Introduction: Navigating the Global Market for torlon 4301

In today’s competitive landscape, international B2B buyers face the daunting challenge of sourcing high-performance materials like Torlon 4301, a specialized polyamide-imide known for its exceptional wear resistance and mechanical strength. As industries increasingly demand materials that can withstand extreme conditions—ranging from cryogenic temperatures to high pressures—understanding the properties, applications, and sourcing options for Torlon 4301 becomes critical. This comprehensive guide aims to equip buyers with the knowledge needed to make informed purchasing decisions, covering essential aspects such as types of Torlon products, their diverse applications in sectors like aerospace, automotive, and medical devices, and effective supplier vetting strategies.

Navigating the global market for Torlon 4301 can be particularly challenging for buyers from regions such as Africa, South America, the Middle East, and Europe, where access to reliable suppliers may be limited. This guide addresses these challenges head-on, offering insights into cost considerations, compliance standards, and regional availability. By leveraging this information, buyers can confidently engage with suppliers, ensuring they acquire the right materials to meet their operational needs while maximizing value. With a focus on empowering B2B buyers to overcome sourcing hurdles, this guide serves as an indispensable resource for those looking to integrate Torlon 4301 into their supply chains.

Understanding torlon 4301 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Torlon 4301-LF | Low flow injection molding grade, enhanced moldability | High-performance components in automotive, aerospace | Pros: Excellent mold release; Cons: Limited flow for intricate designs. |

| Torlon 4301-EXT | High flow extrusion grade, suitable for complex profiles | Industrial parts, piping systems | Pros: Ideal for complex shapes; Cons: May sacrifice some wear resistance. |

| Torlon 4301-GF | Glass fiber reinforced, enhanced mechanical strength | Structural components in construction, automotive | Pros: Superior strength and stiffness; Cons: Higher cost due to reinforcement. |

| Torlon 4301-CF | Carbon fiber reinforced, lightweight with high tensile strength | Aerospace, military applications | Pros: Lightweight with exceptional strength; Cons: Limited availability in some regions. |

| Torlon 4301-HR | High temperature resistant, maintains properties under extreme conditions | Aerospace, oil and gas industries | Pros: Retains performance at high temperatures; Cons: Specialized sourcing may be needed. |

What Are the Key Characteristics of Torlon 4301-LF?

Torlon 4301-LF is engineered for low flow injection molding, making it ideal for producing intricate parts with excellent surface finishes. Its enhanced moldability allows for efficient manufacturing processes, particularly in automotive and aerospace applications. Buyers should consider the trade-off between flow characteristics and the potential need for more complex tooling.

How Does Torlon 4301-EXT Stand Out in Extrusion?

Torlon 4301-EXT is specifically formulated for high flow extrusion, enabling the creation of complex profiles that are essential in various industrial applications. This variant is particularly useful in piping systems where intricate shapes are required. However, buyers should be aware that while it excels in shape versatility, it may not offer the same level of wear resistance as other grades.

What Advantages Does Torlon 4301-GF Offer?

Torlon 4301-GF features glass fiber reinforcement, which significantly boosts its mechanical strength and stiffness. This makes it a preferred choice for structural components in construction and automotive industries. While it provides superior performance, the cost associated with glass fiber reinforcement is a crucial factor for buyers to consider when evaluating budget constraints.

Why Choose Torlon 4301-CF for Aerospace Applications?

Torlon 4301-CF incorporates carbon fiber reinforcement, yielding a lightweight material with high tensile strength, ideal for demanding aerospace and military applications. Its low weight without compromising strength is a considerable advantage. However, potential buyers should note that availability may vary by region, which could impact sourcing strategies.

What Makes Torlon 4301-HR Suitable for High-Temperature Environments?

Torlon 4301-HR is designed to withstand high temperatures while maintaining its mechanical properties, making it suitable for applications in aerospace and oil and gas industries. Its ability to perform under extreme conditions is a significant advantage. Buyers should ensure that their suppliers can meet the specialized sourcing requirements for this variant to avoid delays in production.

Key Industrial Applications of torlon 4301

| Industry/Sector | Specific Application of torlon 4301 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Thrust Washers | Enhanced performance in extreme conditions | Compliance with aerospace standards; weight considerations |

| Automotive | Bushings | Increased durability and reduced maintenance | Availability of custom sizes; high-temperature resistance |

| Oil & Gas | Wear Rings | Superior wear resistance in harsh environments | Chemical resistance; certifications for safety standards |

| Medical Devices | Valve Seats | Reliability in critical applications | Biocompatibility; regulatory compliance in different regions |

| Industrial Equipment | High-Temperature Wear Pads | Prolonged equipment life and reduced downtime | Custom machining capabilities; bulk supply options |

How is Torlon 4301 Used in Aerospace Applications?

In the aerospace sector, Torlon 4301 is commonly utilized for thrust washers due to its exceptional mechanical properties, including high strength and stiffness at elevated temperatures. These washers are crucial for reducing friction in engines and other high-load applications, thereby enhancing overall operational efficiency. For international buyers, particularly from Africa and Europe, it is vital to ensure that the material complies with stringent aerospace standards, as well as to consider the weight implications for fuel efficiency.

