Introduction: Navigating the Global Market for turret cnc lathe

In the dynamic landscape of global manufacturing, sourcing a turret CNC lathe that meets your specific operational needs can be a daunting task. With a myriad of options available, including servo and power turrets, buyers must navigate technical specifications and diverse functionalities to make informed decisions. This comprehensive guide delves into the various types of turret CNC lathes, their applications across industries, and essential considerations for supplier vetting.

International B2B buyers from regions like Africa, South America, the Middle East, and Europe—including key markets such as Germany and Brazil—will find actionable insights tailored to their unique challenges. The guide explores critical factors such as cost implications, maintenance requirements, and the advantages of different turret configurations, enabling businesses to optimize their machining processes and enhance productivity.

By equipping decision-makers with in-depth knowledge and practical strategies, this resource empowers organizations to confidently invest in turret CNC lathes that align with their manufacturing goals. Whether you are looking to streamline operations or enhance production capabilities, this guide serves as a crucial tool for navigating the complexities of the global market for turret CNC lathes.

Understanding turret cnc lathe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Servo Turret | Uses servo motors for precise control, supports multiple tool stations, primarily for turning. | High-volume production, precision parts. | Pros: High flexibility, increased tool capacity. Cons: Limited to turning operations. |

| Power Turret | Capable of both turning and milling, includes a motorized system for tool rotation. | Complex machining tasks, diverse materials. | Pros: Versatile for various applications. Cons: Higher initial investment. |

| BMT Turret | Features a modular design, allowing quick changeovers and integration with live tooling. | Aerospace, automotive, and medical industries. | Pros: Reduced downtime, adaptable. Cons: Requires skilled operators for setup. |

| VDI Turret | Known for its high rigidity and stability, suitable for heavy-duty machining. | Heavy machining, large components. | Pros: Excellent for tough materials. Cons: Heavier and potentially less agile. |

| BOT Turret | Compact design with high-speed indexing, ideal for small parts and intricate designs. | Electronics, small component manufacturing. | Pros: Fast operation, space-efficient. Cons: Limited capability for larger parts. |

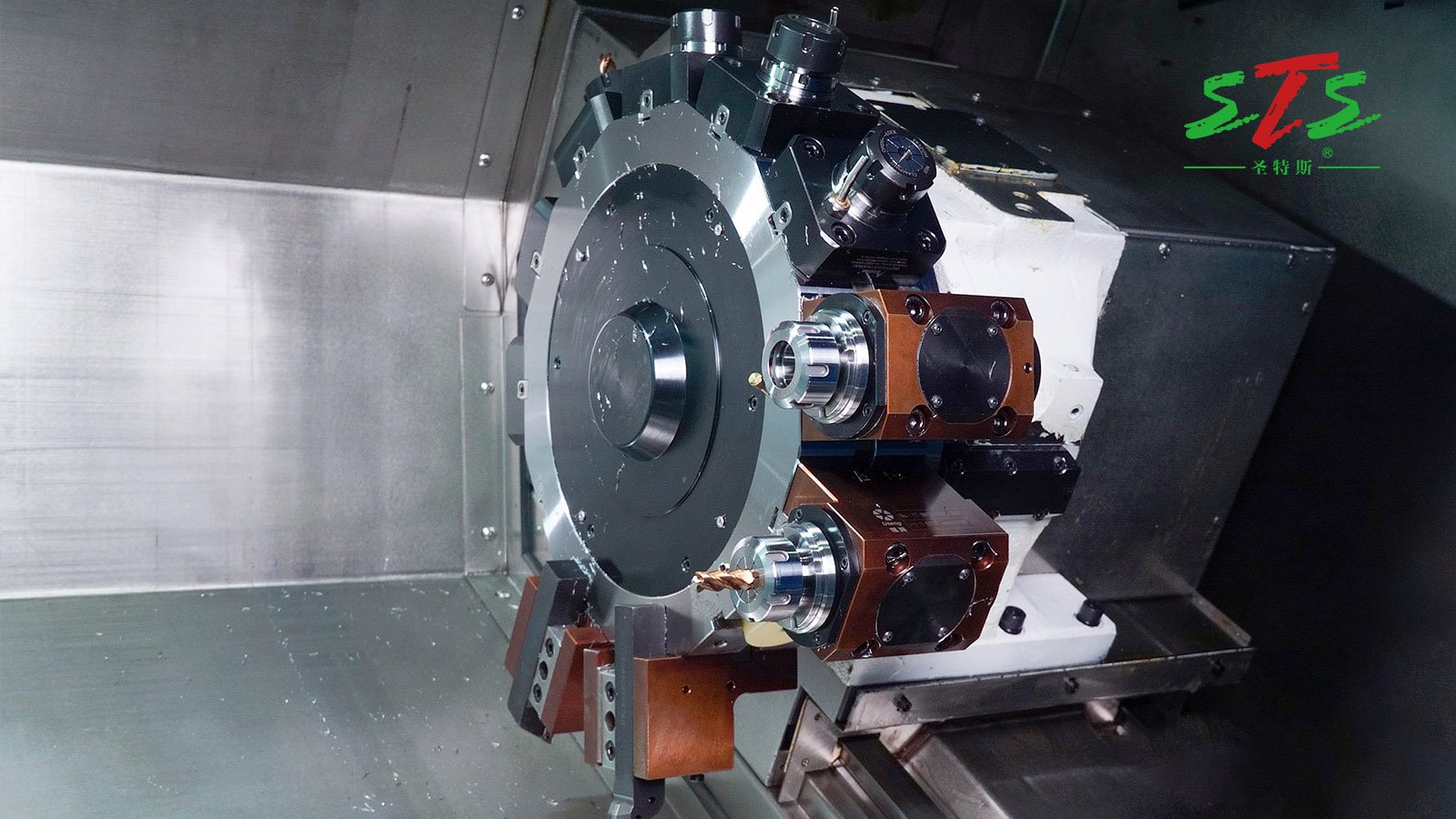

What are the Characteristics of Servo Turrets in CNC Lathes?

