Introduction: Navigating the Global Market for tornos technologies us corporation

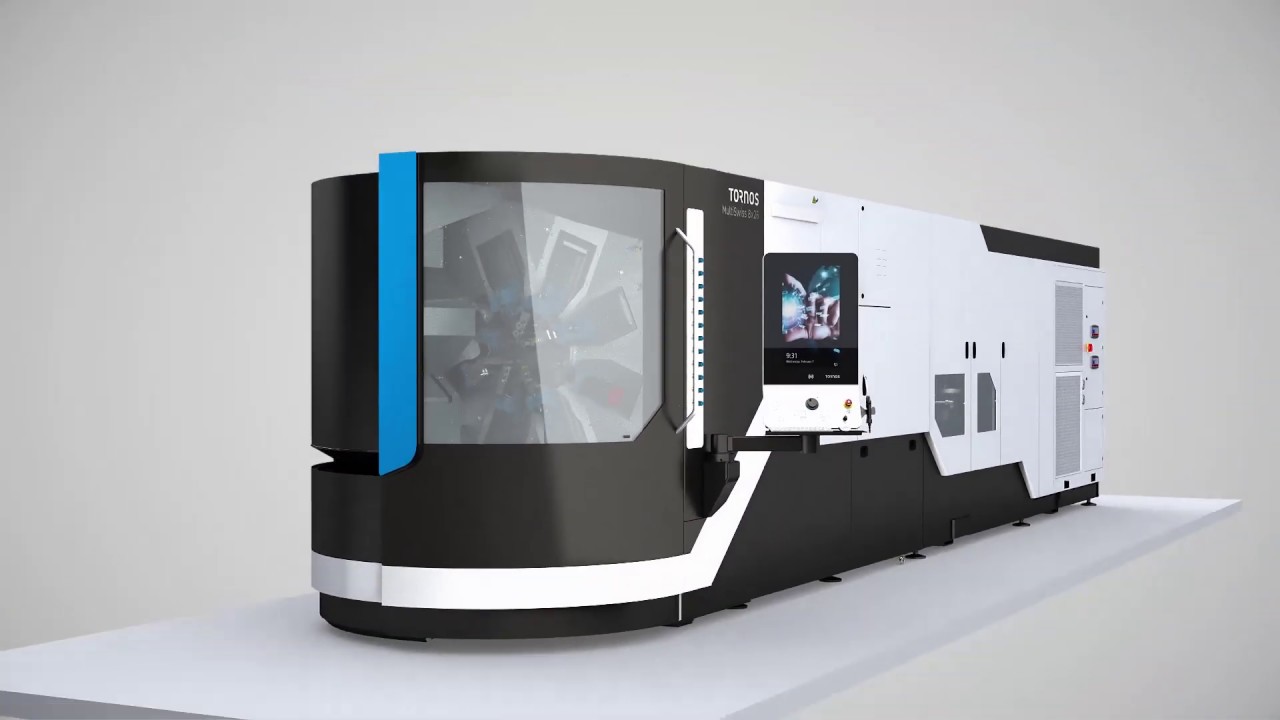

In an increasingly competitive global landscape, sourcing high-precision manufacturing solutions like those offered by Tornos Technologies US Corporation can be a complex challenge for international B2B buyers. Whether your business operates in the medical, automotive, aerospace, or electronics industries, understanding the nuances of Swiss-type lathes and CNC machinery is crucial for maintaining a competitive edge. This guide is designed to navigate the multifaceted offerings of Tornos, detailing various machine types, their applications, and the critical factors to consider when selecting a supplier.

From evaluating the latest technologies to assessing cost implications and supplier reliability, this resource empowers buyers from Africa, South America, the Middle East, and Europe—such as Nigeria and Saudi Arabia—to make informed purchasing decisions. The guide provides insights into Tornos’ product range, including their groundbreaking SwissNano series and modular Swiss DT models, which cater to diverse manufacturing needs with unmatched precision. Additionally, it highlights the importance of service support, training, and maintenance, ensuring that your investment translates into operational excellence.

By leveraging the information contained within this guide, businesses can confidently engage with Tornos Technologies US Corporation, aligning their manufacturing capabilities with the demands of today’s dynamic markets. Discover how to enhance your production processes while ensuring quality and efficiency, setting the stage for long-term success in your industry.

Understanding tornos technologies us corporation Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Swiss Type Lathes | High precision, compact design, multi-spindle options | Medical, aerospace, electronics, automotive | Pros: Exceptional precision, versatile. Cons: Higher initial investment. |

| SwissNano | Small footprint, ergonomic, enhanced spindle output | Micromechanics, medical, dental | Pros: Space-efficient, suitable for small parts. Cons: Limited to specific part sizes. |

| Swiss DT Series | Modular design, scalable performance | Automotive, electronics, medical, dental | Pros: Flexible configurations, future-proof. Cons: Complexity may require training. |

| CNC Multi-Spindle | Multiple spindles for simultaneous machining | High-volume production in various sectors | Pros: Increased productivity, reduced cycle time. Cons: Higher maintenance requirements. |

| Application Engineering | Tailored solutions, on-site training, maintenance support | Across all industries requiring precision parts | Pros: Customized support, enhances operational efficiency. Cons: Dependence on service availability. |

What are the characteristics and suitability of Swiss Type Lathes?

Swiss Type Lathes are renowned for their ability to produce high-precision components in a compact design. They typically feature multiple spindles, allowing for the simultaneous machining of parts, which significantly increases production efficiency. These machines are particularly well-suited for industries like medical, aerospace, and automotive, where precision and reliability are paramount. Buyers should consider their specific production needs and the potential return on investment, as these machines generally require a higher initial outlay.