What Are the Benefits of Torlon 4301 in Automotive Bushings?

Torlon 4301 serves as an ideal material for bushings in the automotive industry, where durability and performance are paramount. Its high wear resistance reduces the frequency of maintenance and replacement, leading to cost savings over time. Buyers from South America and the Middle East should prioritize sourcing options that provide custom sizes to fit various vehicle models, along with assurance of high-temperature resistance to withstand extreme driving conditions.

Why Choose Torlon 4301 for Oil & Gas Wear Rings?

In the oil and gas industry, wear rings made from Torlon 4301 offer superior resistance to wear and chemicals, making them suitable for harsh operational environments. This resilience helps in minimizing downtime and maintenance costs, which is critical for maximizing productivity in this sector. B2B buyers should ensure that their suppliers offer certifications that meet safety and environmental regulations, particularly when sourcing from regions with stringent compliance requirements.

How Does Torlon 4301 Enhance Medical Devices?

For medical devices, Torlon 4301 is often used in valve seats, where reliability and precision are crucial. Its excellent mechanical properties, coupled with chemical resistance, make it suitable for applications that require biocompatibility and durability. Buyers from Europe and other regions should focus on suppliers who can guarantee compliance with medical device regulations and offer extensive documentation to support product safety.

What Advantages Does Torlon 4301 Provide for Industrial Equipment?

In industrial equipment, Torlon 4301 is used for high-temperature wear pads that significantly extend the life of machinery. This material’s wear resistance and stability at high temperatures reduce the likelihood of equipment failure, which can be costly for businesses. International buyers should consider suppliers that can provide custom machining capabilities and reliable bulk supply options to ensure continuous operations.

3 Common User Pain Points for ‘torlon 4301’ & Their Solutions

Scenario 1: Challenges with Wear Resistance in High-Load Applications

The Problem: B2B buyers often face the issue of component failure due to wear and tear in high-load environments. For instance, in industries like aerospace and automotive, parts such as bushings and thrust washers are subjected to extreme pressures and friction. Traditional materials may not withstand these conditions, leading to unexpected downtimes and costly replacements. Buyers may find that while some alternatives claim to offer superior wear resistance, they often fall short in real-world applications, resulting in performance issues and increased operational costs.

The Solution: To effectively mitigate wear issues, buyers should consider specifying Torlon 4301 due to its exceptional wear resistance and mechanical strength. This polyamide-imide resin is designed to handle high-velocity and high-pressure conditions. When sourcing, it’s crucial to work with suppliers who can provide detailed data sheets and case studies that demonstrate Torlon 4301’s performance in similar applications. Buyers should also ensure that the material is machined to precise tolerances, as improper machining can compromise its wear-resistant properties. Regular maintenance checks and performance monitoring can further extend the life of components made from Torlon 4301, ensuring long-term reliability and cost savings.

Scenario 2: Difficulty in Sourcing and Availability of Specialized Materials

The Problem: International buyers, particularly those in regions like Africa and South America, often struggle with sourcing specialized materials like Torlon 4301 due to limited availability and long lead times. This can lead to project delays, increased costs, and even loss of contracts. Furthermore, the lack of local suppliers familiar with high-performance polymers adds another layer of complexity, as buyers may not receive adequate technical support or guidance on material selection.

The Solution: To overcome sourcing challenges, buyers should establish relationships with reputable global suppliers who have a proven track record in distributing Torlon 4301. Engaging with suppliers that have local representatives or distributors can streamline communication and expedite the procurement process. Additionally, buyers can explore options for bulk purchasing or long-term contracts to secure better pricing and availability. It’s also beneficial to participate in industry trade shows and forums to network with suppliers and gather insights on the latest developments in material technology, ensuring that they stay ahead of the curve in sourcing high-performance polymers.

Scenario 3: Misunderstanding Material Properties and Applications

The Problem: Many B2B buyers are unaware of the full range of capabilities and limitations of Torlon 4301, leading to its misuse in applications where it may not perform optimally. For instance, while Torlon 4301 is known for its high heat resistance, some buyers may overlook its suitability for applications involving aggressive chemicals or high thermal cycling, resulting in premature failure. This misunderstanding can stem from inadequate training or a lack of access to comprehensive material data.

The Solution: To address this knowledge gap, it is essential for buyers to invest time in understanding the material properties of Torlon 4301 thoroughly. Engaging with technical experts from the supplier side can provide invaluable insights into the optimal applications for this polymer. Buyers should request detailed technical documentation, including mechanical property data, thermal stability information, and chemical resistance charts. Conducting pilot tests or trials in controlled environments can also help validate performance before full-scale implementation. Furthermore, establishing a continuous feedback loop with end-users can inform future material selections and enhance application success rates.

Strategic Material Selection Guide for torlon 4301

What Are the Key Properties of Torlon 4301 Compared to Other Materials?

Torlon 4301 is a high-performance polyamide-imide (PAI) known for its exceptional mechanical properties and wear resistance. When considering alternatives, it is essential to analyze materials such as PEEK (Polyetheretherketone), Polyimide, and Nylon. Each of these materials has distinct properties that can influence their suitability for specific applications.

