Introduction: Navigating the Global Market for type s transmission

In an increasingly competitive landscape, sourcing the right type S transmission poses significant challenges for international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe. As the demand for high-performance automotive components grows, understanding the nuances of transmission types, their applications, and performance characteristics becomes paramount. This comprehensive guide delves into the intricacies of type S transmissions, offering insights on various models, their suitability for different applications, and essential factors for supplier vetting.

Buyers will find detailed analyses of transmission specifications, performance metrics, and cost considerations, all designed to empower informed purchasing decisions. With a focus on optimizing performance and reliability, this guide not only highlights the key attributes of type S transmissions but also addresses common pitfalls in the procurement process. By leveraging this resource, B2B buyers can effectively navigate the complexities of the global market, ensuring they select the most suitable transmission solutions for their operational needs.

Whether you are looking to enhance your supply chain efficiency or seeking to improve the performance of your automotive offerings, this guide is an essential tool for making strategic, cost-effective choices that align with your business objectives. Prepare to elevate your sourcing strategy and drive your success in the dynamic automotive sector.

Understanding type s transmission Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 6-Speed Manual Transmission | Close-ratio gear ratios, optimized for performance | High-performance vehicles, motorsports | Pros: Enhanced acceleration; Cons: Higher cost and complexity in installation. |

| 5-Speed Manual Transmission | Simpler design, often more accessible and affordable | Daily drivers, budget builds | Pros: Easier to source; Cons: Limited performance compared to 6-speed. |

| K20A2 Transmission | Carbon synchros, designed for high RPM applications | Performance tuning, racing | Pros: Ideal for high horsepower builds; Cons: Requires professional installation and tuning. |

| TSX 6-Speed Transmission | Longer gearing, suitable for both street and track use | Versatile builds, street performance | Pros: Good balance of performance and comfort; Cons: May require additional parts for compatibility. |

| EP3 5-Speed Transmission | 4.7 final drive ratio, focuses on acceleration | Entry-level performance, daily driving | Pros: Better traction for turbo applications; Cons: Not as widely available as other options. |

What Are the Key Characteristics of 6-Speed Manual Transmissions?

The 6-speed manual transmission is characterized by its close-ratio gear setup, which allows for quicker shifts and improved acceleration. This type is particularly suited for high-performance vehicles and motorsports, where every fraction of a second counts. B2B buyers should consider the potential for enhanced performance against the higher cost and complexity of installation. For businesses focused on high-performance applications, this transmission type offers significant advantages in terms of responsiveness and speed.

How Does the 5-Speed Manual Transmission Compare in Terms of Accessibility?

The 5-speed manual transmission is known for its simpler design, making it more accessible and often more affordable than its 6-speed counterpart. This transmission is ideal for daily drivers and budget builds where high performance is not the primary goal. B2B buyers should weigh the ease of sourcing and lower upfront costs against the limitations in performance. This type is commonly recommended for businesses looking to provide reliable, cost-effective solutions for their clients.

What Makes the K20A2 Transmission a Preferred Choice for Performance Tuning?

The K20A2 transmission is distinguished by its use of carbon synchros, which are designed to handle high RPM applications effectively. This transmission is often sought after in performance tuning and racing environments, as it can support significant horsepower increases. Buyers must consider the need for professional installation and tuning to maximize the transmission’s potential. For businesses involved in performance upgrades, this type presents a strong option for meeting client demands for speed and reliability.

Why Is the TSX 6-Speed Transmission Valued for Versatile Builds?

The TSX 6-speed transmission features longer gearing, making it suitable for both street and track use. Its versatility allows it to cater to a wide range of applications, from daily driving to more spirited performance. B2B buyers should note that while it offers a good balance of performance and comfort, compatibility with existing setups may require additional parts. This transmission type is ideal for businesses targeting customers who desire a well-rounded driving experience.

What Are the Benefits of the EP3 5-Speed Transmission for Entry-Level Performance?

The EP3 5-speed transmission is notable for its 4.7 final drive ratio, which enhances acceleration and traction, particularly in turbo applications. This makes it a suitable choice for entry-level performance vehicles and daily drivers. B2B buyers should be aware that while it offers better traction, it may not be as widely available as other options. This type provides a solid entry point for businesses looking to cater to clients interested in performance upgrades without the high costs associated with more advanced transmissions.

Key Industrial Applications of type s transmission

| Industry/Sector | Specific Application of type s transmission | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | High-performance vehicles like sports cars | Enhanced performance and acceleration capabilities | Compatibility with existing vehicle models and parts |

| Motorsports | Racing vehicles requiring precision and speed | Improved traction and gear efficiency during races | Durability under extreme conditions and quick delivery |

| Automotive Aftermarket | Custom builds and performance upgrades | Increased horsepower and torque for modified engines | Availability of specialized components and support |

| Transportation and Logistics | Specialty vehicles for off-road and heavy-duty use | Greater reliability and performance in challenging terrains | Sourcing from reputable suppliers with proven track records |

| Industrial Equipment | Equipment requiring high RPM for operational efficiency | Optimized gear ratios for better output and efficiency | Customization options for specific industrial needs |

How is type s transmission utilized in automotive manufacturing?

In the automotive manufacturing sector, type s transmissions are primarily employed in high-performance vehicles, particularly sports cars. These transmissions are designed to provide superior acceleration and responsiveness, essential for meeting the demands of performance enthusiasts. B2B buyers in this sector must consider compatibility with existing vehicle models and the availability of parts to ensure seamless integration. Additionally, the demand for high-quality materials that enhance performance and durability is critical, especially in competitive markets like Germany and Brazil.