Servo turrets are characterized by their use of servo motors, which provide precise control over tool positioning. They are typically equipped with multiple tool stations, allowing for a variety of tools to be mounted simultaneously. This flexibility makes them ideal for high-volume production environments where precision and efficiency are paramount. Buyers should consider the specific needs of their operations, as servo turrets are primarily suited for turning applications.

How Do Power Turrets Enhance Machining Versatility?

Power turrets stand out for their ability to perform both turning and milling operations, making them highly versatile for complex machining tasks. They incorporate a motorized system that facilitates tool rotation and indexing, enabling the use of various tools for different operations. This adaptability is particularly beneficial for industries that require diverse machining capabilities. However, potential buyers should weigh the higher initial investment against the long-term benefits of increased versatility.

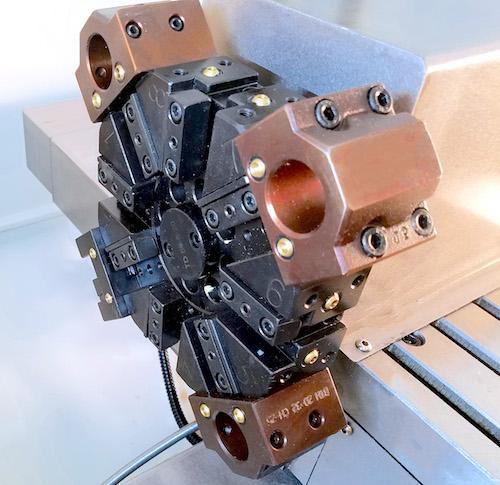

What Makes BMT Turrets Ideal for Modern Manufacturing?

BMT turrets feature a modular design that allows for rapid tool changeovers and seamless integration with live tooling, making them particularly advantageous in industries like aerospace and automotive. Their design minimizes downtime, thus enhancing overall productivity. However, they require skilled operators to set up and optimize effectively, which can be a consideration for businesses looking to implement this technology.

Why Choose VDI Turrets for Heavy-Duty Applications?

VDI turrets are known for their high rigidity and stability, making them suitable for heavy-duty machining applications. They excel in handling tough materials and large components, which is essential in industries such as construction and heavy manufacturing. While their robust design offers significant advantages, buyers must consider the potential trade-off in agility and speed compared to lighter turret options.

What Advantages Do BOT Turrets Offer for Small Parts Production?

BOT turrets are designed for high-speed indexing and are particularly effective for manufacturing small parts and intricate designs. Their compact size allows for efficient use of space, making them ideal for facilities with limited floor space. However, their capabilities may be limited when it comes to larger components, so buyers should assess their specific production needs before investing in this type of turret.

Key Industrial Applications of turret cnc lathe

| Industry/Sector | Specific Application of turret cnc lathe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of complex engine components | Enhanced precision and reduced cycle times | Supplier reliability, technical support, and warranty |

| Aerospace | Machining of turbine components and airframes | High accuracy and compliance with stringent standards | Certifications, material compatibility, and lead times |

| Electronics | Fabrication of connectors and housings | Increased productivity and reduced waste | Tooling versatility, software compatibility, and cost |

| Oil & Gas | Manufacturing of valves and fittings | Durability and reliability in harsh environments | Customization options, maintenance services, and parts availability |

| Medical Devices | Production of surgical instruments and implants | Precision engineering for safety and efficacy | Regulatory compliance, material certifications, and after-sales service |

How is Turret CNC Lathe Used in Automotive Manufacturing?

In the automotive sector, turret CNC lathes are essential for producing intricate engine components such as crankshafts and camshafts. These machines allow for the simultaneous machining of multiple features, significantly enhancing production efficiency. The need for precision is paramount in this industry, as even minor inaccuracies can lead to performance issues. International buyers should prioritize suppliers who offer robust technical support and reliable machinery to ensure consistent output and compliance with automotive standards.

What Role Does Turret CNC Lathe Play in Aerospace Applications?

Aerospace manufacturing relies heavily on turret CNC lathes for machining turbine components and airframes, where precision is critical. These machines can handle complex geometries and tight tolerances, ensuring components meet stringent safety regulations. Buyers in the aerospace sector must consider suppliers with relevant certifications and proven experience in aerospace applications to guarantee compliance and quality. Additionally, material compatibility is crucial due to the specific alloys used in aerospace manufacturing.

How Do Electronics Manufacturers Benefit from Turret CNC Lathes?

In the electronics industry, turret CNC lathes are utilized to fabricate connectors, housings, and other intricate parts. The ability to quickly switch between different tools and operations allows manufacturers to optimize their workflows and reduce waste. For international buyers, sourcing from suppliers that provide tooling versatility and software compatibility is vital to ensure seamless integration into existing production lines and to maintain high productivity levels.

Why Are Turret CNC Lathes Important in Oil & Gas Production?

The oil and gas industry uses turret CNC lathes to manufacture robust valves and fittings that withstand extreme conditions. These machines provide the durability and reliability required for components that operate in harsh environments. Buyers should look for customization options to meet specific project requirements and ensure that suppliers offer comprehensive maintenance services and readily available spare parts to minimize downtime.

How Do Medical Device Manufacturers Utilize Turret CNC Lathes?

In the medical device sector, turret CNC lathes are critical for producing surgical instruments and implants that require high precision. The stringent safety and efficacy standards in this field demand advanced machining capabilities. International buyers should focus on suppliers that comply with regulatory standards and possess the necessary material certifications. Additionally, after-sales service is crucial to address any maintenance or operational issues promptly, ensuring continuous production flow.