How Does PEEK Compare to Torlon 4301?

PEEK is renowned for its high-temperature resistance, maintaining structural integrity up to 300°C (572°F). It exhibits excellent chemical resistance and low friction properties, making it ideal for applications in aerospace and automotive sectors.

Pros: PEEK is highly durable, with a long service life, and is suitable for extreme environments.

Cons: It is more expensive than Torlon 4301 and can be more complex to process, requiring specialized equipment for machining and molding.

Impact on Application: PEEK’s compatibility with aggressive chemicals and high-pressure applications makes it suitable for thrust washers and bearings in oil and gas industries.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of the higher cost implications and the need for specialized processing capabilities when opting for PEEK.

What Advantages Does Polyimide Offer Over Torlon 4301?

Polyimide is another high-performance polymer that can withstand temperatures up to 400°C (752°F). It has excellent dielectric properties and is often used in electrical insulation applications.

Pros: Polyimide provides superior thermal stability and is lightweight, making it suitable for aerospace applications.

Cons: Its mechanical strength is generally lower than that of Torlon 4301, and it can be more expensive.

Impact on Application: Polyimide is ideal for applications requiring high thermal resistance but may not be as effective in wear-intensive environments compared to Torlon 4301.

Considerations for International Buyers: Compliance with international standards such as ASTM and UL is crucial, particularly for electrical applications in Europe and the Middle East.

How Does Nylon Stack Up Against Torlon 4301?

Nylon is a widely used thermoplastic known for its versatility and cost-effectiveness. It can withstand temperatures up to 120°C (248°F) and offers decent chemical resistance.

Pros: Nylon is relatively inexpensive and easy to process, making it a popular choice for mass production.

Cons: Its wear resistance and thermal stability are significantly lower than those of Torlon 4301, limiting its application in high-load scenarios.

Impact on Application: Nylon is suitable for general-purpose applications but may fail in high-temperature or high-wear environments.

Considerations for International Buyers: Buyers in regions like Vietnam and Nigeria may prefer Nylon for its cost-effectiveness, but they should assess the long-term performance implications.

Summary of Material Comparisons

| Material | Typical Use Case for torlon 4301 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PEEK | Aerospace thrust washers | Excellent high-temperature resistance | Higher cost and complex processing | High |

| Polyimide | Electrical insulation components | Superior thermal stability | Lower mechanical strength than Torlon 4301 | Med |

| Nylon | General-purpose mechanical parts | Cost-effective and easy to process | Limited wear resistance and thermal stability | Low |

This analysis provides a comprehensive overview of materials comparable to Torlon 4301, enabling international B2B buyers to make informed decisions based on performance requirements, cost considerations, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for torlon 4301

What Are the Main Stages of the Manufacturing Process for Torlon 4301?

The manufacturing of Torlon 4301 involves several critical stages that ensure the material meets the required specifications for high-performance applications. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality polyamide-imide (PAI) resin, which is crucial for achieving the desired mechanical properties. During this stage, the resin is subjected to drying to remove moisture, which can adversely affect the final product’s performance. The resin may also be blended with additives, such as graphite and PTFE, to enhance wear resistance and reduce friction.

-

Forming: The prepared resin is then shaped into the desired form through techniques such as injection molding, extrusion, or machining. Injection molding is particularly common for producing complex geometries with tight tolerances, while extrusion is suitable for creating continuous shapes like rods and tubes. Each method requires precise temperature control and pressure management to ensure uniformity and structural integrity.

-

Assembly: In applications where multiple components are involved, assembly may be necessary. This involves joining various parts, which may include machining to create precise fittings or using adhesives that are compatible with Torlon 4301. Proper assembly techniques are essential to maintain the material’s integrity and performance characteristics.

-

Finishing: The final stage involves processes that enhance the surface finish and prepare the product for delivery. This may include machining to achieve specific dimensions, polishing, or applying protective coatings. The finishing process not only improves aesthetics but also enhances performance by reducing friction and wear.

How Is Quality Assurance Implemented in the Production of Torlon 4301?

Quality assurance (QA) is a vital component in the production of Torlon 4301, ensuring that the final product meets both international standards and customer expectations. The following outlines key QA processes:

-

Adherence to International Standards: Manufacturers of Torlon 4301 typically comply with international quality management standards such as ISO 9001. This certification demonstrates a commitment to quality management systems, ensuring consistent quality in production processes. Additionally, industry-specific certifications like CE or API may be applicable, depending on the end-use application.

-

Quality Checkpoints: Quality control is integrated at various stages of the manufacturing process, including:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Any non-conforming materials are rejected or reprocessed.

– In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor the process parameters and ensure that they remain within specified limits. This may include temperature, pressure, and material flow rates.

– Final Quality Control (FQC): After production, finished products undergo rigorous testing to verify their mechanical properties, wear resistance, and overall performance. This includes visual inspections, dimensional checks, and mechanical testing. -

Common Testing Methods: Various testing methods are employed to assess the quality of Torlon 4301. These may include:

– Tensile Strength Testing: To measure the maximum stress the material can withstand.

