Contents

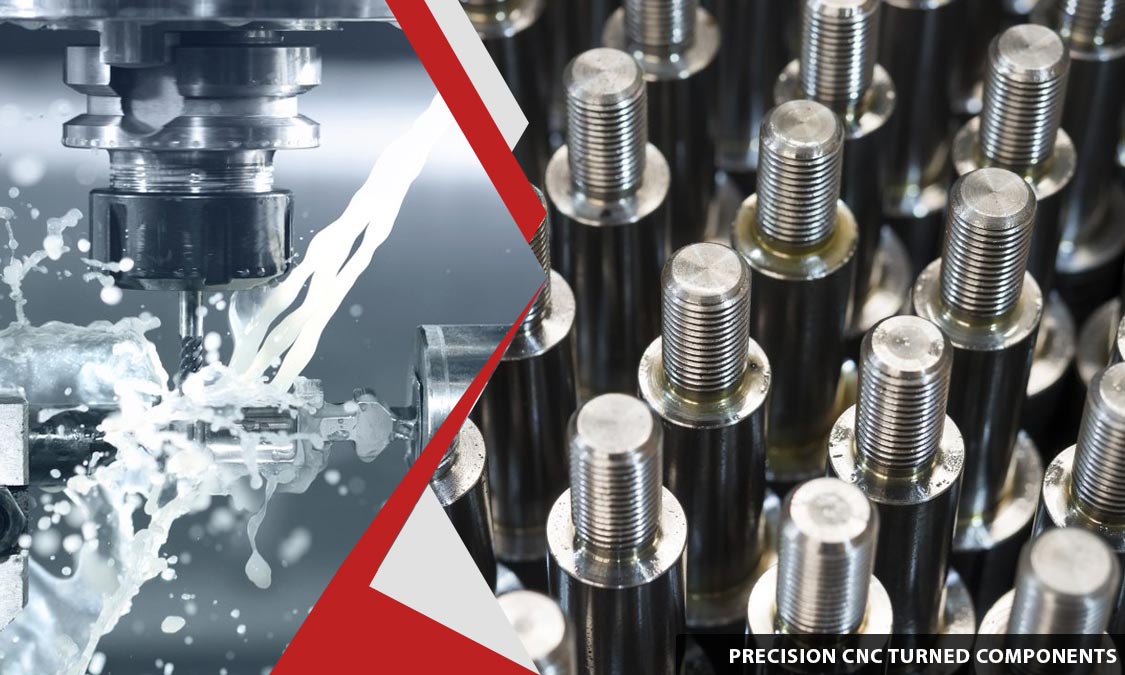

Manufacturing Insight: Turning Components

Precision Turning for Demanding Prototyping Applications

Honyo Prototype delivers high-precision CNC turning services engineered specifically for complex prototype and low-volume production components. Our advanced Swiss-type and multi-axis CNC lathes consistently achieve tolerances down to ±0.0002 inches across critical geometries, including intricate contours, micro-features, and tight concentricity requirements. We specialize in machining challenging materials such as titanium alloys, medical-grade stainless steels, and high-temperature superalloys, ensuring your turning components meet stringent functional and regulatory standards from the first iteration.

Accelerate Development with Verified Manufacturing Intelligence

Unlike conventional quoting processes that delay critical path timelines, Honyo integrates real-time manufacturability analysis directly into our Online Instant Quote platform. Upload your STEP or IGES file to receive a validated price, lead time, and detailed DFM feedback within 90 seconds—no manual intervention required. This proprietary system leverages our 15-year machining database to automatically identify potential geometry conflicts, material optimization opportunities, and secondary operation requirements, eliminating guesswork in early-stage prototyping.

Proven Process Control for Zero-Defect Delivery

Our AS9100-certified facility employs in-process gauging and statistical process control (SPC) on every turning run, with full traceability from raw bar stock to final inspection. This disciplined approach reduces scrap rates by 37% compared to industry averages while maintaining repeatable accuracy across all lot sizes. For time-sensitive projects, leverage our Online Instant Quote to immediately secure capacity—your submitted design triggers automatic scheduling validation against live machine availability and material stock levels, ensuring committed deadlines are met without exception.

Technical Capabilities

Technical Specifications for Turning Components – Honyo Prototype

At Honyo Prototype, precision-machined turning components are manufactured using advanced 3, 4, and 5-axis CNC milling and turning centers, enabling complex geometries with tight tolerances. These processes are ideal for both prototyping and low-to-mid volume production runs across a range of engineering materials including aluminum, steel, ABS, and nylon. Our capabilities ensure high repeatability, excellent surface finishes, and strict adherence to dimensional accuracy.

