Guide Contents

Project Insight: Turning Of Medical Parts

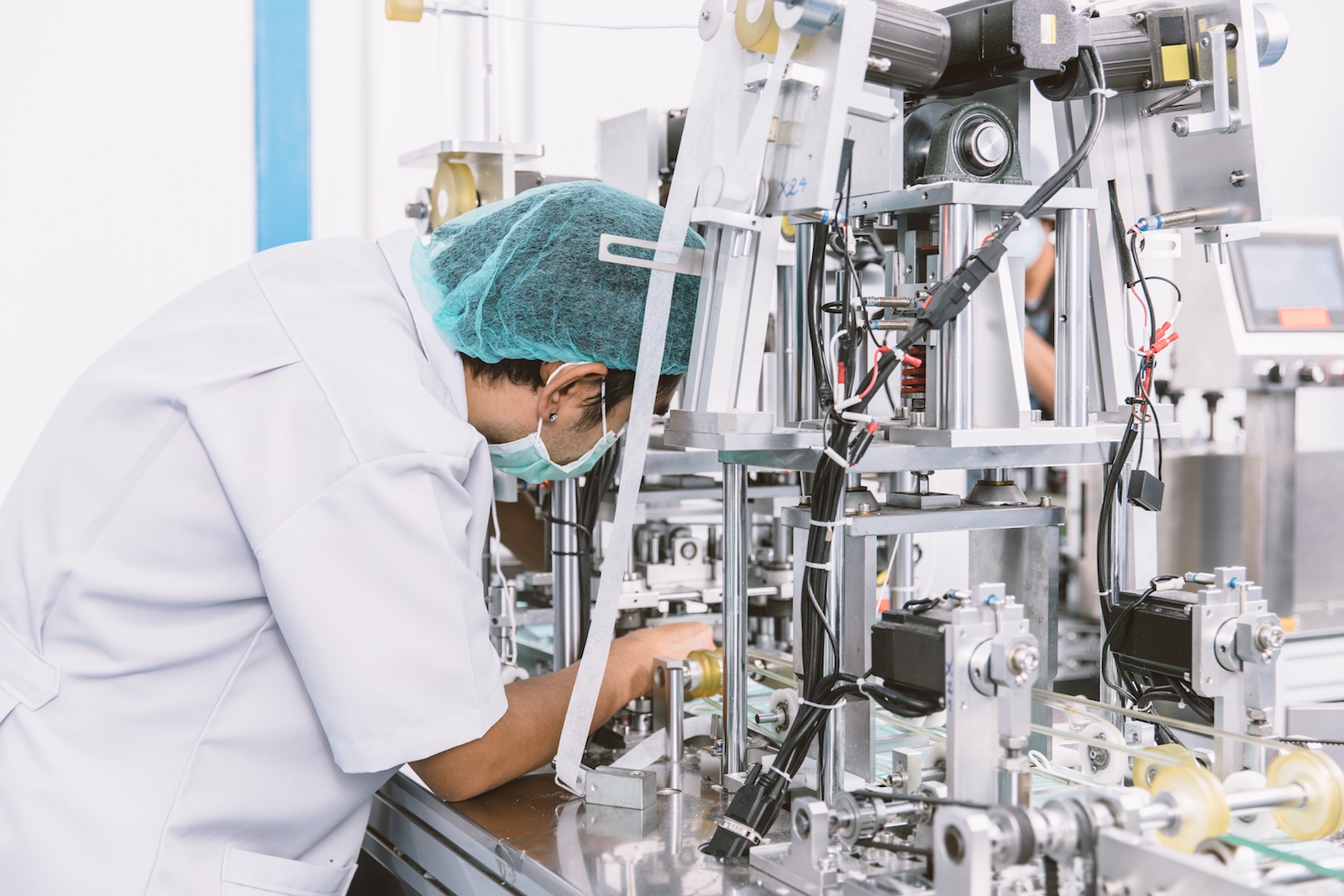

Manufacturing Insight: Turning of Medical Parts

Why Speed and Precision Define Medical Device Success

Safety-Critical Precision: Medical components demand micron-level accuracy (±0.01mm) for biocompatibility, functionality, and regulatory compliance—where even minor deviations risk patient safety.

Time-to-Market Imperative: Delays in prototyping or production can cost startups months of development time and significant revenue opportunities.

