Top 9 Sheet Metal Bending Service Manufacturers & Suppliers List

1. SendCutSend – CNC Sheet Metal Bending Services

Domain: sendcutsend.com

Registered: 2015 (10 years)

Introduction: SendCutSend offers CNC sheet metal bending services to transform flat designs into functional parts. Key features include:

– Accuracy: Bends within one degree or better, with tolerances of +/- 1 degree for sheet metal parts up to 24″ long and +/- 2 degrees for longer bends.

– Materials: Available for 9 metals and 1 plastic, including 5052 H32 Aluminum, Brass, 4130 Chromoly, Copper, G90 Galvanized …

2. OSH Cut – On-Demand Custom Metal Bending Services

Domain: oshcut.com

Registered: 2018 (7 years)

Introduction: On-Demand Custom Metal Bending Services at OSH Cut include:

– Materials: Steel, Stainless Steel, Aluminum, Copper

– Thickness: Up to 5/16″

– Precision Bending: +/- 0.0001″ back-gauge positioning, real-time material thickness measurement, high precision ram placement

– Standard bend angle tolerances: +/- 1.0 degree

– File Formats Supported: DXF, SVG, AI, STEP, SLDPRT, CATPART, IPT, IGS, PAR, I…

3. Fabworks – Precision Sheet Metal Bending Service

Domain: fabworks.com

Registered: 2000 (25 years)

Introduction: Sheet Metal Bending Service at Fabworks offers precision bending with CNC technology, ensuring high-quality custom parts. Key features include:

– Upload 3D STEP files for automatic bending configuration.

– Materials: Aluminum, Steel, Stainless Steel.

– No minimum quantity required.

– Bending angles: 1-135 degrees with +/- 1 degree angle tolerance and +/- .015″ length tolerance.

– Fast turnaro…

4. RMFG – Custom Sheet Metal Bending Service

Domain: rmfg.com

Registered: 2000 (25 years)

Introduction: Sheet Metal Bending Service – Custom bent sheet metal parts available online. Fast turnaround with most parts shipping within 3 days. Precision manufacturing using CNC press brake with ±1° bend angle tolerance. Volume pricing: $4.00/bend for 1 part, $3.00/bend for 2 parts, $2.50/bend for 10 parts, $2.00/bend for 50 parts, and $1.00/bend for 100 parts. Standard tolerances: ±0.015″ for linear dimens…

5. Rapid Direct – Custom Metal Bending Services

Domain: rapiddirect.com

Registered: 2010 (15 years)

Introduction: Custom metal bending services for high-quality prototypes and production bends. Free sheet metal quote with DFM review within 1 day. Lead time as fast as 3-5 days. High-quality parts produced using the latest metal bending technology and rigorous quality control measures. Fast lead time due to CNC bending equipment and streamlined workflows. Engineering support available for material selection and…

6. Prototek – Sheet Metal Bending and Forming Services

Domain: prototek.com

Registered: 1996 (29 years)

Introduction: Sheet Metal Bending and Forming Services at Prototek include: Repeatability, High Dimensional Tolerances, Custom Prototypes and End-Use Parts. Certifications: ISO 9001:2015, AS9100D, ITAR. Lead Time: 1 – 15 Days. Max Dimensions: Press Brake Tonnage: 90 tons, Maximum Sheet Metal Bend Length: 10 ft, Sheet Thickness: 0.003 in – 0.375 in. General Tolerances: ISO 2768 standards or ±0.020 in (±0.508 mm)…

7. Dalsin Industries – Automated Sheet Metal Bending Solutions

Domain: dalsinind.com

Registered: 1998 (27 years)

Introduction: Dalsin Industries offers advanced automated sheet metal panel bending services using Salvagnini technology. Key features include:

– Rapid production cycles for faster project completion without sacrificing quality.

– Ability to perform complex bends with precision, accommodating various shapes and sizes.

– Superior precision and consistency across large production runs.

– Material versatility, wor…

8. eMachineShop – CNC Bending Services

Domain: emachineshop.com

Registered: 1999 (26 years)

Introduction: CNC Bending services for custom sheet metal parts, utilizing advanced CNC bending equipment. Offers bending for 50+ materials with free shipping in the USA and a 100% quality guarantee. Common applications include brackets, enclosures, cams, and decorative items. Bending process involves using a pneumatic or hydraulic press brake to manipulate metal into various shapes and sizes. Compatible materi…

9. LaserBoost – Laser Cutting & Bending Services

Domain: laserboost.com

Registered: 2012 (13 years)

Introduction: This company, LaserBoost – Laser Cutting & Bending Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Introduction: Navigating the Global Market for sheet metal bending service

In the dynamic world of manufacturing, sourcing reliable sheet metal bending services can pose significant challenges for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. Buyers often grapple with issues such as varying material specifications, compliance with local regulations, and the need for precision in complex designs. This guide aims to navigate these complexities by providing an in-depth overview of the types of sheet metal bending services available, their applications across industries, and crucial insights into supplier vetting processes.

