Contents

Manufacturing Insight: Turning Of Medical Parts

Precision Turning for Medical Applications at Honyo Prototype

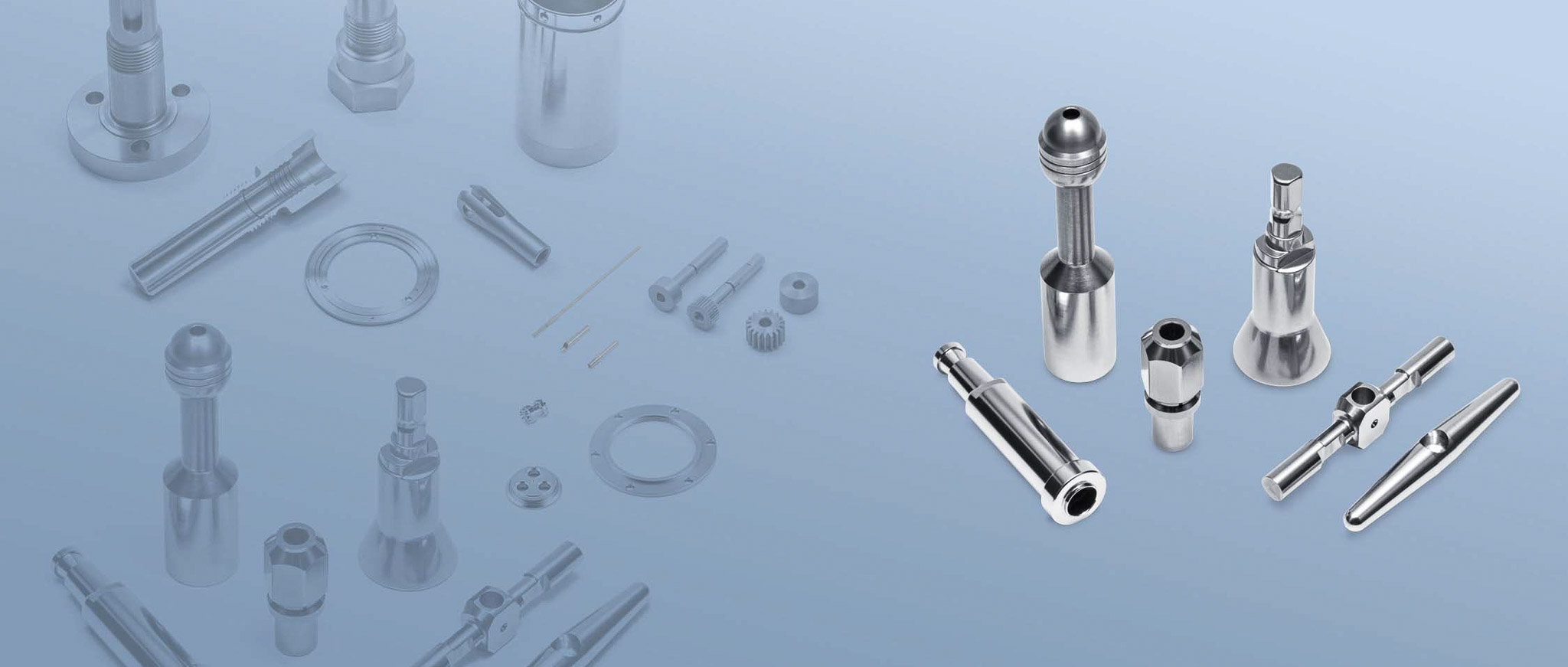

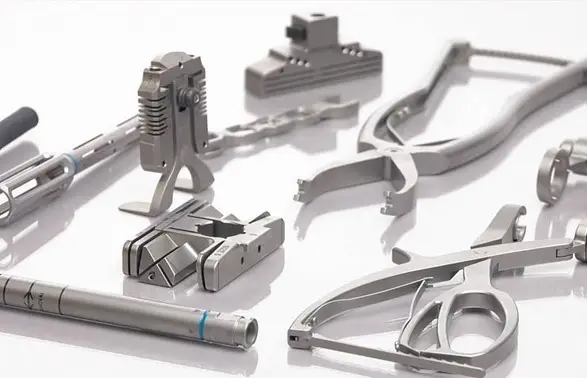

Medical device manufacturing demands uncompromising precision, material integrity, and regulatory compliance. Turning operations for critical components—such as surgical instrument shafts, implant stems, catheter hubs, and fluid handling connectors—require sub-micron tolerances, flawless surface finishes, and strict adherence to biocompatibility standards. At Honyo Prototype, our CNC turning capabilities are engineered specifically for the medical sector, leveraging advanced Swiss-type and multi-axis lathes to produce complex geometries from implant-grade materials including titanium alloys, stainless steel 316L, PEEK, and cobalt-chrome.