What role does type s transmission play in motorsports?

In motorsports, type s transmissions are crucial for racing vehicles that require precision gear shifting and optimal performance. These transmissions enable improved traction and gear efficiency, essential for achieving high speeds and quick acceleration on the track. International buyers, particularly from regions with active motorsport communities, should focus on sourcing transmissions that offer durability under extreme conditions. Quick delivery times and the ability to customize components for specific racing needs are also significant considerations for teams looking to enhance their competitive edge.

How is type s transmission beneficial in the automotive aftermarket?

The automotive aftermarket sector leverages type s transmissions for custom builds and performance upgrades. Enthusiasts seeking to enhance their vehicles often turn to these transmissions to increase horsepower and torque, particularly in modified engines. Buyers in this sector should prioritize sourcing specialized components that ensure compatibility with various aftermarket parts. Additionally, access to technical support and installation services can significantly influence purchasing decisions, especially for buyers in emerging markets like South America and Africa.

Why is type s transmission important for transportation and logistics?

In transportation and logistics, type s transmissions are utilized in specialty vehicles designed for off-road and heavy-duty applications. These transmissions provide greater reliability and performance in challenging terrains, making them ideal for industries such as mining and construction. Buyers must consider the reputation of suppliers and the availability of durable components that can withstand harsh operational environments. Additionally, understanding the specific requirements of their fleet and sourcing transmissions that meet those needs is crucial for maintaining efficiency and reducing downtime.

How does type s transmission enhance industrial equipment performance?

Type s transmissions are increasingly used in industrial equipment that requires high RPM for operational efficiency. By optimizing gear ratios, these transmissions can significantly improve output and energy efficiency in various applications, from manufacturing to agriculture. B2B buyers should focus on customization options to meet specific industrial needs, ensuring that the transmission can handle the workload and performance expectations. Sourcing from reputable suppliers with a proven track record in the industrial sector is vital for long-term reliability and performance.

3 Common User Pain Points for ‘type s transmission’ & Their Solutions

Scenario 1: Difficulty Sourcing Replacement Parts for Type S Transmissions

The Problem: B2B buyers often face challenges in sourcing reliable replacement parts for Type S transmissions, particularly in regions where these components are not readily available. This can lead to prolonged downtime for vehicles, impacting operational efficiency and customer satisfaction. For instance, a supplier in South America may struggle to find a reliable source for remanufactured K20A2 transmissions or specific parts like synchros, which can halt their repair processes and lead to lost revenue.

The Solution: To effectively source replacement parts, B2B buyers should establish relationships with multiple suppliers across different regions. Utilizing online platforms that specialize in automotive parts can broaden access to inventory. Additionally, investing in remanufactured parts from reputable manufacturers ensures quality and reliability. For instance, businesses should look for suppliers that provide warranties and detailed specifications about their parts. Participating in automotive trade shows or industry events can also connect buyers with manufacturers and suppliers who specialize in Type S transmissions, thereby enhancing their sourcing network.

Scenario 2: Misunderstanding Transmission Specifications

The Problem: A frequent issue for B2B buyers is the misunderstanding of transmission specifications, which can result in purchasing incompatible units. For example, a buyer may incorrectly assume that a 5-speed transmission is a direct swap for a 6-speed Type S transmission without considering the differences in shifter and linkage systems. This mistake can lead to costly returns and extended repair times, ultimately affecting the bottom line.

The Solution: To mitigate the risk of purchasing incompatible transmissions, B2B buyers should invest time in understanding the technical specifications of each model. This includes knowing the differences in gear ratios, axle lengths, and compatibility with existing vehicle systems. Creating a comprehensive checklist of these specifications can aid in making informed purchasing decisions. Moreover, buyers should consult with knowledgeable experts or technical representatives from suppliers before finalizing their orders. Implementing a training program for staff to educate them on transmission specifications and compatibility can also enhance the purchasing process.

Scenario 3: Challenges in Maintaining Transmission Performance

The Problem: Maintaining optimal performance of Type S transmissions can be challenging, especially in high-demand environments where vehicles are subjected to rigorous use. B2B buyers may encounter issues such as gear slippage or overheating, particularly when using subpar transmission fluids or failing to perform regular maintenance. This can lead to increased repair costs and diminished vehicle performance, which is detrimental to service quality.

The Solution: To ensure the longevity and performance of Type S transmissions, B2B buyers should prioritize regular maintenance schedules that include fluid changes and inspections. Utilizing high-quality transmission fluids specifically designed for performance applications can help prevent overheating and improve overall efficiency. Buyers should also consider implementing a monitoring system to track transmission performance metrics, allowing for proactive maintenance. Additionally, establishing a relationship with a skilled technician or a specialized service center can provide valuable insights into performance issues and maintenance best practices, ensuring that their fleet operates at peak efficiency.

Strategic Material Selection Guide for type s transmission

What Are the Key Materials Used in Type S Transmissions?

When selecting materials for Type S transmissions, several factors must be considered to ensure optimal performance, durability, and cost-effectiveness. This guide analyzes four common materials used in the construction of Type S transmissions, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Aluminum Alloy Perform in Type S Transmissions?

Aluminum alloys are widely used in Type S transmissions due to their excellent strength-to-weight ratio. They typically exhibit good corrosion resistance and can withstand moderate temperature and pressure ratings. The lightweight nature of aluminum aids in improving fuel efficiency and overall vehicle performance.