How does the SwissNano cater to niche markets?

The SwissNano is designed with a focus on producing small, intricate parts, making it ideal for micromechanics and the medical and dental fields. Its ergonomic design and compact footprint enable it to fit into limited workspace while still delivering high performance. The enhanced spindle output allows for more complex machining operations. Buyers should assess their production volumes and part specifications, as the SwissNano is tailored for specific sizes, which may limit its versatility in broader applications.

What advantages does the Swiss DT Series offer for growing businesses?

The Swiss DT Series features a modular design that allows businesses to scale their operations as needed. This adaptability is particularly beneficial for companies in the automotive and electronics sectors, where production demands may fluctuate. The machines are engineered for high performance, ensuring that buyers can maintain competitive advantages over time. However, the complexity of the system may require additional training for operators, which should be factored into the purchasing decision.

Why consider CNC Multi-Spindle machines for high-volume production?

CNC Multi-Spindle machines are designed for high-volume production, enabling manufacturers to produce large quantities of parts simultaneously. This capability is especially useful in sectors requiring rapid turnaround times, such as automotive and electronics. While these machines significantly enhance productivity and reduce cycle times, they also come with higher maintenance needs, which can impact overall operational costs. Buyers should evaluate their production capacity and maintenance capabilities when considering this option.

How does Application Engineering enhance the value proposition for Tornos buyers?

Application Engineering at Tornos provides tailored solutions and support, including on-site training and maintenance services. This approach ensures that clients across various industries receive customized assistance that enhances operational efficiency. The ability to adapt to specific client needs can significantly improve the overall user experience and productivity. However, buyers should consider the availability and responsiveness of these services, as they can be crucial for maintaining machine performance and minimizing downtime.

Key Industrial Applications of tornos technologies us corporation

| Industry/Sector | Specific Application of Tornos Technologies US Corporation | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical | Precision components for surgical instruments | Ensures high-quality, reliable tools that meet strict regulatory standards | Look for certifications, delivery timelines, and support services. |

| Automotive | Manufacturing of complex engine parts | Enhances performance and efficiency through precision engineering | Consider machine versatility and maintenance support options. |

| Electronics | Production of microelectronic components | Increases production speed while maintaining high precision | Evaluate the machine’s adaptability for various component sizes. |

| Aerospace | Fabrication of lightweight structural components | Reduces weight and improves fuel efficiency in aircraft | Assess the machine’s capability for high-strength materials. |

| Watchmaking | Crafting intricate watch components | Delivers exceptional detail and precision for luxury products | Ensure precision standards and customization options are available. |

How Does Tornos Technologies US Corporation Serve the Medical Industry?

In the medical sector, Tornos technologies are pivotal in producing precision components for surgical instruments. These components must adhere to stringent regulatory standards to ensure safety and efficacy. By utilizing Tornos’ advanced Swiss-type lathes, manufacturers can achieve the necessary precision and consistency in their products, thereby reducing the risk of defects. International buyers, particularly from regions like Africa and the Middle East, should prioritize sourcing machines that are certified and capable of meeting local regulatory requirements, while also ensuring timely delivery and robust service support.

What Are the Applications in the Automotive Sector?

Tornos technologies play a crucial role in the automotive industry, particularly in the manufacturing of complex engine parts. The precision offered by Tornos machines allows for the creation of components that enhance vehicle performance and fuel efficiency. Given the competitive nature of the automotive market, businesses need to consider the versatility of Tornos machines and their maintenance support options. Buyers from South America and Europe should look for machines that can handle varying production volumes and complex geometries, ensuring a long-term return on investment.

How Is Tornos Technologies Utilized in Electronics Manufacturing?

In the electronics sector, Tornos technologies are essential for the production of microelectronic components, where high precision is crucial. The ability to produce these components quickly without compromising quality allows manufacturers to meet the demands of fast-paced electronics markets. International buyers should evaluate the adaptability of Tornos machines for various component sizes and designs. Additionally, understanding the availability of training and support services can significantly impact the operational efficiency of buyers in regions such as Nigeria and Saudi Arabia.

What Role Does Tornos Play in Aerospace Manufacturing?

Tornos technologies are also instrumental in the aerospace industry, particularly for fabricating lightweight structural components. These components are designed to reduce overall aircraft weight, thereby improving fuel efficiency and performance. Buyers in this sector must assess the machine’s capability to work with high-strength materials that meet aerospace standards. International buyers should prioritize sourcing from Tornos due to their reputation for precision and reliability, which are critical for safety in aviation.

How Does Tornos Technologies Support the Watchmaking Industry?

In watchmaking, Tornos technologies facilitate the crafting of intricate watch components that require exceptional detail and precision. The ability to produce high-quality components enhances the luxury appeal of watches, which is vital for market competitiveness. Buyers should ensure that Tornos machines meet the precision standards necessary for luxury products and offer customization options to cater to specific design requirements. This is particularly important for international buyers looking to differentiate their products in a saturated market.

3 Common User Pain Points for ‘tornos technologies us corporation’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Machine for Specific Applications

The Problem: B2B buyers often struggle to identify which Swiss-type lathe model is best suited for their specific manufacturing needs. With a wide range of applications across industries such as medical, automotive, and electronics, the choices can become overwhelming. Buyers may fear investing in a machine that does not meet their precise requirements, leading to suboptimal production efficiency and increased costs. This challenge is exacerbated by a lack of in-depth knowledge about the technical specifications and performance capabilities of each model.