– Wear Testing: To evaluate the material’s resistance to wear under specific conditions.

– Thermal Stability Testing: To ensure the material can maintain its properties at elevated temperatures.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in international markets, verifying the quality control processes of suppliers is essential to ensure they are receiving high-quality materials. Here are some strategies to consider:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their quality management systems. This includes examining their adherence to ISO standards, reviewing their QA documentation, and assessing their manufacturing processes. Buyers should look for transparency and a commitment to continuous improvement.

-

Requesting Quality Reports: Buyers should request quality control reports that detail the results of testing conducted during production. These reports should include information on IQC, IPQC, and FQC, as well as any corrective actions taken for non-conformities. Reviewing these documents helps buyers understand the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s processes and products. These inspections can be conducted at various stages of production, providing assurance that the materials meet the specified standards before shipment.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate several nuances in quality control when sourcing Torlon 4301:

-

Regional Compliance: Different regions may have specific compliance requirements. Buyers should ensure that the materials sourced meet the local regulations and standards applicable in their respective countries, which may differ from those in the supplier’s country.

-

Communication Barriers: Language and cultural differences can pose challenges in understanding product specifications and quality standards. It is advisable for buyers to establish clear communication channels and possibly work with local representatives who understand both the supplier’s and buyer’s needs.

-

Logistics and Shipping Considerations: Quality control does not end at the factory. Buyers should consider how products are transported and stored during shipping. Proper handling and storage conditions are essential to maintaining the integrity of Torlon 4301, especially given its specific temperature and humidity requirements.

-

After-Sales Support and Warranty: Buyers should inquire about the after-sales support offered by suppliers, including warranty terms and conditions. Reliable after-sales support can help address any quality issues that may arise post-purchase.

In conclusion, understanding the manufacturing processes and quality assurance measures for Torlon 4301 is essential for B2B buyers aiming to source high-quality materials. By focusing on supplier verification, compliance with international standards, and effective communication, buyers can ensure they make informed purchasing decisions that align with their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘torlon 4301’

This guide provides a systematic approach for B2B buyers looking to procure Torlon 4301, a high-performance polyamide-imide known for its exceptional mechanical properties and wear resistance. Following these steps will help ensure you select the right supplier and product for your specific needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s essential to have a clear understanding of your technical requirements for Torlon 4301. Consider factors such as temperature resistance (up to 275°C or 525°F), wear resistance, and application-specific needs like thrust washers or bushings. Documenting these specifications will streamline communication with suppliers and help you compare products effectively.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in high-performance polymers, particularly Torlon 4301. Look for companies with a proven track record in your industry and positive customer reviews. Utilize platforms like LinkedIn or industry-specific forums to gather insights about supplier reliability and product quality.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications such as ISO 9001 for quality management and compliance with environmental regulations like RoHS. Certifications not only indicate product quality but also demonstrate the supplier’s commitment to maintaining industry standards. This step is crucial for ensuring that your procurement aligns with regulatory requirements in your region.

Step 4: Request Material Data Sheets

Request detailed material data sheets (MDS) for Torlon 4301 from your shortlisted suppliers. These documents should provide comprehensive information about the material’s properties, including mechanical strength, thermal stability, and chemical resistance. Analyzing this data will help you assess whether the product meets your specific application requirements.

Step 5: Obtain Samples for Testing

Before finalizing your order, ask suppliers for samples of Torlon 4301. Conduct tests to evaluate its performance in your specific application, focusing on factors like wear resistance and thermal stability. This hands-on evaluation can prevent costly mistakes and ensure that the material will perform as expected in your operational environment.

Step 6: Negotiate Pricing and Terms

Once you have selected a supplier, engage in negotiations regarding pricing, delivery timelines, and payment terms. Be transparent about your budget constraints and ask for bulk purchase discounts if applicable. Establishing favorable terms early can foster a long-term relationship and facilitate smoother transactions in the future.

Step 7: Finalize the Order and Monitor Delivery

After reaching an agreement, finalize the order by confirming all specifications and terms in writing. Monitor the delivery process closely to ensure the material arrives on time and meets the agreed-upon quality standards. Establishing clear communication channels with the supplier during this phase can help address any potential issues promptly.

By following this checklist, B2B buyers can navigate the procurement of Torlon 4301 effectively, ensuring they secure high-quality materials that meet their technical and operational requirements.

Comprehensive Cost and Pricing Analysis for torlon 4301 Sourcing

What Are the Key Cost Components for Sourcing Torlon 4301?

When considering the sourcing of Torlon 4301, a comprehensive understanding of its cost structure is essential. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The base material for Torlon 4301 is polyamide-imide (PAI), known for its high strength and wear resistance. The cost of raw materials can fluctuate based on global supply and demand, as well as sourcing location. Additives such as graphite and PTFE, which enhance wear resistance, also contribute to the overall material costs.

-

Labor: Labor costs can vary significantly depending on the region of manufacturing. In countries with higher labor costs, such as those in Europe, the overall cost of Torlon 4301 may be higher compared to regions like Africa or South America where labor costs are typically lower.

