Contents

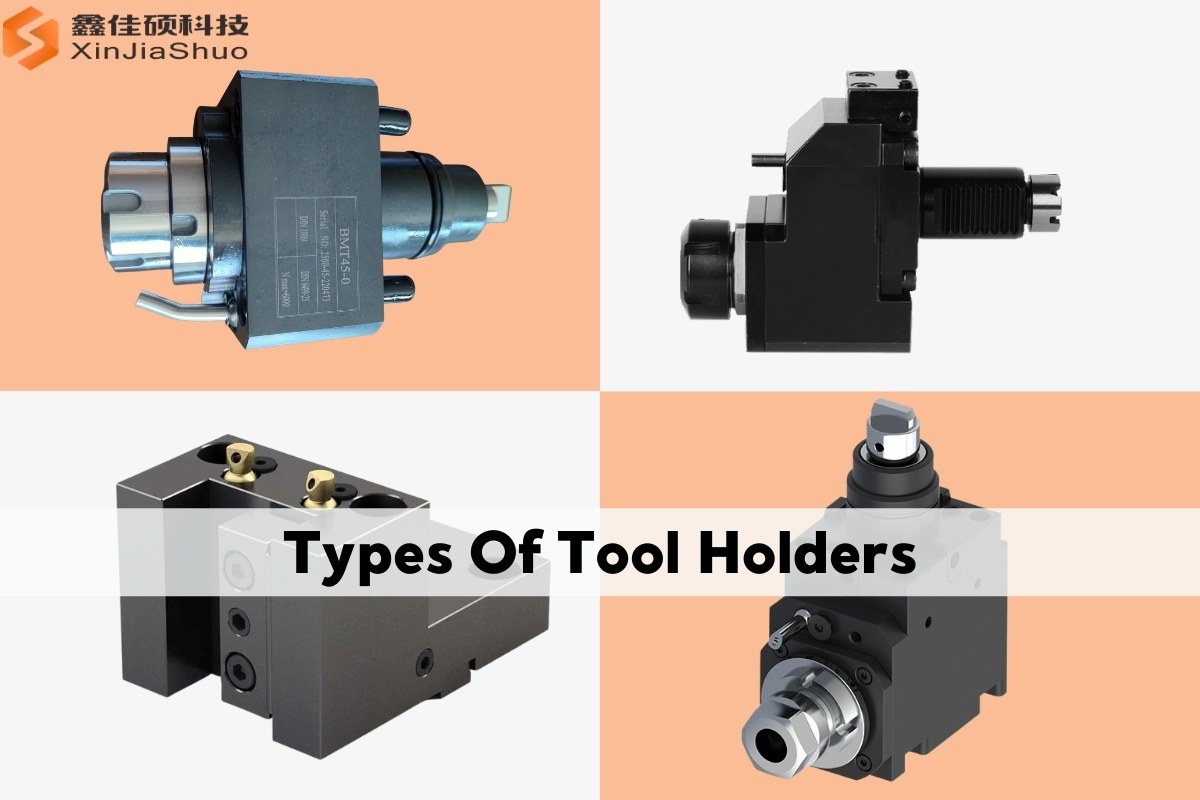

Manufacturing Insight: Types Of Cnc Tool Holder

Precision Tool Holding Systems: The Foundation of CNC Machining Excellence

The performance of any CNC machining operation hinges critically on the stability, accuracy, and compatibility of its tool holding system. Selecting the appropriate CNC tool holder—whether CAT, BT, HSK, or Capto—is not merely a matter of interface compatibility; it directly impacts spindle longevity, dimensional repeatability, surface finish quality, and overall process efficiency. At Honyo Prototype, we recognize that optimal tool holding is non-negotiable for achieving micron-level precision in complex prototyping and low-volume production runs. Our advanced CNC machining services integrate rigorous tool holder selection protocols with state-of-the-art 3-, 4-, and 5-axis platforms to ensure every component meets the most stringent tolerances and material requirements.

Honyo Prototype leverages deep expertise in tool-holding dynamics to eliminate vibration, minimize runout, and maximize metal removal rates across diverse applications—from aerospace titanium components to medical-grade polymer assemblies. Our engineering team collaborates with clients to match tool holder specifications to project demands, ensuring seamless integration with existing workflows while adhering to global standards like ISO 7388 and DIN 69871. This commitment to foundational precision underpins our reputation for delivering first-article accuracy and repeatable high-mix manufacturing outcomes.

