Introduction: Navigating the Global Market for torlon 5030

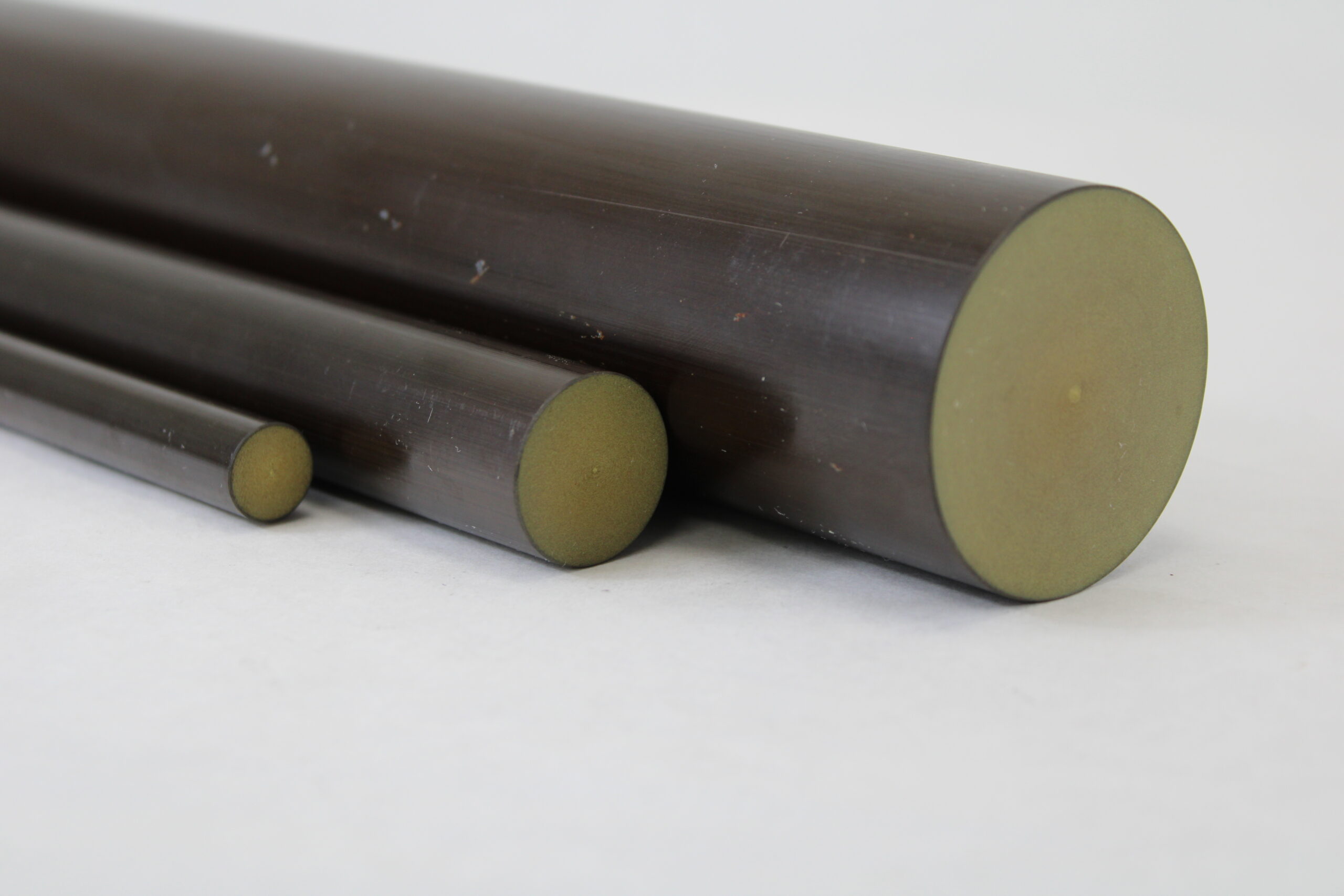

In the quest for high-performance materials, sourcing Torlon 5030 poses a significant challenge for international B2B buyers. This advanced polyamide-imide, reinforced with 30% glass fibers, is renowned for its superior strength, stiffness, and exceptional resistance to wear and creep, making it an ideal choice for demanding applications in various industries. However, understanding the nuances of this material—from its applications in thermal and electrical insulation to its compliance with international standards—can be daunting.

This comprehensive guide is designed to empower B2B buyers by providing in-depth insights into Torlon 5030. We will explore the various types and forms available in the market, including plates, rods, and seamless tubes, while outlining their specific applications. Additionally, we will delve into critical considerations for supplier vetting, ensuring that you partner with reputable manufacturers who meet quality and compliance standards. Cost factors will also be examined, helping you navigate pricing structures across different regions, including Africa, South America, the Middle East, and Europe.

By equipping you with actionable knowledge and strategies for informed decision-making, this guide aims to streamline your procurement process and enhance your competitive advantage in the global marketplace. Whether you are in the aerospace, automotive, or energy sectors, understanding the benefits and applications of Torlon 5030 will enable you to make strategic investments that drive innovation and efficiency in your operations.

