Introduction: Navigating the Global Market for tornos usa

Navigating the complexities of sourcing precision machining solutions can be a daunting challenge for B2B buyers across the globe, especially when considering options like Tornos USA. With a robust portfolio of Swiss-type lathes and advanced manufacturing technologies, Tornos USA stands out as a leader in providing high-quality components across diverse industries, including medical, automotive, and aerospace. This guide aims to equip international buyers from regions such as Africa, South America, the Middle East, and Europe with the essential insights needed to make informed purchasing decisions.

In this comprehensive resource, we delve into various aspects of Tornos USA’s offerings, including machine types, applications, and the crucial factors to consider when vetting suppliers. We will also explore pricing structures, availability of spare parts, and after-sales support services, ensuring that you have a holistic understanding of what to expect when engaging with Tornos USA. By addressing common concerns and providing actionable insights, this guide empowers businesses to navigate the global market confidently, ultimately leading to successful partnerships and enhanced operational efficiency. Whether you’re seeking to optimize production capabilities or expand your manufacturing portfolio, understanding Tornos USA’s value proposition is essential in achieving your business goals.

Understanding tornos usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Swiss DT 7 & 10 | Modular design, high precision, scalable performance | Electronics, Automotive, Medical & Dental | Pros: High adaptability; Cons: Initial investment cost. |

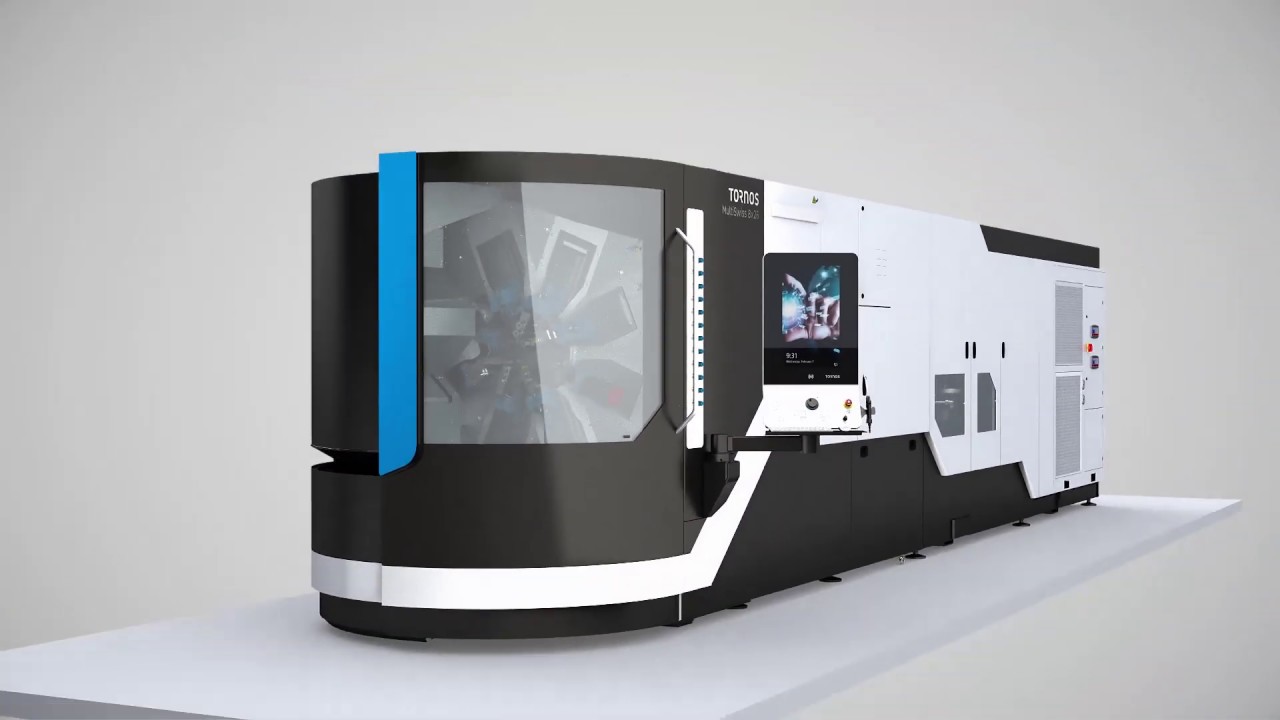

| MultiSwiss 8×26 & 6×32 | Combines multi-spindle and single-spindle technology | Mass production of complex parts | Pros: Efficient cycle times; Cons: Requires skilled operators. |

| SwissNano 10 | Compact design, easy to use, suitable for small parts | Micromechanics, Watchmaking | Pros: Space-efficient; Cons: Limited to smaller components. |

| Deco Series | Versatile CNC lathe, customizable for various tasks | Aerospace, Defense, Medical Devices | Pros: High versatility; Cons: Complexity in setup. |

| EvoDECO | Advanced automation features, user-friendly interface | High-volume production across industries | Pros: Increased productivity; Cons: Higher maintenance needs. |

What are the Key Characteristics of Swiss DT 7 & 10 Machines?