The Solution: To navigate this complexity, B2B buyers should engage directly with Tornos Technologies’ application engineering team. This team specializes in understanding customer needs and can provide tailored recommendations based on specific application requirements. Buyers should prepare a detailed list of their production needs, including part dimensions, material types, and expected production volumes. By sharing this information, Tornos can recommend the most suitable model, whether it’s the SwissNano for small precision parts or the Swiss DT series for scalable production. Additionally, prospective buyers should utilize Tornos’ comprehensive online resources and product documentation to familiarize themselves with machine capabilities and specifications before making a purchase.

Scenario 2: Challenges in Machine Maintenance and Downtime

The Problem: Maintenance of precision machinery is critical, yet B2B buyers often face challenges when it comes to timely servicing and minimizing downtime. Unplanned machine failures can disrupt production schedules and lead to significant financial losses. Moreover, companies may lack the necessary in-house expertise to handle complex maintenance issues or may find it difficult to schedule timely service from external providers, resulting in prolonged equipment inoperability.

The Solution: Tornos Technologies addresses this pain point by offering proactive maintenance services and on-site support. Buyers should take advantage of Tornos’ field service engineers, who can perform regular maintenance checks and provide training to in-house staff on essential upkeep practices. Establishing a maintenance schedule with Tornos can significantly reduce the risk of unexpected breakdowns. Additionally, buyers can implement a predictive maintenance strategy by utilizing Tornos’ training resources to empower their teams with the skills necessary to identify early signs of wear and tear, thus preventing costly downtime.

Scenario 3: Lack of Training and Knowledge on Advanced Technologies

The Problem: As the manufacturing landscape evolves, B2B buyers often encounter difficulties in keeping their teams updated with the latest machining technologies and techniques. This gap in knowledge can hinder their ability to fully utilize advanced features of Tornos machines, resulting in inefficient operations and a potential competitive disadvantage. Without proper training, operators may struggle to maximize machine productivity or fully leverage advanced functionalities such as thread whirling or gear hobbing.

The Solution: To overcome this challenge, companies should take advantage of Tornos’ comprehensive training programs. Tornos offers both in-house and on-site training sessions tailored to specific machine models and technologies. B2B buyers should prioritize investing in these training sessions for their operators and engineers, as this will ensure that their teams are well-versed in the latest machining techniques and can effectively utilize the capabilities of Tornos machines. Additionally, establishing a continuous learning culture within the organization, supported by Tornos’ training resources, can empower employees to stay ahead of industry trends and enhance overall operational efficiency.

Strategic Material Selection Guide for tornos technologies us corporation

What Are the Key Materials for Precision Machining in Tornos Technologies?

In the realm of precision machining, particularly for Tornos Technologies US Corporation, selecting the right materials is crucial for ensuring optimal performance, durability, and compliance with international standards. Below is an analysis of four common materials used in manufacturing precision components, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Stainless Steel Perform in Precision Machining?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high tensile strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°C and can handle moderate pressure levels, making it suitable for various applications.

Pros & Cons: The durability of stainless steel is one of its strongest advantages, as it can endure harsh environments without degrading. However, it is relatively more expensive compared to other materials, and its machining complexity can lead to longer manufacturing times. This can impact overall production costs.

Impact on Application: Stainless steel is particularly effective in applications requiring high hygiene standards, such as medical and dental components. Its resistance to corrosion also makes it suitable for environments exposed to chemicals.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with ASTM standards, as stainless steel grades vary significantly. Familiarity with local regulations regarding material specifications is crucial.

What Role Does Aluminum Play in Tornos Technologies?

Key Properties: Aluminum is lightweight, has excellent thermal conductivity, and is resistant to corrosion. It typically performs well under temperatures up to 200°C and can withstand moderate pressures.

Pros & Cons: The primary advantage of aluminum is its low weight, which makes it ideal for applications where weight reduction is critical. However, it is less durable than stainless steel and may not perform well under high-stress conditions. Additionally, machining aluminum can be easier and faster, reducing manufacturing complexity.

Impact on Application: Aluminum is widely used in the automotive and aerospace industries, where weight savings can lead to improved fuel efficiency. It is also suitable for electronic components due to its thermal conductivity.

Considerations for International Buyers: Buyers should be aware of the common aluminum alloys used in their specific applications and ensure they meet international standards such as JIS or DIN.

How Does Brass Compare in Precision Machining?

Key Properties: Brass is known for its excellent machinability, corrosion resistance, and good thermal and electrical conductivity. It typically performs well under moderate temperatures and pressures.

Pros & Cons: The ease of machining brass makes it a favorite for producing intricate components. However, it is less durable than stainless steel and can be more expensive than aluminum. Additionally, brass is less suitable for high-temperature applications.

Impact on Application: Brass is often used in electrical components and fittings due to its conductivity and resistance to corrosion. It is also popular in decorative applications due to its aesthetic appeal.

Considerations for International Buyers: Compliance with industry standards is essential, especially for electrical components. Buyers should also consider the environmental regulations regarding brass, as it contains copper, which may have restrictions in certain regions.

What Advantages Does Carbon Steel Offer for Tornos Technologies?

Key Properties: Carbon steel is characterized by its high strength and hardness, making it suitable for heavy-duty applications. It can withstand high temperatures and pressures but is prone to corrosion without proper treatment.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and strength, making it ideal for structural applications. However, its susceptibility to rusting means that it often requires protective coatings, adding to manufacturing complexity.

Impact on Application: Carbon steel is commonly used in automotive applications and heavy machinery where strength is paramount. Its ability to be heat-treated enhances its performance in demanding environments.

Considerations for International Buyers: Buyers should ensure that the carbon steel grades they select comply with relevant standards such as ASTM. Understanding local market preferences for material specifications is also important.