Understanding torlon 5030 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Torlon 5030 | 30% glass-fiber reinforcement; high strength and modulus; excellent thermal stability | High-temperature insulators; fasteners; activation balls | Pros: Exceptional creep resistance; low thermal expansion. Cons: Higher cost compared to non-reinforced alternatives. |

| Torlon 5030 HF | High flow variant; enhanced processing properties; similar mechanical properties to standard 5030 | Injection molded components; complex geometries | Pros: Better mold release; suitable for intricate designs. Cons: May not be as readily available in all markets. |

| Torlon 5030 FR | Flame-retardant properties; high hardness; chemical resistance | Aerospace components; automotive parts | Pros: Enhanced safety in flammable environments; excellent durability. Cons: Limited applications due to specialized nature. |

| Torlon 5030-LT | Low-temperature variant; maintains properties at lower temperatures | Cryogenic applications; thermal insulation | Pros: Retains mechanical integrity in extreme conditions. Cons: May have limited availability and higher cost. |

| Torlon 5030-GF | Glass fiber-reinforced; improved mechanical properties | Structural parts; electrical insulators | Pros: High strength and stiffness; excellent wear resistance. Cons: Heavier than non-reinforced polymers, affecting design choices. |

What are the Characteristics of Standard Torlon 5030?

Torlon 5030 is a high-performance polyamide-imide (PAI) characterized by its 30% glass-fiber reinforcement, which significantly enhances its strength and stiffness. It exhibits exceptional creep resistance and thermal stability, making it suitable for applications requiring high mechanical integrity at elevated temperatures. Buyers should consider its lower coefficient of linear thermal expansion (CLTE) similar to aluminum, which ensures dimensional stability in various environments. However, the higher cost compared to non-reinforced polymers may be a consideration for budget-sensitive projects.

How Does Torlon 5030 HF Enhance Processing?

The Torlon 5030 HF variant is tailored for applications requiring improved flow characteristics during processing. This high-flow formulation facilitates the creation of intricate designs through injection molding, making it ideal for complex geometries often found in electronic components and automotive parts. Its mechanical properties mirror those of standard Torlon 5030, ensuring reliability in demanding conditions. Buyers should evaluate the availability of this variant in their region, as it may not be as widely stocked as the standard grade.

Why Choose Torlon 5030 FR for Safety?

Torlon 5030 FR is designed with flame-retardant properties, making it a critical choice for industries such as aerospace and automotive, where safety is paramount. Its high hardness and chemical resistance ensure that it can withstand harsh environments, providing longevity and reliability in safety-critical applications. However, due to its specialized nature, this variant may have limited applications, and buyers should assess whether the additional safety features justify the potential increase in cost.

What Makes Torlon 5030-LT Ideal for Cryogenic Applications?

The low-temperature variant, Torlon 5030-LT, is engineered to maintain its mechanical properties even in cryogenic environments, making it suitable for applications such as thermal insulation in space exploration and scientific research. This variant ensures that parts retain their integrity under extreme conditions, which is essential for reliability in critical applications. Buyers should note that while it offers unique advantages, it may come at a premium price and could have limited availability.

How Does Torlon 5030-GF Improve Structural Integrity?

Torlon 5030-GF incorporates glass fiber reinforcement, enhancing its mechanical properties for applications requiring high strength and wear resistance. This makes it a preferred material for structural components and electrical insulators, where durability is essential. While its improved performance is a significant advantage, buyers should consider the trade-off of increased weight compared to non-reinforced polymers, which may affect design decisions in weight-sensitive applications.

Key Industrial Applications of torlon 5030

| Industry/Sector | Specific Application of torlon 5030 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Thermal and electrical insulators | Ensures reliable performance under extreme conditions | Certifications (e.g., AMS, ASTM) and quality assurance |

| Automotive | High-stress fasteners and connectors | Reduces weight while maintaining structural integrity | Compliance with automotive standards and testing protocols |

| Oil & Gas | Valve seats and activation balls | Enhances durability and reduces maintenance costs | Resistance to harsh chemicals and extreme temperatures |

| Electronics | Test sockets for integrated circuits (ICs) | Improves reliability and longevity of electronic components | Precision in dimensions and thermal stability |

| Energy (Renewable) | Components for wind turbine nacelles | Offers lightweight yet strong alternatives to metals | Availability and lead times for large-scale projects |

How is torlon 5030 Used in Aerospace Applications?

In the aerospace industry, torlon 5030 serves as a high-performance material for thermal and electrical insulators. Its ability to withstand extreme temperatures, combined with its low coefficient of thermal expansion (CTE) similar to aluminum, makes it ideal for applications where weight and reliability are critical. International buyers should prioritize suppliers who provide materials with the necessary certifications, such as AMS and ASTM, to ensure compliance with stringent aerospace standards.

What Role Does torlon 5030 Play in Automotive Fasteners?

Torlon 5030 is increasingly utilized in high-stress automotive fasteners and connectors, providing significant weight savings without compromising strength. This thermoplastic polymer’s exceptional creep resistance ensures that fasteners maintain integrity under high loads and temperatures. Buyers in the automotive sector should focus on sourcing from manufacturers that adhere to industry standards and can offer rigorous testing results to validate performance claims.

Why is torlon 5030 Essential for Oil & Gas Applications?

In the oil and gas sector, torlon 5030 is employed in valve seats and activation balls due to its superior chemical resistance and durability in harsh environments. The material’s ability to withstand extreme temperatures while maintaining structural integrity leads to lower maintenance costs and extended service life. Buyers should consider the material’s compatibility with specific chemicals and temperature ranges to ensure optimal performance in their applications.

How is torlon 5030 Beneficial in Electronics?

Torlon 5030 is a preferred choice for test sockets in integrated circuit (IC) applications, where its excellent electrical insulating properties enhance the reliability of electronic components. The high modulus and strength of torlon 5030 contribute to the longevity of these sockets, reducing the frequency of replacements. Buyers should ensure that the sourcing partners provide precise dimensions and maintain thermal stability to meet the evolving demands of the electronics market.

In What Ways Does torlon 5030 Support Renewable Energy?

In renewable energy, particularly in wind turbine nacelles, torlon 5030 is used to manufacture lightweight yet strong components. Its high strength-to-weight ratio allows for more efficient designs while ensuring durability against environmental factors. Buyers in this sector should consider lead times and availability of torlon 5030, especially for large-scale projects, to avoid delays in production and installation.