The Swiss DT 7 and 10 models are recognized for their modular design, allowing businesses to scale operations seamlessly. They deliver exceptional precision, making them ideal for intricate components in electronics, automotive, and medical sectors. When considering these machines, buyers should evaluate the long-term return on investment against the initial costs, as these models provide high adaptability for evolving production needs.

How Do MultiSwiss Machines Enhance Production Efficiency?

The MultiSwiss 8×26 and 6×32 variants merge the benefits of multi-spindle and single-spindle technology, achieving remarkable cycle times. These machines are particularly suited for mass production of complex parts, catering to industries such as automotive and electronics. Buyers must ensure their workforce is adequately skilled to handle the advanced technology, as this can significantly impact overall productivity.

What Makes SwissNano 10 Suitable for Micromechanics?

The SwissNano 10 is designed for compactness and ease of use, focusing on the production of small, precise parts, making it ideal for micromechanics and watchmaking applications. Its space-efficient design is a significant advantage for companies with limited floor space. Buyers should consider the machine’s capabilities in relation to their specific production requirements, particularly if they specialize in small components.

Why Choose the Deco Series for Aerospace and Medical Devices?

The Deco series stands out due to its versatility and customization options, catering to a wide range of applications, including aerospace and medical devices. Its advanced CNC capabilities allow for complex machining tasks, but potential buyers should be aware of the complexity involved in setup and operation. A thorough understanding of the specific tasks required can help in maximizing the machine’s potential.

How Does EvoDECO Improve High-Volume Production?

EvoDECO machines are equipped with advanced automation features and user-friendly interfaces, making them suitable for high-volume production across various industries. Their design focuses on boosting productivity while maintaining quality. However, businesses should be prepared for higher maintenance needs, as the complexity of automation can lead to increased operational costs. Understanding the balance between productivity gains and maintenance will be crucial for potential buyers.

Key Industrial Applications of tornos usa

| Industry/Sector | Specific Application of Tornos USA | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Precision components for surgical instruments | Enhanced product reliability and safety in medical procedures. | Compliance with stringent medical regulations and certifications. |

| Automotive | High-volume production of engine components | Improved efficiency and reduced production costs. | Need for scalability and flexibility in machining processes. |

| Electronics | Manufacturing of micro-components for devices | Increased precision and reduced waste in production. | Access to advanced technology for small part production. |

| Aerospace | Production of lightweight, high-strength components | Enhanced performance and reduced weight in aircraft design. | Adherence to strict aerospace standards and quality assurance. |

| Watchmaking | Creation of intricate watch parts | Superior craftsmanship and precision enhancing brand value. | Requirement for specialized machining capabilities and materials. |

How is Tornos USA Applied in the Medical Device Industry?

In the medical device sector, Tornos USA specializes in manufacturing precision components for surgical instruments and diagnostic devices. By employing Swiss-type lathes, these machines ensure that each part meets stringent quality and safety standards. International B2B buyers need to consider regulatory compliance and certification requirements specific to their countries, particularly in regions like Europe and the Middle East, where medical regulations can be exceptionally rigorous. Tornos USA not only provides high-quality components but also offers valuable support in training and maintenance, ensuring that manufacturers maintain operational efficiency.

What Role Does Tornos USA Play in Automotive Production?

In the automotive industry, Tornos USA machines are crucial for the high-volume production of engine components, such as valves and pistons. These machines deliver enhanced efficiency, significantly reducing production costs while maintaining high precision. For buyers from regions like South America and Africa, the ability to scale production rapidly without compromising quality is a key consideration. Tornos USA’s commitment to innovation means that automotive manufacturers can benefit from the latest technologies, ensuring they remain competitive in a fast-evolving market.

How Does Tornos USA Support the Electronics Sector?

Tornos USA caters to the electronics industry by producing micro-components for various devices, including smartphones and IoT devices. The precision of Tornos machines minimizes waste and maximizes yield, which is essential in this cost-sensitive sector. Buyers from Europe and Asia, particularly those focusing on high-tech products, must prioritize sourcing from manufacturers that offer advanced technology and rapid turnaround times. Tornos USA’s expertise in micro-machining positions it as a valuable partner for electronics manufacturers seeking to enhance their production capabilities.

In What Ways Does Tornos USA Benefit the Aerospace Industry?

The aerospace sector relies on Tornos USA for the production of lightweight, high-strength components that meet the industry’s rigorous performance standards. Tornos machines facilitate the manufacturing of complex geometries required in aircraft design, contributing to overall weight reduction and fuel efficiency. International buyers, especially from the Middle East and Europe, should consider the importance of adhering to aerospace-specific quality assurance standards. Tornos USA not only provides precision machining but also offers extensive service support to ensure compliance and performance.

How is Tornos USA Utilized in the Watchmaking Industry?

In watchmaking, Tornos USA excels in creating intricate watch parts that reflect superior craftsmanship and precision. The machines are capable of producing complex designs that enhance the aesthetic and functional qualities of timepieces. For buyers in Europe, particularly in Switzerland and Germany, the demand for high-quality, precise components is paramount. Tornos USA’s specialized capabilities in this area enable watch manufacturers to uphold their brand value while meeting the high expectations of discerning customers. Access to advanced machining technology allows for customization and innovation in watch design, making Tornos a critical partner in this luxury sector.