-

Manufacturing Overhead: This includes costs related to the operation of machinery, utilities, and facility maintenance. Efficient manufacturing processes can help reduce overhead costs, impacting the final price of Torlon 4301.

-

Tooling: Custom tooling may be required for specific applications or sizes, adding to the initial investment. Buyers should consider whether the tooling costs are one-time expenses or recurring, as this will influence long-term pricing.

-

Quality Control: Given the high-performance nature of Torlon 4301, rigorous quality control measures are necessary. This includes testing for mechanical properties and compliance with industry standards, which can increase costs but ensure product reliability.

-

Logistics: Shipping and handling costs can vary widely depending on the distance and mode of transport. Incoterms play a crucial role in determining who bears these costs, which can significantly affect the total cost of acquisition.

-

Margin: Suppliers will apply a profit margin based on their own cost structures and market positioning. Understanding the competitive landscape can help buyers gauge what constitutes a fair margin.

What Influences Pricing for Torlon 4301?

Several factors can influence the pricing of Torlon 4301, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to lower per-unit costs. Understanding a supplier’s MOQ can help buyers strategize their purchasing to maximize cost efficiency.

-

Specifications and Customization: Customized specifications can lead to higher prices due to additional tooling and production time. Buyers should clearly define their needs to avoid unexpected costs.

-

Material Quality and Certifications: Higher quality materials and recognized certifications can increase costs but also improve product performance and compliance with industry regulations.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: The choice of Incoterms can influence the total cost, as they determine the allocation of shipping, insurance, and customs duties between the buyer and seller.

What Are Effective Buyer Tips for Sourcing Torlon 4301?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective sourcing strategies can lead to better pricing outcomes:

-

Negotiation: Engage in discussions with suppliers to negotiate better terms, especially for larger orders. Building a strong relationship can lead to favorable pricing adjustments.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, handling, and potential costs related to failure or replacement. Evaluate suppliers based on their ability to provide long-term value.

-

Pricing Nuances: Be aware of currency fluctuations and regional tariffs that could affect pricing. Understanding these nuances can aid in better budgeting and financial planning.

-

Research and Compare: Conduct thorough market research and compare prices from multiple suppliers. This helps identify competitive pricing and potential red flags regarding quality.

-

Request Quotations: Always ask for detailed quotations, including a breakdown of costs. This transparency can aid in better negotiations and budget management.

Disclaimer

Prices for Torlon 4301 can vary widely based on the aforementioned factors. The information provided is indicative and should be verified with suppliers for accurate pricing.

Alternatives Analysis: Comparing torlon 4301 With Other Solutions

Exploring Alternatives to Torlon 4301: A Comparative Analysis

In the realm of high-performance materials, Torlon 4301 stands out for its exceptional wear resistance and mechanical properties. However, businesses often seek alternatives that may provide comparable benefits at different costs or with varying ease of implementation. This section compares Torlon 4301 with two notable alternatives: PEEK (Polyetheretherketone) and Vespel (Polyimide).

Comparison Table

| Comparison Aspect | Torlon 4301 | PEEK | Vespel |

|---|---|---|---|

| Performance | High strength, excellent wear resistance, operates up to 275°C (525°F) | Superior thermal stability, excellent chemical resistance | High-temperature stability, good wear resistance |

| Cost | Moderate to high | High | Very high |

| Ease of Implementation | Moderate, requires precise machining | Moderate, can be molded and machined | High, specialized machining required |

| Maintenance | Low, durable under stress | Low, resistant to wear and chemicals | Moderate, needs careful handling |

| Best Use Case | High-load bushings, thrust washers | Aerospace, automotive applications | High-performance seals, bearings |

Detailed Breakdown of Alternatives

PEEK (Polyetheretherketone)

PEEK is a thermoplastic known for its remarkable thermal stability and chemical resistance. It can withstand temperatures up to 300°C (572°F) and is often used in demanding applications such as aerospace and automotive sectors. Its high performance comes at a premium price, making it a significant investment for companies. While PEEK can be easier to process than Torlon 4301, it still requires specialized equipment for molding and machining.

Pros: Exceptional thermal and chemical resistance, versatile in application.

Cons: Higher cost compared to Torlon 4301, requires specialized processing.

Vespel (Polyimide)

Vespel is another high-performance polymer that excels in extreme temperature environments, often used in aerospace and semiconductor applications. It offers good wear resistance and can handle temperatures exceeding 300°C (572°F). However, Vespel is significantly more expensive and typically requires advanced machining techniques, which can increase production lead times and costs.

Pros: Excellent high-temperature performance, good mechanical properties.

Cons: Very high cost, complex machining requirements.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right material for your application, it is crucial to consider specific operational requirements, budget constraints, and the intended use case. Torlon 4301 is an excellent choice for applications requiring a balance of wear resistance and mechanical strength, particularly in high-load scenarios. PEEK offers superior thermal stability but at a higher cost, while Vespel provides exceptional performance in extreme conditions but may not be financially viable for all projects. B2B buyers should conduct a thorough analysis of their operational needs and financial parameters to determine the most appropriate solution for their specific applications.