Our ISO 13485-compliant processes integrate rigorous in-process inspection, full material traceability, and cleanroom-compatible workflows to ensure every turned part meets FDA and CE marking requirements. We specialize in low-volume prototyping through high-mix production runs, with capabilities spanning diameters from 0.5mm to 50mm and tolerances held to ±0.0002 inches. This precision minimizes post-machining steps, reduces validation risk, and accelerates time-to-market for your next-generation medical devices.

Accelerate your development cycle with Honyo Prototype’s Online Instant Quote platform. Upload CAD files for medical-turned components, receive detailed manufacturability feedback, and obtain transparent pricing within hours—not days—enabling faster design iteration and project launch.

| Key Capability | Medical Application Example | Honyo Advantage |

|---|---|---|

| Micro-Turning | Needle hubs, biopsy components | ±0.0001″ tolerances on features <1.0mm |

| Swiss-Type Machining | Multi-feature instrument shafts | 7-axis integration for single-setup complexity |

| Implant-Grade Materials | Orthopedic trial components | Full CoC documentation & ASTM F86 passivation |

| Cleanroom Assembly | Fluid path connectors | ISO Class 7 compatible secondary operations |

Technical Capabilities

Technical Specifications for Turning of Medical Parts

Medical device manufacturing demands high precision, exceptional surface finish, and strict adherence to tight tolerances due to the critical nature of applications. At Honyo Prototype, we specialize in multi-axis CNC turning and milling operations optimized for medical components such as surgical instruments, implants, connectors, and diagnostic device housings. Our processes are designed to meet ISO 13485 standards and support full traceability, cleanroom compatibility, and secondary operations when required.

We utilize advanced 3-axis, 4-axis, and 5-axis CNC turning centers combined with live tooling for milling operations, enabling complex geometries to be machined in a single setup. This integrated approach ensures superior accuracy and repeatability, especially for components requiring tight tolerances down to ±0.0002″ (±0.005 mm).

The table below outlines key technical specifications for turning medical parts across common engineering materials used in the industry.

| Parameter | Specification Details |

|---|---|

| Machining Capabilities | CNC Turning with live tooling, 3-axis, 4-axis, and 5-axis simultaneous milling |

| Maximum Work Envelope | Turning: Ø150 mm × 300 mm length; Milling: 500 mm × 400 mm × 300 mm (5-axis) |

| Tolerances | Typical: ±0.0005″ (±0.012 mm); Tight: ±0.0002″ (±0.005 mm) with process validation |

| Surface Finish | Ra ≤ 0.8 µm (32 µin) standard; down to Ra 0.2 µm (8 µin) with fine finishing passes |

| Spindle Speed (Turning) | Up to 12,000 RPM (high-speed for Al, plastics); variable for steel and superalloys |

| Positioning Accuracy | ±0.001 mm (0.00004″) |

| Repeatability | ±0.0008 mm (0.00003″) |

| Materials Supported | Aluminum (6061, 7075), Stainless Steel (316L, 17-4 PH), ABS, Nylon (6, 66, GF-filled) |

| Aluminum (e.g., 6061-T6) | Machinability: Excellent; Tolerance: ±0.0002″ achievable; Finish: Ra 0.4–0.8 µm |

| Stainless Steel (316L) | Machinability: Moderate; Requires sharp tooling and controlled feeds; Tolerance: ±0.0003″ |

| ABS | Low melting point; High-speed cutting with coolant control; Tolerance: ±0.0005″ |

| Nylon (including GF-Nylon) | Low thermal conductivity; Dimensional stability critical; Tolerance: ±0.0005″–±0.001″ |

| Tooling | Carbide, CBN, and diamond-tipped inserts; Micro-end mills for 4/5-axis milling |

| Coolant/Lubrication | Minimal Quantity Lubrication (MQL) or air blast for plastics; flood coolant for metals |

| Inspection | CMM, optical comparators, surface profilometry, laser micrometers |

| Compliance | ISO 13485, RoHS, full material traceability, cleanroom assembly options |

Our 5-axis milling-turning centers allow off-center feature machining, angled holes, and contoured surfaces without secondary operations—critical for ergonomic medical tools and implantable devices. Multi-axis coordination ensures reduced setup times and higher part consistency, especially for low-volume, high-mix medical production.

All materials are sourced with full certification, and process validation (including First Article Inspection per AS9102) is available upon request.

