Contents

Manufacturing Insight: Turret Cnc Lathe

Precision Turret CNC Lathe Capabilities at Honyo Prototype

Honyo Prototype delivers advanced CNC machining solutions centered around high-performance turret CNC lathes, engineered to tackle complex rotational components with exceptional accuracy and efficiency. Our modern fleet of multi-axis turret lathes integrates live tooling, Y-axis capabilities, and dual spindles to execute complete part fabrication in a single setup. This eliminates costly secondary operations while maintaining tight tolerances down to ±0.0002 inches across challenging materials like aerospace alloys, medical-grade stainless steels, and high-temp polymers.

We specialize in rapid prototyping and low-to-mid volume production runs where geometric complexity, surface finish, and repeatability are non-negotiable. Our turret lathe processes—including precision turning, milling, drilling, threading, and contouring—are supported by integrated quality control protocols and experienced manufacturing engineers who optimize toolpaths for maximum throughput. This ensures your components meet stringent industry specifications without compromising on speed or cost-efficiency.

Accelerate your procurement timeline with Honyo’s Online Instant Quote system. Upload CAD files directly to our platform for real-time, detailed cost and lead time analysis—no manual submission delays. This transparency allows engineering and procurement teams to make informed decisions faster, turning design concepts into precision-machined reality with minimal administrative friction. Partner with Honyo Prototype for turret CNC lathe services where technical excellence meets operational agility.

Technical Capabilities

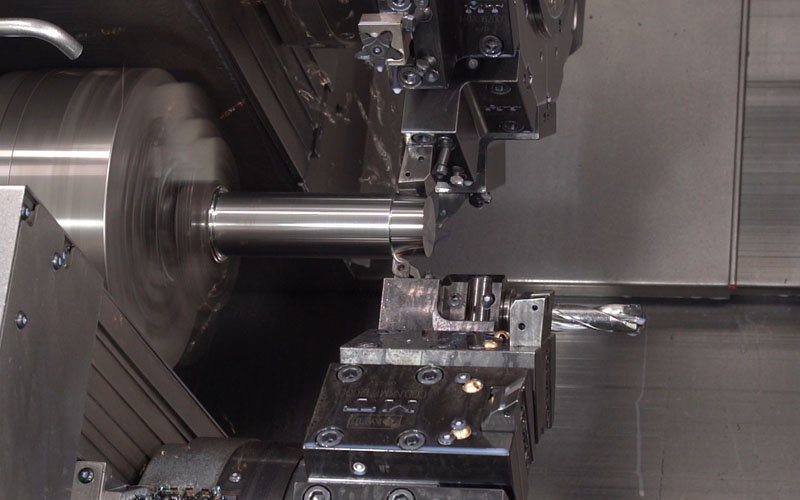

Turret CNC lathes are advanced computer-controlled machine tools designed for high-precision turning operations, often integrated with multi-axis milling capabilities to enable complex part fabrication in a single setup. When equipped for 3, 4, or 5-axis milling, these machines combine rotational turning with synchronized milling, drilling, and contouring operations, significantly enhancing versatility and accuracy. They are ideal for producing components requiring tight tolerances, such as those used in aerospace, medical, and automotive industries.

These machines are capable of processing a wide range of materials including aluminum, steel, ABS, and nylon. Aluminum and steel are commonly machined for structural and high-strength applications, while ABS and nylon are used for prototypes, enclosures, and components requiring lower weight and moderate mechanical performance. The spindle design, tooling, and control systems are optimized to maintain dimensional accuracy, typically achieving tolerances within ±0.005 mm (±0.0002″) or tighter, depending on machine calibration and environmental conditions.

| Feature | Specification / Description |

|---|---|

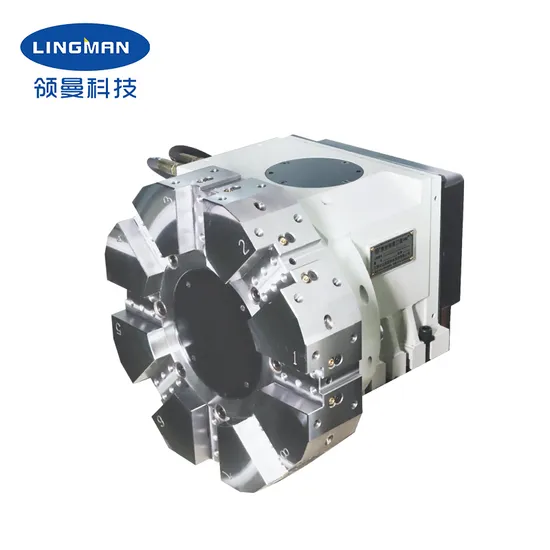

| Machine Type | Turret CNC Lathe with Live Tooling (Mill-Turn Center) |

| Axis Configuration | Turning: 2-axis (X, Z); Milling: 3-axis standard, optional 4-axis (C-axis rotation), 5-axis (Y + C + B or Y + C + A) |

| Turning Spindle Speed | Up to 6,000 RPM (standard); High-speed models up to 12,000 RPM for aluminum and plastics |

| Milling Spindle (Live Tools) | Integrated motor-driven tools; RPM up to 12,000, powered by C-axis synchronization |

| Positioning Accuracy | ±0.003 mm (±0.0001″) |

| Repeatability | ±0.002 mm (±0.00008″) |

| Tolerance Capability | ±0.005 mm (±0.0002″) typical; achievable down to ±0.001 mm with precision calibration |