3 Common User Pain Points for ‘turret cnc lathe’ & Their Solutions

Scenario 1: Limited Tool Capacity Hindering Production Efficiency

The Problem: B2B buyers often face the challenge of limited tool capacity on their turret CNC lathes. For companies engaged in high-volume production, having a turret that can accommodate only a few tools can significantly slow down the machining process. This limitation forces operators to frequently change tools, leading to increased downtime and reduced overall productivity. Additionally, businesses that require a diverse range of machining operations may find themselves unable to efficiently meet varying customer demands.

The Solution: To overcome this challenge, businesses should consider investing in turret CNC lathes equipped with servo turrets that offer a higher number of tool stations—typically ranging from eight to twelve or more. This increase in capacity allows for more tools to be stored and accessed simultaneously, minimizing the need for tool changes during production runs. Furthermore, it’s crucial to work closely with suppliers to ensure the chosen turret CNC lathe is compatible with a wide array of tools relevant to your machining needs. By conducting a thorough assessment of your operational requirements and collaborating with manufacturers who specialize in versatile turret solutions, you can enhance your production capabilities and respond more effectively to fluctuating market demands.

Scenario 2: High Maintenance Costs Affecting ROI

The Problem: Maintenance costs can be a significant burden for companies using turret CNC lathes. Frequent breakdowns or performance issues often lead to costly repairs and unscheduled downtime, which can erode profit margins. B2B buyers are particularly concerned about the long-term operational costs associated with maintaining their machinery, especially if the equipment is not designed for durability or ease of service.

The Solution: To mitigate high maintenance costs, it is essential to invest in high-quality turret CNC lathes known for their reliability and low maintenance requirements. When sourcing equipment, look for models that come with robust warranties and service agreements, which can provide peace of mind and reduce unexpected expenses. Moreover, implementing a proactive maintenance program that includes regular inspections and timely servicing can help identify potential issues before they lead to significant downtime. Collaborating with suppliers who offer training on proper machine use and maintenance can also empower your workforce to operate the equipment more efficiently, further reducing wear and tear.

Scenario 3: Difficulty in Tool Changeover Slowing Down Operations

The Problem: Many B2B buyers encounter issues with tool changeover times, especially when dealing with complex machining tasks that require different tools for different operations. The inefficiency associated with manual tool changes can lead to extended lead times, ultimately impacting customer satisfaction and the ability to fulfill orders promptly. This scenario is particularly critical for manufacturers operating in fast-paced industries where time is of the essence.

The Solution: To address the challenge of slow tool changeovers, consider investing in turret CNC lathes that feature automatic tool changers or quick-change tooling systems. These technologies can drastically reduce the time required for tool changes, allowing for faster transitions between different machining operations. Additionally, standardizing tool holders and utilizing a consistent set of tools across various jobs can streamline the changeover process. Training your operators on the best practices for tool management and changeover procedures can further enhance efficiency. By implementing these strategies, you can significantly reduce cycle times and improve overall workflow, ensuring that you remain competitive in the market.

Strategic Material Selection Guide for turret cnc lathe

What Are the Key Materials for Turret CNC Lathes?

When selecting materials for turret CNC lathes, several factors come into play, including the operational environment, machining requirements, and regulatory compliance. Below are analyses of four common materials used in turret CNC lathe construction, along with their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Steel Perform in Turret CNC Lathes?

Key Properties:

Steel, particularly alloy steel, is known for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty machining applications.

Pros & Cons:

Steel offers excellent wear resistance and can be heat-treated to enhance its properties. However, it can be more expensive than other materials and may require complex manufacturing processes, such as machining and welding.

Impact on Application:

Steel’s robustness makes it ideal for applications involving hard materials. However, its susceptibility to corrosion can be a concern in humid or chemically aggressive environments.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A36 or DIN 17100. In regions like Europe and the Middle East, corrosion-resistant coatings may be necessary to meet local environmental regulations.

What Advantages Does Aluminum Provide for CNC Turrets?

Key Properties:

Aluminum is lightweight and has good corrosion resistance. It also has excellent thermal conductivity, which can be beneficial in dissipating heat during machining.

Pros & Cons:

The primary advantage of aluminum is its low weight, which can lead to faster machining speeds. However, it is less durable than steel and may not be suitable for heavy-duty applications. Additionally, its cost can be higher than steel in some markets.

Impact on Application:

Aluminum is highly compatible with non-ferrous materials and is often used in aerospace and automotive applications. Its lower strength limits its use in high-stress environments.

Considerations for International Buyers:

Buyers should be aware of specific aluminum grades, such as 6061 or 7075, and their compliance with standards like ASTM B221. In regions like Africa and South America, sourcing may be affected by local availability and import tariffs.

How Does Cast Iron Compare for CNC Lathe Applications?

Key Properties:

Cast iron is known for its excellent vibration dampening properties and thermal stability. It can withstand high temperatures and is resistant to deformation under stress.

Pros & Cons:

Cast iron is durable and cost-effective, making it a popular choice for machine bases and structural components. However, it is brittle and can fracture under excessive stress, limiting its use in dynamic applications.

Impact on Application:

The vibration dampening properties of cast iron make it suitable for precision machining applications. However, its weight can be a disadvantage in mobile or modular setups.

Considerations for International Buyers:

Buyers should consider compliance with standards like ASTM A48. In regions with a focus on sustainability, sourcing recycled cast iron may be a preferred option.

What Role Does Composite Material Play in CNC Lathe Construction?