Pros: Aluminum alloys are relatively inexpensive and easy to machine, making them suitable for mass production. They also provide good thermal conductivity, which helps in dissipating heat during operation.

Cons: While they are durable, aluminum alloys can be susceptible to fatigue and may not perform well under extreme conditions. Additionally, they may require protective coatings to enhance corrosion resistance, which can add to manufacturing complexity.

Impact on Application: Aluminum is compatible with various media, including lubricants and coolants, but care should be taken to avoid aggressive chemicals that may lead to corrosion.

Considerations for International Buyers: Compliance with standards such as ASTM or DIN is crucial. Buyers from regions like Europe and South America should ensure that the aluminum used meets local regulations regarding recycling and environmental impact.

What Role Does Steel Play in Type S Transmission Design?

Steel is another common material used in Type S transmissions, particularly for gears and shafts. It offers superior strength and durability, making it ideal for high-torque applications. Steel can also withstand high-temperature environments, ensuring reliable performance under stress.

Pros: Steel’s high tensile strength and wear resistance make it suitable for heavy-duty applications. It can be treated for enhanced properties, such as hardening, which increases its lifespan.

Cons: The primary drawback of steel is its weight, which can negatively impact fuel efficiency. Additionally, steel components may require additional machining and finishing processes, increasing manufacturing complexity and cost.

Impact on Application: Steel is generally compatible with a wide range of lubricants and can withstand harsh operating conditions, making it suitable for various media.

Considerations for International Buyers: Buyers should be aware of the different grades of steel and their compliance with international standards. In regions like the Middle East, where high temperatures are common, selecting the right grade is essential for performance.

How Do Composite Materials Enhance Type S Transmissions?

Composite materials, such as carbon-fiber reinforced plastics, are increasingly being used in Type S transmissions to reduce weight while maintaining strength. These materials offer excellent resistance to fatigue and corrosion, making them suitable for high-performance applications.

Pros: The lightweight nature of composites can significantly enhance vehicle performance and fuel efficiency. They also provide excellent thermal and chemical resistance.

Cons: Composites can be more expensive to produce and may require specialized manufacturing techniques. Their performance can be affected by temperature fluctuations, which may limit their application in certain environments.

Impact on Application: Composites are compatible with various lubricants but should be evaluated for chemical resistance against specific media used in transmissions.

Considerations for International Buyers: Buyers must consider the availability of composite materials in their region and the associated costs. Compliance with international standards for composites is also essential, especially in Europe.

What Benefits Do Synthetic Materials Offer for Type S Transmissions?

Synthetic materials, such as engineered plastics, are utilized in Type S transmissions for components like seals and gaskets. These materials are designed to withstand a range of temperatures and pressures while providing excellent chemical resistance.

Pros: Synthetic materials are lightweight, cost-effective, and can be produced in various shapes and sizes. They also offer good insulation properties, which can be beneficial in reducing heat transfer.

Cons: While synthetic materials are durable, they may not have the same strength as metals and can degrade under extreme conditions. This limitation may restrict their use in high-stress areas of the transmission.

Impact on Application: Synthetic materials are compatible with most lubricants and coolants, making them versatile for use in various applications.

Considerations for International Buyers: Buyers should ensure that synthetic materials meet local compliance standards and are suitable for the specific conditions of their operational environment.

Summary of Material Selection for Type S Transmissions

| Material | Typical Use Case for type s transmission | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy | Transmission housing and casing | Lightweight and good corrosion resistance | Susceptible to fatigue under stress | Medium |

| Steel | Gears and shafts | High strength and durability | Heavy and requires more machining | Medium |

| Composite Materials | Structural components | Excellent strength-to-weight ratio | Higher production costs | High |

| Synthetic Materials | Seals and gaskets | Good chemical resistance and lightweight | Limited strength compared to metals | Low |

This guide provides a comprehensive overview of materials used in Type S transmissions, aiding international B2B buyers in making informed decisions based on performance, cost, and compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for type s transmission

What Are the Key Stages in Manufacturing Type S Transmissions?

The manufacturing of Type S transmissions involves several critical stages that ensure the final product meets performance and durability standards. These stages include material preparation, forming, assembly, and finishing, each employing various techniques tailored for high-performance automotive components.

Material Preparation: Selecting the Right Components

The manufacturing process begins with the selection of high-quality materials. Typically, manufacturers utilize high-strength alloys for gears and housings, ensuring optimal performance under stress. Materials are often sourced from certified suppliers who adhere to international standards, minimizing the risk of defects.

Once materials are selected, they undergo preparation processes such as cutting and machining. Precision machining is crucial at this stage, as it ensures that all components fit together accurately. Advanced CNC (Computer Numerical Control) machines are commonly used to achieve high tolerances, which are essential for the smooth operation of the transmission.

How Are Type S Transmissions Formed?

After material preparation, the forming stage involves shaping components through processes like forging, casting, or stamping. For Type S transmissions, forging is often preferred for critical components such as gears due to its ability to enhance material strength and toughness.

Casting may also be employed for less critical parts, such as the transmission housing. Manufacturers often utilize techniques like sand casting or die casting, depending on the complexity and volume of the components required. The choice of forming method directly impacts the performance characteristics of the final product.

What Does the Assembly Process Involve?

Once the individual components are formed, they move on to the assembly stage. This process typically involves several key activities:

- Sub-Assembly: Components like gears, shafts, and synchronizers are first assembled into sub-units.