Essential Technical Properties and Trade Terminology for torlon 4301

What Are the Key Technical Properties of Torlon 4301 That B2B Buyers Should Know?

1. Material Grade: Polyamide-Imide (PAI)

Torlon 4301 is a high-performance polyamide-imide, a thermoplastic polymer known for its exceptional strength and thermal stability. This material is crucial for applications requiring durability under extreme conditions, such as high temperatures (up to 275°C or 525°F) and aggressive environments. For B2B buyers, understanding the material grade helps ensure that the selected product meets specific operational demands.

2. Coefficient of Linear Thermal Expansion (CLTE)

Torlon 4301 exhibits a low CLTE, which is significant for applications where dimensional stability is critical. A low CLTE minimizes the risk of warping or deformation under temperature fluctuations, making it ideal for precision components. B2B buyers should consider this property when selecting materials for parts that must maintain tight tolerances in varying thermal environments.

3. Wear Resistance

One of the standout features of Torlon 4301 is its tenfold increase in wear resistance compared to non-reinforced Torlon grades. This property is vital for components like bushings and thrust washers that experience high friction and wear. For businesses, investing in wear-resistant materials can lead to lower maintenance costs and longer service life for machinery and equipment.

4. Compliance and Specifications

Torlon 4301 meets various industry specifications such as ASTM 5204 and AMS 3670, making it compliant for use in critical applications, including aerospace and automotive sectors. Understanding these compliance standards is essential for B2B buyers, as adherence to specifications can impact product approval and marketability.

5. Chemical Resistance

This material is resistant to a range of chemicals, including acids and oils, which is crucial in industries such as oil and gas, automotive, and medical devices. Buyers must evaluate the chemical compatibility of materials to prevent degradation and ensure operational reliability.

What Are Common Trade Terms in the Context of Torlon 4301?

1. OEM (Original Equipment Manufacturer)

In the context of Torlon 4301, an OEM refers to companies that manufacture products using this material in their final goods. Understanding OEM relationships can be vital for buyers looking to source components or materials that meet specific application requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For Torlon 4301, knowing the MOQ helps businesses plan their inventory and budget effectively, especially in international markets where shipping and logistics can add significant costs.

3. RFQ (Request for Quotation)

An RFQ is a document that businesses send to suppliers to solicit pricing information for specific products, like Torlon 4301. Crafting an RFQ ensures that buyers receive competitive quotes, allowing for better decision-making and negotiation.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce, which clarify responsibilities between buyers and sellers in international transactions. For Torlon 4301, understanding Incoterms can help B2B buyers manage shipping costs, delivery schedules, and risk during transportation.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. For critical materials like Torlon 4301, understanding lead times is essential for project planning and avoiding delays in production.

6. Custom Fabrication

This term describes the process of creating customized parts from materials like Torlon 4301. For B2B buyers, knowing about custom fabrication options allows them to source tailored solutions that meet unique specifications, enhancing product performance and compatibility.

By understanding these essential properties and trade terms, B2B buyers can make informed decisions when sourcing Torlon 4301 for their specific industrial applications.

Navigating Market Dynamics and Sourcing Trends in the torlon 4301 Sector

What Are the Key Market Trends Influencing the Torlon 4301 Sector?

The Torlon 4301 market is experiencing robust growth driven by a surge in demand for high-performance materials across diverse industries. This polyamide-imide (PAI) resin is favored for its exceptional wear resistance, mechanical strength, and stability at elevated temperatures, making it ideal for applications in aerospace, automotive, and industrial machinery. As global industries increasingly prioritize performance materials that can withstand harsh conditions, Torlon 4301 has emerged as a go-to solution.

Emerging technologies, such as advanced manufacturing techniques and additive manufacturing, are reshaping sourcing strategies. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, the ability to source materials like Torlon 4301 through digital platforms has streamlined procurement processes. Moreover, the growing trend toward customization has led suppliers to offer tailored solutions, further enhancing the appeal of Torlon 4301.

Market dynamics are also influenced by geopolitical factors and supply chain challenges. Buyers must navigate fluctuating raw material costs and regional availability, particularly since Torlon 4301 is not widely available in certain markets, such as Africa and the Middle East. Strategic partnerships with suppliers that can provide consistent quality and reliable delivery are essential for mitigating these risks.

How Does Sustainability and Ethical Sourcing Affect the Torlon 4301 Market?

Sustainability has become a cornerstone of sourcing strategies in the B2B landscape, and the Torlon 4301 sector is no exception. As companies face increasing pressure to reduce their environmental footprint, the demand for eco-friendly materials and ethical supply chains is on the rise. Torlon 4301, while a high-performance material, also presents opportunities for sustainable practices through responsible sourcing and waste reduction.

Buyers are increasingly interested in suppliers who prioritize sustainability, such as those with certifications that verify their commitment to environmental standards. Certifications like ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are becoming essential for suppliers in the Torlon 4301 market. These certifications not only demonstrate compliance with environmental regulations but also enhance brand reputation among environmentally conscious buyers.