3 Common User Pain Points for ‘torlon 5030’ & Their Solutions

Scenario 1: Ensuring Optimal Performance in High-Temperature Applications

The Problem: B2B buyers in industries such as aerospace and automotive often face the challenge of selecting materials that can withstand extreme temperatures without compromising performance. For instance, manufacturers working on components that operate in environments exceeding 300°F struggle to find materials that maintain their structural integrity while also providing excellent electrical insulation properties. The risk of material failure can lead to costly downtimes and safety hazards, making it imperative to choose the right polymer.

The Solution: To overcome these challenges, buyers should consider sourcing Torlon 5030 due to its exceptional thermal stability and high modulus properties. When specifying Torlon 5030, it is crucial to consult detailed material data sheets to ensure compatibility with specific temperature ranges and mechanical stress scenarios. Engaging with suppliers who can provide samples for testing in real-world applications is also beneficial. This hands-on approach allows for the assessment of how Torlon 5030 behaves under operational conditions, thus enabling buyers to make informed decisions that enhance performance while minimizing the risk of failure.

Scenario 2: Managing Production Costs While Maintaining Quality

The Problem: In regions like Africa and South America, where production costs can significantly impact profit margins, manufacturers are often caught between the need to maintain high-quality standards and the desire to reduce expenses. The challenge lies in sourcing materials that are both cost-effective and capable of meeting stringent industry specifications, especially for components like electrical insulators and fasteners.

The Solution: To address this issue, buyers should adopt a strategic sourcing approach by leveraging the long-term durability and performance characteristics of Torlon 5030. While the upfront cost may be higher than lower-grade alternatives, the material’s superior wear resistance and lower coefficient of thermal expansion (CLTE) can lead to reduced maintenance costs and extended service life. Buyers should also consider bulk purchasing agreements or long-term contracts with suppliers to negotiate better pricing. Additionally, engaging in a thorough cost-benefit analysis that includes potential savings from reduced failures and maintenance can further justify the investment in Torlon 5030.

Scenario 3: Navigating Compliance and Regulatory Challenges

The Problem: B2B buyers in the manufacturing sector often encounter complex compliance and regulatory hurdles, particularly when dealing with materials for high-performance applications. Ensuring that the chosen materials meet industry standards—such as ASTM and military specifications—can be daunting, especially in regions with diverse regulatory landscapes.

The Solution: To navigate these challenges effectively, it is essential for buyers to partner with suppliers who have a proven track record in compliance. When selecting Torlon 5030, buyers should confirm that their supplier can provide documentation and certifications for all relevant standards, such as ASTM 5204 and AMS 3670/4. Additionally, investing time in training and resources to understand the specific compliance requirements for their industry can empower buyers to make more informed decisions. Regular audits and updates from suppliers about any changes in material specifications can also help maintain compliance, thereby reducing the risk of costly penalties or product recalls.

Strategic Material Selection Guide for torlon 5030

What are the Key Properties of Torlon 5030 Compared to Other Materials?

Torlon 5030 is a high-performance polyamide-imide (PAI) known for its exceptional strength and thermal stability, making it suitable for demanding applications. When comparing it to other materials commonly used in similar applications, such as PEEK, polyimide, and nylon, several key properties emerge that are relevant for B2B buyers.

How Does PEEK Compare to Torlon 5030?

PEEK (Polyetheretherketone) is another high-performance thermoplastic that offers excellent mechanical properties and thermal resistance. It can withstand temperatures up to 260°C (500°F) and is known for its chemical resistance.

- Pros: PEEK is highly durable and has excellent wear resistance. It is also FDA compliant, making it suitable for food and medical applications.

- Cons: The cost of PEEK is generally higher than that of Torlon 5030, which may be a consideration for budget-sensitive projects. Additionally, PEEK is more challenging to machine due to its toughness.

- Impact on Application: PEEK is ideal for applications requiring high chemical resistance but may not provide the same dimensional stability as Torlon 5030 under thermal stress.

What About Polyimide?

Polyimide is a thermosetting polymer known for its high thermal stability and electrical insulation properties, often used in aerospace and electronics.

- Pros: Polyimide can operate at temperatures above 300°C (572°F) and has excellent dielectric properties.

- Cons: It is generally more brittle than Torlon 5030, which could lead to failure under mechanical stress. Additionally, processing polyimide can be complex and costly.

- Impact on Application: While polyimide is suitable for high-temperature applications, its brittleness limits its use in structural components where flexibility is needed.

How Does Nylon Compare?

Nylon is a widely used thermoplastic known for its versatility and ease of processing.

- Pros: It is cost-effective, easy to machine, and offers good mechanical properties.

- Cons: Nylon has a lower thermal resistance compared to Torlon 5030 and is susceptible to moisture absorption, which can affect its dimensional stability.

- Impact on Application: Nylon is suitable for general-purpose applications but may not perform well in high-temperature or chemically aggressive environments.

What Should International B2B Buyers Consider?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, compliance with regional standards is critical. Torlon 5030 meets various specifications such as ASTM and MIL standards, making it a reliable choice for industries requiring certification. Buyers should also consider local availability, as some materials may not be readily accessible in certain regions, impacting lead times and costs.

Summary Table of Material Comparisons

| Material | Typical Use Case for torlon 5030 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PEEK | Aerospace components, medical devices | Excellent chemical resistance | Higher cost, challenging to machine | High |

| Polyimide | Aerospace, electronics | High thermal stability | Brittle, complex processing | Med |

| Nylon | General-purpose applications, consumer goods | Cost-effective, easy to machine | Lower thermal resistance, moisture absorption | Low |

| Torlon 5030 | High-temperature insulators, structural parts | Exceptional strength and thermal stability | Limited availability in some regions | Med |

This detailed analysis provides a comprehensive overview of Torlon 5030 and its comparative materials, enabling B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for torlon 5030

What Are the Key Manufacturing Processes for Torlon 5030?

