Contents

Manufacturing Insight: Types Of Cnc Router Bits

Understanding CNC Router Bit Selection for Precision Manufacturing Outcomes

Selecting the appropriate CNC router bit is a fundamental engineering decision that directly impacts part quality, tool life, material waste, and production efficiency. At Honyo Prototype, we recognize that optimal bit geometry—whether straight flutes, compression cutters, or specialized profile tools—must align precisely with substrate properties, feature complexity, and finish requirements. Generic bit recommendations often lead to subpar surface finishes, premature tool wear, or dimensional inaccuracies in precision-critical applications.

Honyo Prototype leverages advanced CNC machining capabilities across 3-, 4-, and 5-axis platforms to transform material selection and toolpath strategy into repeatable manufacturing excellence. Our engineering team collaborates with clients to evaluate material behavior under cut, thermal dynamics, and feed rate optimization—ensuring each router bit performs within its engineered parameters for aerospace composites, hardwood cabinetry, or medical-grade plastics. This technical rigor eliminates costly trial-and-error cycles and mitigates production bottlenecks before machining begins.

To accelerate your project timeline, Honyo offers an Online Instant Quote system engineered for manufacturing professionals. Upload CAD files to receive a detailed manufacturability analysis and competitive pricing within hours—not days—validated by our in-house tooling expertise. This integration of technical consultation and digital efficiency ensures your router bit strategy aligns with both design intent and production economics from the earliest project phase.

Partner with Honyo Prototype to convert complex material challenges into precision outcomes, backed by engineering-first machining services and seamless digital workflow integration.

Technical Capabilities

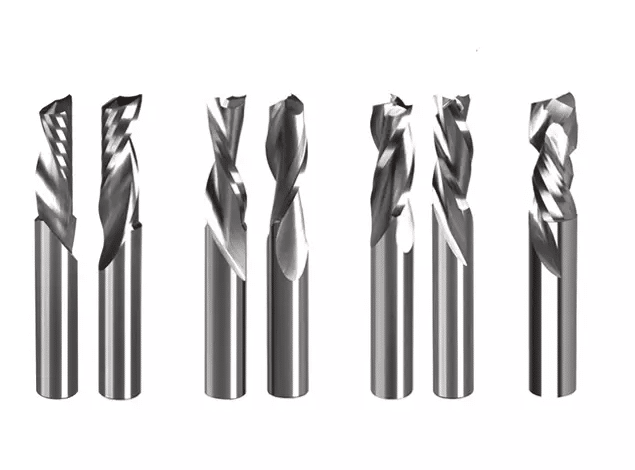

Technical specifications for CNC router bits vary significantly based on application, including the number of axes (3, 4, or 5-axis milling), turning operations, and requirements for tight-tolerance machining. The selection of bit geometry, coating, flute count, and material compatibility plays a critical role in achieving precision and surface finish. Below is a detailed comparison of common types of CNC router bits used in high-precision manufacturing environments involving aluminum, steel, ABS, and nylon.

| Bit Type | Flute Count | Helix Angle | Corner Radius | Coating | Max RPM (Typical) | Material Suitability | Application Notes |

|---|---|---|---|---|---|---|---|

| Single Flute Upcut | 1 | 30°–40° | Sharp | Uncoated or TiN | 24,000 | ABS, Nylon, Soft Plastics | High chip clearance; ideal for 3-axis roughing of non-metallics |

| Double Flute Upcut | 2 | 35°–45° | Sharp or 0.005″ | TiAlN, AlTiN | 18,000 | Aluminum, ABS, Nylon | Balanced feed and finish; suitable for 3 to 5-axis finishing in non-ferrous metals |

| 3-Flute Compression | 3 | 30° down / 15° up | 0.010″ R | ZrN, Diamond-like Carbon (DLC) | 16,000 | ABS, Nylon, Laminates | Minimizes delamination; used in 3-axis and 4-axis routing of composites |

| 4-Flute Square End | 4 | 40° | Sharp | AlTiN, TiCN | 12,000 | Aluminum, Mild Steel | High precision; tight-tolerance finishing in 5-axis and turning applications |