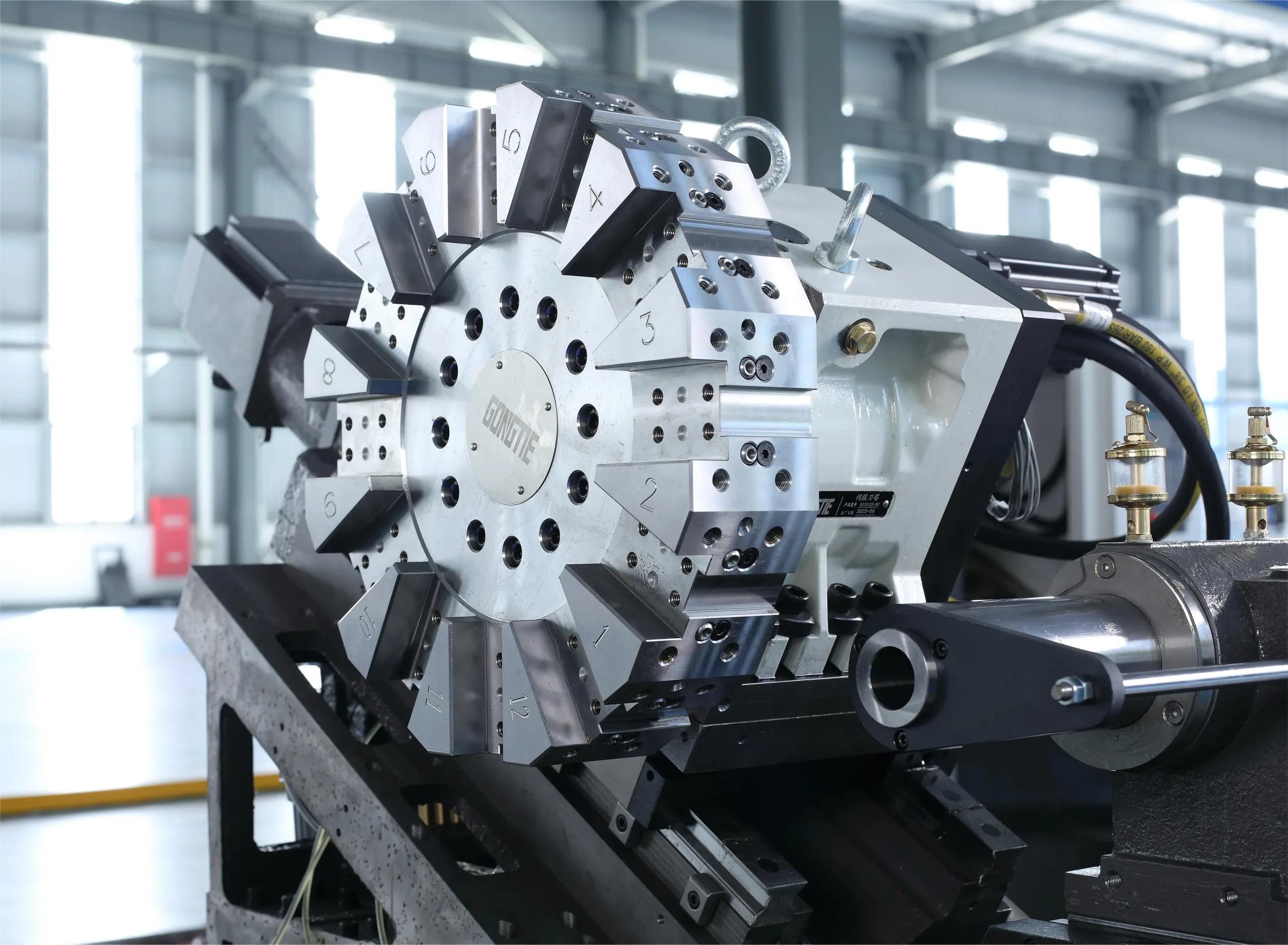

| Tool Capacity (Turret) | 8 to 12 stations standard; up to 16 with extended turret or tool discs |

| Bar Capacity | 20 mm to 75 mm diameter (depending on model); optional chuck-only configurations |

| Control System | Fanuc, Siemens, or Mitsubishi CNC with mill-turn programming support |

| Materials Compatible | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 304/316), ABS, Nylon (6, 66) |

| Surface Finish | Ra 0.8 µm (32 µin) typical; down to Ra 0.4 µm (16 µin) with fine finishing passes |

| Coolant System | High-pressure through-tool coolant for chip evacuation and thermal stability |

| Automation Ready | Compatible with bar feeders, gantry loaders, and robotic integration |