Torlon 5030 is produced through a meticulously controlled manufacturing process that ensures its exceptional performance characteristics. Understanding these processes can help B2B buyers evaluate suppliers and the quality of the products they offer.

What Are the Main Stages of Torlon 5030 Manufacturing?

-

Material Preparation:

The manufacturing process begins with the selection and preparation of raw materials. Torlon 5030 is a polyamide-imide (PAI) resin reinforced with 30% glass fibers. The glass fibers are processed to achieve the desired length and aspect ratio, which is crucial for enhancing the mechanical properties of the final product. The resin is also compounded to ensure uniform distribution of the glass fibers. -

Forming:

The prepared materials undergo various forming techniques, primarily through injection molding or compression molding. In injection molding, the glass-fiber-reinforced resin is heated until it flows easily and is then injected into molds to form the desired shapes. Compression molding involves placing the material into a heated mold, which is then closed to compress the material and shape it. Both methods ensure that the final product achieves the necessary dimensional stability and strength. -

Assembly:

In applications where multiple components are used, the assembly stage involves combining various molded parts. This stage may include the use of adhesives or mechanical fasteners, depending on the design requirements. It is essential that the assembly process maintains the integrity of the material properties, particularly for high-stress applications. -

Finishing:

The final stage involves finishing processes that enhance the surface quality and performance of Torlon 5030 products. This may include machining to achieve precise dimensions, surface treatment to improve wear resistance, or coating for additional protection against environmental factors. The finishing stage is critical for ensuring that the products meet the stringent specifications required in various industries.

How Is Quality Assurance Implemented in Torlon 5030 Production?

Quality assurance is a cornerstone of the manufacturing process for Torlon 5030, ensuring that the final products meet international standards and customer expectations.

What Are the Relevant International Standards for Quality Control?

Torlon 5030 manufacturing adheres to several international quality standards, such as ISO 9001, which provides a framework for effective quality management systems. Additionally, industry-specific standards may apply, including:

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards.

- API Standards: Relevant for applications in the oil and gas industry, ensuring that materials can withstand the specific demands of this sector.

What Are the Key Quality Control Checkpoints?

-

Incoming Quality Control (IQC):

This initial checkpoint involves inspecting raw materials upon delivery. Suppliers are evaluated based on their compliance with material specifications, including the quality of the glass fibers and the resin. Any discrepancies at this stage can lead to significant issues later in the production process. -

In-Process Quality Control (IPQC):

During the manufacturing process, continuous monitoring is conducted to ensure that all parameters remain within specified limits. This includes temperature control during molding, pressure levels, and material flow rates. Regular sampling and testing of the products during this stage help identify any deviations in real-time. -

Final Quality Control (FQC):

The final inspection involves comprehensive testing of the finished products. This typically includes mechanical testing for strength, thermal analysis to assess thermal stability, and dimensional checks to ensure adherence to specifications. Certifications and compliance documents are generated during this phase, providing traceability and accountability.

What Testing Methods Are Commonly Used for Torlon 5030?

Several testing methods are employed to verify the performance characteristics of Torlon 5030. Common tests include:

- Tensile Strength Testing: Determines the material’s strength under tension, which is crucial for structural applications.

- Thermal Conductivity Testing: Assesses the thermal management capabilities of the material, especially important for electrical insulators.

- Flammability Testing: Evaluates the material’s resistance to combustion, ensuring compliance with safety regulations.

- Dimensional Stability Testing: Measures the material’s ability to maintain its shape under varying temperature and humidity conditions.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high standards of quality control, B2B buyers can take several steps:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing processes and quality control measures firsthand. This includes reviewing documentation related to quality management systems and past compliance records.

-

Requesting Quality Reports: Buyers should ask for quality assurance reports, including details about testing results, certifications, and compliance with international standards. This documentation serves as proof of the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an impartial assessment of the supplier’s quality control processes. These inspections often include random sampling and testing of products to verify compliance with specifications.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, it’s essential to understand the specific challenges that may arise in the procurement process:

-

Regulatory Compliance: Buyers must ensure that suppliers comply with local regulations and international standards. This includes understanding specific certifications that may be required in their target markets.

-

Cultural Differences: Navigating language barriers and cultural differences in business practices can impact communication and expectations regarding quality assurance. Establishing clear agreements and expectations upfront can mitigate misunderstandings.

-

Logistical Challenges: Shipping and logistics can introduce risks to product integrity. Buyers should verify that suppliers have robust packaging and handling procedures to protect materials during transport.

By understanding the manufacturing processes and quality assurance measures for Torlon 5030, B2B buyers can make informed decisions that align with their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘torlon 5030’

To assist B2B buyers in effectively sourcing Torlon 5030, this guide provides a structured checklist to ensure a successful procurement process. Torlon 5030, a high-performance polyamide-imide resin reinforced with glass fibers, is essential for applications requiring exceptional strength, thermal stability, and chemical resistance. Following this checklist will help you make informed decisions and secure high-quality materials.

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for Torlon 5030 based on your application needs. Consider factors such as temperature resistance, mechanical properties, and dimensions. This step is crucial as it guides the selection process and ensures that the material meets the performance criteria for your intended use.