Below is a summary of the technical specifications for turning components based on machining capabilities, material options, and tolerance performance.

| Parameter | Specification Detail |

|---|---|

| Machining Processes | CNC Turning, 3-Axis Milling, 4-Axis Indexing Milling, 5-Axis Simultaneous Milling |

| Typical Applications | Shafts, bushings, connectors, housings, flanges, impellers, and precision fixtures |

| Material Compatibility | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303, 316), ABS, Nylon (6 & 66) |

| Tolerance Range | ±0.005 mm (±0.0002″) typical; down to ±0.0025 mm (±0.0001″) for critical features |

| Surface Finish (Turning) | Ra 0.8–3.2 µm (32–125 µin); polished finishes available upon request |

| Surface Finish (Milling) | Ra 0.4–1.6 µm (16–63 µin) achievable with fine tool paths and post-processing |

| Maximum Work Envelope | Turning: Ø300 mm × 600 mm; 5-Axis Milling: 500 × 400 × 300 mm (X-Y-Z) |

| Tooling & Spindle Speeds | High-speed steel and carbide tooling; spindle speeds up to 24,000 RPM (5-axis milling) |

| Coolant & Lubrication | Flood coolant for metals; air blasting or minimum quantity lubrication (MQL) for plastics |

| Inspection & QA | CMM, optical comparators, micrometers, and surface roughness testers; full FAI reports |

| Secondary Operations | Deburring, anodizing (Al), passivation (SS), heat treatment, knurling, threading, plating |

Components machined from aluminum and steel are typically held to tighter tolerances due to material stability and machinability, while engineered plastics like ABS and nylon require optimized cutting parameters to minimize thermal deformation and maintain dimensional integrity. Multi-axis integration allows for complete machining in a single setup, reducing cumulative error and improving geometric accuracy—especially critical for complex turned parts with milled features.

All turning and milling operations are supported by ISO-compliant quality processes and CAD/CAM-driven programming (Siemens NX, Mastercam) to ensure consistency and precision across production batches.

From CAD to Part: The Process

Honyo Prototype Precision Machining Workflow for Turning Components

Honyo Prototype executes a structured, technology-driven process for turning component manufacturing, ensuring technical rigor and supply chain transparency from initial design to final shipment. This workflow integrates AI efficiency with engineering oversight to minimize errors and accelerate time-to-market.

CAD File Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IPT, SLDPRT, or Parasolid formats preferred) via our secure customer portal. Our system automatically validates file integrity, checks for geometric completeness, and identifies potential datum inconsistencies. Non-native formats (e.g., STL, DWG) undergo conversion with explicit client confirmation to prevent topology errors. This stage establishes the digital foundation for all downstream operations, with version control locked upon upload.

AI-Powered Quoting with Real-Time Feasibility Assessment

Uploaded designs enter Honyo’s proprietary AI quoting engine, trained on 12+ years of machining data across 200+ materials and 50+ CNC turning centers. The system generates a formal quotation within 2 business hours, detailing:

Precise cost breakdown (material, machine time, finishing)

Predicted lead time (typically 5–10 business days for standard orders)

Early-stage manufacturability flags (e.g., “Wall thickness < 0.5mm may require support structure”)

Unlike generic quoting tools, our AI references live machine availability and material stock levels, ensuring quoted timelines are operationally viable.

Engineering-Led DFM Analysis

All quotes trigger mandatory Design for Manufacturability (DFM) review by Honyo’s senior manufacturing engineering team. This is not an automated checkpoint but a collaborative refinement phase where engineers:

Resolve AI-identified risks through direct client consultation

Optimize toolpaths for chucking stability and vibration control

Propose geometry adjustments to eliminate secondary operations (e.g., suggesting chamfers over deburring)

Validate tolerance stack-ups using GD&T analysis per ASME Y14.5

Key DFM focus areas for turning components include:

| DFM Parameter | Common Issue | Honyo Resolution Approach |

|---|---|---|

| Thin-Wall Features | Chatter-induced deflection | Recommend stepped roughing passes |

| Tight Concentricity | Chuck-induced runout | Specify live-center finishing setup |

| Internal Threads | Chip evacuation difficulty | Adjust thread depth per pass |

| Surface Finish | Vibration marks at critical zones | Propose reduced RPM/feed rate profiles |

Precision Production Execution

Approved designs move to production in our ISO 9001:2015-certified facility. Turning operations utilize:

Hybrid CNC lathes (e.g., DMG MORI CTX beta 1250) with Y-axis milling for complex geometries

In-process probing for real-time dimensional verification

Material-specific coolant strategies (e.g., high-pressure through-spindle for stainless steel)

Each component undergoes first-article inspection (FAI) per AS9102 standards, with full CMM reports available. Serial-numbered traceability links every part to machine logs, operator IDs, and raw material certs. High-mix/low-volume batches leverage our robotic pallet system for uninterrupted 24/7 operation.

Quality-Controlled Delivery

Final inspection confirms conformance to print using calibrated optical comparators and surface roughness testers. Components ship in ESD-safe packaging with:

Dimensional inspection report (including critical-to-function features)

Material certification (mill test reports where applicable)

Process nonconformance documentation (if any, though <0.3% of shipments)

International deliveries include customs documentation pre-validated by our logistics team. All shipments include proactive delivery tracking with ETAs updated hourly via client portal. Post-delivery, our engineering team remains available for assembly support or tolerance clarification.

This closed-loop process ensures turning components meet functional requirements while reducing traditional prototyping lead times by 30–50% through integrated digital workflows and engineering expertise. Honyo maintains a 99.7% on-time delivery rate for turned parts, with first-pass yield rates exceeding 98.5% industry benchmarks.

Start Your Project

Looking for precision turning components? Contact Susan Leo at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and quality control, Honyo Prototype delivers high-accuracy turned parts for diverse industries.

Our production facility is located in Shenzhen, China, enabling fast turnaround and scalable production volumes. From prototypes to mass production, we support tight tolerances, a wide range of materials, and secondary operations including threading, grooving, and parting.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.