Cost Efficiency at Scale: Processing time accounts for 20-50% of manufacturing costs—optimizing this without sacrificing quality is essential for viable medical device production.

How Honyo Prototype Accelerates Your Medical Device Journey

Online Instant Quote: Upload your CAD file and receive an accurate, transparent quote within seconds—no manual quotes, no delays. See pricing, lead times, and material options instantly.

AI-Powered DFM Optimization: Our platform analyzes your design for manufacturability, optimizing toolpaths for 3/4/5-axis CNC machining to reduce machining time (a key cost driver at 20-50% of total costs) while maintaining ±0.01mm tolerances for critical medical components.

Fast Turnaround Guarantee: Prototypes delivered in 24-72 hours, production runs in days. Our automated workflow and advanced 5-axis capabilities ensure precision for complex geometries, accelerating your time-to-market without compromise.

Precision Engineered for Real-World Medical Applications

From functional prototypes to FDA-compliant end-use parts, we deliver consistent quality across all production volumes with tight tolerances (+/- 0.01mm) and 3/4/5-axis capabilities.

Rigorous in-process inspections and final quality checks ensure every component meets ISO 13485 and industry-specific standards.

Trusted by hardware startups and product engineers worldwide to transform complex designs into reliable, high-performance medical solutions.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities for Medical Parts

Advanced CNC Turning Technology

Multi-Axis Precision: 3/4/5-axis machining for intricate geometries and complex medical components, ensuring optimal functionality and performance.

Ultra-Tight Tolerances: Consistently achieve ±0.01mm precision—critical for implants, surgical tools, and diagnostic devices requiring micron-level accuracy.

Material Expertise: Specialized processing of medical-grade materials including titanium alloys (Grade 5), PEEK, stainless steel (316L), and biocompatible polymers.

Scalable Production Capacity

Prototyping to Full-Scale Production: Seamlessly transition from 1 prototype to 10,000+ units without retooling, accelerating time-to-market for startups and scaling with your growth.

Flexible Batch Sizes: Cost-optimized for both low-volume R&D iterations and high-volume end-use production, eliminating unnecessary overhead.

Rigorous Quality Assurance

ISO 13485 Certified: Full compliance with international medical device quality standards, ensuring regulatory readiness for FDA, CE, and other global certifications.

End-to-End Traceability: Real-time GD&T checks, CMM verification, and digital documentation for every part—no compromises on safety or reliability.

Digital-First Efficiency

Instant Online Quoting: AI-powered platform delivers real-time pricing and DFM feedback in seconds—optimize designs before production to cut costs and avoid delays.

Accelerated Turnaround: 24–48 hours for prototypes, with expedited options for urgent medical device projects.

Seamless Collaboration: Cloud-based project dashboards for transparent communication, iterative design refinement, and on-time delivery—every time.

Engineered for innovation. Built for life-saving impact.

Materials & Surface Finishes

Material Options & Finishes for Precision Medical Turning

At Honyo Prototype, we understand that material and surface finish selection is critical for medical parts—where biocompatibility, regulatory compliance, and performance are non-negotiable. Our precision CNC turning services are engineered to meet the highest medical standards, ensuring your components perform flawlessly in life-critical applications.

Material Selection Criteria for Medical Applications

Stainless Steel 316 (Medical Grade)

Ideal for implants and surgical instruments due to superior corrosion resistance and biocompatibility.

Meets ISO 13485 and FDA standards for long-term internal use.

Excellent strength-to-weight ratio for high-stress applications.

Stainless Steel 304

Cost-effective solution for non-implantable components like housings and external fixtures.

Good general corrosion resistance but less suitable for saline or acidic environments compared to 316.

Often used in diagnostic equipment and non-invasive devices.

Aluminum 6061/7075

Lightweight and strong for non-implantable medical devices (e.g., imaging equipment housings).

Requires anodizing or specialized coatings to meet biocompatibility standards.

Avoid for direct tissue contact; best for structural components where weight savings are critical.

Brass

Limited use in medical applications due to copper content (potential leaching risks).

Suitable for non-critical electrical connectors or non-implantable fixtures requiring conductivity.

Always verify regulatory compliance for specific use cases.

PEEK (Polyetheretherketone)

High-performance polymer for implants, surgical tools, and sterilizable components.

Biocompatible, radiation-resistant, and chemically inert.

Ideal for applications requiring lightweight, high-strength, and fatigue-resistant parts.