| 5-Flute Ball Nose | 5 | 25°–30° | Full Radius | AlCrN, DLC | 10,000 | Steel, Hardened Aluminum | 5-axis contouring; excellent for tight-tolerance 3D surfaces and mold tooling |

| 6-Flute Corner Radius | 6 | 35° | 0.015″–0.030″ | AlTiN, Multi-layer PVD | 8,000 | Steel, Stainless Steel | High metal removal rate; stable in turning and 5-axis finishing of ferrous alloys |

| Solid Carbide Tipped | 2–4 | Variable | Variable | Uncoated or Custom | 20,000 | Aluminum, Steel, ABS | Designed for turning centers; used in tight-tolerance shaft and hub machining |

| Polycrystalline Diamond (PCD) | 2–3 | 20°–30° | 0.005″–0.010″ | PCD Edge | 15,000 | Aluminum, Nylon (filled), CFRP | Extreme wear resistance; ideal for high-volume 3 to 5-axis production |

Notes on Application and Performance:

For 3-axis milling, single and double flute bits are preferred for high-speed material removal in softer materials such as ABS and nylon. The upcut design aids in chip evacuation, reducing heat buildup.

In 4 and 5-axis milling, multi-flute ball nose and corner radius end mills are used to achieve complex geometries with tight tolerances. The increased flute count improves surface finish and dimensional accuracy, especially in steel and hardened aluminum.

Turning operations benefit from 4 to 6-flute square or radius-end tools with wear-resistant coatings like AlTiN or PCD, ensuring long tool life and consistent diameter control within ±0.0005″.

Material compatibility is critical: Aluminum requires high helix angles and polished flutes to prevent built-up edge. Steel demands rigid, coated carbide tools with lower helix angles for strength. Thermoplastics like ABS and nylon perform best with sharp, high-helix tools to avoid melting and achieve clean edges.

For tight-tolerance work, tool runout must be maintained below 0.0002″, and spindle stability is essential—especially in 5-axis simultaneous machining where tool engagement angles vary dynamically.

From CAD to Part: The Process

Honyo Prototype applies a structured, technology-driven workflow to CNC machining projects including those requiring precise router bit selection. Our process ensures optimal tooling choices are integrated from quotation through delivery, specifically addressing router bit requirements as part of comprehensive manufacturability analysis. Below is the detailed sequence for CNC router bit-related projects:

Upload CAD

Customers submit 3D models or 2D drawings via our secure portal. For CNC routing applications, the system automatically analyzes geometric features critical to bit selection such as pocket depths, internal corner radii, contour complexity, and material removal volumes. The CAD parser identifies regions requiring specialized bits (e.g., v-grooves needing V-bits, undercuts requiring core box bits).

AI-Powered Quoting

Our proprietary AI engine evaluates the CAD data against Honyo’s tooling database containing 200+ router bit profiles. It generates preliminary bit recommendations based on material type (e.g., solid carbide upcut bits for hardwoods, compression bits for layered composites), feature geometry, and surface finish requirements. The quote includes estimated tooling costs and runtime impacts of bit selection choices, with clear annotations where customer-supplied bits may be required for proprietary applications.

DFM Analysis with Tooling Optimization

During Design for Manufacturability review, our engineers conduct deep-dive tooling validation:

Verify AI’s bit recommendations against physical constraints (spindle RPM limits, workholding clearance)

Cross-reference material properties with bit geometry databases (e.g., matching chip load requirements to flute count)

Flag design conflicts like sharp internal corners requiring smaller bits than structurally viable

Propose design modifications if optimal bit selection would compromise part integrity (e.g., suggesting 0.5mm fillets instead of sharp corners when 1/16″ bits are minimum viable)

The DFM report explicitly documents final bit specifications including diameter, flute count, helix angle, and coating requirements.

