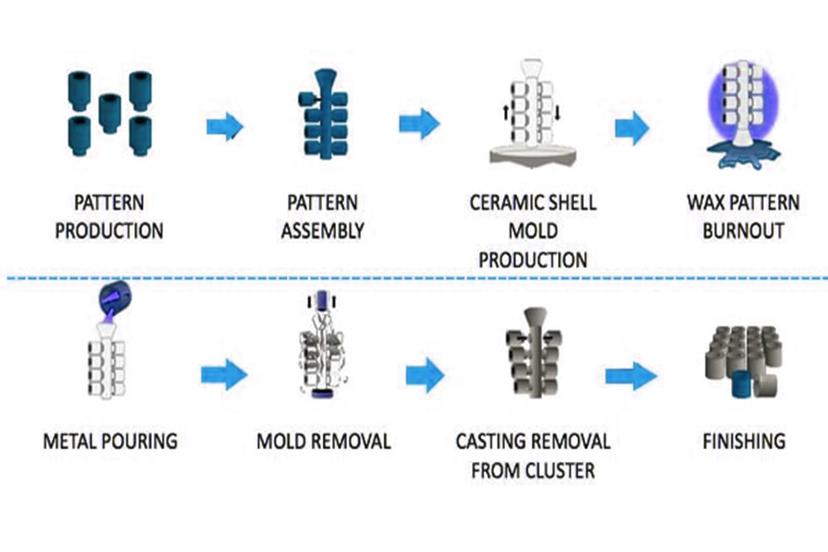

Honyo Prototype executes a streamlined, technology-driven workflow for metal casting projects, ensuring precision, cost efficiency, and rapid turnaround. Our end-to-end process begins with client CAD data and culminates in certified delivery, integrating AI tools with expert engineering oversight. Below is a technical breakdown of each phase.

Upload CAD

Clients initiate the process by uploading 3D CAD models via our secure portal, supporting native formats including STEP, IGES, Parasolid, and native CAD software files (e.g., SolidWorks, Creo, CATIA). Our system performs automated geometry validation, checking for watertightness, unit consistency, and minimum feature size compliance. Non-conforming files trigger immediate feedback, specifying required corrections to prevent downstream delays. This stage establishes the digital foundation for manufacturability analysis and quoting.

AI-Powered Quoting

Uploaded geometry undergoes AI-driven analysis to generate a preliminary quote within hours. Our proprietary algorithm evaluates part volume, surface area, complexity factors (e.g., undercuts, thin walls), and material density against real-time shop floor data. The AI cross-references historical production costs, alloy pricing fluctuations, and machine utilization rates to calculate material, labor, and overhead estimates. Crucially, this phase identifies potential high-risk geometries requiring engineering review, flagging them for the DFM stage. The output is a transparent, itemized quote with lead time projections, excluding only non-standard secondary operations not evident in the CAD.

Engineering-Driven DFM Analysis

Quotes transition to Honyo’s manufacturing engineering team for rigorous Design for Manufacturability (DFM) validation. Engineers use specialized simulation software (e.g., Flow-3D, MAGMA) to assess casting feasibility, focusing on:

Solidification patterns and shrinkage risk

Mold/die fill dynamics and turbulence prediction

Optimal gate/runner system design

Draft angle and parting line validation

Distortion compensation via thermal modeling

Clients receive a formal DFM report detailing actionable recommendations—such as localized wall thickness adjustments or rib repositioning—to enhance yield and reduce costs. This phase typically reduces casting defects by 40–60% and is mandatory before production commitment.

Precision Production Execution

Approved designs move to our ISO 9001:2015-certified facility, where process selection aligns with part specifications and volume requirements. We deploy the following casting methodologies based on DFM outcomes:

| Casting Method | Typical Alloys | Tolerance Range (mm) | Surface Finish (Ra µm) | Volume Suitability |

|---|---|---|---|---|

| High-Pressure Die | A380, ADC12, Zamak | ±0.10 – ±0.25 | 0.8 – 3.2 | High (10k+ units) |

| Low-Pressure Sand | A356, A360, Ductile Iron | ±0.30 – ±0.50 | 6.3 – 12.5 | Medium (100–10k) |