Surface Finishes for Medical Compliance

Electropolishing

Removes microscopic imperfections, enhancing corrosion resistance and reducing bacterial adhesion.

Critical for stainless steel implants and instruments requiring smooth, sterile surfaces.

Passivation

Eliminates surface contaminants and free iron from stainless steel parts.

Standard process to ensure compliance with medical device regulations.

Anodizing (Type III Hard Coat)

For aluminum components needing wear resistance and non-conductive properties.

Must be sealed and validated for biocompatibility in medical environments.

Mechanical Polishing

Achieves ultra-smooth surfaces (Ra < 0.4 µm) for critical medical components.

Ensures easy sterilization and minimizes contamination risks.

Medical-Grade Painting

Only for non-contact external housings with FDA-approved coatings.

Not recommended for internal or implantable parts due to potential flaking risks.

Why Honyo’s AI-Powered Platform Accelerates Medical Manufacturing

Instant Online Quotes

Get real-time pricing for your medical part in seconds—no delays, no guesswork.

Our AI platform dynamically calculates costs based on material, tolerance, and finish requirements.

Smart DFM Optimization

AI-driven design feedback reduces machining time by up to 30% while maintaining precision.

Proactively identifies cost-saving opportunities without compromising regulatory compliance.

Fast Turnaround Guaranteed

Prototype to production in as little as 3 days with ISO 13485-certified processes.

Shenzhen-based facility ensures rapid delivery with full traceability for FDA audits.

Innovate with confidence. Honyo Prototype’s end-to-end solution transforms medical part manufacturing from concept to compliance—faster, smarter, and with surgical precision. Get your instant quote now.

From Quote to Part: Our Process

How It Works: From CAD to Certified Medical Parts in Record Time

At Honyo Prototype, our AI-driven workflow transforms your CAD designs into precision medical components with unmatched speed and transparency. From upload to delivery, every step is optimized for efficiency, compliance, and cost control—so you can focus on innovation.

1. Upload Your CAD File

Seamless Integration: Submit STEP, STP, IGES, or native CAD files via our cloud platform—no proprietary software required.

Instant Validation: Automated checks ensure file integrity and manufacturability readiness, eliminating delays before production begins.

2. Get Instant AI-Powered Quote

Real-Time Pricing: Our AI engine analyzes geometry, tolerances (±0.01mm), materials, and quantities in seconds—delivering a transparent cost breakdown with zero hidden fees.

Optimization Insights: See how material choices, machining complexity, and surface finishes impact your budget, with actionable suggestions to reduce costs without compromising quality.

3. DFM Analysis & Optimization

Proactive Engineering Review: AI-driven design-for-manufacturability checks flag potential issues early, slashing rework risks and accelerating time-to-market.

Regulatory Compliance Assurance: Tailored recommendations ensure your design aligns with medical device standards (e.g., ISO 13485) and regulatory requirements from day one.

4. Precision Production & Delivery

Micron-Level Accuracy: 3/4/5-axis CNC machining with ±0.01mm tolerances for complex, functional medical components—perfect for prototypes and end-use parts.

Rapid Turnaround: Most orders ship within 3–5 days; expedited options available. Real-time tracking via our customer portal ensures complete visibility at every stage.

Honyo Prototype: Where innovation meets precision for medical device manufacturing.

Start Your Project with Honyo

Start Your Project with Honyo

Transform your medical device concepts into precision-engineered components with Honyo’s advanced CNC turning services. Designed for startups and engineers who demand accuracy, speed, and cost efficiency.

Precision at Every Step

🚀 Instant Online Quoting: Upload your CAD file to our AI-powered platform for immediate cost estimates, including material, machining time, and finishing options tailored to medical standards.

⚙️ AI-Driven DFM Optimization: Our system analyzes designs to reduce waste, shorten cycle times, and ensure compliance with ISO 13485—saving up to 30% in production costs.

⏱️ 72-Hour Prototype Delivery: From design review to first-article inspection, accelerate your development cycle with our Shenzhen/Dongguan facilities and dedicated medical manufacturing team.

Connect with Our Experts

🌟 Founder Susan Leo and our engineering team are ready to collaborate on your project—whether you need functional prototypes or production-ready parts.

✉️ Contact Us: [email protected] | +86 139 2843 8620

🏭 Visit Our Facilities: Explore our precision machining capabilities at our Shenzhen and Dongguan campuses.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.