3 Common User Pain Points for ‘tornos usa’ & Their Solutions

Scenario 1: Managing Downtime Due to Equipment Malfunction

The Problem: Equipment downtime can significantly impact production schedules and profit margins for B2B buyers in manufacturing sectors such as automotive and aerospace. A common scenario involves a Tornos lathe experiencing unexpected mechanical issues, halting production and leading to potential delivery delays. This can create a ripple effect, causing missed deadlines and straining client relationships. Buyers often feel anxious about the uncertainty of repair times and the availability of spare parts, as any delay could jeopardize their reputation in a competitive market.

The Solution: Tornos USA addresses this issue with a robust spare parts inventory and responsive customer support. Buyers should proactively engage with Tornos to understand the maintenance schedules and common issues related to their specific machines. By developing a relationship with Tornos’ service team, buyers can gain insights into preventive maintenance practices that minimize the risk of breakdowns. Additionally, Tornos maintains a significant stock of spare parts—over 22,000 individual items—which allows for a 90% delivery rate within two days. Buyers should familiarize themselves with the online parts ordering system, enabling them to quickly source necessary components by entering their machine’s serial number. This proactive approach not only reduces downtime but also enhances operational efficiency and strengthens trust with end clients.

Scenario 2: Difficulty in Training Staff on Advanced Machinery

The Problem: In industries that rely on high-precision machining, such as medical devices and electronics, the complexity of Tornos machines can pose a significant training challenge. B2B buyers often struggle with ensuring their operators are well-versed in the latest technologies and machine capabilities, leading to suboptimal performance and increased error rates. This gap in knowledge can result in increased waste, lower productivity, and ultimately, higher operational costs.

The Solution: Tornos USA offers comprehensive training solutions to help buyers maximize their investment in machinery. B2B clients should take advantage of both in-house and on-site training sessions led by Tornos’ application engineers. By scheduling tailored training programs, companies can ensure that their staff receives hands-on experience with the specific machines they will be operating. Tornos also provides ongoing support and resources, including access to updated technical documentation and best practices for machine operation. Investing in this training not only empowers staff but also leads to better utilization of machine capabilities, enhancing overall productivity and reducing costs associated with errors and inefficiencies.

Scenario 3: Challenges in Adapting to Market Changes

The Problem: Rapid market changes demand flexibility and adaptability in manufacturing processes. B2B buyers often find themselves needing to pivot quickly to meet new customer demands, whether that involves increasing production volume or transitioning to different part specifications. This can be particularly challenging for companies using older machinery that lacks the modular capabilities to adjust to these new requirements efficiently.

The Solution: Tornos USA provides advanced, modular machinery such as the Swiss DT series and MultiSwiss, designed for scalability and versatility. Buyers should assess their current production capabilities and consider investing in these next-gen technologies that allow for rapid changeovers and adjustments. Engaging with Tornos’ sales team can provide valuable insights into which machines best fit their evolving production needs. Furthermore, potential buyers should explore financing options or leasing arrangements that allow them to acquire state-of-the-art equipment without significant upfront capital. By strategically upgrading their machinery, companies can enhance their responsiveness to market demands, ensuring they remain competitive and can capitalize on new opportunities as they arise.

Strategic Material Selection Guide for tornos usa

What Are the Key Properties of Common Materials Used in Tornos USA Products?

Tornos USA specializes in manufacturing precision components across various industries, utilizing a range of materials that enhance product performance. Below, we analyze four common materials used in Tornos products, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 600°F (315°C) and can handle moderate pressure applications.

Pros & Cons:

The durability of stainless steel makes it suitable for demanding environments, particularly in the medical and automotive sectors. However, it is more expensive than carbon steel and can be challenging to machine due to its hardness, potentially increasing manufacturing complexity.

Impact on Application:

Stainless steel is compatible with various media, including water, oils, and gases, making it versatile for different applications. Its resistance to corrosion is particularly beneficial in environments prone to moisture.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A276 or DIN 1.4301. Understanding local preferences for specific grades of stainless steel is also crucial.

2. Aluminum

Key Properties:

Aluminum is lightweight, has excellent thermal conductivity, and offers good corrosion resistance. Its temperature rating can vary, but it generally performs well in applications up to 400°F (204°C).

Pros & Cons:

The lightweight nature of aluminum makes it ideal for applications requiring reduced weight, such as in aerospace and automotive sectors. However, its lower strength compared to steel can be a limitation in high-stress applications, and it may require surface treatments for enhanced durability.

Impact on Application:

Aluminum is compatible with various media, but its performance can be affected by certain chemicals, requiring careful selection based on the application.

Considerations for International Buyers:

International buyers should be aware of the common standards for aluminum, such as ASTM B221 and JIS H4000. Preferences for specific alloys may vary by region, especially in industries like automotive and aerospace.

3. Brass

Key Properties:

Brass is known for its excellent machinability, good corrosion resistance, and antimicrobial properties. It typically performs well in applications with temperatures up to 300°F (149°C).

Pros & Cons:

The machinability of brass allows for intricate designs and faster production times. However, its cost can be higher than other materials, and it may not be suitable for high-pressure applications.

Impact on Application:

Brass is particularly suitable for plumbing and electrical components due to its conductivity and resistance to corrosion in moisture-rich environments.