Summary Table of Material Selection

| Material | Typical Use Case for Tornos Technologies US Corporation | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Medical and dental components | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Aluminum | Automotive and aerospace applications | Lightweight and good thermal conductivity | Less durable under stress | Medium |

| Brass | Electrical components and decorative applications | Excellent machinability and conductivity | Less durable and higher cost than aluminum | Medium |

| Carbon Steel | Heavy machinery and automotive applications | Cost-effective and high strength | Prone to corrosion without treatment | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for tornos technologies us corporation

What Are the Key Manufacturing Processes at Tornos Technologies US Corporation?

Tornos Technologies US Corporation employs a comprehensive manufacturing process to ensure precision and quality in its Swiss-type lathes and components. Understanding these processes is crucial for B2B buyers looking to evaluate the reliability and capability of their suppliers.

What Are the Main Stages of Manufacturing?

-

Material Preparation

– The manufacturing process begins with the careful selection of raw materials. Tornos prioritizes high-quality metals and alloys that meet stringent specifications for strength and durability.

– The materials undergo rigorous inspection upon arrival, ensuring they comply with international standards. This initial quality control (IQC) step is vital for maintaining the integrity of the final product. -

Forming

– Once the materials are verified, they enter the forming stage. Tornos utilizes advanced CNC machining techniques, including turning, milling, and drilling, to shape components with high precision.

– Technologies such as swarf removal and multi-spindle machining enhance efficiency and reduce cycle times, ensuring the production of complex geometries required by industries like aerospace, automotive, and medical. -

Assembly

– After forming, parts are assembled in a controlled environment to minimize contamination and defects. Skilled technicians use precise tools and methods to ensure that every component fits perfectly.

– Tornos emphasizes modularity in its designs, allowing for easy assembly and scalability depending on customer needs. This flexibility is particularly beneficial for international B2B buyers who may have varying production requirements. -

Finishing

– The finishing stage includes processes such as surface treatment, coating, and polishing to enhance the durability and aesthetic appeal of the products.

– Tornos employs techniques like heat treatment and electroplating, which not only improve the appearance but also extend the lifespan of components.

How Does Tornos Ensure Quality Assurance in Manufacturing?

Quality assurance (QA) is a cornerstone of Tornos’s operations, ensuring that all products meet both internal and external standards.

What International and Industry-Specific Standards Does Tornos Adhere To?

Tornos Technologies US Corporation operates under several internationally recognized quality standards, including:

- ISO 9001: This standard outlines criteria for a quality management system and is essential for organizations to consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in the European Economic Area, Tornos ensures compliance with safety, health, and environmental protection standards.

- API Standards: In the oil and gas sector, adherence to API standards is crucial for components used in exploration and production.

These certifications not only bolster Tornos’s credibility but also provide assurance to international buyers regarding the quality and safety of the products.

What Are the Key Quality Control Checkpoints?

-

Incoming Quality Control (IQC)

– The first line of defense in Tornos’s quality assurance process, IQC involves verifying that raw materials meet specifications before they enter production. -

In-Process Quality Control (IPQC)

– During manufacturing, IPQC checkpoints are established to monitor critical parameters and ensure that processes remain within acceptable limits. This includes regular inspections and measurements at various stages of production. -

Final Quality Control (FQC)

– Once products are completed, FQC involves comprehensive testing and inspection of finished goods. Tornos conducts dimensional checks, functional tests, and performance evaluations to guarantee compliance with quality standards.

What Common Testing Methods Are Used in Quality Assurance?

Tornos employs a variety of testing methods to ensure product quality, including:

- Dimensional Inspection: Utilizing precision measuring instruments to confirm that components meet specified dimensions.

- Functional Testing: Assessing the performance of products under simulated operational conditions to ensure they operate as intended.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic and magnetic particle testing are used to identify internal flaws without damaging the components.

These methods not only ensure compliance with quality standards but also enhance customer confidence in the reliability of Tornos’s products.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are some effective strategies:

-

Conducting Audits

– Buyers can schedule audits to inspect the manufacturing facilities and quality control processes in person. This provides an opportunity to assess compliance with industry standards and practices. -

Reviewing Quality Reports

– Tornos provides detailed quality assurance reports that outline testing methodologies, results, and certifications. Buyers should request these documents to evaluate the supplier’s commitment to quality. -

Engaging Third-Party Inspectors

– Employing third-party inspection services can provide an unbiased assessment of the supplier’s quality processes and products. This is particularly useful for buyers who are unable to visit the manufacturing site.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances when sourcing from Tornos Technologies US Corporation:

- Understanding Local Regulations: Buyers should be aware of local quality regulations and standards that may differ from international norms. Compliance with these regulations is crucial for smooth market entry.

- Cultural Considerations: Building trust with suppliers may require understanding cultural differences in business practices and communication styles.

- Logistics and Supply Chain Management: Quality control extends beyond manufacturing. Buyers should consider logistics and supply chain processes to ensure that products remain compliant during transport and storage.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when partnering with Tornos Technologies US Corporation, ensuring they receive high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tornos technologies us corporation’

In the ever-evolving landscape of precision manufacturing, sourcing the right machinery and technology is critical for businesses aiming to maintain competitive advantages. This guide serves as a practical checklist for B2B buyers looking to procure solutions from Tornos Technologies US Corporation, a leader in Swiss type lathes and precision components. By following these steps, you can ensure a well-informed procurement process that meets your operational needs.

Step 1: Define Your Technical Specifications

Before initiating contact with Tornos, clarify your technical requirements. This includes understanding the type of precision parts you need, the materials to be machined, and the expected production volume. Having a detailed specification helps Tornos provide tailored solutions that align with your manufacturing goals.