Understanding the nuances of sheet metal bending—from material selection to post-processing options—empowers buyers to make informed purchasing decisions. This comprehensive resource will cover essential topics such as cost structures, lead times, and quality control measures, ensuring that buyers can effectively evaluate potential suppliers.

Furthermore, by highlighting best practices and common pitfalls in sourcing, this guide equips decision-makers with the knowledge necessary to enhance their procurement strategies. Whether you’re seeking to innovate in product design or streamline manufacturing processes, this guide serves as your essential tool for successfully navigating the global market for sheet metal bending services, ultimately driving efficiency and competitiveness in your operations.

Understanding sheet metal bending service Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Bending | Utilizes computer-controlled machinery for precision bending. | Aerospace, automotive, electronics | Pros: High accuracy, repeatability. Cons: Higher initial setup costs. |

| Manual Bending | Hand-operated tools for bending metal sheets. | Small-scale fabrication, prototypes | Pros: Cost-effective for low volumes. Cons: Less precision and speed. |

| Press Brake Bending | Uses hydraulic or mechanical presses to form bends. | Heavy machinery, structural components | Pros: Suitable for thick materials, high production rates. Cons: Limited to certain thicknesses and shapes. |

| Air Bending | Bending method that relies on air pressure for flexibility. | HVAC systems, ductwork | Pros: Versatile for various shapes. Cons: Requires skilled operators for accuracy. |

| Rotary Bending | Employs rotating tools to achieve bends. | Custom parts, artistic designs | Pros: Capable of complex geometries. Cons: Slower production speed. |

What is CNC Bending and When Should Businesses Use It?

CNC bending is a highly precise method that employs computer-controlled machinery to bend sheet metal with exceptional accuracy. This technique is ideal for industries such as aerospace and automotive, where precision is paramount. Buyers should consider CNC bending for projects requiring complex designs or tight tolerances, although initial setup costs can be higher compared to manual methods.

How Does Manual Bending Compare for Small Projects?

Manual bending utilizes hand-operated tools, making it a cost-effective option for small-scale fabrication and prototypes. This method is particularly suitable for businesses that require quick adjustments or low-volume runs. However, manual bending is often less precise and slower than automated methods, which may impact production timelines for larger projects.

What Are the Advantages of Press Brake Bending?

Press brake bending employs hydraulic or mechanical presses to form sheet metal into desired shapes. This method is commonly used in heavy machinery and structural components due to its ability to handle thicker materials and achieve high production rates. While it offers efficiency and strength, buyers should be aware of its limitations regarding the types of materials and shapes that can be processed.

How is Air Bending Used in HVAC Applications?

Air bending is a versatile method that uses air pressure to create bends in sheet metal, making it particularly useful in HVAC systems and ductwork. This approach allows for various shapes and sizes, accommodating the unique requirements of different installations. However, it requires skilled operators to ensure accuracy, which can be a consideration for businesses prioritizing precision.

What Makes Rotary Bending Suitable for Custom Parts?

Rotary bending employs rotating tools to achieve bends, making it ideal for custom parts and artistic designs. This method allows for complex geometries that may not be possible with other bending techniques. However, buyers should consider that rotary bending can be slower in production speed, which may affect timelines for larger orders.

Key Industrial Applications of sheet metal bending service

| Industry/Sector | Specific Application of sheet metal bending service | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of chassis components and brackets | Enhanced structural integrity and weight reduction | Material specifications, precision tolerances, and lead times |

| Aerospace | Fabrication of aircraft structural parts | Compliance with stringent safety and quality standards | Certifications, material traceability, and custom bending capabilities |

| Construction | Custom metal framing and support structures | Improved durability and design flexibility | Availability of materials, bending accuracy, and local regulations |

| Electronics | Manufacturing of enclosures and housings | Enhanced aesthetics and protection of components | Compatibility with electronic components, surface finishes, and rapid prototyping |

| HVAC Systems | Creation of ductwork and ventilation components | Increased energy efficiency and reduced installation costs | Material compatibility, dimensional accuracy, and custom design capabilities |

How Is Sheet Metal Bending Service Used in the Automotive Industry?

In the automotive sector, sheet metal bending services are crucial for producing components such as chassis parts and brackets. These bent parts provide enhanced structural integrity while reducing overall vehicle weight, which can improve fuel efficiency. Buyers from regions like Africa and South America need to consider material specifications, as well as precision tolerances to ensure that the components meet safety standards. Quick turnaround times are also vital, particularly for manufacturers facing tight production schedules.