Considerations for International Buyers:

Buyers should consider compliance with standards like ASTM B16 and DIN 17660. Understanding local regulations regarding the use of brass, especially in plumbing applications, is essential.

4. Carbon Steel

Key Properties:

Carbon steel is known for its high strength and durability, making it suitable for high-pressure applications. It typically has a temperature rating of up to 500°F (260°C).

Pros & Cons:

The cost-effectiveness of carbon steel makes it a popular choice for many applications. However, it is prone to corrosion, which can limit its use in certain environments unless properly treated.

Impact on Application:

Carbon steel is compatible with various media but may require protective coatings when used in corrosive environments.

Considerations for International Buyers:

International buyers should ensure compliance with ASTM A36 and similar standards. Understanding local preferences for carbon steel grades is crucial for ensuring product compatibility.

Summary Table of Material Selection for Tornos USA

| Material | Typical Use Case for Tornos USA | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Medical devices, automotive parts | Excellent corrosion resistance | Higher cost, machining complexity | High |

| Aluminum | Aerospace components, automotive | Lightweight and good thermal conductivity | Lower strength than steel | Medium |

| Brass | Plumbing fittings, electrical parts | Excellent machinability and antimicrobial properties | Higher cost, limited pressure use | Medium |

| Carbon Steel | Structural components, machinery | High strength and durability | Prone to corrosion without treatment | Low |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in Tornos USA products, helping them make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for tornos usa

What Are the Main Stages of Tornos USA’s Manufacturing Process?

Tornos USA employs a meticulous manufacturing process designed to ensure the production of high-quality Swiss type lathes. The primary stages of this process include material preparation, forming, assembly, and finishing.

Material Preparation

The manufacturing journey begins with selecting superior raw materials. Tornos USA sources high-grade metals and alloys, which are essential for the durability and precision of their machines. These materials undergo rigorous inspection to verify compliance with predefined specifications. The selected materials are then cut into manageable sizes, prepared for further processing.

What Forming Techniques Does Tornos USA Use?

In the forming stage, advanced machining technologies come into play. Tornos utilizes CNC (Computer Numerical Control) machining, which allows for precise shaping and cutting of components. The Swiss-type lathe technology employed by Tornos enables the production of complex geometries with tight tolerances, essential for industries such as medical and aerospace. Additionally, multi-spindle machines can perform multiple operations simultaneously, significantly enhancing productivity and efficiency.

How Does Tornos USA Handle Assembly?

Once individual components are machined, they proceed to the assembly phase. Tornos USA emphasizes a systematic approach to assembly, where trained technicians meticulously piece together machines while adhering to stringent quality standards. Each assembly line is equipped with specialized tools and jigs to facilitate precision and ensure that every component fits perfectly. This stage also involves initial testing to confirm that components function as intended.

What Finishing Processes Are Involved?

Finishing is the final stage in the manufacturing process. Tornos USA employs various techniques such as surface treatment, coating, and polishing to enhance the aesthetic and functional qualities of the machines. These processes not only improve the machines’ appearances but also contribute to their longevity and performance. Rigorous inspections during the finishing stage ensure that each machine meets Tornos’s high-quality standards before it is packaged and shipped.

How Does Tornos USA Ensure Quality Assurance?

Quality assurance is integral to Tornos USA’s operations, ensuring that every product meets international standards and customer expectations. The company adheres to various quality standards, including ISO 9001, which governs quality management systems across industries.

What International Quality Standards Does Tornos USA Follow?

Tornos USA complies with several international quality standards, including:

- ISO 9001: This standard ensures a consistent quality management system, focusing on customer satisfaction and continuous improvement.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Certification: Relevant for clients in the oil and gas sector, API standards ensure that products meet specific industry requirements.

These certifications not only enhance Tornos’s credibility but also reassure B2B buyers of the quality and reliability of their products.

What Are the Key Quality Control Checkpoints?

Tornos USA implements a comprehensive quality control (QC) framework comprising several checkpoints:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival to ensure they meet Tornos’s specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the quality of components at various stages. This proactive approach allows for the immediate identification and rectification of any issues.

- Final Quality Control (FQC): Before dispatch, every machine undergoes a final inspection to verify that it meets all quality standards and operational specifications.

This multi-tiered QC system ensures that quality is maintained throughout the manufacturing process.

What Common Testing Methods Are Used at Tornos USA?

To validate the integrity and performance of their machines, Tornos USA employs a range of testing methods:

- Functional Testing: Each machine is tested to ensure it operates correctly under specified conditions.

- Dimensional Inspection: Precision measuring tools are used to verify that components adhere to the required tolerances.

- Material Testing: This includes hardness testing and metallurgical analysis to confirm the quality of the materials used.

These testing methods guarantee that Tornos products are reliable and meet industry standards.

How Can B2B Buyers Verify Supplier Quality Control?

International B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should consider several strategies to verify the quality control practices of Tornos USA:

- Supplier Audits: Conducting on-site audits can provide firsthand insight into Tornos’s manufacturing processes and quality assurance measures. This can help buyers assess compliance with industry standards.

- Requesting Quality Reports: Tornos USA can provide documentation related to their quality control processes, including inspection reports and certifications. These documents are crucial for buyers to evaluate the supplier’s commitment to quality.