- Key Properties to Consider:

- Operating temperature range (up to 500°F)

- Creep resistance and strength characteristics

- Dimensional stability (low coefficient of thermal expansion similar to aluminum)

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in high-performance polymers like Torlon 5030. Look for companies with a strong reputation in the industry and experience in handling similar materials. This helps to ensure reliability and consistency in the quality of the product.

- What to Look For:

- Supplier certifications (ISO, RoHS, etc.)

- Industry experience and customer testimonials

- Product availability and lead times

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier, verify their certifications and compliance with industry standards. This step is vital to ensure that the materials provided are safe, reliable, and meet regulatory requirements.

- Important Certifications:

- ASTM standards relevant to Torlon 5030

- Compliance with environmental regulations (e.g., WEEE, RoHS)

- Quality management certifications (e.g., ISO 9001)

Step 4: Request Samples for Testing

Always request samples of Torlon 5030 to conduct preliminary testing. This will allow you to assess the material’s performance in your specific application and ensure it meets your technical specifications.

- Testing Parameters:

- Mechanical strength tests

- Thermal stability assessments

- Chemical resistance evaluations

Step 5: Discuss Pricing and Payment Terms

Engage in discussions with potential suppliers about pricing structures and payment terms. Understanding the cost implications and financial agreements upfront will help you manage your budget effectively.

- Key Considerations:

- Bulk purchase discounts

- Payment terms (net 30, net 60, etc.)

- Shipping costs and delivery timelines

Step 6: Review Supply Chain and Logistics

Evaluate the supplier’s logistics and supply chain capabilities to ensure timely delivery of Torlon 5030. This step is crucial to avoid production delays and maintain project timelines.

- Logistics Factors:

- Shipping methods and times

- Inventory management practices

- Supplier’s geographic location and its impact on delivery

Step 7: Establish a Long-Term Relationship

Once you have successfully sourced Torlon 5030, focus on building a long-term relationship with your supplier. Strong partnerships can lead to better pricing, priority service, and access to new materials as they become available.

- Benefits of a Long-Term Relationship:

- Consistent quality and reliability

- Collaborative problem-solving and innovation

- Enhanced communication and support for future projects

By following this checklist, B2B buyers can streamline their sourcing process for Torlon 5030 and ensure they procure high-quality materials suited to their specific needs.

Comprehensive Cost and Pricing Analysis for torlon 5030 Sourcing

What are the Key Cost Components in Torlon 5030 Sourcing?

Understanding the cost structure for sourcing Torlon 5030 is critical for B2B buyers aiming to optimize their procurement strategies. The primary cost components include:

-

Materials: The primary cost driver is the polyamide-imide (PAI) resin itself, which is reinforced with 30% glass fibers. The quality of these materials can significantly influence pricing, as higher-grade resins will command a premium.

-

Labor: Labor costs associated with the manufacturing process can vary based on the region. Skilled labor for machining and molding is often required, which can add to the overall cost, particularly in regions with higher wage standards.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and administrative expenses. Depending on the production scale, these costs may be spread over a larger volume, reducing the per-unit cost.

-

Tooling: Custom tooling may be necessary for specific applications, especially if unique specifications are required. This one-time investment can significantly affect initial costs but may lead to lower long-term production costs.

-

Quality Control (QC): Ensuring that the produced Torlon 5030 meets required standards involves quality assurance testing and inspections. The extent of QC measures can vary by supplier and influence the price.

-

Logistics: Transporting materials and finished products can incur substantial costs, particularly for international shipments. Factors like distance, shipping method, and any tariffs or customs duties applicable to the destination country can impact overall expenses.

-

Margin: Suppliers will typically add a markup to cover their costs and achieve profitability. Understanding typical margins for this material can provide insight into fair pricing.

How Do Price Influencers Impact Torlon 5030 Costs?

Several factors can influence the pricing of Torlon 5030, making it essential for buyers to consider these when negotiating:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers determine the most cost-effective purchasing strategy.

-

Specifications and Customization: Custom specifications can lead to increased costs due to additional tooling or manufacturing processes. Buyers should weigh the necessity of customization against potential cost savings from standard products.

-

Material Quality and Certifications: The presence of industry certifications (e.g., ASTM, UL) can influence pricing. Higher-quality materials with certifications may have a higher upfront cost but can lead to long-term savings through durability and reduced failure rates.

-

Supplier Factors: The reputation and location of suppliers can greatly affect pricing. Established suppliers may charge a premium for their reliability and quality assurances, while emerging suppliers may offer competitive pricing to gain market share.

-

Incoterms: Understanding the chosen Incoterms (International Commercial Terms) is crucial for managing logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, affecting the total landed cost.

What Are the Best Practices for Negotiating Torlon 5030 Prices?

Buyers should adopt strategic approaches to ensure cost-efficiency when sourcing Torlon 5030:

-

Conduct Market Research: Understanding current market prices and trends can empower buyers during negotiations. Having data on competitor pricing can also provide leverage.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the TCO, which includes installation, maintenance, and potential failure costs. This broader view can justify higher upfront costs for superior materials.

-

Foster Long-Term Relationships: Establishing a rapport with suppliers can lead to better pricing terms over time. Long-term contracts may also provide stability in pricing, protecting against market fluctuations.

-

Leverage Group Purchasing: Consider joining forces with other buyers to increase order volumes, which can lead to better pricing and terms.

-

Clarify Terms and Conditions: Ensure all agreements on pricing, delivery schedules, and quality standards are documented clearly to avoid misunderstandings that could lead to unexpected costs.

Conclusion

Navigating the complexities of sourcing Torlon 5030 requires a thorough understanding of its cost structure and pricing influencers. By employing strategic negotiation techniques and considering the Total Cost of Ownership, international B2B buyers can secure favorable terms while ensuring they receive high-quality materials suited for their applications. It’s advisable to approach this process with a clear strategy and a focus on long-term value.