Key Properties:

Composite materials, such as reinforced plastics or carbon fiber, are lightweight and offer excellent resistance to corrosion and chemicals. They can also be engineered for specific mechanical properties.

Pros & Cons:

The main advantage of composites is their versatility and the ability to tailor properties for specific applications. However, they can be more expensive and may require specialized manufacturing techniques.

Impact on Application:

Composites are particularly useful in applications requiring lightweight components without sacrificing strength. However, they may not be suitable for high-temperature environments.

Considerations for International Buyers:

Buyers should ensure that composite materials meet relevant standards, such as ASTM D3039 for tensile properties. In Europe, compliance with REACH regulations may also be necessary.

Summary Table of Material Selection for Turret CNC Lathes

| Material | Typical Use Case for turret cnc lathe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty machining | High strength and durability | Higher cost and complex manufacturing | High |

| Aluminum | Aerospace and automotive applications | Lightweight and good corrosion resistance | Less durable than steel | Medium |

| Cast Iron | Machine bases and structural components | Excellent vibration dampening | Brittle and heavy | Low |

| Composite | Lightweight, specialized components | Tailored properties and corrosion resistance | Higher cost and specialized manufacturing | High |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their turret CNC lathe applications while considering factors such as performance, cost, and compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for turret cnc lathe

What Are the Key Stages in the Manufacturing Process of Turret CNC Lathes?

The manufacturing process for turret CNC lathes involves several critical stages that ensure the final product meets the high standards required in precision machining. Each stage plays a vital role in determining the quality, efficiency, and longevity of the machines.

1. Material Preparation

The first step in the manufacturing of turret CNC lathes is material preparation. High-quality materials, such as alloy steel and cast iron, are selected based on their durability and machinability. Suppliers often provide certifications to verify the material properties, and it’s crucial for B2B buyers to ensure that these materials comply with international standards.

The materials undergo rigorous inspections to check for defects or inconsistencies before they proceed to the next stage. This can involve visual inspections as well as more advanced non-destructive testing methods to identify internal flaws.

2. Forming Processes

Once the materials are prepared, they undergo various forming processes. This may include machining, forging, and casting, depending on the component being produced. For turret CNC lathes, precision machining is particularly significant, as components like the turret head and tool holders must meet stringent tolerances.

Advanced techniques such as Computer Numerical Control (CNC) machining are employed to ensure high precision. The use of CNC allows for repeatable accuracy and efficiency in producing complex geometries. Buyers should look for suppliers that utilize state-of-the-art machinery to enhance production capabilities.

3. Assembly of Components

After forming, the components are assembled to create the turret CNC lathe. This stage requires skilled technicians who can accurately fit together various parts, including the motor, turret head, and tool holders. The assembly process is crucial, as any misalignment can lead to operational inefficiencies and decreased machine lifespan.

During assembly, various checks are performed to ensure that components fit correctly and operate smoothly. This may involve the use of alignment tools and gauges. B2B buyers can inquire about the assembly protocols followed by suppliers to ensure they adhere to best practices.

4. Finishing Touches

The final stage in the manufacturing process is finishing. This includes processes like grinding, polishing, and coating, which enhance the durability and aesthetics of the turret CNC lathe. For instance, surface treatments such as anodizing or powder coating can improve corrosion resistance, which is essential for machines used in diverse environments.

Quality control during the finishing stage ensures that the appearance and functional attributes of the lathe meet specifications. Buyers should assess whether the supplier conducts thorough finishing inspections to guarantee quality.

What Quality Assurance Measures Are Commonly Implemented for Turret CNC Lathes?

Quality assurance is a critical component of the manufacturing process for turret CNC lathes, ensuring that each machine meets both international and industry-specific standards.

International Standards for Quality Control

B2B buyers should be aware of relevant international standards such as ISO 9001, which outlines quality management systems and ensures consistent quality in manufacturing processes. Certification to ISO 9001 indicates that the supplier has implemented a quality management system that is regularly audited and updated.

Additionally, for manufacturers targeting specific markets, certifications like CE for Europe or API for the oil and gas industry may be necessary. These certifications assure buyers of compliance with safety and performance standards.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated throughout the manufacturing process to ensure product integrity. Key checkpoints include:

-

Incoming Quality Control (IQC): Before production begins, raw materials are inspected for compliance with specifications. This step is crucial in identifying defects early in the process.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed on components to ensure they meet design specifications. This can include dimensional checks and functional tests.

-

Final Quality Control (FQC): Once the turret CNC lathe is fully assembled, a comprehensive inspection is conducted. This may involve running the machine through various operational tests to confirm performance and reliability.

Buyers should ask suppliers about their quality control procedures and request documentation of these inspections.

What Testing Methods Are Utilized in Quality Control?

Various testing methods are employed to ensure the quality of turret CNC lathes. Common methods include:

-

Functional Testing: Machines are run under typical operational conditions to verify performance.

-

Dimensional Inspection: Precision measuring tools are used to confirm that components meet specified dimensions and tolerances.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle testing are used to detect internal flaws without damaging the component.

B2B buyers should verify that suppliers utilize these testing methods and can provide detailed reports on the results.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, verifying a supplier’s quality control practices is essential to ensure they receive a reliable product. Here are some effective strategies:

-

Supplier Audits: Conducting audits can provide insights into the supplier’s manufacturing processes and quality assurance protocols. Buyers should consider scheduling regular audits to maintain oversight.

-

Quality Reports: Requesting quality reports and certificates for each batch of products can help verify compliance with standards and specifications.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control practices. This is particularly important for buyers from regions with strict import regulations.

What Nuances Should International B2B Buyers Consider in Quality Control?

International buyers must navigate various nuances in quality control when sourcing turret CNC lathes:

-

Cultural Differences: Different regions may have varying standards and practices in manufacturing. Understanding these cultural differences can help buyers set realistic expectations.