What Role Does Sheet Metal Bending Play in Aerospace Manufacturing?

Aerospace applications require precision in every component, making sheet metal bending services essential for fabricating structural parts of aircraft. These components must comply with stringent safety and quality standards, necessitating high accuracy and durability. International buyers, particularly from the Middle East and Europe, should prioritize suppliers who can provide necessary certifications and material traceability, ensuring that the products meet regulatory requirements. Custom bending capabilities are also critical for accommodating unique designs.

Why Is Sheet Metal Bending Important for Construction Projects?

In construction, sheet metal bending is widely used for creating custom metal framing and support structures. This service allows for improved durability and design flexibility, enabling architects and builders to execute innovative designs. Buyers must focus on the availability of high-quality materials and the bending accuracy offered by suppliers. Additionally, understanding local regulations regarding construction materials is essential for compliance and safety.

How Does Sheet Metal Bending Benefit the Electronics Sector?

In the electronics industry, sheet metal bending services are utilized to manufacture enclosures and housings that protect sensitive components. The bending process not only enhances the aesthetic appeal but also ensures that the enclosures provide adequate protection against environmental factors. Buyers should consider compatibility with electronic components, desired surface finishes, and the ability to produce prototypes rapidly, especially when entering new markets in regions like Europe or Asia.

What Advantages Does Sheet Metal Bending Offer in HVAC Systems?

For HVAC systems, sheet metal bending services are vital for creating ductwork and ventilation components that maximize energy efficiency. Properly bent ducts reduce air leakage and improve airflow, leading to lower energy costs for consumers. Buyers should assess the compatibility of materials with existing systems, ensure dimensional accuracy for proper fit, and seek suppliers with custom design capabilities to meet specific project requirements.

3 Common User Pain Points for ‘sheet metal bending service’ & Their Solutions

Scenario 1: Managing Complex Designs and Specifications

The Problem: B2B buyers often struggle with the intricacies of designing parts that require precise bending specifications. Issues arise when designs have complex geometries, such as multiple perpendicular flanges or odd shapes. Without adequate clearance between flanges, parts may collide during the bending process, leading to costly rework or delays. Furthermore, varying material specifications and bending tolerances can complicate the design process, especially for international buyers unfamiliar with local manufacturing standards.

The Solution: To mitigate these challenges, buyers should invest time in understanding their material and bending specifications before placing orders. Utilize design software that includes built-in guidelines for sheet metal bending, such as Autodesk Fusion. This software often features gauge tables and bending calculators that help ensure designs meet the necessary clearance and tolerance requirements. Additionally, engaging with the service provider early in the design phase can provide valuable insights into material capabilities and limitations. Always check the provider’s bending guidelines and request a preliminary consultation to review your designs. This proactive approach not only streamlines the process but also enhances the likelihood of receiving accurate and high-quality parts.

Scenario 2: Ensuring Quality and Precision in Production

The Problem: Quality assurance is a significant concern for B2B buyers, particularly when sourcing custom sheet metal components. Variations in production techniques and human error can lead to parts that do not meet specified tolerances, resulting in additional costs for rework or even project delays. This is especially critical in industries where precision is paramount, such as aerospace or automotive manufacturing.

The Solution: Buyers should prioritize partnering with manufacturers that utilize advanced CNC bending technologies and have a proven track record of quality assurance. Look for certifications such as ISO 9001, which indicate adherence to high-quality manufacturing standards. Additionally, request detailed information on the provider’s quality control processes, including how they measure and verify tolerances during production. Establishing clear communication regarding quality expectations, including detailed specifications and tolerances upfront, can also help ensure that the final products align with your standards. Consider implementing a feedback loop where you can report any discrepancies, fostering a continuous improvement mindset between you and your supplier.

Scenario 3: Navigating Lead Times and Delivery Challenges

The Problem: International B2B buyers often face unpredictable lead times when sourcing sheet metal bending services, which can disrupt project timelines. Factors such as shipping delays, customs clearance, and varying production capacities can lead to extended waiting periods. This unpredictability can be particularly frustrating for businesses that rely on just-in-time manufacturing practices or have tight project deadlines.

The Solution: To effectively navigate lead time challenges, buyers should work with suppliers that offer transparency regarding their production schedules and shipping timelines. Utilize platforms that provide instant quotes and real-time updates on order status. It’s advisable to build a relationship with suppliers who can accommodate urgent requests or provide expedited service options when necessary. Additionally, consider diversifying your supplier base to mitigate risks associated with single-source dependencies. Establishing a clear timeline and buffer periods in your project plans can also help accommodate potential delays, ensuring that your operations remain smooth and uninterrupted.