- Main Assembly: The sub-units are then integrated into the transmission case, often requiring specialized tools and fixtures to ensure precise alignment.

- Installation of Additional Features: Features such as the differential and shift mechanisms are installed at this stage.

Quality control checkpoints are critical during assembly to ensure that each component meets design specifications.

What Finishing Techniques Are Employed for Type S Transmissions?

Finishing processes enhance the durability and aesthetics of the transmission. Common techniques include surface hardening, coating, and cleaning.

- Surface Hardening: Methods like carburizing or nitriding are employed to increase surface hardness, thereby improving wear resistance.

- Coating: Anti-corrosion coatings may be applied to protect components from environmental factors, extending the lifespan of the transmission.

- Cleaning: After assembly, transmissions are thoroughly cleaned to remove any debris or contaminants that could impair performance.

Each finishing technique is selected based on the specific requirements of the Type S transmission and the intended application.

How Is Quality Assurance Implemented in Type S Transmission Manufacturing?

Quality assurance is a fundamental aspect of the manufacturing process, particularly for high-performance automotive components like the Type S transmission. Manufacturers typically adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system.

What International Standards Are Relevant?

ISO 9001 certification signifies that a manufacturer has implemented a robust quality management system that focuses on continual improvement and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for components interacting with lubricants may also apply.

What Are the Key Quality Control Checkpoints?

Quality control throughout the manufacturing process involves several critical checkpoints:

- Incoming Quality Control (IQC): This checkpoint ensures that all raw materials and components meet specified quality standards before they enter production.

- In-Process Quality Control (IPQC): During the manufacturing stages, various tests and inspections are conducted to monitor the quality of the components being produced.

- Final Quality Control (FQC): Once the transmission is fully assembled, a final inspection is performed to check for any defects and ensure that the product meets performance specifications.

These checkpoints help identify and rectify issues early in the production process, minimizing the risk of defective products reaching the market.

What Testing Methods Are Commonly Used?

Several testing methods are employed to validate the quality and performance of Type S transmissions, including:

- Functional Testing: This simulates real-world conditions to assess the operational performance of the transmission.

- Fatigue Testing: Components are subjected to cyclic loading to determine their durability and lifespan.

- Leak Testing: Ensures that the transmission is sealed properly and does not leak fluids, which could lead to failures.

Each testing method provides critical data that informs quality assurance processes and helps in the continuous improvement of manufacturing practices.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of potential suppliers is essential.

What Steps Can Buyers Take?

- Supplier Audits: Conducting on-site audits of suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards.

- Requesting Quality Reports: Suppliers should be able to provide documentation that details their quality control processes, including results from testing and inspections.

- Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance, ensuring that the products meet specified standards before shipment.

What Are the QC and Certification Nuances for International Buyers?

International buyers should be aware of the nuances in quality certification and compliance across different regions. For example, while ISO certifications are recognized globally, specific markets may have additional requirements. Understanding local regulations and standards can help buyers make informed decisions when sourcing Type S transmissions.

In summary, the manufacturing processes and quality assurance practices for Type S transmissions are designed to ensure high performance, durability, and reliability. By understanding these processes, B2B buyers can make informed choices and establish partnerships with suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘type s transmission’

This guide serves as a comprehensive checklist for B2B buyers interested in sourcing Type S transmissions. By following these steps, you can ensure a well-informed procurement process, ultimately leading to enhanced performance and reliability in your automotive applications.

1. Define Your Technical Specifications

Clearly outline the technical requirements for the Type S transmission you need. This includes engine compatibility, gear ratios, and torque capacity. Understanding these specifications helps narrow your search and ensures that the transmission will meet the performance demands of your application.

- Key Considerations:

- Engine model and year compatibility.

- Desired gear ratios for performance optimization.

- High-performance needs, such as racing or daily driving.

2. Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of Type S transmissions. Look for companies with a proven track record in the automotive industry and positive customer reviews. This step is critical to avoid issues with quality and service down the line.

- Action Points:

- Review supplier websites for product offerings and testimonials.

- Utilize industry forums and social media to gauge supplier reputation.

- Compile a list of at least three potential suppliers for further evaluation.

3. Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and industry standards compliance. Certifications such as ISO 9001 indicate a commitment to quality management, which is essential for ensuring the reliability of the transmission.

- What to Look For:

- ISO or equivalent certifications.

- Warranty terms and conditions that protect your investment.

- Evidence of quality control processes in place.

4. Request Detailed Product Information

When you have shortlisted potential suppliers, request detailed product specifications and technical documentation for the Type S transmissions. This information should include assembly details, maintenance guidelines, and installation requirements.

- Specific Documents:

- Technical data sheets outlining gear ratios and torque specs.

- Installation manuals or guides for ease of reference.

- Maintenance schedules to ensure long-term reliability.

5. Assess Pricing and Payment Terms

Evaluate the pricing structure of the Type S transmissions from different suppliers. Look for competitive pricing, but also consider the total cost of ownership, including shipping, taxes, and potential duties.

- Important Considerations:

- Breakdown of costs (transmission, shipping, and taxes).

- Payment terms and conditions (e.g., deposits, payment schedules).

- Discounts for bulk purchases or long-term contracts.

6. Check Availability and Lead Times

Inquire about the availability of the Type S transmissions and the expected lead times for delivery. Understanding these timelines is crucial for planning your projects and ensuring that you can meet your operational deadlines.