Step 2: Research Tornos Product Offerings

Explore the range of machines and technologies Tornos offers, from entry-level to advanced Swiss type lathes. Pay particular attention to innovations like the SwissNano, which provides high precision for various applications. Understanding the product lineup will help you identify the best fit for your specific applications, whether in the medical, automotive, or electronics sectors.

Step 3: Evaluate Supplier Certifications and Quality Standards

Verify that Tornos adheres to recognized industry standards and certifications. Look for compliance with ISO 9001 or other relevant quality management systems. This step is crucial as it ensures that you are partnering with a manufacturer committed to maintaining high-quality products that meet global standards.

Step 4: Assess Customer Support and Service Capabilities

Investigate the level of customer service and technical support offered by Tornos. Consider factors such as availability of field service engineers, training programs for your team, and responsiveness to inquiries. Reliable support is essential for minimizing downtime and ensuring that your operations run smoothly.

Step 5: Request Case Studies and Client References

Ask Tornos for case studies or references from clients within your industry. Understanding how Tornos solutions have performed in similar applications provides insights into their reliability and effectiveness. This information can help you gauge the potential return on investment and operational improvements you can expect.

Step 6: Inquire About After-Sales Support and Maintenance

Clarify what after-sales support and maintenance services Tornos offers. This includes warranty terms, availability of spare parts, and scheduled maintenance options. A strong after-sales service ensures that your machinery remains operational and efficient over its lifecycle.

Step 7: Negotiate Terms and Finalize the Agreement

Once you have gathered all necessary information, prepare to negotiate terms, including pricing, delivery timelines, and payment conditions. Having a clear understanding of your budget and expectations will facilitate a smoother negotiation process. Ensure that all agreements are documented to protect your interests.

By following this comprehensive checklist, you will be well-equipped to make informed decisions when sourcing from Tornos Technologies US Corporation, ultimately enhancing your manufacturing capabilities and operational efficiency.

Comprehensive Cost and Pricing Analysis for tornos technologies us corporation Sourcing

What Are the Key Cost Components in Sourcing from Tornos Technologies US Corporation?

When considering sourcing from Tornos Technologies US Corporation, buyers should be aware of several cost components that contribute to the overall price of Swiss-type lathes and other machinery. These include:

-

Materials: The cost of high-quality materials is a significant factor in manufacturing precision machinery. Tornos emphasizes the use of premium materials to ensure durability and performance, which may result in higher upfront costs but ultimately leads to greater reliability.

-

Labor: Skilled labor is essential for the production of complex machinery. Tornos invests in training its workforce to maintain high standards of quality and efficiency, which can influence labor costs.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as facility maintenance and utilities. Tornos’s advanced manufacturing facilities are designed to optimize productivity, which can impact overall pricing.

-

Tooling: Specialized tooling is often required for precision machining. Tornos’s commitment to innovation may lead to higher tooling costs, but this investment typically results in superior product quality.

-

Quality Control (QC): Rigorous quality control processes ensure that each machine meets Tornos’s high standards. The costs associated with QC are vital in maintaining the brand’s reputation for excellence.

-

Logistics: Shipping and transportation costs can vary significantly based on the destination. For international buyers, understanding the logistics involved in importing machinery from the U.S. is crucial.

-

Margin: Tornos aims to provide exceptional value, which is reflected in its pricing strategy. The company balances competitive pricing with the need to sustain quality and service.

How Do Price Influencers Impact Sourcing Decisions for Tornos Technologies?

Several factors can influence the pricing of machinery from Tornos Technologies, which potential buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Pricing can vary based on the order size. Larger orders may qualify for discounts, making it essential to evaluate purchasing strategies.

-

Specifications and Customization: Custom machinery designed to meet specific requirements often incurs additional costs. Buyers should clearly communicate their needs to receive accurate quotes.

-

Materials: The choice of materials can significantly affect pricing. High-performance materials may be more expensive but offer long-term savings through enhanced durability.

-

Quality and Certifications: Tornos’s adherence to international quality standards can impact pricing. Buyers should consider the value of certifications and quality assurance in their purchasing decisions.

-

Supplier Factors: The reputation and reliability of Tornos as a supplier can influence pricing. Established suppliers often command higher prices due to their track record of delivering quality products.

-

Incoterms: Understanding the terms of shipping and delivery is crucial for international transactions. Different Incoterms can affect the total cost, including duties and insurance.

What Are the Best Negotiation Tips for International Buyers Sourcing from Tornos Technologies?

International buyers from regions such as Africa, South America, the Middle East, and Europe should consider the following negotiation strategies:

-

Focus on Total Cost of Ownership (TCO): Rather than solely negotiating the purchase price, consider the TCO, including maintenance, operational costs, and potential downtime. This broader perspective can lead to more informed purchasing decisions.

-

Leverage Volume Discounts: If feasible, consolidate orders to meet or exceed MOQs. This strategy can open up opportunities for bulk discounts, lowering the per-unit cost.

-

Explore Customization Options: Engage in discussions about potential customizations that may provide better value without significantly increasing costs. Tailored solutions often enhance performance and efficiency.

-

Build Relationships: Establishing a rapport with Tornos representatives can facilitate more favorable terms and pricing. Long-term partnerships often yield better support and service.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of currency fluctuations, import duties, and local taxes that can impact the final cost.

Disclaimer on Indicative Prices

Pricing for Tornos Technologies’ products can fluctuate based on various factors, including market conditions and specific project requirements. Therefore, it’s advisable to consult directly with Tornos for the most accurate and current pricing information tailored to your sourcing needs.