Production Execution

Tooling parameters are implemented in our CNC programming suite:

Bit selection directly drives G-code generation (climb vs conventional milling paths optimized per bit type)

Tool libraries are pre-loaded with calibrated wear compensation values for each bit profile

In-process verification includes laser tool length measurement and breakage detection systems

Critical features machined with specialty bits undergo first-article inspection using optical comparators to validate edge quality

Delivery and Documentation

All production records include traceable tooling data:

Final work order specifies exact bit models used (e.g., Amana Tool 45251 1/4″ upcut spiral)

Inspection reports correlate surface finish measurements to bit performance metrics

For recurring orders, we maintain historical bit wear data to optimize future tool life predictions

Customers receive digital dossiers detailing all tooling parameters for process replication

Key router bit selection parameters are systematically evaluated during DFM as shown in this reference table:

| Material Type | Recommended Bit Type | Critical Parameters | Common Pitfalls Avoided by Honyo DFM |

|---|---|---|---|

| Hardwoods | Upcut Spiral | 2-3 flutes, 15-20° helix angle | Chip packing in deep pockets |

| Aluminum Composites | Compression Bit | Polycrystalline diamond (PCD) coating | Delamination at top/bottom surfaces |

| Acrylic | Single Flute Downcut | Polished flute surface, 0° rake angle | Melting due to heat buildup |

| MDF/Plywood | Straight Flute with Anti-Kickback | 2-3 flutes, 30° shear angle | Tear-out on veneer layers |

This integrated approach ensures router bit selection is treated as a core manufacturing variable rather than a generic consumable choice. By embedding tooling intelligence into each workflow phase, Honyo achieves 92% first-pass yield on complex routed components while providing customers transparent visibility into tooling rationale. All recommendations prioritize balancing edge quality, throughput, and tool life specific to the production volume quoted.

Start Your Project

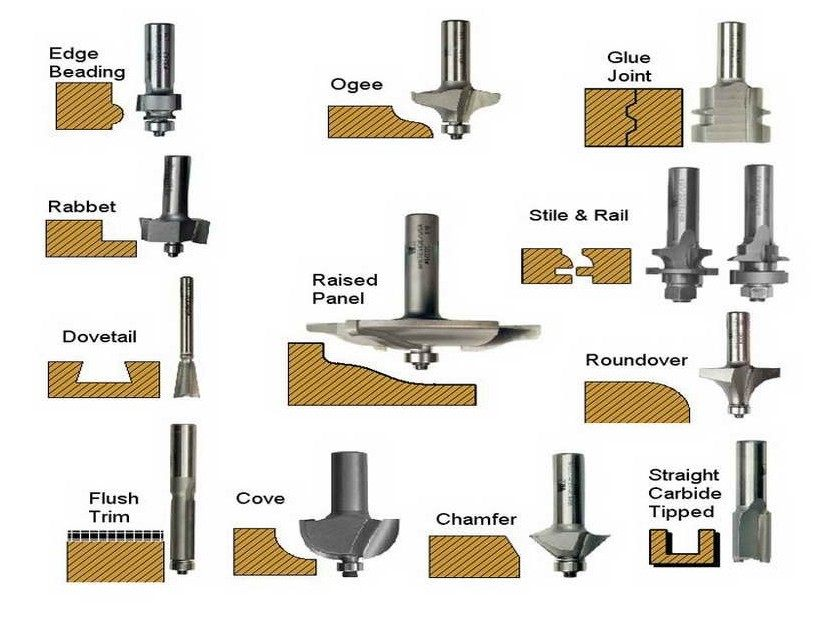

Learn more about the various types of CNC router bits and how they can enhance your precision machining projects. From end mills to v-groove and ball nose cutters, choosing the right bit is critical for achieving optimal surface finish, accuracy, and tool life.

For technical guidance or custom bit selection tailored to your application, contact Susan Leo at [email protected]. As a trusted manufacturing partner with a state-of-the-art facility in Shenzhen, Honyo Prototype delivers high-performance cutting tools and CNC services backed by rigorous quality control and engineering expertise.

Let us help you optimize your CNC operations with the right tooling solutions. Reach out today for product specifications, pricing, or application support.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.