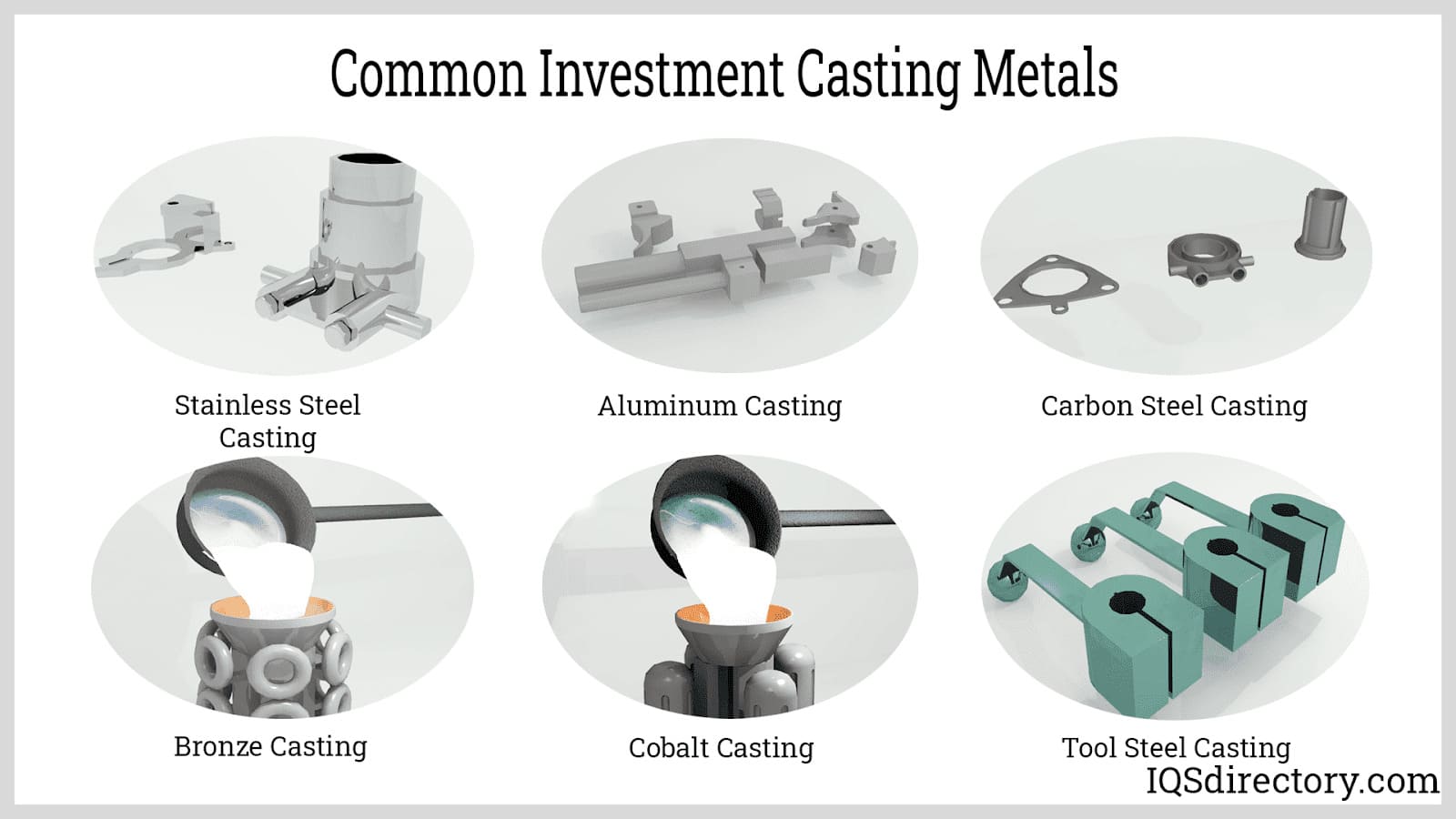

| Investment Casting | Stainless Steels, Inconel | ±0.05 – ±0.15 | 1.6 – 6.3 | Low (1–500) |

| Gravity Die | Aluminum, Copper Alloys | ±0.20 – ±0.40 | 3.2 – 6.3 | Medium (500–5k) |

Production includes in-process inspections at critical checkpoints: dimensional verification via CMM after shakeout, porosity screening via X-ray for aerospace/medical parts, and mechanical testing per ASTM/EN standards. Real-time data from IoT-enabled foundry equipment adjusts parameters dynamically to maintain conformance.

Certified Delivery

Final parts undergo comprehensive quality assurance, including first-article inspection reports (FAIR), material test certificates (MTC), and dimensional compliance documentation. All shipments include traceability logs linking castings to specific melt batches and process parameters. Delivery timelines are tracked via client-accessible dashboards, with expedited logistics options for time-sensitive projects. Every order concludes with a post-delivery review to capture lessons learned, ensuring continuous process refinement.

This integrated approach—combining AI efficiency with deep metallurgical expertise—enables Honyo to deliver complex metal castings with 25% faster time-to-part versus industry averages while maintaining >98% first-pass yield rates. Clients retain full visibility at every stage through our digital thread infrastructure.

Start Your Project

Explore our range of metal casting solutions engineered for precision and performance. From aluminum die casting to investment casting and sand casting, Honyo Prototype delivers high-quality metal components tailored to your specifications. Our state-of-the-art facility in Shenzhen ensures tight tolerances, rapid turnaround, and consistent quality for prototyping and low-volume production.

For expert guidance on selecting the right casting method for your project, contact Susan Leo at [email protected]. Let’s build your next innovation together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.