Alternatives Analysis: Comparing tornos technologies us corporation With Other Solutions

Understanding Alternatives in Precision Manufacturing Solutions

In the competitive landscape of precision manufacturing, it’s essential for B2B buyers to explore various options beyond a single supplier. By analyzing alternatives, companies can make informed decisions that align with their operational goals, budget constraints, and specific industry requirements. This section compares Tornos Technologies US Corporation with two notable alternatives: Citizen Machinery and Haas Automation.

| Comparison Aspect | Tornos Technologies US Corporation | Citizen Machinery | Haas Automation |

|---|---|---|---|

| Performance | High precision; specializes in Swiss type lathes; versatile for various industries. | Excellent precision; known for advanced CNC technology; strong in medical and automotive sectors. | Robust performance; offers a range of CNC machines suitable for high-volume production. |

| Cost | Moderate to high; premium quality justifies price. | Generally higher due to advanced technology and precision capabilities. | Competitive pricing; offers good value for performance. |

| Ease of Implementation | Requires skilled operators; training programs available for smooth transition. | Steeper learning curve; extensive training may be necessary. | User-friendly interface; easier for teams to adapt quickly. |

| Maintenance | Regular maintenance support; field engineers available. | Requires specialized knowledge for maintenance; support may vary by region. | Strong support network; accessible spare parts and service options. |

| Best Use Case | Ideal for industries needing high precision like medical, dental, and aerospace. | Best for high-precision applications in complex parts manufacturing. | Suitable for high-volume production across diverse industries, including automotive and machining. |

In-Depth Look at Alternative Solutions

Citizen Machinery

Citizen Machinery is a leader in precision CNC technology, especially recognized for its advanced features that cater to complex machining needs. Its machines are engineered for high precision, making them ideal for industries like medical and automotive. The primary drawback is the higher cost associated with acquiring and maintaining Citizen machines, which can be a barrier for smaller firms. Additionally, the learning curve can be steep, requiring extensive training for operators to utilize the advanced features effectively.

Haas Automation

Haas Automation offers a wide range of CNC machines that are highly regarded for their reliability and performance. Their machines are designed for high-volume production and are known for being user-friendly, which can significantly reduce the time required for operator training. While Haas products are competitively priced, they may not deliver the same level of precision as Tornos or Citizen, particularly in specialized applications. However, their strong support network and availability of spare parts make them a practical choice for businesses that prioritize operational efficiency and cost-effectiveness.

Conclusion: How to Choose the Right Solution for Precision Manufacturing Needs

Selecting the right precision manufacturing solution requires a thorough understanding of your specific operational needs, budget, and the complexities of your production environment. Tornos Technologies US Corporation excels in delivering high precision, particularly for specialized industries, while Citizen Machinery stands out for advanced CNC capabilities, albeit at a higher cost. Conversely, Haas Automation provides a balance of performance and affordability, making it suitable for high-volume applications. By weighing the pros and cons of each option, B2B buyers can align their choice with their long-term manufacturing goals, ensuring they invest in a solution that not only meets their immediate needs but also supports future growth and innovation.

Essential Technical Properties and Trade Terminology for tornos technologies us corporation

What Are the Key Technical Properties of Tornos Technologies’ Swiss Type Lathes?

When engaging with Tornos Technologies US Corporation, understanding the technical specifications of their Swiss type lathes is crucial for making informed purchasing decisions. Here are some critical properties to consider:

-

Material Grade

The material grade of the machine components, often classified by standards like ASTM or ISO, determines the durability and performance of the lathe. High-grade materials can withstand higher stress and wear, ensuring longevity and reliability in production. This is particularly important for industries such as aerospace and automotive, where component failure can have severe consequences. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of a part. For example, a tolerance of ±0.01 mm indicates that the actual measurement can deviate from the specified dimension by one hundredth of a millimeter. In precision manufacturing, tighter tolerances are essential, especially in sectors like medical devices, where even minor discrepancies can lead to product failures or safety issues. -

Spindle Speed

This specification indicates the maximum speed at which the spindle can rotate, typically measured in revolutions per minute (RPM). Higher spindle speeds can lead to faster production rates and improved surface finishes, making them vital for high-volume manufacturing applications. B2B buyers should assess spindle speed in relation to the materials they plan to machine to optimize efficiency. -

Bar Capacity

Bar capacity indicates the maximum diameter and length of the material that can be fed into the lathe. For instance, Tornos’ SwissNano can handle bar diameters up to 7 mm. Understanding bar capacity helps manufacturers select machines that can accommodate their specific production needs without causing bottlenecks. -

Tooling Options

Tooling options, which include the number and types of tools that can be mounted on the machine, are critical for versatility in machining operations. For instance, Tornos lathes might offer a variety of standard and specialized tools for operations such as threading, drilling, and milling. A diverse tooling capacity allows manufacturers to perform multiple operations in a single setup, reducing downtime and improving productivity. -

Thermal Stability

Thermal stability refers to the machine’s ability to maintain precise dimensions under varying temperature conditions. Machines with high thermal stability are less likely to experience dimensional changes due to heat generated during machining. This is particularly important in high-precision applications where thermal expansion can lead to significant inaccuracies.

What Trade Terms Should Buyers Know When Working with Tornos Technologies?