Alternatives Analysis: Comparing torlon 5030 With Other Solutions

Understanding Alternatives for Torlon 5030 in High-Performance Applications

In the competitive landscape of high-performance polymers, it is crucial for B2B buyers to explore various alternatives to Torlon 5030. This polyamide-imide (PAI) resin is renowned for its exceptional strength, thermal stability, and low coefficient of thermal expansion (CLTE). However, understanding how it compares with other materials can help businesses make informed decisions that align with their specific application needs and budget considerations.

Comparison Table

| Comparison Aspect | Torlon 5030 | Vespel® SP-21 | PEEK (Polyetheretherketone) |

|---|---|---|---|

| Performance | Excellent high-temperature resistance; high modulus and creep resistance | High thermal and chemical resistance; superior dimensional stability | Excellent mechanical properties; good thermal and chemical resistance |

| Cost | Moderate to high | Very high | Moderate to high |

| Ease of Implementation | Requires specialized machining techniques | Complex machining and fabrication | Readily machinable with standard methods |

| Maintenance | Low maintenance due to durability | Requires careful handling; sensitive to contamination | Low maintenance; highly durable |

| Best Use Case | High-stress applications like electrical insulators and fasteners | Aerospace, automotive, and semiconductor applications | Medical devices, aerospace components, and high-performance machinery |

Detailed Breakdown of Alternatives

Vespel® SP-21

Vespel® SP-21 is a polyimide that excels in high-temperature environments, providing exceptional mechanical and thermal properties. It is particularly useful in aerospace and semiconductor applications where dimensional stability is critical. However, its cost is significantly higher than Torlon 5030, which may not be justifiable for all applications. Additionally, the complex machining requirements can increase production time and costs. Despite these drawbacks, its performance in extreme conditions makes it a preferred choice for critical applications.

PEEK (Polyetheretherketone)

PEEK is another high-performance polymer that offers excellent mechanical and thermal properties, making it suitable for a variety of applications, including medical devices and aerospace components. It is known for its chemical resistance and ability to withstand high temperatures, similar to Torlon 5030. PEEK is generally more cost-effective than Vespel® SP-21, and its machinability is better, allowing for easier implementation. However, while PEEK is highly durable, it may not match the creep resistance and dimensional stability of Torlon 5030 in extremely high-stress environments.

How to Choose the Right Solution for Your Needs

When selecting the right material for your application, it is essential to consider the specific performance requirements, budget constraints, and ease of implementation. Torlon 5030 is an excellent choice for high-stress and high-temperature applications, particularly when low CLTE is a priority. However, if your application requires exceptional chemical resistance or operates in extreme environments, alternatives like Vespel® SP-21 or PEEK may be more suitable. Ultimately, understanding the strengths and weaknesses of each option will enable B2B buyers to make a more strategic decision that aligns with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for torlon 5030

What Are the Key Technical Properties of Torlon 5030 for B2B Buyers?

1. Material Grade:

Torlon 5030 is classified as a polyamide-imide (PAI) resin, specifically reinforced with 30% glass fibers. This material grade is crucial for applications requiring high thermal stability and mechanical strength, making it suitable for demanding environments. In B2B procurement, understanding material grade helps buyers assess compatibility with their specific applications, ensuring optimal performance and longevity.

2. Coefficient of Linear Thermal Expansion (CLTE):

Torlon 5030 exhibits a CLTE that is significantly lower than non-reinforced grades, approximating that of aluminum. This characteristic is vital for applications where dimensional stability is critical, such as in aerospace and automotive components. Buyers should prioritize CLTE specifications to avoid issues related to thermal expansion and contraction, which can lead to component failure.

3. Maximum Operating Temperature:

The material can withstand temperatures up to 500°F (approximately 260°C), making it ideal for high-temperature applications. This property is essential for industries like oil and gas, where equipment is often exposed to extreme conditions. Buyers should ensure that the maximum operating temperature aligns with their operational requirements to maintain efficiency and safety.

4. Creep Resistance:

Creep resistance refers to a material’s ability to withstand deformation under sustained load over time. Torlon 5030 exhibits exceptional creep resistance, which is a critical property for components subjected to constant stress, such as fasteners and structural parts. Understanding creep resistance is important for B2B buyers to predict product longevity and maintenance needs.

5. Compliance Standards:

Torlon 5030 adheres to several industry standards, including ASTM 5204 and AMS 3670/4. Compliance with these standards is crucial for industries such as aerospace and automotive, where safety and reliability are paramount. Buyers must verify compliance to ensure that the materials meet regulatory requirements and industry best practices.

6. Electrical Insulation Properties:

This material offers excellent dielectric properties, making it suitable for electrical insulators and components in electronic devices. For buyers in the electronics sector, understanding electrical insulation properties is essential to ensure product reliability and performance in high-voltage applications.

What Are Common Trade Terms Related to Torlon 5030 in B2B Transactions?

1. OEM (Original Equipment Manufacturer):

An OEM refers to a company that manufactures products that are sold under another company’s brand. In the context of Torlon 5030, buyers often source materials from OEMs to integrate them into their own products. Recognizing the role of OEMs helps buyers navigate supply chains and establish partnerships.

2. MOQ (Minimum Order Quantity):

MOQ represents the smallest quantity of a product that a supplier is willing to sell. For Torlon 5030, understanding the MOQ is vital for budget management and inventory planning. Buyers should negotiate MOQs to align with their production schedules and avoid excess inventory costs.

3. RFQ (Request for Quotation):

An RFQ is a formal document requesting pricing and terms from suppliers. When sourcing Torlon 5030, buyers typically issue RFQs to compare costs and terms from multiple vendors. This process is essential for making informed purchasing decisions and achieving cost efficiency.