-

Regulatory Compliance: Compliance with local regulations in the buyer’s region is crucial. Suppliers should be familiar with the necessary certifications required for importation.

-

Communication Barriers: Clear communication regarding quality expectations is vital. Buyers should ensure that language and technical jargon do not impede understanding.

By taking these factors into account, B2B buyers can make informed decisions when sourcing turret CNC lathes, ensuring they select suppliers that meet their quality and performance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘turret cnc lathe’

This guide aims to assist B2B buyers in making informed decisions when sourcing turret CNC lathes. By following this step-by-step checklist, you can ensure that you evaluate your options thoroughly and select the best machine that meets your specific needs.

Step 1: Define Your Technical Specifications

Before beginning the procurement process, it’s essential to outline your technical requirements. This includes the type of turret (servo or power), the number of tool stations needed (four, eight, or more), and the specific materials you will be machining. Having clear specifications will help you narrow down potential suppliers who can meet your needs.

- Considerations:

- What types of operations will the lathe perform—turning, milling, or both?

- What is the maximum diameter and length of the parts you intend to produce?

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the market. Look for manufacturers that specialize in turret CNC lathes and have positive reviews from previous customers.

- Key Actions:

- Utilize industry forums, trade shows, and online directories to compile a list of potential suppliers.

- Verify their experience in your specific industry or application.

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that the suppliers you are considering possess the necessary certifications and comply with international quality standards. This step is critical to ensure the reliability and safety of the equipment you will be purchasing.

- Important Certifications:

- ISO 9001 for quality management systems.

- CE marking for compliance with European health, safety, and environmental protection standards.

Step 4: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that include pricing, lead times, and warranty information. A comprehensive quote will help you compare options effectively.

- What to Look For:

- Breakdown of costs including machine price, shipping, and any additional fees.

- Warranty terms and after-sales support.

Step 5: Assess Technical Support and Training

Inquire about the technical support and training provided by the supplier. Proper training is vital to ensure that your operators can utilize the machine efficiently and safely.

- Considerations:

- Does the supplier offer on-site training or remote assistance?

- What are the available resources for troubleshooting and maintenance?

Step 6: Check References and Case Studies

Before making a final decision, check references and case studies from other businesses that have purchased similar equipment. This will provide insights into the supplier’s reliability and the performance of their machines.

- Action Steps:

- Request contact information for past clients and ask about their experiences.

- Look for case studies that detail specific applications of the turret CNC lathes.

Step 7: Finalize the Contract and Payment Terms

After selecting a supplier, ensure that all terms are clearly outlined in a contract. Pay attention to payment terms, delivery schedules, and service agreements.

- Important Points:

- Clarify the payment structure (e.g., deposits, milestones).

- Make sure to include clauses for warranty, maintenance, and support services.

By following this checklist, you can navigate the sourcing process for turret CNC lathes more effectively, ensuring that you make a well-informed investment that meets your operational needs.

Comprehensive Cost and Pricing Analysis for turret cnc lathe Sourcing

What are the Key Cost Components in Turret CNC Lathe Sourcing?

When sourcing turret CNC lathes, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality and type of materials used in manufacturing turret CNC lathes significantly affect pricing. High-grade steel and durable components will generally lead to higher costs but ensure longevity and performance.

-

Labor: Labor costs can vary depending on the region and the complexity of the machinery. Skilled labor for assembly and calibration often commands a premium, especially in countries with higher wage standards.

-

Manufacturing Overhead: This includes expenses related to factory operations, maintenance, and utilities. Manufacturers with advanced technology and efficient processes may have lower overhead, which can influence the final price.

-

Tooling: The cost of tooling, such as inserts and holders, is a critical factor. Custom tooling for specific applications can add to initial costs but may enhance efficiency and precision in machining.

-

Quality Control (QC): Rigorous QC processes ensure the reliability of the lathes. Suppliers that invest in comprehensive QC measures might charge more, but this often results in better product performance and reduced defects.

-

Logistics: Shipping and handling costs can vary widely based on the size and weight of the lathe, as well as the distance to the buyer. Incoterms play a crucial role here, dictating who bears the costs and risks during transportation.

-

Margin: Suppliers typically include a profit margin based on their operational costs and market positioning. Understanding the market average can help buyers assess whether a quote is reasonable.

How Do Price Influencers Affect Turret CNC Lathe Costs?

Several factors can influence the pricing of turret CNC lathes:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to reduced per-unit costs. Buyers should negotiate for better pricing based on potential long-term orders.

-

Specifications and Customization: Customized lathes tailored to specific requirements can significantly increase costs. Buyers should evaluate whether they need custom features or if standard models suffice.

-

Materials and Quality Certifications: High-quality materials and certifications (like ISO) can elevate prices but are essential for performance and reliability. Buyers should weigh the benefits of certified products against their budgets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but often provide better service and support.

-

Incoterms: The chosen Incoterms can affect total costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers calculate the total landed cost accurately.

What Are the Best Buyer Tips for Negotiating Turret CNC Lathe Prices?

-

Negotiate Effectively: Building a good relationship with suppliers can lead to better pricing and terms. Leverage your purchasing power and express interest in long-term partnerships.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, operational efficiency, and potential downtime costs.

-

Understand Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe must be mindful of currency fluctuations, import tariffs, and trade regulations that can impact final costs.

-

Request Detailed Quotations: Ensure quotes break down costs clearly. This transparency allows buyers to identify areas for negotiation or adjustment.

-

Consider After-Sales Support: Evaluate the availability of parts and service. A lower initial price may not be advantageous if after-sales support is lacking.