Strategic Material Selection Guide for sheet metal bending service

When selecting materials for sheet metal bending services, it is crucial to understand the properties and applications of various materials. This knowledge enables international B2B buyers to make informed decisions that align with their specific needs and compliance requirements. Below, we analyze four common materials used in sheet metal bending: aluminum, stainless steel, carbon steel, and copper.

What Are the Key Properties of Aluminum in Sheet Metal Bending?

Aluminum is lightweight, corrosion-resistant, and has excellent thermal and electrical conductivity. It typically has a temperature rating of up to 600°F (315°C) before significant deformation occurs. Its low density makes it suitable for applications where weight is a concern, such as in the automotive and aerospace industries.

Pros and Cons:

The primary advantage of aluminum is its excellent corrosion resistance, which makes it ideal for outdoor applications. However, it is softer than other metals, which can lead to deformation under high stress. Additionally, while aluminum is generally more expensive than carbon steel, it offers better performance in specific environments.

Impact on Application:

Aluminum is compatible with various media, including water and chemicals, making it suitable for food and beverage processing. Its lightweight nature also enhances fuel efficiency in transportation applications.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should be aware of compliance with standards such as EN 573 for aluminum alloys. Understanding local preferences for specific aluminum grades can also impact sourcing decisions.

How Does Stainless Steel Perform in Sheet Metal Bending?

Stainless steel is renowned for its strength, durability, and resistance to corrosion and staining. It can withstand temperatures up to 1500°F (815°C) and is often used in environments where high temperatures and corrosive substances are present.

Pros and Cons:

The key advantage of stainless steel is its exceptional durability and aesthetic appeal, making it suitable for both functional and decorative applications. However, it is more expensive than carbon steel and can be more challenging to bend due to its hardness.

Impact on Application:

Stainless steel is ideal for applications involving food processing, pharmaceuticals, and chemical handling due to its hygienic properties. Its resistance to rust and corrosion ensures longevity in harsh environments.

Considerations for International Buyers:

Compliance with standards such as ASTM A240 for stainless steel is essential for buyers in Africa and South America. Understanding local regulations regarding food safety and hygiene can also influence material selection.

What Are the Characteristics of Carbon Steel in Sheet Metal Bending?

Carbon steel is a versatile material known for its strength and affordability. It typically has a temperature rating of around 800°F (427°C) and is commonly used in construction and manufacturing applications.

Pros and Cons:

The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for large-scale projects. However, its susceptibility to rust and corrosion necessitates protective coatings or treatments, which can add to the overall cost.

Impact on Application:

Carbon steel is suitable for applications where strength is paramount, such as in structural components. However, its lack of corrosion resistance limits its use in outdoor environments without proper treatment.

Considerations for International Buyers:

Buyers should be aware of compliance with standards like ASTM A36 for carbon steel. Understanding local market preferences for galvanized versus untreated carbon steel can also influence procurement strategies.

What Are the Unique Properties of Copper in Sheet Metal Bending?

Copper is known for its excellent electrical conductivity and thermal properties. It can withstand temperatures up to 2000°F (1093°C) without losing its structural integrity, making it ideal for electrical applications.

Pros and Cons:

The primary advantage of copper is its superior conductivity, making it essential in electrical and electronic applications. However, it is more expensive than aluminum and carbon steel, and its softness can lead to deformation under heavy loads.

Impact on Application:

Copper is often used in electrical wiring, plumbing, and roofing applications. Its resistance to corrosion in various environments enhances its suitability for outdoor use.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM B370 for copper. Understanding the local demand for copper products in electrical applications can guide sourcing decisions.

Summary Table of Material Selection for Sheet Metal Bending

| Material | Typical Use Case for sheet metal bending service | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace, automotive components | Lightweight and corrosion-resistant | Softer, prone to deformation | Medium |

| Stainless Steel | Food processing, pharmaceuticals | Durable and hygienic | Higher cost, harder to bend | High |

| Carbon Steel | Structural components, construction | Cost-effective and strong | Susceptible to rust, requires treatment | Low |

| Copper | Electrical wiring, plumbing | Excellent conductivity | Expensive, softer material | High |

This guide provides a comprehensive overview of material selection for sheet metal bending services, helping B2B buyers navigate their options effectively.

In-depth Look: Manufacturing Processes and Quality Assurance for sheet metal bending service

What Are the Main Stages of the Sheet Metal Bending Manufacturing Process?