- Key Questions:

- What is the average lead time for the desired transmission?

- Are there any potential delays due to supply chain issues?

- Can the supplier accommodate urgent requests or rush orders?

7. Finalize the Purchase Agreement

Once you have selected a supplier, finalize the purchase agreement. Ensure that all terms discussed are documented, including warranties, return policies, and support services.

- Final Checklist:

- Review the contract for clarity on terms and conditions.

- Confirm warranty coverage and support for installation issues.

- Ensure there is a clear process for returns or exchanges if necessary.

By following this structured sourcing guide, B2B buyers can confidently navigate the procurement of Type S transmissions, ensuring they select the right product for their needs while minimizing risks associated with quality and supplier reliability.

Comprehensive Cost and Pricing Analysis for type s transmission Sourcing

What Are the Key Cost Components in Type S Transmission Sourcing?

When sourcing Type S transmissions, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality of materials significantly impacts the cost. High-performance components, such as carbon synchros and high-grade metals, are essential for durability and performance but can increase initial costs.

-

Labor: Skilled labor is required for the assembly and quality control of these transmissions. Labor costs may vary based on geographic location and the complexity of the transmission.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with production facilities. In regions with higher operational costs, this can be a substantial portion of the overall price.

-

Tooling: Custom tooling may be necessary for unique specifications or modifications. This upfront investment can be amortized over larger production runs, reducing per-unit costs.

-

Quality Control (QC): Rigorous QC processes ensure reliability and performance. While this adds to costs, it is essential for maintaining product standards, particularly in high-performance applications.

-

Logistics: Shipping and handling costs can vary significantly, especially for international shipments. Factors like distance, shipping method, and customs can influence the total logistics cost.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the industry standards for margins can aid buyers in assessing whether a quoted price is competitive.

How Do Price Influencers Affect Type S Transmission Costs?

Several factors can influence the pricing of Type S transmissions:

-

Volume and Minimum Order Quantity (MOQ): Higher volume purchases often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their operational needs.

-

Specifications and Customization: Custom modifications can lead to increased costs. Buyers must assess whether the benefits of customization outweigh the additional expenses.

-

Materials and Quality Certifications: Premium materials and certifications can enhance performance but will also increase costs. Buyers should evaluate the trade-offs between cost and quality.

-

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers may command higher prices due to their quality assurance and service levels.

-

Incoterms: Understanding the implications of Incoterms can help buyers better manage costs related to shipping, insurance, and customs duties.

What Tips Can Help Buyers Negotiate Better Prices?

To achieve cost-efficient sourcing of Type S transmissions, consider the following strategies:

-

Leverage Volume Discounts: Engage suppliers in discussions about pricing structures based on anticipated order volumes. This can lead to significant savings.

-

Conduct a Total Cost of Ownership (TCO) Analysis: Evaluate not just the purchase price but the long-term costs associated with maintenance, potential downtime, and performance. This perspective can justify higher upfront costs for more reliable products.

-

Negotiate Terms and Conditions: Beyond price, negotiate payment terms, warranty conditions, and return policies. Favorable terms can enhance overall cost-effectiveness.

-

Research Local and International Suppliers: Compare prices from various suppliers in different regions. Local suppliers may offer advantages in logistics and customs, while international suppliers might provide competitive pricing on high-quality products.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, tariffs, and local market conditions that can affect pricing. This knowledge is particularly vital for buyers in Africa, South America, the Middle East, and Europe, where these factors may vary widely.

Conclusion

While sourcing Type S transmissions, B2B buyers must consider a comprehensive range of cost components and price influencers. By leveraging negotiation strategies and understanding the total cost of ownership, buyers can optimize their purchasing decisions and achieve better outcomes in their sourcing efforts. Remember, prices can vary widely, so continuous market analysis and supplier engagement are key to maintaining a competitive edge.

Alternatives Analysis: Comparing type s transmission With Other Solutions

Introduction to Alternative Transmission Solutions

In the competitive landscape of automotive performance, particularly within the B2B sector, understanding the alternatives to Type S transmission can significantly influence purchasing decisions. Buyers must evaluate their unique requirements, including performance expectations, budget constraints, and the operational environment. This analysis will compare Type S transmission with two viable alternatives: the 5-Speed Manual Transmission and the CVT (Continuously Variable Transmission), providing insights tailored for international buyers from regions such as Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | Type S Transmission | 5-Speed Manual Transmission | CVT (Continuously Variable Transmission) |

|---|---|---|---|

| Performance | High RPM capability, suitable for track and street | Excellent for high horsepower; short gear ratios | Smooth acceleration, optimized for fuel efficiency |

| Cost | Higher initial investment | Generally more affordable | Mid-range cost; varies by model |

| Ease of Implementation | Requires specific engine compatibility | Direct swap with compatible models | More complex installation, may need special mounts |

| Maintenance | Higher maintenance due to complexity | Easier to service, common parts | Requires specialized knowledge for repairs |

| Best Use Case | Performance enthusiasts, racing applications | Daily driving, performance tuning | Urban driving, efficiency-focused applications |

Detailed Breakdown of Alternatives

5-Speed Manual Transmission

The 5-speed manual transmission is a popular choice among performance enthusiasts due to its robust nature and high torque capacity. This option provides excellent acceleration and is particularly effective in high horsepower applications. Its affordability compared to Type S transmission makes it appealing for budget-conscious buyers. However, while it excels in performance, it may require more frequent maintenance due to its mechanical complexity, and the experience of the driver is essential to maximize its potential.