Understanding industry jargon can significantly enhance communication and negotiation with Tornos Technologies. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For Tornos, being an OEM means they provide high-quality, precision machinery that meets the specific needs of various industries, allowing B2B buyers to source reliable equipment for their production lines. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum quantity of a product that a supplier is willing to sell. For buyers, understanding the MOQ helps in budgeting and inventory management. Tornos may have MOQs for specific machine models or parts, which can impact purchasing decisions, especially for smaller manufacturers. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. When considering Tornos’ machinery, an RFQ can help clarify pricing, delivery times, and terms of service, enabling buyers to compare offers from different suppliers effectively. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and responsibilities, which is crucial when importing machinery from Tornos. -

Lead Time

Lead time refers to the time taken from the placement of an order until the product is delivered. For B2B buyers, understanding lead times is essential for planning production schedules and inventory levels, especially in industries that require just-in-time manufacturing. -

Warranty

A warranty is a guarantee from the manufacturer regarding the condition of the product and the commitment to repair or replace defective parts. For buyers of Tornos machinery, knowing the warranty terms is crucial for assessing long-term investment security and minimizing operational risks.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can navigate their purchasing journey with Tornos Technologies more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the tornos technologies us corporation Sector

What Are the Key Market Dynamics and Trends Affecting Tornos Technologies US Corporation?

The global manufacturing landscape is rapidly evolving, driven by technological advancements and shifting buyer preferences. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. Key trends include the rise of automation and smart manufacturing, which enhance efficiency and reduce operational costs. Tornos Technologies US Corporation, as a leader in precision machinery, aligns with these trends by offering advanced Swiss-type lathes that cater to industries such as medical, automotive, and aerospace.

Emerging markets, particularly in Africa and South America, are witnessing a surge in demand for high-quality precision components. This demand is fueled by industrialization efforts and a growing middle class that seeks reliable products. Tornos’s focus on providing customized solutions allows it to tap into these markets effectively. Additionally, sustainability is becoming increasingly important, with buyers preferring suppliers that prioritize eco-friendly practices. Tornos’s commitment to innovation ensures they remain competitive by integrating sustainable practices into their operations, such as energy-efficient machinery and waste reduction strategies.

How Is Sustainability and Ethical Sourcing Addressed by Tornos Technologies US Corporation?

In today’s B2B environment, sustainability and ethical sourcing are paramount for both manufacturers and their clients. Tornos Technologies US Corporation recognizes the environmental impact of its operations and aims to mitigate it through responsible practices. This includes sourcing materials from suppliers that adhere to environmental standards and implementing recycling processes within their production facilities.

Furthermore, ethical supply chains are becoming a focal point for buyers, particularly in regions like Europe and the Middle East, where regulatory frameworks demand transparency and accountability. Tornos is actively pursuing certifications that demonstrate its commitment to sustainable practices, such as ISO 14001 for environmental management. These certifications not only enhance the company’s reputation but also provide international buyers with the assurance that they are partnering with a responsible supplier. As global awareness of environmental issues rises, Tornos’s proactive stance on sustainability will likely resonate well with B2B buyers seeking long-term partnerships based on shared values.

What Is the Historical Context of Tornos Technologies US Corporation Relevant to B2B Buyers?

Tornos Technologies US Corporation has a rich history that dates back to its establishment in 1959, marking over six decades of excellence in precision manufacturing. Originally founded in Switzerland, the company expanded its operations to the United States to better serve the North American market. This strategic move allowed Tornos to leverage the region’s advanced manufacturing ecosystem while providing localized support to its clients.

The company has continually evolved, introducing innovative products like the SwissNano, which has set new benchmarks for precision in small part machining. This commitment to innovation and customer service has solidified Tornos’s position as a trusted partner for international B2B buyers, making it a key player in the global manufacturing supply chain. As Tornos continues to expand its capabilities and adapt to market demands, its historical foundation in quality and precision will remain a significant asset for potential partners looking to enhance their manufacturing processes.

Frequently Asked Questions (FAQs) for B2B Buyers of tornos technologies us corporation

-

How do I solve issues with CNC machine maintenance?

To resolve CNC machine maintenance issues, engage Tornos’ field service engineers who provide on-site support. They not only perform necessary maintenance but also offer training to your operators, ensuring they understand how to keep the machines running smoothly. Regular maintenance schedules and proactive checks can prevent unexpected downtime. Additionally, utilizing Tornos’ customer support can help troubleshoot specific problems quickly, minimizing disruptions to your production processes. -

What is the best Swiss-type lathe for precision machining?

The Tornos SwissNano is highly regarded for precision machining, especially in the medical, dental, and electronics sectors. It offers exceptional ergonomics and a compact design while allowing for a range of operations, including turning, drilling, and finishing. Its unique kinematics and increased capacity make it suitable for both small and larger diameter parts, ensuring it meets diverse machining needs efficiently. Evaluating your specific production requirements will help determine if this model aligns with your operational goals. -

What are the minimum order quantities (MOQ) for Tornos products?

Tornos typically operates with flexible MOQ policies tailored to customer needs, often depending on the specific machine or component being ordered. For custom solutions or specialized equipment, discussing your project details with a Tornos sales representative can clarify minimum requirements. This flexibility enables businesses of various sizes, including startups and larger manufacturers, to access high-quality precision machinery without excessive initial investment. -

How can I ensure the quality of Tornos products before purchasing?

To verify the quality of Tornos products, consider visiting their state-of-the-art customer center in Chicago, where you can see the machinery in action. Additionally, request product demonstrations and case studies from Tornos that showcase successful implementations in your industry. Engaging with existing customers and reading reviews can also provide insights into the performance and reliability of Tornos machines, ensuring you make an informed purchasing decision. -

What payment terms does Tornos offer for international buyers?

Tornos offers flexible payment terms that can accommodate international buyers, including options for wire transfers, letters of credit, or payment upon delivery. It’s best to discuss specific terms directly with your Tornos sales representative, as they can tailor arrangements to suit your financial capabilities and project timelines. Understanding the payment structure early on can facilitate smoother transactions and help in budgeting for your equipment investments. -

How does Tornos support international shipping and logistics?