The sheet metal bending manufacturing process is a structured sequence of stages designed to transform raw materials into precision-engineered parts. This process typically includes material preparation, forming, assembly, and finishing.

-

Material Preparation

– The initial stage involves selecting appropriate raw materials, which can range from aluminum and copper to various types of steel. Each material has specific properties that affect bending processes, such as tensile strength and ductility.

– The materials are often cut to size using techniques such as laser cutting or waterjet cutting, ensuring that they are ready for the bending operation. Proper handling and storage of materials are crucial to avoid warping or contamination. -

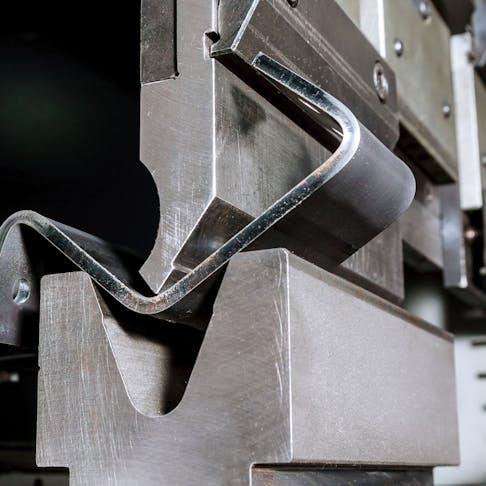

Forming

– The core of the bending process is executed using CNC (Computer Numerical Control) bending machines, which provide precise control over the bending angles and radii. This stage is where the actual bending occurs, and it is vital to adhere to the specifications outlined in the design files.

– Techniques such as air bending, bottom bending, and coining may be utilized, depending on the desired angle and material thickness. Each technique has its advantages and is chosen based on the specific requirements of the project. -

Assembly

– For projects requiring multiple components, assembly may be necessary after bending. This stage can include welding, fastening, or integrating additional parts to create the final product.

– It’s essential to ensure that all components fit together accurately, as misalignment can lead to functional issues in the final assembly. -

Finishing

– After assembly, the components often undergo finishing processes, which can include surface treatments like powder coating, anodizing, or polishing. These processes not only enhance aesthetics but also improve corrosion resistance and durability.

– The finishing stage is crucial for achieving the desired performance characteristics, especially for parts used in demanding environments.

How Is Quality Assurance Integrated into Sheet Metal Bending Services?

Quality assurance (QA) is a critical aspect of the sheet metal bending process, ensuring that the final products meet international standards and client specifications. This involves several key checkpoints and methodologies.

-

International Standards and Certifications

– Many sheet metal bending service providers adhere to recognized international quality standards such as ISO 9001, which focuses on maintaining quality management systems. Compliance with these standards is vital for B2B buyers as it indicates a commitment to quality and consistency.

– Other industry-specific certifications may include CE marking for products sold in Europe, API certifications for oil and gas applications, and AS9100 for aerospace components. Understanding these certifications can help buyers assess the suitability of suppliers for their specific needs. -

Quality Control Checkpoints

– Quality control is typically integrated into various stages of the manufacturing process:- Incoming Quality Control (IQC) involves inspecting raw materials upon arrival to verify they meet specified standards.

- In-Process Quality Control (IPQC) ensures that production processes are monitored continuously, with checks at critical points to catch any deviations early.

- Final Quality Control (FQC) involves a thorough inspection of finished products, ensuring they conform to design specifications and tolerances before shipment.

-

Common Testing Methods for Quality Assurance

– Testing methods can include dimensional inspections, visual inspections, and functional testing to ensure that parts meet the required specifications. Advanced techniques such as non-destructive testing (NDT) may also be employed, especially for high-stakes applications in industries like aerospace and defense.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, it is essential to establish trust in their suppliers’ quality control processes. Here are effective strategies for verification:

-

Supplier Audits

– Conducting audits of potential suppliers can provide deep insights into their manufacturing processes, quality control measures, and adherence to international standards. This can include on-site visits to assess facilities and equipment. -

Requesting Quality Assurance Documentation

– Buyers should request comprehensive documentation regarding the supplier’s quality assurance processes, including inspection reports, certifications, and compliance records. This transparency can help mitigate risks associated with sourcing. -

Third-Party Inspections

– Engaging third-party inspection services can offer an unbiased assessment of a supplier’s capabilities. These services often conduct thorough evaluations of manufacturing practices and can provide certification that meets the buyer’s standards.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International B2B buyers must navigate specific nuances in quality control that can vary by region. Understanding these differences is crucial for ensuring compliance and quality in the supply chain.