Conclusion

While the costs associated with turret CNC lathes can vary widely, understanding the components and influencers allows B2B buyers to make more strategic decisions. Always consider the long-term implications of your purchase, not just the upfront costs. Remember to consult multiple suppliers to ensure competitive pricing and optimal terms. Prices mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific requirements.

Alternatives Analysis: Comparing turret cnc lathe With Other Solutions

Exploring Alternatives to Turret CNC Lathes

When considering machining solutions, it’s essential for B2B buyers to evaluate various options against their specific needs. Turret CNC lathes are popular for their versatility and efficiency, but other alternatives may provide more tailored benefits depending on the application. Below, we compare turret CNC lathes with two viable alternatives: Gang Tool CNC Lathes and Multi-Slide CNC Lathes.

| Comparison Aspect | Turret CNC Lathe | Gang Tool CNC Lathe | Multi-Slide CNC Lathe |

|---|---|---|---|

| Performance | High precision; supports multiple tools and operations; ideal for complex parts | Very high-speed machining; optimized for simple parts with rapid tool changes | Excellent for high-volume production; multiple tools can operate simultaneously |

| Cost | Moderate initial investment; higher operational costs due to complexity | Generally lower upfront costs; cost-effective for simpler tasks | Higher upfront investment; cost-efficient for mass production due to reduced cycle times |

| Ease of Implementation | Requires skilled operators; setup can be complex | Easier to set up and operate; fewer moving parts | Complex setup; requires skilled labor for optimization |

| Maintenance | Regular maintenance needed for precision; can be costly | Lower maintenance; simpler design leads to fewer breakdowns | Requires regular maintenance; complex systems can lead to higher repair costs |

| Best Use Case | Suitable for versatile machining needs with various materials | Best for high-speed production of simpler, repetitive parts | Ideal for high-volume production runs with complex geometries |

In-Depth Look at Alternatives

Gang Tool CNC Lathes

Gang tool CNC lathes utilize a fixed tooling system, where tools are mounted on a stationary block, allowing for quick tool changes. This design facilitates high-speed machining and is particularly advantageous for producing simple, repetitive parts. The primary benefits include reduced setup times and lower operational costs. However, their limitations arise in versatility; they may not be suitable for complex part geometries and require a greater number of setups for varied tasks.

Multi-Slide CNC Lathes

Multi-slide CNC lathes are designed for high-volume production, featuring multiple slides and tool stations that enable simultaneous operations. This technology excels in producing complex parts quickly and efficiently, making it a favorite in industries requiring mass production. The upfront investment can be significant due to the complexity of the machinery. Maintenance can also be more demanding, as the intricate systems require skilled technicians to ensure optimal performance. Nonetheless, for businesses focused on large-scale production, the speed and efficiency can result in significant long-term savings.

Making the Right Choice for Your Business Needs

When selecting between turret CNC lathes and their alternatives, consider your specific production requirements, budget constraints, and operational capabilities. Turret CNC lathes offer exceptional versatility, making them suitable for a wide range of applications, while gang tool lathes provide cost-effective solutions for simpler tasks. On the other hand, multi-slide lathes are ideal for businesses focused on high-volume production. By assessing these factors, B2B buyers can make informed decisions that align with their strategic goals and operational efficiencies.

Essential Technical Properties and Trade Terminology for turret cnc lathe

What Are the Key Technical Properties of a Turret CNC Lathe?

When evaluating a turret CNC lathe for purchase, understanding its critical specifications is essential for making informed decisions. Here are some key properties that B2B buyers should consider:

1. Tool Station Capacity

The number of tool stations on a turret CNC lathe can significantly impact machining efficiency. Common configurations include 4, 8, 10, and 12 tool stations. A higher number of stations allows for more tools to be installed, reducing the time required for tool changes and increasing productivity. For businesses with diverse machining needs, opting for a lathe with a greater tool station capacity can enhance versatility and operational efficiency.

2. Spindle Speed

Spindle speed, usually measured in revolutions per minute (RPM), is a critical performance metric. It determines how fast the turret can rotate, influencing machining time and surface finish quality. High spindle speeds are necessary for cutting softer materials quickly, while lower speeds are preferable for harder materials to prevent tool wear. Buyers should align spindle speed capabilities with their specific production requirements to optimize performance.

3. Maximum Turning Diameter and Length

The maximum turning diameter and length refer to the largest workpiece that can be effectively machined by the lathe. This specification is crucial for industries that work with large components, such as automotive or aerospace. Understanding these dimensions ensures that the lathe can accommodate the intended applications without limitations, thereby maximizing investment.

4. Material Grade and Construction

The material grade of the turret and other components directly affects durability and performance. High-grade materials, such as hardened steel or cast iron, can withstand the rigors of machining while providing stability. Buyers should consider the material specifications to ensure longevity and reliability, especially in high-volume production environments.

5. Control System Type

The control system—whether it’s a basic or advanced CNC interface—plays a pivotal role in machining precision and ease of use. Advanced control systems often come with features such as real-time monitoring, automated tool setting, and programmable logic, which can enhance operational efficiency. B2B buyers should assess their technical capabilities and the level of automation required for their operations when choosing a control system.

What Are Common Trade Terms Used in the CNC Lathe Industry?

Familiarity with industry jargon can facilitate smoother negotiations and better understanding between buyers and suppliers. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of turret CNC lathes, this term is significant for buyers looking to source machines or components from reputable manufacturers known for quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory levels and ensure they are not overcommitting resources. Negotiating favorable MOQs can lead to better pricing and reduced risk.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. This process allows buyers to compare costs, terms, and conditions from various vendors, ensuring they make an informed purchasing decision. Crafting a clear and detailed RFQ can lead to more accurate and competitive responses.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and negotiate better shipping arrangements, thereby reducing the risk of unexpected costs.