- Third-Party Inspections: Engaging independent third-party inspectors can offer an unbiased review of Tornos’s manufacturing and quality assurance practices. This can be particularly important for buyers in regulated industries.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from different regions must be aware of specific nuances related to quality control and compliance. For example:

- Regulatory Requirements: Different countries have varying regulations regarding machine safety and performance. Buyers should ensure that Tornos USA’s products comply with local regulations in their respective markets.

- Cultural Differences: Understanding the cultural context surrounding quality assurance in different regions can aid in navigating supplier relationships. For instance, communication styles and expectations can vary significantly across countries.

By being informed and proactive, international B2B buyers can effectively navigate the complexities of quality assurance when partnering with Tornos USA, ensuring they receive top-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tornos usa’

This practical sourcing guide provides international B2B buyers with a structured checklist to efficiently procure products and services from Tornos USA. By following these steps, you can ensure that your sourcing process is thorough, informed, and aligned with your operational needs.

Step 1: Define Your Technical Specifications

Understanding your specific technical requirements is essential before reaching out to suppliers. This includes determining the type of machining processes you require, the materials you’ll be working with, and the desired precision levels. Clearly defined specifications will help streamline communications with Tornos and ensure that the solutions offered are tailored to your operational needs.

Step 2: Research Tornos USA Product Offerings

Familiarize yourself with the range of machines Tornos offers, such as Swiss type lathes, multispindle machines, and newer technologies like the SwissNano series. Each machine has unique features and benefits that cater to various industries, including automotive, aerospace, and medical. Understanding these offerings will enable you to select the right machinery that aligns with your production goals.

Step 3: Evaluate Support and Service Options

Consider the level of support and service Tornos provides, which is critical for maintaining operational efficiency. Tornos USA boasts a comprehensive customer service program, including on-site maintenance and training sessions. Evaluate their availability of spare parts and support response times to ensure minimal downtime for your operations.

- Inquire about training programs: Ensure that your team will have access to training that enhances their skills in operating Tornos machinery.

Step 4: Verify Supplier Certifications and Standards

It’s important to confirm that Tornos USA adheres to industry standards and certifications, which reflect their commitment to quality and safety. Look for certifications related to manufacturing processes, environmental compliance, and operational excellence. These certifications can give you confidence in the reliability and performance of their products.

Step 5: Request and Analyze Quotations

Once you have identified your preferred machines and services, request detailed quotations from Tornos USA. Analyze the pricing structures, payment terms, and delivery timelines provided in their proposals. Ensure that all costs are transparent and that you understand any additional fees that may arise during the procurement process.

Step 6: Check References and Case Studies

Before finalizing your decision, reach out to existing customers of Tornos USA for references. Ask for case studies or testimonials that demonstrate their experience in your industry. This feedback can provide invaluable insights into the supplier’s reliability and the performance of their machinery in real-world applications.

Step 7: Negotiate Terms and Finalize the Agreement

Once you are satisfied with your research and have gathered all necessary information, proceed to negotiate terms with Tornos USA. Focus on delivery timelines, warranty conditions, and ongoing support services. A well-negotiated agreement can lead to a fruitful long-term partnership that enhances your production capabilities.

By following this checklist, you can ensure a comprehensive approach to sourcing from Tornos USA, ultimately leading to a successful procurement experience that meets your business objectives.

Comprehensive Cost and Pricing Analysis for tornos usa Sourcing

What Are the Key Cost Components for Tornos USA Products?

Understanding the cost structure of Tornos USA products is vital for B2B buyers looking to optimize their sourcing strategies. The primary cost components include:

-

Materials: High-quality raw materials are essential for the production of precision machinery. Tornos sources premium metals and components that ensure durability and performance, which can significantly impact pricing.

-

Labor: Skilled labor is crucial in manufacturing Swiss-type lathes and other precision equipment. Tornos employs experienced engineers and technicians whose expertise contributes to the overall cost structure.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, maintenance of machinery, and facility costs. Tornos maintains a high standard in its facilities to ensure optimal production efficiency.

-

Tooling: Specialized tooling is often required for precision machining. The cost of tooling can vary depending on the complexity of the parts being produced and whether custom tools are necessary.

-

Quality Control (QC): Tornos implements stringent QC processes to maintain its reputation for precision and reliability. The cost of these processes is factored into the final pricing, ensuring that customers receive only the highest quality products.

-

Logistics: Shipping and handling costs are essential considerations, particularly for international buyers. Tornos has a well-established logistics network that helps manage these costs effectively.

-

Margin: Tornos aims for a competitive yet sustainable profit margin, which is reflected in its pricing strategy.

How Do Price Influencers Affect Tornos USA Sourcing?

Several factors can influence the pricing of Tornos products, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs. Buyers should consider the MOQ when planning their purchasing strategy to maximize cost efficiency.

-

Specifications and Customization: Custom orders tailored to specific applications may incur additional costs. Understanding the balance between standard and custom specifications is crucial for budget planning.

-

Materials: The choice of materials can significantly affect pricing. High-grade materials may increase costs but can also enhance product longevity and performance.

-

Quality Certifications: Products that meet specific industry certifications may come at a premium due to the additional costs associated with compliance and testing.