To accelerate your path from design to physical prototype, Honyo Prototype offers an Online Instant Quote platform. Upload CAD files, specify materials and tolerances, and receive a detailed machining assessment within hours—not days. This transparent, data-driven quoting process reflects our dedication to operational agility without compromising the engineering rigor that defines Honyo’s CNC capabilities.

For projects demanding uncompromising precision, trust Honyo Prototype’s integrated approach to tool holding and CNC execution. Initiate your next precision machining project with confidence through our streamlined digital workflow.

Technical Capabilities

CNC tool holders are critical components in precision machining, ensuring secure attachment of cutting tools to spindles while maintaining rigidity, accuracy, and repeatability. For 3-, 4-, and 5-axis milling and turning operations—especially those requiring tight tolerances—the choice of tool holder type, interface standard, and material compatibility directly impacts performance. Below is a technical comparison of common CNC tool holder types used in high-precision applications.

| Tool Holder Type | Interface Standard | Max RPM (Typical) | Taper Accuracy (µm) | Runout (Typical @ 3x D) | Materials Compatible (Workpiece) | Key Applications | Notes |

|---|---|---|---|---|---|---|---|

| CAT (BT / ISO) | CAT40, CAT50, BT30, BT40 | 12,000 – 20,000 | ±3 to ±5 | ≤5 µm | Steel, Aluminum, ABS | 3-axis milling, heavy cutting | Common in North America; robust but less precision than HSK |

| HSK (A, E, F Types) | HSK-A63, HSK-E40 | 20,000 – 40,000 | ±2 to ±3 | ≤3 µm | Aluminum, Steel, Nylon | 5-axis milling, high-speed | Dual contact (taper + face); excellent for tight tolerance and high RPM |

| ER Collet Chuck | ER20, ER25, ER32 | 15,000 – 25,000 | N/A (collet-based) | ≤8 µm | Aluminum, ABS, Nylon | Light milling, turning, finishing | High versatility; moderate rigidity; ideal for small tools |

| Hydraulic Expansion | Custom / ISO 2768 | 20,000 – 30,000 | ±2 | ≤3 µm | Aluminum, Steel | 5-axis, micro-milling, tight tolerance | Superior damping and concentricity; sensitive to coolant exposure |

| Shrink Fit | ISO A1 – A8 | 25,000 – 40,000 | ±1 to ±2 | ≤2 µm | Steel, Aluminum | High-precision 3–5 axis milling | Excellent grip and runout; requires thermal tool insertion/removal |

| Milling Arbors (End Mill Holders) | Straight Shank, Weldon | 10,000 – 18,000 | ±5 | ≤10 µm | Steel, Aluminum | Slotting, side milling | Mechanical clamping; lower precision; suitable for roughing |

| Capto (C4, C5, C6) | C5, C6 | 10,000 – 15,000 | ±3 | ≤4 µm | Steel, Aluminum | Turning, multitasking machines | Polygon taper; high torque transmission; common in turning centers |

| Power Chuck (Turning) | ISO 5211, Custom Face | 6,000 – 10,000 | N/A | N/A | Steel, Aluminum, ABS, Nylon | CNC turning, bar feeding | Used for holding workpieces; not tool holders per se; high repeatability |

Notes on Material Compatibility:

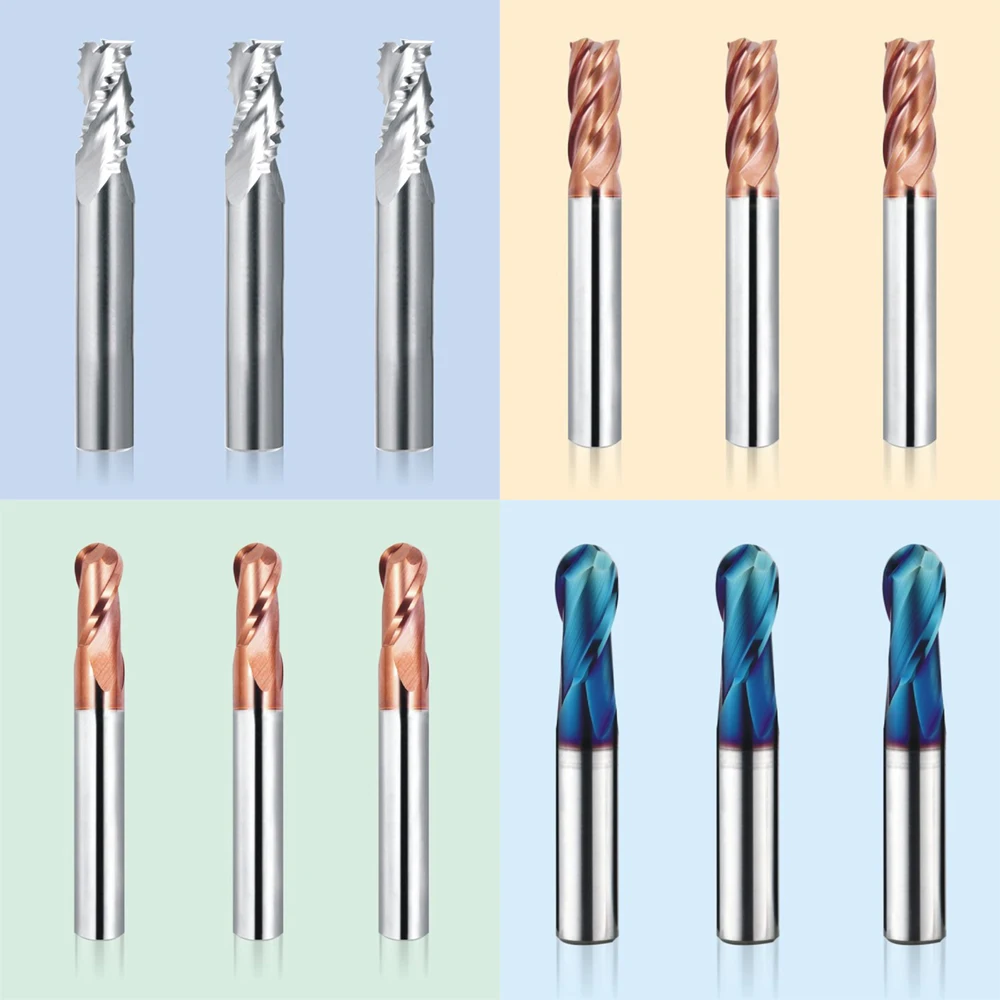

Aluminum: Requires high-speed, low-vibration holders (e.g., HSK, shrink fit) to avoid chatter and achieve fine surface finishes.

Steel: Demands high rigidity and thermal stability; HSK and CAT holders with high clamping force are preferred.

ABS & Nylon: Low-melting thermoplastics require low cutting forces and heat management. ER collets or hydraulic holders with low runout are ideal to prevent tool pull-out and burring.

Tight Tolerance Considerations:

For tolerances below ±0.005 mm, tool holders with runout <5 µm (e.g., HSK, shrink fit, hydraulic) are essential. Thermal and dynamic stability, spindle interface precision, and damping characteristics are critical in 5-axis and continuous contouring operations.

Conclusion:

Selection of a CNC tool holder must align with machine capability, workpiece material, and required precision. For tight tolerance 5-axis milling of aluminum or steel, HSK or shrink fit holders are optimal. In turning applications with mixed materials, Capto or precision ER systems offer balance between rigidity and flexibility.

From CAD to Part: The Process

Honyo Prototype executes a rigorously defined workflow for manufacturing precision CNC tool holders including CAT, BT, HSK, and DIN styles. This process ensures dimensional accuracy, balance compliance, and material integrity critical for high-speed machining applications. The sequence begins with customer-supplied CAD data and progresses through controlled engineering and production stages.

Upload CAD

Customers initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid) via our secure client portal. Our system performs immediate validation against ISO 26623 and ASME B5.50 standards for taper geometry, flange dimensions, and pull stud specifications. Files undergo automated checks for unit consistency, model integrity, and critical feature completeness such as retention knob threads and coolant through-holes. Incomplete or non-compliant submissions trigger immediate feedback to the client for correction prior to quote generation.