CVT (Continuously Variable Transmission)

CVT technology offers a different approach to vehicle performance, emphasizing smooth and efficient acceleration without the distinct gear shifts found in traditional transmissions. This transmission type is particularly advantageous for urban driving, providing fuel efficiency and a comfortable driving experience. However, it may not perform as well under high-stress conditions such as racing or heavy loads, and its maintenance can be more complex and costly. Buyers considering CVT should assess their driving environment to determine if its benefits align with their needs.

Conclusion: Choosing the Right Transmission Solution

Selecting the appropriate transmission solution involves a careful assessment of specific operational requirements and performance goals. For businesses focused on high-performance applications, the Type S transmission may be ideal, offering advanced capabilities at a premium price. Conversely, those seeking affordability and ease of use might find the 5-speed manual transmission a more suitable choice. Lastly, for urban environments where fuel efficiency is paramount, the CVT presents a compelling option. By weighing these factors, B2B buyers can make informed decisions that align with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for type s transmission

What Are the Key Technical Properties of Type S Transmission?

Understanding the technical specifications of Type S transmission is crucial for B2B buyers, especially those involved in automotive performance and aftermarket modifications. Here are several essential properties:

1. Gear Material Composition

The Type S transmission typically utilizes high-strength alloys, often including carbon steel and aluminum, which contribute to weight reduction and durability. This material choice is vital for high-performance applications, as it ensures that the transmission can withstand the stresses of high RPMs and torque outputs. Buyers should consider the material grade when sourcing transmissions to ensure they meet specific performance criteria.

2. Gear Ratios

Gear ratios are critical in determining how power is transferred from the engine to the wheels. The Type S transmission often features close-ratio gear setups that allow for quicker acceleration by minimizing power loss between shifts. Understanding gear ratios is essential for buyers looking to optimize vehicle performance, particularly in racing or high-torque scenarios.

3. Tolerance Levels

Precision engineering is vital in automotive transmissions. Tolerance levels, which measure the allowable deviation from specified dimensions, are crucial for ensuring proper fit and function. A Type S transmission may have tight tolerances to minimize backlash and enhance shifting accuracy. Buyers should inquire about these tolerances to ensure compatibility with their vehicles and to maintain performance integrity.

4. Differential Type

Many Type S transmissions come equipped with a Limited Slip Differential (LSD). This feature enhances traction by distributing power more evenly between the wheels, which is particularly beneficial in high-performance driving conditions. Understanding the type of differential is crucial for buyers who require specific handling characteristics for their applications.

5. Synchronization Technology

Modern Type S transmissions often utilize advanced synchronization technology, such as carbon synchros, which improve shifting performance and reduce wear. This technology can significantly enhance the longevity of the transmission and the driving experience. Buyers should consider the type of synchronization technology when evaluating the reliability and performance of a transmission.

What Are Common Trade Terms Related to Type S Transmission?

Navigating the B2B landscape requires familiarity with industry terminology. Here are some common trade terms relevant to Type S transmission:

1. OEM (Original Equipment Manufacturer)

OEM refers to the original manufacturer of the vehicle’s components, including transmissions. When sourcing Type S transmissions, buyers often prefer OEM parts for their guaranteed compatibility and quality. Understanding OEM standards can help buyers avoid aftermarket components that may not meet their performance needs.

2. MOQ (Minimum Order Quantity)

MOQ denotes the minimum number of units a supplier is willing to sell. For Type S transmissions, suppliers may set an MOQ based on manufacturing costs and inventory levels. Buyers should be aware of MOQ requirements to plan their procurement strategies effectively, especially for bulk purchases.

3. RFQ (Request for Quotation)

An RFQ is a formal process by which buyers request price quotes from suppliers for specific products or services. When sourcing Type S transmissions, submitting an RFQ can help buyers obtain competitive pricing and terms. A well-prepared RFQ can streamline negotiations and ensure that buyers receive the best value.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade transactions. Understanding these terms is crucial for B2B buyers involved in importing Type S transmissions, as they dictate who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms can help buyers mitigate risks and ensure compliance.

5. Lead Time

Lead time refers to the time it takes from placing an order until delivery. This is particularly important for B2B buyers of Type S transmissions, as longer lead times can impact project timelines and vehicle modifications. Buyers should communicate clearly with suppliers about lead times to plan their operations effectively.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Type S transmissions, ensuring they meet their performance and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the type s transmission Sector

What Are the Global Drivers Influencing the Type S Transmission Market?

The Type S transmission sector is witnessing a significant transformation driven by various global factors. Key among these is the increasing demand for high-performance vehicles, particularly in emerging markets such as Africa and South America. As economies in these regions grow, so does the interest in automotive modifications and enhancements, leading to a rise in the aftermarket for performance components like Type S transmissions. Furthermore, technological advancements in transmission systems are enhancing vehicle performance and fuel efficiency, which are critical selling points for international buyers.

Another trend is the shift towards electrification and hybrid vehicles, influencing transmission design and functionality. As manufacturers adapt to these changes, the focus on lightweight, efficient transmissions that can handle higher torque loads is becoming paramount. Additionally, the European market, particularly in countries like Germany, is pushing for innovations that meet stringent emissions regulations, which further drives the demand for advanced transmission technologies.

How Are Current and Emerging B2B Tech Trends Shaping the Sourcing Landscape?