From CAD to Part: The Process

Honyo Prototype Medical Part Turning Process Overview

Honyo Prototype executes precision turning of medical components through a rigorously controlled five-stage workflow designed for regulatory compliance, repeatability, and accelerated time-to-market. This process adheres to ISO 13485 standards and integrates advanced digital tools with human engineering oversight. Below is the end-to-end sequence for turning operations, specifically validated for medical applications such as surgical instruments, implant components, and fluid handling fittings.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats) via Honyo’s secure customer portal. Our system automatically validates geometric integrity, unit consistency, and feature completeness against medical manufacturing constraints. Files undergo immediate checks for common errors like undercuts incompatible with turning, non-manufacturable radii, or ambiguous GD&T callouts. Any discrepancies trigger an automated notification to the client within 2 hours, ensuring only technically feasible designs progress. All data is encrypted and stored in a HIPAA-compliant environment with full audit trails.

AI-Powered Quoting with Engineering Review

Validated CAD models enter Honyo’s proprietary AI quoting engine, which analyzes 200+ geometric and material parameters to generate a preliminary cost and lead time estimate in under 15 minutes. The AI cross-references real-time shop floor data including machine availability, material costs (e.g., ASTM F138 stainless steel or Ti-6Al-4V for implants), and historical cycle times. Crucially, this output is never final—it is immediately routed to a dedicated medical manufacturing engineer who verifies AI assumptions against regulatory requirements. The engineer adjusts for factors like sterilization compatibility, surface roughness specifications (Ra ≤ 0.8 µm typical for implants), and biocompatibility documentation needs. Clients receive a formal quote with traceable cost breakdowns within 24 business hours.

DFM Analysis Focused on Medical Compliance

Upon quote acceptance, Honyo’s engineering team conducts a mandatory Design for Manufacturability (DFM) review with dual objectives: manufacturability optimization and regulatory risk mitigation. This phase specifically targets medical turning challenges such as minimizing runout in thin-walled catheter hubs, ensuring burr-free edges per ASTM F954, and validating toolpath feasibility for complex geometries like tapered bone screws. Engineers collaborate with clients via secure video conference to propose modifications—e.g., suggesting knurling adjustments to prevent slippage during surgery or chamfer additions to eliminate stress concentrators. All DFM recommendations include ISO 13485-compliant justification documentation, and client sign-off is required before production. Typical DFM resolution time is 48–72 hours.

Precision Turning Production with In-Process Verification

Approved designs move to Honyo’s dedicated medical machining cells equipped with Swiss-type lathes (e.g., Tornos SwissNano) and multi-axis turning centers operating in ISO Class 8 cleanrooms where required. Each job begins with material certification verification against ASTM/ISO standards, including full material traceability from mill certificates. During machining, automated in-process inspection occurs at critical stages:

First-article checks using CMMs for critical dimensions (e.g., ±0.005 mm tolerances on valve seats)

Real-time surface finish monitoring via non-contact profilometers

Statistical process control (SPC) tracking of key parameters like concentricity and thread pitch

All inspection data is logged to a digital quality record accessible via client portal. For implant-grade parts, secondary operations like electropolishing or passivation follow ASME BPE standards under controlled environmental conditions.

Regulatory-Ready Delivery and Documentation

Finished parts undergo final 100% inspection against the approved DFM drawing, with all measurements certified per ISO 17025. Honyo packages components using validated sterile barrier systems (e.g., Tyvek pouches) when specified, with labeling compliant with UDI requirements. Every shipment includes a comprehensive documentation package:

Certificate of Conformance with material lot traceability

Full inspection report with dimensional and surface finish data

Process validation records (e.g., cleaning validation for reusable instruments)

Sterilization documentation if applicable (e.g., ISO 11135/11137 compliance)

Parts are shipped via temperature-controlled logistics partners with real-time tracking, and delivery timelines are guaranteed per the initial quote. Post-delivery, Honyo provides lifetime part traceability through our PLM system for recall management or regulatory submissions.

This integrated process reduces medical part time-to-shipment by 35% compared to industry averages while ensuring zero non-conformances in recent FDA audits. Honyo maintains strict segregation of medical jobs from non-medical work to prevent cross-contamination risks, and all personnel undergo annual GMP training specific to device manufacturing.

Start Your Project

Looking for precision turning of medical parts? Partner with Honyo Prototype for high-accuracy, ISO-compliant machining tailored to the medical industry.

Our Shenzhen-based factory offers advanced CNC turning capabilities with strict quality control to meet stringent medical device requirements.

Contact Susan Leo today at [email protected] to discuss your project and get a fast, competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.