AI Quote

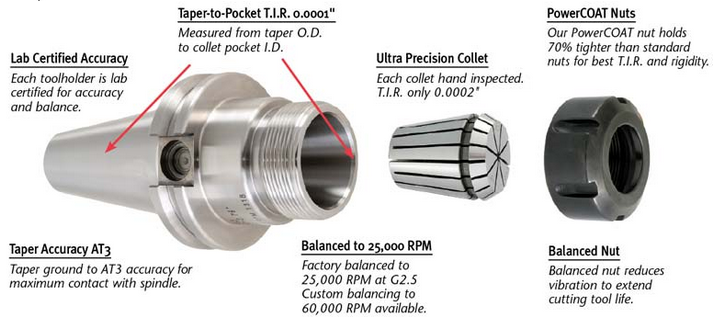

Validated CAD data feeds into our proprietary AI quotation engine which analyzes over 200 geometric and material parameters. The system evaluates material selection (typically SCM415, 4340, or equivalent alloy steel), heat treatment requirements, surface finish specifications, and dynamic balance grade (typically G2.5 at 25,000 RPM per ISO 1940-1). Real-time machine availability and toolpath complexity calculations generate a technically validated cost estimate within 90 minutes, including explicit notes on any non-standard manufacturing challenges such as sub-5µm taper tolerances or asymmetric geometries.

DFM Analysis

Engineers conduct a formal Design for Manufacturing review within 4 business hours of quote acceptance. This phase addresses critical tool holder considerations including taper interference fit calculations, residual stress mitigation strategies for asymmetric designs, and balancing hole placement optimization. We verify compatibility with common spindle interfaces and identify potential runout risks through finite element analysis. Clients receive a detailed DFM report with actionable recommendations such as adjusting wall thickness near the retention knob cavity or specifying alternative heat treatment sequences to prevent distortion. No production proceeds without written client approval of DFM outcomes.

Production

Approved designs enter our climate-controlled production cell with dedicated CNC grinding and milling resources. Tool holder manufacturing follows this sequence

Precision turning of external contours on dual-spindle lathes with live tooling

Taper grinding using diamond dressable wheels achieving IT5 tolerances (±0.003mm)

Hard milling of retention grooves and coolant channels post-heat treatment

Dynamic balancing to specified G-grade with laser weight correction

Final inspection including 3D tactile measurement of taper geometry against master gauges

All processes adhere to IATF 16949 protocols with real-time SPC monitoring of critical dimensions.

Delivery

Finished tool holders undergo final validation against the approved DFM package. Each unit receives a comprehensive inspection certificate documenting taper runout (typically <0.003mm TIR), balance report, and material traceability. Standard lead time is 72 hours post-DFM approval with expedited 24-hour options for critical spares. Shipments include serialized calibration documentation and packaging certified for spindle interface protection during transit. We maintain 99.8% on-time delivery performance for this product category based on 2023 Q4 metrics.

Critical manufacturing parameters consistently achieved across all tool holder types include the following specifications

| Parameter | Typical Tolerance | Measurement Method |

|---|---|---|

| Taper Angle | ±2 arc seconds | Optical comparator |

| Flange Face Runout | ≤0.002 mm | CMM with rotary table |

| Retention Knob Thread Pitch | ±0.005 mm | Thread micrometer |

| Dynamic Balance (G2.5) | ≤1.0 g·mm/kg | Balancing machine |

| Surface Roughness (Taper) | Ra 0.2 µm | Portable profilometer |

This integrated workflow eliminates traditional handoff errors between quoting and production while ensuring every tool holder meets the stringent performance demands of modern CNC machining centers. All processes are traceable through our digital thread system providing clients with full visibility from CAD submission to certified delivery.

Start Your Project

Looking to learn more about the different types of CNC tool holders and how they can enhance your machining performance? Contact Susan Leo today at [email protected] for expert guidance and customized solutions. With our advanced manufacturing facility located in Shenzhen, Honyo Prototype delivers high-precision CNC tool holders built to meet the demands of modern machining applications. Reach out now to discuss your requirements and discover the right tool holder for your operations.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.