-

Supplier Factors: The reputation and reliability of Tornos as a supplier can influence pricing. A trusted supplier often justifies higher prices through superior service and product quality.

-

Incoterms: Understanding the terms of delivery can impact overall costs. Buyers must consider whether the price includes shipping, insurance, and customs duties, particularly for international transactions.

What Are the Best Buyer Tips for Negotiating with Tornos USA?

When negotiating with Tornos, international B2B buyers should consider the following tips:

-

Leverage Volume Discounts: If you anticipate a consistent need for Tornos products, consider negotiating a bulk purchase agreement to secure better pricing.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with maintenance, spare parts, and operational efficiency. Tornos offers a robust inventory of spare parts, which can enhance TCO.

-

Be Aware of Pricing Nuances: International buyers, especially from Africa, South America, the Middle East, and Europe, should be mindful of currency fluctuations, tariffs, and regional pricing differences when negotiating contracts.

-

Build a Relationship: Establishing a strong relationship with Tornos representatives can lead to better support and potentially more favorable pricing terms.

-

Ask About Financing Options: Tornos may offer financing solutions or leasing options that can make higher-priced equipment more accessible.

Disclaimer for Indicative Prices

Pricing information provided by Tornos is indicative and may vary based on market conditions, order specifications, and other factors. Buyers are encouraged to consult directly with Tornos representatives for the most accurate and up-to-date pricing information tailored to their specific needs.

Alternatives Analysis: Comparing tornos usa With Other Solutions

Introduction: Exploring Alternatives to Tornos USA

In the competitive landscape of precision machining, B2B buyers often seek alternatives to established solutions like Tornos USA. Understanding the various options available can help businesses make informed decisions tailored to their specific operational needs. This analysis compares Tornos USA against two notable alternatives: Citizen Machinery and Haas Automation. Each of these solutions offers distinct advantages and may suit different production requirements.

Comparison Table

| Comparison Aspect | Tornos USA | Citizen Machinery | Haas Automation |

|---|---|---|---|

| Performance | High precision, Swiss-type lathes; excels in complex parts | Advanced multi-axis CNC; high-speed machining | Versatile CNC machining centers; solid reliability |

| Cost | Premium pricing; long-term ROI through durability | Competitive pricing; good value for multi-tasking | Generally lower cost; cost-effective for standard machining |

| Ease of Implementation | Requires skilled operators; robust training available | User-friendly; quick setup for multi-tasking | Intuitive interface; extensive support and training resources |

| Maintenance | Strong service support; rapid parts availability | Reliable; some parts may require longer lead times | Extensive network for service; straightforward maintenance |

| Best Use Case | Ideal for industries requiring extreme precision (medical, aerospace) | Best for high-volume production with complex geometries | Suitable for general machining needs across various industries |

Detailed Breakdown of Alternatives

Citizen Machinery

Citizen Machinery is renowned for its multi-axis CNC lathes, which enable complex part production with high speed and precision. The key advantages of Citizen include its competitive pricing and the efficiency of its machines, which can significantly reduce cycle times. However, while it offers a robust solution for high-volume manufacturing, the complexity of its setups may require skilled operators, which can lead to longer training periods for new employees.

Haas Automation

Haas Automation provides a range of CNC machining centers that are particularly appealing for businesses seeking cost-effective solutions. The machines are known for their reliability and ease of use, making them accessible to operators at various skill levels. Haas’s extensive customer support network and training resources facilitate smoother implementation. However, while they are versatile, they may not offer the same level of precision for highly specialized applications as Tornos or Citizen.

Conclusion: How to Choose the Right Solution

Selecting the right machining solution depends on various factors, including the specific needs of your operation, budget constraints, and the complexity of the parts you intend to produce. For businesses focused on extreme precision in critical industries, Tornos USA remains a strong choice. However, if your needs lean towards high-volume production with diverse geometries, Citizen Machinery may offer the best return on investment. Conversely, for general machining applications that prioritize cost-effectiveness and ease of use, Haas Automation could be the optimal solution. Assessing these aspects will empower B2B buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for tornos usa

What Are the Key Technical Properties of Tornos USA Machines?

-

Material Grade

Tornos machines are typically constructed from high-grade steel and other durable materials that ensure longevity and reliability. The selection of material is crucial as it impacts the machine’s ability to withstand wear and tear, especially in high-volume production environments. For B2B buyers, investing in machines made from superior materials translates into reduced downtime and lower maintenance costs. -

Tolerance Levels

Precision is paramount in industries served by Tornos, such as medical and aerospace. Tornos machines can achieve tight tolerances often within ±0.005 mm or better. This level of precision is essential for manufacturers who require components that fit seamlessly into larger assemblies. Understanding tolerance levels helps buyers ensure that their production meets industry standards and customer expectations. -

Spindle Speed and Power

The spindle speed of Tornos machines can vary significantly, with options ranging from 1,000 RPM to over 10,000 RPM depending on the model. Higher spindle speeds allow for faster machining, which can lead to increased productivity. Buyers should consider spindle power as it relates to the types of materials being machined, as more robust materials require higher power levels to maintain efficiency. -

Multi-Spindle Configuration

Tornos offers multi-spindle machines that can operate multiple tools simultaneously. This capability is vital for high-volume production runs where time efficiency is crucial. B2B buyers looking for cost-effective solutions will find multi-spindle configurations beneficial for reducing cycle times and increasing output. -

Automation Features

Many Tornos machines come equipped with automation capabilities, such as automatic tool changers and integrated monitoring systems. These features enhance operational efficiency and can significantly reduce labor costs. Understanding these automation options helps buyers choose machines that align with their production goals and workforce capabilities.