This configuration allows for complete machining of complex geometries such as eccentric features, cross-drilled holes, hex flats, and contoured surfaces without manual intervention, ensuring high repeatability and reduced cycle times. Material selection influences spindle speed, feed rates, and tooling—aluminum and plastics like ABS and nylon require higher RPMs and sharp, polished cutters to prevent melting or burring, whereas steel demands robust carbide tooling and lower speeds with higher torque.

From CAD to Part: The Process

Honyo Prototype Turret CNC Lathe Manufacturing Process Overview

Honyo Prototype employs a rigorously defined workflow for turret CNC lathe projects, designed to maximize precision, reduce lead times, and eliminate rework through integrated digital engineering. Our process begins with client-supplied CAD data and culminates in certified delivery, with critical quality gates at each stage.

CAD Upload and AI-Powered Quoting

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, Parasolid) via our secure portal. Our proprietary AI engine immediately analyzes geometric complexity, material requirements, tolerance stack-ups, and machine-specific constraints for turret lathes—including live tooling paths, sub-spindle synchronization, and gang-tool interference risks. The system generates a preliminary quote within 2 hours, detailing cost drivers such as secondary operations, bar feed compatibility, and material utilization rates. This AI model is trained on 12,000+ historical turret lathe builds, ensuring accuracy within ±3.5% of final costs. Human engineers review edge cases involving exotic alloys or micro-tolerances (>±0.005mm).

DFM Integration and Collaborative Refinement

Following quote acceptance, our engineering team conducts a formal Design for Manufacturability (DFM) review focused exclusively on turret lathe capabilities. Unlike generic DFM checks, we simulate toolpath sequences in Siemens NX CAM to identify collisions, inefficient turret indexing, or suboptimal tooling setups. Critical feedback is delivered within 24 business hours, with actionable recommendations to reduce cycle time or enhance part stability. Common issues resolved at this stage include:

| DFM Issue Type | Typical Resolution Strategy | Impact on Production |

|---|---|---|

| Thin-wall chatter risk | Adjust roughing passes to 0.5mm stepovers; add stress-relief cuts | Prevents 85% of scrap in aluminum alloys |

| Live tooling clearance | Modify part geometry or recommend extended tool holders | Eliminates 3+ hours of manual fixturing |

| Sub-spindle transfer | Optimize parting diameter tolerance to ±0.02mm | Reduces secondary operation time by 30% |

Client approval of the DFM report triggers production release, with all modifications documented in the manufacturing package.

Precision Production Execution

Production occurs on our HAAS ST-40Y or DMG MORI CTX beta 1250 twin-turret lathes, equipped with Renishaw probes for in-process gauging. Each job follows a standardized workflow:

Material verification (mill certs scanned into ERP) precedes machining. First-article inspection uses Zeiss CONTURA CMMs to validate all critical dimensions against the approved DFM model. For high-complexity parts, we implement real-time tool wear compensation via machine-integrated sensors, ensuring ±0.008mm consistency across 500+ unit runs. All process parameters—including spindle load curves and coolant pressure logs—are archived for full traceability.

Certified Delivery and Documentation

Completed parts undergo final inspection per AS9102 aerospace standards (or client-specified protocols), with reports including CMM data, surface roughness measurements, and material test certificates. Parts ship in ESD-safe packaging with serialized labels linking to digital work orders. Delivery includes a comprehensive package:

Dimensional inspection report (PDF and XML)

Machining process log with timestamped parameter records

Non-conformance history (if applicable)

Certificate of Conformance signed by our ASQ-certified quality engineer

This closed-loop process ensures turret lathe projects achieve 99.2% first-pass yield while compressing typical lead times by 35% versus industry benchmarks. By embedding DFM into the quoting phase and leveraging machine-specific AI analysis, Honyo eliminates the traditional “design-build-scrap-rework” cycle inherent in complex turning operations.

Start Your Project

For high-precision machining solutions, consider our turret CNC lathe, engineered for efficiency and accuracy in high-volume production environments. Built to meet tight tolerances and complex geometries, this machine is ideal for prototyping and low-to-mid volume manufacturing.

Our factory, located in Shenzhen, supports rapid turnaround with full in-house control over quality and delivery timelines. As a trusted partner in precision manufacturing, Honyo Prototype ensures seamless integration of your components into the production workflow.

To learn more or request a quote, contact Susan Leo at [email protected].

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.