4. Incoterms (International Commercial Terms):

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers of Torlon 5030, as it affects overall costs and risk management in global trade.

5. Lead Time:

Lead time refers to the time taken from placing an order to delivery. For Torlon 5030, lead time is a critical factor in project planning and inventory management. Buyers should consider lead times when placing orders to ensure timely project execution.

6. Technical Data Sheet (TDS):

A TDS provides detailed information about the properties and specifications of a material. For Torlon 5030, reviewing the TDS is essential for buyers to understand its performance characteristics and application suitability. This document aids in making informed decisions regarding material selection and application design.

Navigating Market Dynamics and Sourcing Trends in the torlon 5030 Sector

What Are the Current Market Trends Influencing the Torlon 5030 Sector?

The global market for Torlon 5030, a high-performance polyamide-imide (PAI) resin, is experiencing significant growth driven by increased demand across various industries, including aerospace, automotive, and electronics. Key trends include the rising need for lightweight materials that can withstand extreme temperatures and harsh environments, which Torlon 5030 effectively addresses due to its superior strength and thermal stability. Additionally, advancements in manufacturing technologies, such as injection molding and machining, are enabling more efficient production processes, making it easier for international buyers to source high-quality materials at competitive prices.

Emerging markets in Africa, South America, and the Middle East are increasingly investing in infrastructure and industrial projects, creating a burgeoning demand for materials like Torlon 5030. In Europe, regulatory pressures for lightweight and high-performance materials in automotive and aerospace applications are pushing companies to explore alternative polymers. Furthermore, digitalization in the B2B sector is transforming sourcing strategies, allowing buyers to leverage e-commerce platforms for real-time pricing and inventory availability, enhancing the procurement process.

How Important Is Sustainability and Ethical Sourcing in the Torlon 5030 Market?

Sustainability is becoming a critical consideration for B2B buyers of Torlon 5030, as companies face increasing pressure to adopt environmentally responsible practices. The production of PAI resins, while highly beneficial in terms of performance, can have environmental implications that necessitate careful management. Buyers are encouraged to seek suppliers who prioritize sustainable manufacturing processes, such as reducing waste and emissions during production.

Ethical sourcing is another vital aspect, as companies strive to ensure their supply chains are transparent and responsible. Certifications like ISO 14001 for environmental management and compliance with RoHS (Restriction of Hazardous Substances) standards can provide assurance to buyers about the sustainability of their materials. Furthermore, the market is seeing a push for ‘green’ materials that not only perform well but also contribute to a reduced carbon footprint. By prioritizing these factors, businesses can enhance their brand reputation and meet the growing consumer demand for sustainable products.

What Is the Evolution of Torlon 5030 in the B2B Landscape?

The development of Torlon 5030 represents a significant evolution in the field of high-performance polymers. Initially introduced to meet the demands of aerospace and defense industries, its unique properties—such as high modulus, exceptional creep resistance, and chemical stability—have made it a preferred choice across various sectors. Over the years, advancements in material science have further enhanced its performance characteristics, allowing it to compete effectively against other high-temperature polymers like PEEK.

As industries increasingly adopt advanced materials for critical applications, Torlon 5030 has solidified its position as a vital component in the design and manufacturing of high-stress components. Today, its application ranges from electrical insulators to structural parts in extreme environments, showcasing its versatility and continued relevance in the B2B marketplace. This evolution not only highlights the material’s importance but also underscores the ongoing innovation within the polymer industry, driven by the need for enhanced performance and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of torlon 5030

-

How do I choose the right supplier for Torlon 5030?

When selecting a supplier for Torlon 5030, consider their experience in the industry, product quality, and certifications. Look for suppliers with a proven track record of delivering high-performance polymers and those who can provide detailed material data sheets. Additionally, assess their manufacturing capabilities and whether they can meet your specific requirements regarding dimensions and tolerances. Request samples to evaluate the material’s performance before making a bulk purchase. -

What are the key properties of Torlon 5030 that make it suitable for high-temperature applications?

Torlon 5030 is a high modulus polyamide-imide reinforced with 30% glass fibers, offering exceptional strength and stiffness. It maintains its mechanical integrity at temperatures up to 275°C (525°F) while exhibiting low coefficients of thermal expansion (CLTE) similar to aluminum. Its outstanding creep resistance and chemical stability further enhance its suitability for high-temperature applications, such as electrical insulators and structural components in aerospace and automotive industries. -

What is the minimum order quantity (MOQ) for Torlon 5030?

The MOQ for Torlon 5030 can vary by supplier and is typically influenced by production capabilities and the specific configuration of the material. Commonly, MOQs range from 50 kg to several hundred kilograms for standard shapes like rods and plates. It is advisable to discuss your project requirements directly with suppliers to negotiate favorable terms, especially if you are looking for customized dimensions or specific grades. -

What payment terms should I expect when sourcing Torlon 5030 internationally?

Payment terms for international orders can vary widely based on supplier policies and your negotiation leverage. Common options include payment in advance, letters of credit, or net 30/60/90 days after delivery. It’s essential to clarify payment methods, currency options, and potential fees for international transactions upfront. Establishing a clear agreement can help mitigate risks and ensure smooth transactions. -

How can I ensure the quality of Torlon 5030 before purchasing?

To ensure quality, request detailed documentation from suppliers, including material safety data sheets (MSDS) and certification of compliance with relevant industry standards. Conduct a supplier audit, if feasible, to assess their quality control processes. Additionally, consider obtaining a small batch for testing before committing to larger orders. Performing mechanical tests can also validate the material’s properties in your specific application. -

What are the logistics considerations for importing Torlon 5030?