Moreover, the focus on circular economy principles is influencing sourcing decisions. Suppliers that incorporate recycled materials or promote recyclability in their products are gaining traction. For Torlon 4301, promoting its durability and longevity can resonate with buyers looking to invest in materials that contribute to sustainability goals while maintaining high performance.

What Is the Historical Context Behind the Development of Torlon 4301?

The development of Torlon 4301 can be traced back to advancements in polymer science, particularly in the late 20th century when the demand for high-performance thermoplastics surged. Originally formulated to meet the rigorous demands of aerospace and industrial applications, Torlon 4301 has evolved to incorporate advanced fillers such as graphite and PTFE, enhancing its wear resistance and thermal stability.

As industries recognized the limitations of traditional materials, the evolution of Torlon 4301 marked a significant shift towards utilizing high-modulus polyamide-imides. This transition not only addressed the need for more robust materials but also paved the way for innovations in processing methods, such as injection molding and machining, allowing for greater versatility in applications. The ongoing refinement of Torlon 4301 reflects the dynamic nature of material science and its crucial role in meeting the needs of modern industries.

Frequently Asked Questions (FAQs) for B2B Buyers of torlon 4301

-

How do I ensure the quality of Torlon 4301 when sourcing from international suppliers?

To ensure the quality of Torlon 4301, request detailed material data sheets, certifications, and compliance documents from potential suppliers. It’s crucial to inquire about their quality assurance processes, including testing methods and standards met (e.g., ASTM, AMS). Establish a sample order to evaluate the material’s performance before committing to larger orders. Additionally, consider conducting factory audits or third-party inspections to verify manufacturing practices and quality control measures. -

What are the key properties of Torlon 4301 that make it suitable for high-temperature applications?

Torlon 4301 exhibits exceptional mechanical properties, including high flexural and compressive strength, making it ideal for applications requiring durability at elevated temperatures. It maintains structural integrity up to 275°C (525°F) and offers outstanding wear resistance, creep resistance, and low thermal expansion. These characteristics make it suitable for components like thrust washers and bushings in industries such as aerospace, automotive, and energy. -

What is the minimum order quantity (MOQ) for Torlon 4301, and how does it vary by supplier?

Minimum order quantities for Torlon 4301 can vary significantly between suppliers, typically ranging from 10 kg to 100 kg or more. Some suppliers may offer flexibility based on customer needs, while others may have strict MOQs due to manufacturing constraints. It’s advisable to discuss your specific requirements with potential suppliers to negotiate terms that align with your business needs and project timelines. -

What payment terms should I expect when sourcing Torlon 4301 internationally?

Payment terms can vary by supplier and region. Common options include advance payment, letter of credit, or payment upon delivery. When negotiating, consider factors such as your creditworthiness, supplier relationships, and order size. It’s essential to clarify these terms before finalizing contracts to ensure smooth transactions and mitigate risks associated with international trade. -

How can I customize Torlon 4301 products to fit my specific application needs?

Customization options for Torlon 4301 can include variations in size, shape, and reinforcement materials (like carbon or glass fiber). Discuss your specific application requirements with suppliers to explore available customization options. Many manufacturers also offer engineering support to help optimize designs for performance, ensuring the final product meets your operational needs effectively. -

What logistical considerations should I keep in mind when importing Torlon 4301?

When importing Torlon 4301, consider shipping methods, customs regulations, and lead times. Choose a reliable logistics partner familiar with international trade to ensure timely delivery. Be aware of any import tariffs or duties that may apply in your country. It’s also prudent to plan for potential delays by allowing extra time in your project timeline, especially if sourcing from distant suppliers. -

What industries commonly use Torlon 4301, and what are its typical applications?

Torlon 4301 is widely used across various industries, including aerospace, automotive, oil and gas, and medical devices. Its excellent wear resistance and high-temperature stability make it suitable for applications such as thrust washers, bearings, wear rings, and valve seats. Understanding the common uses of Torlon 4301 can help you identify its potential benefits for your specific industry needs. -

How do I vet potential suppliers of Torlon 4301 for reliability and performance?

To vet suppliers effectively, start by reviewing their industry reputation through customer testimonials and case studies. Check for certifications like ISO 9001, which indicate adherence to quality management standards. Additionally, request references from existing clients and inquire about their experience with product performance and support. Engaging in direct communication with suppliers can also provide insights into their reliability and responsiveness to customer needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Torlon 4301 Manufacturers & Suppliers List