The B2B landscape for Type S transmissions is increasingly shaped by digital technologies and e-commerce platforms. International buyers are leveraging online marketplaces to source components, allowing for easier price comparison and supplier evaluation. This shift not only enhances transparency but also enables buyers to access a wider range of products from global suppliers, increasing competition and driving down costs.

Moreover, the integration of data analytics and AI in supply chain management is becoming a game-changer. These technologies enable businesses to forecast demand more accurately, manage inventory efficiently, and optimize sourcing strategies. As a result, B2B buyers can make informed decisions, reducing lead times and ensuring they have the right components available for their performance upgrades.

What Role Does Sustainability and Ethical Sourcing Play in the Type S Transmission Sector?

Sustainability is increasingly becoming a focal point in the Type S transmission market. As global awareness of environmental issues rises, buyers are more inclined to partner with suppliers who prioritize sustainable practices. This includes utilizing recycled materials in transmission manufacturing and ensuring that production processes minimize waste and energy consumption.

Ethical sourcing is also critical. B2B buyers are scrutinizing their supply chains for compliance with labor laws and environmental standards, seeking suppliers with certifications that demonstrate their commitment to ethical practices. This shift not only enhances brand reputation but also aligns with consumer preferences, particularly in regions like Europe, where sustainability is a significant purchasing factor.

What Are the Key Certifications and Materials for Sustainable Sourcing in Type S Transmission?

In the context of Type S transmissions, several certifications can guide buyers toward sustainable sourcing. Look for suppliers with ISO 14001 certification, which indicates effective environmental management systems. Additionally, certifications such as the Forest Stewardship Council (FSC) can be relevant for suppliers using wood-based materials in packaging.

Moreover, the use of advanced materials that reduce weight without compromising strength is a growing trend. For instance, components made from high-strength aluminum alloys or composites are favored for their performance benefits and lower environmental impact. Buyers should actively seek suppliers who can provide transparency regarding their material sourcing and environmental practices, ensuring a sustainable supply chain.

How Has the Type S Transmission Market Evolved Over Time?

The Type S transmission market has evolved significantly since its inception. Originally designed for performance-oriented vehicles, these transmissions have adapted to the changing automotive landscape. The introduction of advanced technologies, such as dual-clutch systems and variable valve timing, has enhanced the performance and efficiency of Type S transmissions, making them more attractive to both manufacturers and aftermarket enthusiasts.

In recent years, the focus has shifted towards integrating smart technologies, such as adaptive shifting and real-time monitoring systems, that enhance driving dynamics and fuel efficiency. This evolution reflects the broader trends in the automotive industry towards innovation and sustainability, positioning Type S transmissions as critical components in the high-performance vehicle segment.

Conclusion

As international B2B buyers navigate the Type S transmission market, understanding these dynamics—ranging from market drivers and sourcing trends to sustainability practices—will be crucial for making informed purchasing decisions. By prioritizing ethical sourcing and leveraging technological advancements, businesses can position themselves for success in this competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of type s transmission

-

How do I choose the right Type S transmission for my application?

Choosing the right Type S transmission involves assessing your specific needs, such as horsepower requirements, intended use (street or track), and compatibility with your vehicle. For high-performance applications, consider a 5-speed transmission for better acceleration and traction, especially if using turbo setups. Additionally, evaluate the final drive ratios, as these can significantly impact performance. Collaborating with a knowledgeable supplier can provide insights into the best options for your unique application. -

What is the best Type S transmission for high horsepower applications?

For high horsepower applications, many enthusiasts recommend the 5-speed Type S transmission. Its gearing allows for better torque delivery and acceleration. However, if you prefer a longer sixth gear for highway cruising, consider the 6-speed transmission, ensuring it is suitable for your power levels. Each option has its advantages, so weigh the benefits against your performance goals and vehicle setup. -

What are the typical lead times for ordering Type S transmissions?

Lead times for Type S transmissions can vary based on the supplier and the specific model you are ordering. Generally, expect delivery times between 8 to 18 business days for remanufactured units, as they often require assembly and quality checks. To ensure timely delivery, consider placing your order well in advance and communicate your timeline needs with the supplier to find a solution that meets your schedule. -

What should I consider when vetting suppliers for Type S transmissions?

When vetting suppliers, evaluate their reputation, product quality, and warranty policies. Look for suppliers who offer remanufactured transmissions with new components and rigorous testing processes. Request references or customer reviews, and inquire about their experience with international shipping, especially if you’re in Africa, South America, the Middle East, or Europe. Confirm that they provide adequate support for installation and maintenance, as this can be crucial for long-term satisfaction. -

What are the minimum order quantities (MOQs) for Type S transmissions?

Minimum order quantities (MOQs) can vary widely among suppliers. Some may offer single units for individual buyers, while others might have higher MOQs for bulk orders aimed at dealerships or workshops. It’s essential to clarify these details upfront to avoid surprises and ensure that the terms align with your purchasing strategy. If you require smaller quantities, consider negotiating or finding suppliers who specialize in lower volume orders. -

What payment terms are typically available for international orders?

Payment terms for international orders can differ based on the supplier’s policies and your negotiation. Common options include advance payment, partial payments, or letters of credit. Ensure to discuss and agree on terms that protect both parties, especially concerning currency exchange and transaction fees. Additionally, inquire about any available financing options if you require flexibility in payment schedules. -

How can I ensure the quality of Type S transmissions purchased internationally?