What Are Common Trade Terms Used in the Tornos USA Context?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of Tornos, this term is important for buyers looking to purchase machines or components that are integral to their production lines, ensuring compatibility and quality. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest number of units a supplier is willing to sell. For B2B buyers, understanding MOQs is crucial for budgeting and inventory management. Tornos may have specific MOQs for spare parts or machines, influencing purchasing strategies for companies with varying production scales. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a company solicits price quotes from suppliers. B2B buyers should utilize RFQs when considering Tornos machines or services to ensure they receive competitive pricing and terms tailored to their specific needs. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers, especially when importing Tornos equipment, as they dictate shipping costs, risk transfer, and delivery timelines. -

Lead Time

Lead time refers to the amount of time from the placement of an order until it is delivered. For businesses relying on Tornos machines, understanding lead times is vital for planning production schedules and maintaining inventory levels. Longer lead times can affect operational efficiency, making this an essential consideration for B2B buyers. -

Service Level Agreement (SLA)

An SLA is a contract that outlines the expected level of service between a provider and a customer. In the context of Tornos, SLAs can specify response times for maintenance and support, ensuring that B2B buyers receive timely assistance and minimizing downtime in their operations.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when considering Tornos USA as a supplier for their manufacturing needs.

Navigating Market Dynamics and Sourcing Trends in the tornos usa Sector

What Are the Key Market Dynamics and Trends Influencing Tornos USA?

The Tornos USA sector operates within a rapidly evolving landscape, driven by technological advancements and shifting market demands. Global drivers such as the rise of Industry 4.0, the Internet of Things (IoT), and automation are reshaping the manufacturing process, enhancing productivity, and enabling real-time data analytics. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must adapt to these changes by sourcing advanced machining solutions that meet their specific industry needs.

Emerging trends include the increasing demand for precision manufacturing, particularly in sectors like medical devices, automotive, and aerospace. Buyers are looking for suppliers that offer not only high-quality Swiss-type lathes but also comprehensive support services, including training and maintenance. Tornos USA has positioned itself strategically to meet these needs by providing a robust service framework, including on-site training and rapid response maintenance, which is crucial for minimizing downtime in production.

Another significant trend is the shift toward customized solutions. As businesses in various sectors seek to differentiate themselves, the ability to produce tailored components quickly and efficiently becomes a competitive advantage. Tornos’ commitment to providing versatile machinery, such as the MultiSwiss and SwissNano, aligns with this need, offering buyers the flexibility to scale operations in response to market demands.

How Is Sustainability Impacting B2B Sourcing in the Tornos USA Sector?

Sustainability has become a core focus for businesses across the globe, and the Tornos USA sector is no exception. With growing awareness of environmental impacts, international buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing and sustainable practices. This includes minimizing waste, reducing carbon footprints, and utilizing environmentally friendly materials in production processes.

Tornos USA has embraced these principles by implementing sustainable manufacturing practices and striving for energy-efficient operations. The company’s emphasis on maintaining a substantial inventory of spare parts—over $4 million worth—ensures that machines remain operational longer, reducing the need for new manufacturing and the associated environmental impact. Additionally, Tornos is exploring partnerships with suppliers who offer green certifications and sustainable materials, aligning with the values of environmentally conscious buyers.

Ethical supply chains are also gaining traction, as companies seek to ensure that their sourcing practices do not exploit labor or contribute to social inequities. By focusing on ethical partnerships, Tornos USA can enhance its brand reputation and appeal to a growing segment of B2B buyers who prioritize corporate social responsibility in their procurement decisions.

How Has Tornos Evolved to Meet B2B Buyer Needs?

Founded with a commitment to precision and quality, Tornos has evolved significantly since its inception. Originally focused on traditional machining, the company has embraced technological advancements to remain competitive in a global market that demands efficiency and precision. The integration of advanced CNC technologies and automation in their machinery reflects Tornos’ responsiveness to the evolving needs of B2B buyers.

Over the years, Tornos has expanded its product offerings to include a range of machines suited for various applications, from single-spindle to multi-spindle lathes. This diversification has enabled the company to cater to a wide array of industries, including medical, automotive, and aerospace, solidifying its position as a leader in the Swiss machine-tool manufacturing sector.

As Tornos continues to adapt to market dynamics, its focus on customer service excellence and technical support remains paramount. The company’s commitment to providing tailored solutions and training ensures that B2B buyers can maximize their operational efficiency and maintain a competitive edge in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of tornos usa

-

How do I ensure the quality of Tornos machines before purchasing?

To verify the quality of Tornos machines, request detailed specifications and production standards from Tornos USA. Additionally, consider visiting their facilities or authorized distributors to see the machines in operation. Engage with current users through testimonials or case studies to understand their experiences. Tornos also offers comprehensive service and support, including training and maintenance, which can be a crucial factor in ensuring long-term quality and reliability. -

What are the customization options available for Tornos machines?