When importing Torlon 5030, consider shipping methods, lead times, and customs regulations in your region. Choose a reliable logistics partner experienced in handling industrial materials to ensure timely delivery. Understand the import duties and taxes applicable to your shipment, as well as any documentation required for customs clearance. Planning ahead can help avoid delays and additional costs. -

Can Torlon 5030 be customized for specific applications?

Yes, Torlon 5030 can often be customized to meet specific application requirements. Suppliers may offer variations in dimensions, shapes, and mechanical properties tailored to your needs. Discuss your project specifications with potential suppliers, including any unique performance criteria or environmental considerations. Custom formulations, such as different fiber reinforcements, may also be available to enhance particular properties. -

What industries commonly use Torlon 5030, and what are its typical applications?

Torlon 5030 is widely used in industries such as aerospace, automotive, and electronics due to its high strength and thermal stability. Typical applications include electrical insulators, test sockets for integrated circuits, fasteners, and components in high-stress environments. Its excellent wear and creep resistance also make it suitable for metal replacement in critical applications, providing durability and reliability under extreme conditions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Torlon 5030 Manufacturers & Suppliers List

1. Drake Plastics – Torlon 5030

Domain: drakeplastics.com

Registered: 1999 (26 years)

Introduction: Torlon 5030 is a high modulus polyamide-imide containing 30% glass fibers, suitable for highly loaded structural parts, electrical insulators, and thermal isolators operating at temperatures above 300°F. It has a 50% lower coefficient of linear thermal expansion (CLTE) than non-reinforced Torlon 4203, with a CLTE similar to aluminum. It offers unmatched strength and creep resistance among high tem…

2. Syensqo – Torlon® 5030 HF

Domain: syensqo.com

Registered: 2023 (2 years)

Introduction: {“product_name”: “Torlon® 5030 HF”, “description”: “A 30% glass-fiber reinforced grade of polyamide-imide (PAI) resin that offers high strength and modulus, exceptional creep resistance, and excellent dimensional stability. It has the highest strength and stiffness of any thermoplastic up to 275°C (525°F).”, “key_features”: [“Fuel Resistant”, “Acid Resistant”, “Mineral/Synthetic Oil Resistant”, “D…

3. Drake Plastics – Torlon 5030 Plate

Domain: store.drakeplastics.com

Registered: 1999 (26 years)

Introduction: {‘product_name’: ‘Torlon 5030 Plate’, ‘available_lengths’: [‘1ft’, ‘2ft’, ‘3ft’, ‘4ft’, ‘1m’], ‘thickness_options’: [3.2, 4.8, 6.4, 9.5, 12.7, 16, 19.1, 25.4, 31.8, 34.2, 44.5], ‘width_options’: [76.2, 101.6, 304.8], ‘certifications’: [‘AI023G30’, ‘AMS 3670 /4C’, ‘ASTM D5204’, ‘BMS8-269C’, ‘Class 3’, ‘Type I’, ‘GE A50TF190’, ‘Class B’, ‘Honeywell MCS7004’, ‘Type 5’, ‘HS MS29.04-05’, ‘Form 2’, ‘Gra…

4. Syensqo – Torlon® 5030

Domain: ulprospector.com

Registered: 2014 (11 years)

Introduction: Torlon® 5030 is a 30% glass-fiber reinforced grade of polyamide-imide (PAI) resin supplied by Syensqo. It offers high strength and modulus, exceptional creep resistance, and thermal expansion characteristics similar to aluminum, providing excellent dimensional stability. It maintains the highest strength and stiffness of any thermoplastic up to 275°C (525°F) and has outstanding resistance to wear,…

5. Boedeker – Torlon ® 5030 Glass Filled PAI

6. Syensqo – Torlon 5030-LF

Domain: specialchem.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “Torlon 5030-LF”, “Supplier”: “Syensqo”, “Last Updated”: “Apr 1, 2024”, “Description”: “Low flow, flame retardant polyamide-imide (PAI) grade reinforced with 30% glass fiber.”, “Processing Method”: “Injection molding”, “Key Properties”: {“Strength and Stiffness”: “Highest of any thermoplastic up to 275°C”, “Chemical Resistance”: “Good”, “Wear Resistance”: “Good”, “Creep Resistance…

7. Mcam – Duratron™ T5030 PAI

Domain: mcam.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “Duratron™ T5030 PAI”, “material”: “30% glass-reinforced polyamide-imide”, “properties”: [“high rigidity”, “retention of stiffness”, “low expansion rate”, “outstanding load-carrying capabilities”, “chemical resistant”, “creep resistant”, “dimensional stability”, “high strength and stiffness”, “wear-resistant”], “temperature_stability”: “up to 260°C (500°F)”, “applications”: [“stru…

Strategic Sourcing Conclusion and Outlook for torlon 5030

The strategic sourcing of Torlon 5030 presents a compelling opportunity for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. With its superior mechanical properties, including high strength, stiffness, and exceptional creep resistance, Torlon 5030 stands out as a material capable of meeting the rigorous demands of high-temperature applications. Its glass-fiber reinforcement enhances dimensional stability, making it suitable for critical components in industries ranging from aerospace to automotive.

Investing in Torlon 5030 not only ensures access to a high-performance polymer but also positions businesses to leverage its unique properties for product innovation and competitive advantage. As global markets continue to evolve, the ability to source advanced materials like Torlon 5030 will be crucial for companies aiming to enhance their operational efficiency and product reliability.

Looking ahead, it is essential for B2B buyers to engage with reliable suppliers who can provide not only the product but also the necessary support and insights for successful implementation. By prioritizing strategic sourcing of Torlon 5030, businesses can secure a robust foundation for future growth and innovation in their respective industries.