5. CNC (Computer Numerical Control)

CNC refers to the automation of machine tools through the use of computers executing pre-programmed sequences. This technology enhances precision and repeatability in machining operations, making it essential for modern manufacturing processes. Understanding CNC technology is vital for buyers looking to invest in advanced turret lathes.

By grasping these technical properties and trade terms, B2B buyers can navigate the turret CNC lathe market more effectively, ensuring that their procurement aligns with operational goals and industry standards.

Navigating Market Dynamics and Sourcing Trends in the turret cnc lathe Sector

What Are the Current Market Dynamics and Key Trends Affecting Turret CNC Lathes?

The turret CNC lathe market is witnessing significant growth driven by advancements in manufacturing technology, the demand for precision machining, and the increasing need for automation in production processes. International B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, are particularly focused on sourcing equipment that enhances operational efficiency while offering versatility in machining capabilities. The rise of Industry 4.0 is a key trend, promoting the integration of IoT and smart technology into CNC lathes, enabling real-time monitoring and predictive maintenance, which reduces downtime and operational costs.

Furthermore, the shift towards high-performance machines, such as servo and power turrets, is reshaping sourcing strategies. Servo turrets are increasingly favored for their ability to accommodate more tool stations and perform complex operations, enhancing productivity. Conversely, power turrets are being sought after for applications requiring both turning and milling capabilities, reflecting a growing trend towards multifunctional machinery. B2B buyers are advised to assess their specific machining needs and choose turret CNC lathes that align with their operational goals, considering factors such as tool flexibility, automation features, and maintenance requirements.

How Can Sustainability and Ethical Sourcing Influence Decisions in the Turret CNC Lathe Sector?

As global awareness of environmental sustainability rises, B2B buyers in the turret CNC lathe sector are prioritizing ethical sourcing and sustainable manufacturing practices. The environmental impact of manufacturing processes, including energy consumption and waste generation, is prompting companies to seek suppliers who adhere to sustainable practices. This includes using ‘green’ materials and obtaining certifications such as ISO 14001, which signifies a commitment to environmental management.

Ethical supply chains are becoming increasingly important, with buyers focusing on suppliers who demonstrate transparency and responsibility in their operations. This includes ensuring fair labor practices and reducing carbon footprints through efficient resource management. By selecting suppliers that prioritize sustainability, international B2B buyers not only contribute to environmental conservation but also enhance their brand reputation, which is vital in competitive markets across Africa, South America, the Middle East, and Europe.

What Is the Brief Evolution of Turret CNC Lathes and Their Significance for B2B Buyers?

The evolution of turret CNC lathes has transformed the landscape of machining technology. Initially, turret lathes were manually operated, limiting their efficiency and precision. The introduction of CNC (Computer Numerical Control) technology revolutionized this sector, enabling automated operations that significantly increased production speed and accuracy.

Over the decades, advancements such as servo and power turrets have emerged, offering greater flexibility and the ability to perform complex machining tasks. This evolution is crucial for B2B buyers, as it allows for the optimization of machining processes, leading to higher quality outputs and reduced operational costs. Understanding this historical context enables buyers to appreciate the technological advancements that inform their purchasing decisions and to identify machines that align with contemporary manufacturing needs.

Frequently Asked Questions (FAQs) for B2B Buyers of turret cnc lathe

-

How do I choose between a servo turret and a power turret for my CNC lathe?

Choosing between a servo turret and a power turret depends on your specific machining needs. A servo turret is ideal for operations focused solely on turning due to its efficiency in handling multiple tool stations. In contrast, a power turret is suited for complex tasks requiring both turning and milling capabilities, making it versatile for various applications. Consider the type of materials you will be machining and the complexity of your projects when making your decision. -

What is the best turret CNC lathe for small to medium enterprises?

For small to medium enterprises, a CNC lathe with a servo turret is often the best choice. Models with 8 to 12 tool stations provide flexibility and efficiency for diverse machining tasks. Look for machines that offer a balance of cost-effectiveness and reliability, such as those featuring basic CNC control systems like Siemens or Mitsubishi, which are user-friendly and widely supported in the market. -

What are the minimum order quantities (MOQs) for turret CNC lathes?

Minimum order quantities can vary significantly by supplier and model. Many manufacturers may have an MOQ of one unit for standard models, while customizations could require higher MOQs, typically ranging from 5 to 10 units. It’s essential to discuss your specific needs with suppliers to negotiate favorable terms, especially when sourcing from different regions. -

How can I ensure the quality of the turret CNC lathe I am purchasing?

To ensure quality, verify the manufacturer’s certifications, such as ISO 9001, which indicates adherence to international quality standards. Request detailed product specifications, and consider asking for samples or demonstrations. Additionally, seek reviews or testimonials from other B2B buyers who have purchased from the supplier to assess their reliability and product performance. -

What payment terms are typically offered for turret CNC lathe purchases?

Payment terms can vary widely, but common practices include a 30% deposit upon order confirmation, with the balance due prior to shipment. Some suppliers may offer credit terms or financing options for established businesses. Always clarify payment conditions in the contract to avoid misunderstandings and ensure a smooth transaction process. -

What logistics considerations should I keep in mind when importing turret CNC lathes?

When importing turret CNC lathes, consider shipping costs, customs duties, and delivery timelines. Collaborate with a logistics provider experienced in heavy machinery to navigate potential challenges. Ensure that the supplier provides all necessary documentation, including certificates of origin and compliance, to facilitate customs clearance in your country. -

Are there customization options available for turret CNC lathes?

Yes, many manufacturers offer customization options to meet specific machining requirements. Customizations can include additional tool stations, specific spindle speeds, or unique control systems. Discuss your needs with suppliers to explore available options and ensure that the modifications align with your operational goals. -

How do I vet suppliers when sourcing turret CNC lathes internationally?