Tornos USA provides a range of customization options tailored to meet specific industry needs. Buyers can work with Tornos’ application engineers to configure machines based on part complexity, production volume, and specific machining requirements. This flexibility allows for adaptations in tooling, software, and additional features that enhance performance and efficiency. Early discussions regarding customization can significantly impact the effectiveness of the solution provided. -

What is the minimum order quantity (MOQ) for Tornos machines and parts?

The minimum order quantity for Tornos machines and parts typically varies based on the specific model and configuration. Generally, larger machinery purchases may not have a strict MOQ, while spare parts can usually be ordered individually. It is advisable to contact Tornos USA directly to discuss your particular needs and receive guidance on order quantities, especially for international buyers who may have unique logistical considerations. -

What payment terms can I expect when purchasing from Tornos USA?

Tornos USA offers flexible payment terms, which can include upfront payments, net 30, or net 60 days, depending on the order size and buyer’s creditworthiness. International buyers may also need to consider factors like currency fluctuations and import duties. It’s essential to clarify payment terms during negotiations to ensure alignment with your financial planning and cash flow management. -

How does Tornos handle logistics for international shipments?

Tornos USA collaborates with reliable logistics partners to facilitate the shipping of machines and parts worldwide. They ensure compliance with international shipping regulations and can assist in coordinating customs clearance. Buyers should discuss shipping options, lead times, and potential duties or taxes during the ordering process to avoid surprises and ensure smooth delivery to their location. -

What kind of after-sales support does Tornos provide?

Tornos USA prides itself on exceptional after-sales support, which includes installation, training, and ongoing maintenance. Their field service engineers are available for on-site support to ensure machines are operating efficiently. Additionally, Tornos offers a robust inventory of spare parts, with 90% of orders shipped within two days, ensuring minimal downtime for your operations. -

How can I assess the reliability of Tornos as a supplier?

To assess Tornos’ reliability, research their industry reputation and history, including customer reviews and case studies. Consider their experience in your specific sector, such as medical or automotive, as well as their adherence to international quality standards. Engaging with existing clients can also provide insights into their customer service and support responsiveness, which are critical for a long-term supplier relationship. -

What industries does Tornos USA specialize in?

Tornos USA specializes in providing precision machining solutions for a variety of industries, including medical, dental, automotive, electronics, watchmaking, aerospace, and defense. Each industry has unique requirements, and Tornos offers tailored solutions to meet these challenges. Understanding Tornos’ expertise in your specific sector can help you leverage their technology for optimal performance and efficiency in your production processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Tornos Usa Manufacturers & Suppliers List

1. Tornos – Swiss-Type Lathes and Multispindle Solutions

Domain: tornos.com

Registered: 2000 (25 years)

Introduction: Tornos Technologies US Corporation specializes in Swiss-type lathes, including models such as SwissDECO, EvoDECO, DECO 10 Plus, Swiss XT, Swiss GT, SwissNano, Swiss DT, Swiss DT 7 & Swiss DT 10, and Multispindle MultiSwiss. They also offer SAS 16 Plus Milling, BA 1008 XT, and BA 1008 HP. Their technology includes peripherals, automation, bar feeders, and software solutions like TISIS, Active Chip …

2. IMTS – Precision Machining Equipment

Domain: directory.imts.com

Registered: 1996 (29 years)

Introduction: Gear Hobbing Machines, Deep Hole Drilling Machines (Gundrilling), Multi-Spindle Cam-Type Screw Machines, Multi-Spindle CNC Screw Machines, Single-Spindle Cam-Type Screw Machines, Single-Spindle CNC Screw Machines, Swiss Cam-Type Screw Machines, Swiss CNC Screw Machines, Thread Cutting Machines, Thread Rolling Machines, Pipe and Bar Threading and Cut-Off Machines, CNC Turn/Mill Machines.

3. Tornos Technologies – Swiss Machine Tools

Domain: productionmachining.com

Registered: 1997 (28 years)

Introduction: This company, Tornos Technologies – Swiss Machine Tools, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for tornos usa

In conclusion, Tornos USA stands out as a pivotal partner for international B2B buyers seeking precision-engineered solutions. Their commitment to quality is evident through their extensive range of Swiss-type lathes and multi-spindle machines, catering to critical industries such as medical, automotive, and aerospace. Strategic sourcing from Tornos not only ensures access to advanced technology but also guarantees exceptional customer service and rapid support, crucial for maintaining productivity in today’s fast-paced markets.

As global industries continue to evolve, sourcing high-quality machinery and support services will be paramount for maintaining competitive advantage. Tornos USA’s robust inventory, with over 22,000 spare parts readily available, exemplifies their dedication to minimizing downtime and enhancing operational efficiency.

For international buyers from regions such as Africa, South America, the Middle East, and Europe, engaging with Tornos USA offers a clear path to innovation and growth. As you consider your strategic sourcing options, remember that partnering with Tornos means investing in reliability, precision, and a commitment to your success. Reach out today to explore how Tornos USA can elevate your manufacturing capabilities to meet the demands of tomorrow.