Tornos has established logistics processes to support international shipping, ensuring timely delivery of machinery and components. Their customer service team can assist with customs documentation and provide updates on shipping status. Additionally, partnering with reliable freight forwarders can help navigate import regulations and ensure your equipment arrives safely and on schedule. Early communication about your location and needs will help Tornos facilitate a seamless logistics experience. -

Can Tornos customize machines to fit specific industry requirements?

Yes, Tornos specializes in customizing machines to meet specific industry requirements, whether for medical, automotive, or aerospace applications. Their engineering team works closely with clients to understand unique machining needs and develop tailored solutions. This customization can include modifications to existing models or the development of entirely new machines, ensuring that you receive equipment that perfectly aligns with your production goals. -

What is Tornos’ approach to customer service and support?

Tornos prioritizes exceptional customer service by offering dedicated support through their experienced engineers and regional managers. They provide both in-house and on-site training sessions to ensure that your team is well-equipped to operate and maintain the machinery. Their commitment to customer satisfaction includes proactive communication and responsive troubleshooting assistance, ensuring that your operations run smoothly and efficiently, enhancing your overall experience with Tornos.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Tornos Technologies Us Corporation Manufacturers & Suppliers List

1. Tornos – Swiss-type Lathes

Domain: tornos.com

Registered: 2000 (25 years)

Introduction: Tornos specializes in Swiss-type lathes, offering a range of products including SwissDECO, EvoDECO, DECO 10 Plus, Swiss XT, Swiss GT, SwissNano, Swiss DT, Swiss DT 7 & Swiss DT 10, and Multispindle MultiSwiss. Additional products include SAS 16 Plus and BA 1008 XT/HP. The company provides various technologies and peripherals such as automation solutions, bar feeders, and software like TISIS, Activ…

2. Tornos Technologies – Swiss Machine Tools

Domain: productionmachining.com

Registered: 1997 (28 years)

Introduction: This company, Tornos Technologies – Swiss Machine Tools, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Tornos Group – Swiss-Type Automatic Lathes

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Tornos Group – Swiss-Type Automatic Lathes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Tornos Technologies – Swiss Type Automatic Screw Machines

Domain: machinetools.com

Registered: 1995 (30 years)

Introduction: Tornos Technologies U.S. Corporation specializes in new machinery, particularly in the small parts turning industry. Key product types include Magazine Type Bar Loaders, Multiple Spindle Automatic Screw Machines, and Swiss Type Automatic Screw Machines. The company is known for its DECO 2000 concept, which offers innovative solutions and high performance.

5. IMTS – Precision Machining Solutions

Domain: directory.imts.com

Registered: 1996 (29 years)

Introduction: Gear Hobbing Machines, Deep Hole Drilling Machines (Gundrilling), Multi-Spindle Cam-Type Screw Machines, Multi-Spindle CNC Screw Machines, Single-Spindle Cam-Type Screw Machines, Single-Spindle CNC Screw Machines, Swiss Cam-Type Screw Machines, Swiss CNC Screw Machines, Thread Cutting Machines, Thread Rolling Machines, Pipe and Bar Threading and Cut-Off Machines, CNC Turn/Mill Machines

6. Tornos Technologies – DECO 8sp Multi-Axis Machine

Domain: newequipment.com

Registered: 1996 (29 years)

Introduction: Tornos Technologies US Corp offers a range of machine tools and metalworking technologies, including the DECO 8sp single-spindle Swiss-type multi-axis, multi-function machine and the DECO 20s Swiss-type turning center. The DECO 8sp provides 1 micron precision and is designed for North American markets. The DECO 20s is targeted at companies producing moderately complex parts up to 20 mm in diameter…

7. Tornos Technologies – Key Models

Domain: techspex.com

Registered: 1995 (30 years)

Introduction: Models Offered by Tornos Technologies U.S. Corporation: 1. BA 1008 – Horizontal, 7 axes 2. BA 1008 HP – Horizontal, 6 axes 3. BA 1008 XT – Horizontal, 7 axes 4. CU 1007 – Vertical, 3 axes, Max HP: 4.00, Top RPM: 30,000, Max X Travel: 11.020, Max Y Travel: 4.720, Max Z Travel: 8.710 5. CU 2007 – Vertical, 3 axes, Max HP: 4.90, Top RPM: 12,000, Max X Travel: 19.700, Max Y Travel: 15.700, Max Z Trave…

8. Tornos Technologies – Bar Feed Mechanisms

Domain: mmsonline.com

Registered: 1997 (28 years)

Introduction: This company, Tornos Technologies – Bar Feed Mechanisms, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for tornos technologies us corporation

In today’s competitive landscape, strategic sourcing from Tornos Technologies US Corporation offers significant advantages for international B2B buyers seeking precision manufacturing solutions. With a proven track record in producing Swiss type lathes, Tornos stands out for its commitment to quality across diverse sectors such as medical, automotive, and aerospace. The company’s robust support system, including on-site training and maintenance services, ensures that clients can maximize the value of their investments while enhancing operational efficiency.

Tornos’ innovative product offerings, such as the advanced SwissNano and modular Swiss DT series, demonstrate their dedication to meeting evolving market needs. By leveraging these cutting-edge technologies, businesses can achieve superior machining capabilities while staying ahead of industry trends.

As you consider sourcing precision machinery, Tornos Technologies US Corporation is well-positioned to be your partner in success. By choosing Tornos, you are not just investing in high-quality equipment but also gaining access to unparalleled customer support and expertise. Engage with Tornos today to explore how their solutions can empower your business and drive growth in the dynamic markets of Africa, South America, the Middle East, and Europe. Together, let’s turn precision into progress.