To vet suppliers, conduct thorough research on their reputation, including checking for certifications and industry experience. Utilize platforms like Alibaba or ThomasNet to find credible suppliers and read reviews from other buyers. Engage in direct communication to assess their responsiveness and willingness to provide references. Visiting the supplier’s facility, if feasible, can also provide valuable insights into their manufacturing capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Turret Cnc Lathe Manufacturers & Suppliers List

1. Smart Lathe – Servo vs. Power Turrets in CNC Lathes

Domain: smartlathe.com

Registered: 2022 (3 years)

Introduction: The text discusses the differences between servo turrets and power turrets in CNC lathes. Key details include:

1. **Turret Types**: CNC turrets are primarily electric and can be vertical or horizontal, with configurations of four, eight, ten, or twelve stations.

2. **Power Turret**: Designed for turning and milling, it includes a motor within a box, featuring a hollow spline shaft connected to …

2. Haas – Custom Lathes and Live Tooling

Domain: haascnc.com

Registered: 1996 (29 years)

Introduction: This company, Haas – Custom Lathes and Live Tooling, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Tool Holder Now – CNC Lathe Turrets

Domain: toolholdernow.com

Registered: 2022 (3 years)

Introduction: Types of CNC Lathes Turrets: BMT, VDI, and BOT Tool Turrets. BMT Turrets: Bolt-on design, bolted directly onto lathe’s cross-slide, modular nature for quick tool changes, active tool holders, multiple tool stations for simultaneous mounting. VDI Turrets: Standardized interface for tool holder interchangeability, modular design, quick-change system for rapid tool changes, enhances precision and rep…

4. LICO – CNC Turret Type Automatic Lathe

Domain: licomachinery.com

Registered: 2004 (21 years)

Introduction: This company, LICO – CNC Turret Type Automatic Lathe, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Nidec – Parallel Twin-Spindle CNC Lathe

Domain: nidec.com

Registered: 1997 (28 years)

Introduction: Product Name: Parallel Twin-Spindle, Twin-Turret CNC Lathe (TT-Series)\nKey Features: \n- Twin-spindle, Twin-turret design with spindles oriented front and arranged in parallel.\n- Independent control of left and right machining.\n- CM specification available for mixed turning and milling processes.\n- Equipped with TAKISAWA’s gantry loader with turnover unit for automation.\n- Capable of simultan…

6. Turret Lathe – Hardinge

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Turret Lathe for sale on eBay. Brands include Hardinge, Warner & Swasey, DMG MORI, and Okuma. Related searches include Turret Lathe Tooling, Vertical Turret Lathe, Hardinge Turret Lathe, Turret Lathe Tool Holders, Bullard Vertical Turret Lathe, Table Top Lathe, and Engine Lathe. Categories include CNC, Metalworking & Manufacturing, and Metalworking Equipment.

7. Turret Lathe Specialists – Precision Machining Services

Domain: turretlathespecialists.com

Registered: 2002 (23 years)

Introduction: Turret Lathe Specialists, Inc offers precision machining services since 1973, serving industries such as aerospace, defense, cryogenics, commercial, medical, and oil and energy. Key features include: a 20,000-square-foot machining facility, over 15 CNC machines, ISO 9001:2015 certification, a commitment to quality with a mature Quality Management System (QMS), guaranteed on-time delivery, and a ne…

8. CNC New – C326 Hydraulic Turrets

Domain: cncnew.com

Registered: 2001 (24 years)

Introduction: C326 Hydraulic Turrets are designed for turret model lathes, offering a selection of static tool and driven live tool turrets. Key features include:

– Static tooling turret with 30mm dove tail gang tool post tool holder options for the GT-15 lathe model.

– Rigid and versatile design that allows for the preservation of complex setups and permanent tool stations.

– 10-Station Turret with a parall…

9. MYLAS – CNC Multi-tasking Turning Center

Domain: mylascnc.com

Registered: 2018 (7 years)

Introduction: CNC Multi-tasking Turning Center: Single Spindle Single Turret with Y-axis

**Model Variants:** MY-TURN T42/52/60DSY

**Key Features:**

– Twin spindle configuration for front and back machining.

– C-axis functionality on both main and sub-spindle.

– Y-axis functionality for side and face milling, drilling, and tapping.

– A2-5 spindle nose.

– 12-station live turret for efficient milling, drilling, …

10. Reddit – Turret Lathe for Side Hustles

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Turret lathe, capable of high production, suitable for making small parts like bushings and candle holders, considered for side hustle opportunities, but viewed as obsolete compared to CNC lathes.

Strategic Sourcing Conclusion and Outlook for turret cnc lathe

As the demand for precision manufacturing continues to rise globally, strategic sourcing of turret CNC lathes offers significant advantages for businesses operating in competitive markets across Africa, South America, the Middle East, and Europe. Understanding the differences between servo and power turrets is crucial, as these choices affect operational efficiency and cost-effectiveness. For instance, servo turrets provide flexibility with multiple tool stations, while power turrets enable both turning and milling capabilities, making them suitable for diverse machining tasks.

Investing in high-quality turret CNC lathes not only enhances productivity but also ensures the longevity of your manufacturing processes. By aligning with reputable suppliers and leveraging the latest technology, international buyers can optimize their supply chains and reduce operational risks.

Looking ahead, the evolution of CNC technology promises even greater innovations in machining efficiency and versatility. Now is the time for B2B buyers to assess their needs and explore strategic partnerships that can elevate their manufacturing capabilities. Embrace the future of machining—invest in turret CNC lathes that meet your business objectives and drive success in a rapidly changing global landscape.