-

Regulatory Compliance

– Different countries have varying regulatory requirements that can affect product quality. Buyers must familiarize themselves with local standards, especially when exporting goods or entering new markets. -

Cultural Differences in Quality Perception

– Quality expectations may differ based on regional practices and cultural perceptions. Buyers should communicate their quality requirements clearly and ensure that suppliers understand these expectations. -

Logistical Challenges

– International shipping and logistics can introduce risks that impact quality. Buyers should consider how suppliers manage packaging and shipping to prevent damage during transit.

Conclusion

The manufacturing processes and quality assurance mechanisms in sheet metal bending services are integral to delivering high-quality products that meet client expectations. By understanding the stages of manufacturing, the importance of quality control, and how to verify supplier practices, B2B buyers can make informed decisions that enhance their supply chain efficiency and product reliability. This knowledge is particularly valuable in the context of the diverse international markets, where quality standards and expectations may vary significantly.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sheet metal bending service’

To effectively procure sheet metal bending services, it is essential to follow a structured approach that ensures quality, efficiency, and alignment with your project needs. This guide provides a comprehensive checklist to help international B2B buyers navigate the sourcing process.

Step 1: Define Your Technical Specifications

Clearly outline your project requirements, including material type, thickness, bend angles, and tolerances. This clarity is crucial as it informs potential suppliers about your exact needs and helps in obtaining accurate quotes. Consider factors such as:

– Material Properties: Specify if you need aluminum, steel, or other metals.

– Bend Radius and Tolerances: Define acceptable tolerances to ensure the final product meets your quality standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in the sheet metal bending industry. Look for companies that specialize in the types of services you require and have a proven track record. Key aspects to evaluate include:

– Industry Experience: Suppliers with experience in your specific sector often understand unique challenges and requirements.

– Customer Reviews and Testimonials: Check for feedback from previous clients to gauge reliability and service quality.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with industry standards. Certifications such as ISO 9001:2015 indicate adherence to quality management practices. This step is crucial because:

– Quality Assurance: Certified suppliers are more likely to maintain consistent quality.

– Regulatory Compliance: Understanding if the supplier meets regional regulations can prevent legal issues later on.

Step 4: Request Detailed Quotes

Ask for detailed quotes from shortlisted suppliers, including pricing, lead times, and any additional services they offer. A comprehensive quote should also address:

– Cost Breakdown: Ensure the quote includes costs for materials, labor, and finishing services.

– Lead Times: Confirm production and shipping timelines to align with your project schedule.

Step 5: Assess Production Capabilities

Examine the supplier’s production capabilities to ensure they can meet your volume and complexity requirements. Consider:

– Technology and Equipment: Suppliers using advanced CNC machinery are likely to produce higher precision parts.

– Scalability: Ensure the supplier can handle both small prototypes and large-scale production runs as your needs grow.

Step 6: Check for Value-Added Services

Identify if the supplier offers additional services that can enhance your project. Services such as post-processing, finishing options, and assembly can provide a more comprehensive solution. Look for:

– Customization Options: Ensure the supplier can accommodate specific finishes like powder coating or anodizing.

– Logistics Support: Suppliers offering shipping and project management can simplify the procurement process.

Step 7: Establish Clear Communication Channels

Once you’ve selected a supplier, establish clear communication protocols to facilitate smooth interactions. Effective communication ensures that any issues are addressed promptly and can include:

– Regular Updates: Schedule updates on production progress and any potential delays.

– Feedback Mechanisms: Set up a system for providing feedback on samples and prototypes to ensure alignment with expectations.

By following these steps, B2B buyers can confidently source high-quality sheet metal bending services that meet their operational needs and project specifications.

Comprehensive Cost and Pricing Analysis for sheet metal bending service Sourcing

What Are the Key Cost Components of Sheet Metal Bending Services?

Understanding the cost structure for sheet metal bending services is crucial for B2B buyers looking to make informed purchasing decisions. The main components of cost include:

-

Materials: The choice of materials significantly impacts pricing. Common materials include aluminum, stainless steel, and low-carbon steel, each with its own cost profile. Specialty materials or custom alloys can increase costs further.

-

Labor: Skilled labor is essential for precise bending operations. Labor costs vary based on location and the complexity of the bending required. Regions with higher labor costs may lead to increased overall expenses.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, equipment maintenance, and facility costs. Efficient operations can reduce overhead, allowing for more competitive pricing.

-

Tooling: Custom tooling for specific bends can be a significant upfront investment. While it can increase initial costs, effective tooling can improve efficiency and reduce per-part costs in high-volume orders.

-

Quality Control (QC): Ensuring that parts meet specified tolerances requires investment in quality control processes. This is particularly important for industries with strict compliance requirements, as any rework can lead to additional costs.