To ensure quality, request detailed specifications, warranties, and quality assurance processes from suppliers. Reputable suppliers often provide certifications for their products and transparent information about their remanufacturing processes. Consider asking for sample transmissions or third-party inspections before making a large purchase. Building a strong relationship with your supplier and maintaining open communication can also help address quality concerns proactively. -

What logistics considerations should I keep in mind when importing Type S transmissions?

When importing Type S transmissions, consider customs regulations, shipping methods, and potential tariffs that may apply to your order. Work with logistics partners who have experience in automotive parts to navigate these complexities smoothly. Additionally, confirm that your supplier can handle shipping logistics and provide tracking information. Proper planning can help minimize delays and ensure your transmissions arrive safely and on time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Type S Transmission Manufacturers & Suppliers List

1. Acura – RSX Manual Transmission

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Complete Manual Transmissions for Acura RSX for sale on eBay. Related searches include RSX Transmission, Acura RSX Manual, RSX Type S Transmission, and more. Categories include Automatic Transmission, Manual Transmission Parts, Clutch Parts & Kits, and other Transmission & Drivetrain components.

2. Acura – Integra Type S & TLX Type S

Domain: acura.com

Registered: 1996 (29 years)

Introduction: {“models”:[{“name”:”Integra Type S”,”starting_price”:”$33,000*”,”horsepower”:”320-HP*”,”engine”:”2.0L VTEC® Turbo”,”transmission”:”Close-Ratio 6-Speed Manual Transmission”,”features”:”Triple-Outlet Exhaust with Active Exhaust Valve”},{“name”:”TLX Type S”,”starting_price”:”$45,400*”,”horsepower”:”355-HP*”,”engine”:”Turbo V-6″,”features”:”Super Handling All-Wheel Drive™ (SH-AWD®), High-Performance C…

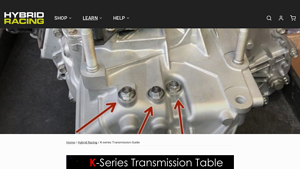

3. Hybrid Racing – Transmission Compatibility Insights

Domain: hybrid-racing.com

Registered: 2003 (22 years)

Introduction: 1) 01-06 Accord Euro-R and 05-06 RSX-S have the same transmission. 2) 01-06 ITR has the same 1-3 gear ratios as the 02-06 RSX-S, Euro-R, and 06 Si but different 4-6 gear ratios. 3) K20A2, K20A Euro-R, K20Z1 all have the same 1-6 gear ratios. 4) All 6-speed transmissions except 02-04 RSX-S & 06+ CTR have the same 4.764 final drive. 5) 06 Si and 04-06 TSX have the same 6th gear.

4. KSeriesParts – Key Products

Domain: kseriesparts.com

Registered: 2008 (17 years)

Introduction: Key product details include: 1. Categories: Countershaft / Final Drive Gear Sets, Individual Gears, Mainshaft Rebuild Kits, Shift Forks, Sleeve Sets, Synchros. 2. Products: MFactory K-Series 1st-4th Drag Gear Set (Part Number: MF-TRS-01K20) priced at $2,099.95; SynchroTech 05-06 RSX Type-S / 06-11 Civic Si / 05-08 TSX Carbon Master Rebuild Kit (Part Number: MK-SYN117) priced at $808.45; SynchroTec…

5. Gear Driven Inc – RSX K-Series Manual Transmission Rebuild

Domain: geardriveninc.com

Registered: 2015 (10 years)

Introduction: RSX K-Series Manual Transmission K20Z1 Street/Track Rebuild

6. IPG Parts – Transmission Rebuild Kits

Domain: ipgparts.com

Registered: 2007 (18 years)

Introduction: Transmission Rebuild Parts for various models including B Series, D Series, and K Series. Categories include 3-4 shift fork, clutch & transmission accessories, OEM Honda & Acura parts, K Series rebuild kits, synchro sets, and more. Specific parts mentioned are k20 pulse plate, k24 pulse plate, and k series replacement gears.

7. ClubRSX – Type-S Manual Swap Parts

Domain: clubrsx.com

Registered: 2001 (24 years)

Introduction: Type-S parts compatible with Base model RSX for Auto to Manual swap include: 1) Five- or six-speed manual transmission (same year as the car), 2) Vehicle speed sensor (if applicable), 3) Rear transmission bracket (Honda PN 50827-S7C-000), 4) RSX or ’01-’05 Civic Si clutch pedal, 5) RSX or ’01-’05 Civic Si brake pedal, 6) RSX or ’01-’05 Civic (non-Si) stick shifter box mechanism and hardware, 7) RS…

Strategic Sourcing Conclusion and Outlook for type s transmission

As the automotive market continues to evolve, the strategic sourcing of Type S transmissions presents significant opportunities for international B2B buyers. Key insights highlight the importance of aligning transmission specifications with performance requirements, especially for high horsepower applications. Buyers should consider factors such as gear ratios, ease of integration, and the potential for modifications to optimize performance. Collaborating with reputable suppliers can ensure access to high-quality remanufactured transmissions, such as those featuring advanced carbon synchros and limited-slip differentials, which enhance durability and driving dynamics.

Moreover, the global demand for reliable, high-performance transmissions is on the rise, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By prioritizing strategic sourcing, buyers can mitigate risks and capitalize on market trends while ensuring their supply chains remain robust and responsive.

Looking ahead, it is crucial for international buyers to stay informed about technological advancements and shifts in consumer preferences. Engaging with industry experts and participating in relevant networks will empower businesses to make informed decisions. Seize this opportunity to enhance your offerings and drive competitive advantage in the automotive sector.