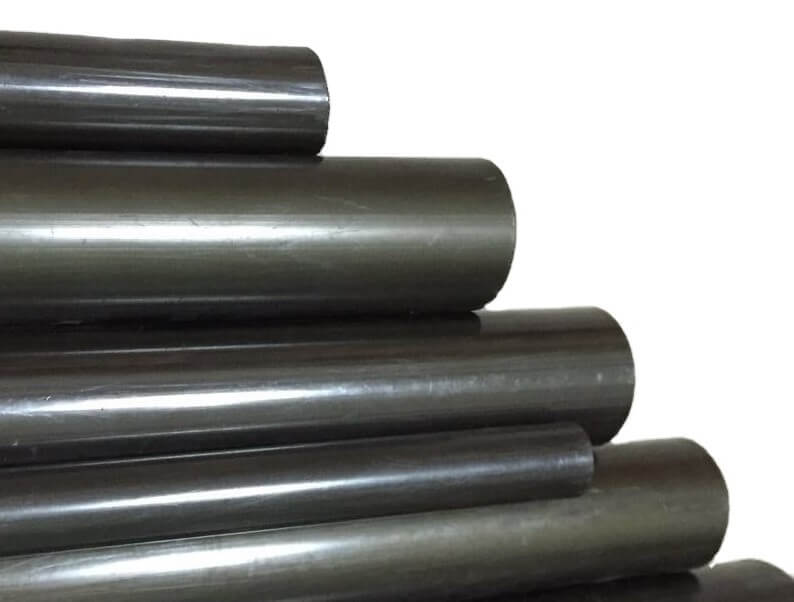

1. Drake Plastics – Torlon 4301

Domain: drakeplastics.com

Registered: 1999 (26 years)

Introduction: Torlon 4301 is a high modulus polyamide-imide containing graphite and PTFE for improved wear resistance. It is the general purpose wear grade of Torlon with an excellent balance of strength and impact resistance. It offers 10 times more wear resistance than non-reinforced Torlon 4203 and has a CLTE that approaches that of many metals. Ideal applications include highly loaded bushings, high tempera…

2. Syensqo – Torlon® 4301 PAI Resin

Domain: syensqo.com

Registered: 2023 (2 years)

Introduction: Torlon® 4301 is a wear-resistant grade of polyamide-imide (PAI) resin. It offers a good balance of mechanical properties and wear resistance, with high flexural and compressive strength, low coefficient of friction, and outstanding wear resistance under high velocity and high pressure conditions. It has the highest strength and stiffness of any thermoplastic up to 275°C (525°F) and exhibits excell…

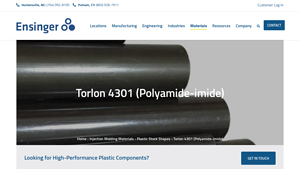

3. Ensinger – Torlon 4301 (Polyamide-imide)

Domain: ensinger-pc.com

Registered: 2015 (10 years)

Introduction: {“product_name”: “Torlon 4301 (Polyamide-imide)”, “properties”: {“coefficient_of_friction”: {“static”: 0.25, “dynamic”: 0.2}, “specific_gravity”: 1.45, “tensile_strength_yield”: 15000, “tensile_modulus”: 900000, “tensile_elongation”: 3, “flexural_strength”: 23000, “flexural_modulus”: 800000, “shear_strength”: 16400, “compressive_strength”: {“ultimate”: null, “2_percent_deformation”: 10000, “10_per…

4. Curbell Plastics – Torlon® 4301 Bearing Grade PAI

Domain: curbellplastics.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Torlon® 4301 Bearing Grade PAI”, “material_type”: “Extruded Polyamide-Imide”, “features”: [“High wear resistance”, “Very low expansion rate”, “Low friction coefficient”, “Exhibits little to no slip-stick”], “applications”: [“Non-lubricated bearings”, “Seals”, “Bushings”, “Thrust washers”, “Bearing cages”, “Reciprocating compressor parts”], “available_forms”: [“Rod”, “Sheet”], “si…

5. Boedeker – Torlon 4301

Domain: boedeker.com

Registered: 1997 (28 years)

Introduction: Torlon 4301 is a high-performance polyamide-imide (PAI) resin known for its exceptional mechanical properties and thermal stability. It is designed for applications requiring high strength and stiffness at elevated temperatures. The material exhibits excellent chemical resistance and low friction properties, making it suitable for use in bearings, seals, and other wear applications. Torlon 4301 is…

6. Professional Plastics – Torlon® 4301 Rod & Plate

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: Torlon® 4301 Rod & Plate – Order Online. The product is part of a wide range of plastic sheets, rods, tubing, profiles, and parts offered since 1984. For inquiries, contact at 1-888-995-7767.

Strategic Sourcing Conclusion and Outlook for torlon 4301

As businesses increasingly seek high-performance materials to enhance their operational efficiency, Torlon 4301 stands out as a premier choice for various applications. Its remarkable wear resistance, coupled with superior mechanical properties, makes it ideal for components that endure high stress and temperature fluctuations. By strategically sourcing Torlon 4301, companies can significantly reduce maintenance costs and improve product longevity, particularly in sectors such as aerospace, automotive, and industrial equipment.

For international buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the specific advantages of Torlon 4301 can facilitate informed decision-making. This material’s compliance with various industry standards ensures reliability and quality, giving businesses a competitive edge. Furthermore, as markets evolve, the demand for innovative materials like Torlon 4301 is expected to grow, presenting lucrative opportunities for suppliers and manufacturers alike.

As you explore your sourcing options, consider forging partnerships with reputable suppliers who can provide not just the material but also the technical support necessary for optimal application. Embrace the potential of Torlon 4301 to drive your business forward—secure your competitive advantage today.