-

Logistics: Transportation and shipping costs can vary widely, especially for international buyers. Factors such as distance, shipping methods, and Incoterms affect logistics costs and overall pricing.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market conditions and competition. Understanding this aspect can help buyers evaluate pricing fairness.

How Do Price Influencers Impact the Cost of Sheet Metal Bending Services?

Several factors influence the pricing of sheet metal bending services, making it essential for buyers to consider these variables:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes often lead to lower per-unit costs due to economies of scale. Suppliers may have minimum order quantities, which can affect pricing for smaller projects.

-

Specifications and Customization: Complex designs or specific tolerances can increase production time and costs. Providing detailed specifications can help suppliers give more accurate quotes.

-

Material Selection: The choice of material not only affects cost but also the bending process. For instance, thicker materials may require specialized equipment, impacting overall pricing.

-

Quality and Certifications: Parts requiring specific certifications (e.g., ISO, AS9100) may incur additional costs due to the rigorous quality assurance processes involved.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge a premium but often provide higher reliability and quality assurance.

-

Incoterms: The chosen Incoterms can significantly affect logistics costs. Understanding responsibilities for shipping, insurance, and tariffs is vital for accurate total cost assessments.

What Are the Best Tips for Negotiating Sheet Metal Bending Service Prices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to cost savings:

-

Leverage Volume Discounts: If your business has ongoing needs, negotiating based on anticipated volume can secure better pricing. Suppliers are often willing to offer discounts for long-term contracts.

-

Understand Total Cost of Ownership (TCO): Consider not just the upfront costs but also long-term implications, including maintenance, shipping, and potential rework costs. A lower initial price may not always mean a better deal.

-

Research and Compare Suppliers: Obtain quotes from multiple suppliers to benchmark pricing. This can provide leverage during negotiations and ensure you are getting competitive rates.

-

Be Clear About Requirements: Clearly define your specifications and requirements upfront to avoid misunderstandings that could lead to increased costs later.

-

Explore Regional Suppliers: For international buyers, sourcing from local suppliers can reduce logistics costs and lead times. This may also provide additional negotiation leverage.

Conclusion

Understanding the cost structure and pricing influencers in sheet metal bending services is critical for B2B buyers. By considering key components such as materials, labor, and logistics, as well as employing effective negotiation strategies, buyers can make informed decisions that align with their operational needs. As pricing can vary widely based on specific circumstances, it’s essential to engage in thorough research and open communication with suppliers.

Alternatives Analysis: Comparing sheet metal bending service With Other Solutions

Introduction: What Are the Alternatives to Sheet Metal Bending Services?

When considering sheet metal fabrication, businesses often evaluate various methods to achieve their production goals. While sheet metal bending services are a popular choice due to their precision and efficiency, it’s essential to explore alternative solutions that may better fit specific project requirements. This analysis compares sheet metal bending services with two viable alternatives: welding and 3D printing for metal parts. Each method has unique advantages and limitations that can influence a buyer’s decision.

Comparison Table

| Comparison Aspect | Sheet Metal Bending Service | Welding | 3D Printing for Metal Parts |

|---|---|---|---|

| Performance | High precision; tight tolerances | Good for strong joints; less precise | Complex geometries; variable quality |

| Cost | Moderate; varies by volume and material | Generally lower for large volumes | Higher initial costs; variable per part |

| Ease of Implementation | Simple; requires CAD files | Requires skilled labor; setup time | Easy for small runs; longer for larger |

| Maintenance | Low; minimal upkeep | Moderate; equipment requires upkeep | Low; technology evolving |

| Best Use Case | Complex parts needing exact angles | Structural components and frames | Prototyping and low-volume production |

Detailed Breakdown of Alternatives

Welding

Welding is a traditional method used to join metal pieces by melting them together. It is advantageous when creating structural components or heavy-duty frames, as welded joints can be exceptionally strong. However, while welding can be cost-effective for large volumes, it often lacks the precision of bending services, leading to potential quality control issues. Additionally, the requirement for skilled labor can complicate the implementation process, particularly in regions where skilled welders are scarce.

3D Printing for Metal Parts

3D printing, or additive manufacturing, offers a modern approach to metal fabrication, allowing for the creation of complex geometries that are difficult to achieve through traditional methods. This technique is particularly beneficial for prototyping or low-volume production runs, as it can produce parts quickly without the need for tooling. However, the cost per part can be significantly higher than bending or welding, especially for larger components. Furthermore, the quality of printed parts can vary based on the technology used, necessitating careful selection of the 3D printing process and material.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right metal fabrication solution depends on various factors, including project specifications, budget, and desired outcomes. For projects requiring high precision and tight tolerances, sheet metal bending services are typically the best choice. If the goal is to create strong structural components at a lower cost for large volumes, welding may be more appropriate. Alternatively, for innovative designs or rapid prototyping, 3D printing offers unique advantages despite its higher costs. By assessing these alternatives in the context of their specific needs, B2B buyers can make informed decisions that align with their manufacturing goals and operational capabilities.

Essential Technical Properties and Trade Terminology for sheet metal bending service

What Are the Key Technical Properties of Sheet Metal Bending Services?

When considering sheet metal bending services, understanding the technical properties involved is crucial for making informed purchasing decisions. Here are some essential specifications to keep in mind:

1. Material Grade

The material grade refers to the specific type of metal used for bending, such as stainless steel, aluminum, or copper. Each material has unique properties, such as tensile strength, corrosion resistance, and malleability. For B2B buyers, selecting the appropriate material grade is vital as it impacts the durability and functionality of the final product, aligning with project requirements and industry standards.

2. Bend Radius

The bend radius is the smallest radius a sheet metal part can be bent without causing material failure. It varies depending on the material thickness and type. A smaller bend radius may lead to increased stress and potential cracking. Understanding the bend radius is essential for B2B buyers to ensure that the designed components will meet their application needs without compromising structural integrity.

3. Tolerance

Tolerance refers to the allowable deviation from specified dimensions in the bending process. This includes parameters like edge-to-edge, hole-to-hole, and angle tolerances. In B2B transactions, precise tolerances are critical for ensuring parts fit together correctly in assemblies, thus reducing the likelihood of costly rework or product failures.

4. Minimum Flange Length

Minimum flange length is the shortest length of a flange that can be effectively bent without compromising the part’s integrity. This specification is particularly important in designs that involve multiple bends and connections. B2B buyers must consider minimum flange lengths to avoid design flaws that could hinder assembly or functionality.

5. K-Factor

The K-factor is a ratio that describes the relationship between the material thickness and the bend allowance. It helps in calculating the flat length of the sheet metal before bending. This property is essential for B2B buyers to ensure accurate part dimensions and effective material utilization, minimizing waste and costs.

What Are Common Trade Terms in Sheet Metal Bending Services?

Understanding industry jargon is key to navigating the sheet metal bending services landscape. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, partnering with OEMs can provide access to high-quality, specialized components that meet stringent industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to produce or sell. Understanding the MOQ is crucial for B2B buyers, as it impacts inventory management and cost-effectiveness. Suppliers with lower MOQs can provide flexibility, especially for smaller projects or prototypes.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers. It typically includes specifications for the desired parts or services. For B2B buyers, issuing an RFQ helps in comparing multiple suppliers to find the best fit for their project needs.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. B2B buyers should be familiar with Incoterms to ensure smooth logistics and minimize risk in cross-border transactions.

5. CNC (Computer Numerical Control)

CNC refers to the automated control of machining tools by a computer. In sheet metal bending, CNC technology ensures precision and repeatability in the bending process. For B2B buyers, choosing suppliers that utilize CNC technology can enhance product quality and reduce lead times.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions, ultimately leading to successful partnerships and projects in the sheet metal bending industry.

Navigating Market Dynamics and Sourcing Trends in the sheet metal bending service Sector

What Are the Key Market Drivers and Trends in the Sheet Metal Bending Service Sector?

The sheet metal bending service market is witnessing significant growth, driven by a surge in demand across various sectors such as automotive, aerospace, construction, and consumer goods. Rapid urbanization and infrastructure development, particularly in emerging markets in Africa, South America, and the Middle East, are propelling the need for custom metal components. Additionally, advancements in technology, including the integration of CNC (Computer Numerical Control) systems and automation, are enhancing precision and efficiency in bending processes, allowing for quick turnaround times and cost-effective production.

International B2B buyers are increasingly seeking suppliers who can offer not only high-quality products but also flexibility in design and manufacturing capabilities. The rise of digital platforms for instant quoting and real-time project management is reshaping sourcing strategies, enabling businesses to streamline their procurement processes. Furthermore, trends towards just-in-time (JIT) manufacturing are prompting buyers to collaborate with service providers who can guarantee timely delivery and scalability.

In markets like Europe and Asia, regulations related to material specifications and safety standards are becoming more stringent. This creates opportunities for suppliers who can comply with these regulations while offering innovative solutions tailored to specific industry needs. As a result, buyers must stay informed about regional market dynamics and the capabilities of potential suppliers to ensure alignment with their operational requirements.

How Is Sustainability and Ethical Sourcing Influencing the Sheet Metal Bending Service Industry?

Sustainability has emerged as a pivotal concern for international B2B buyers in the sheet metal bending sector. The environmental impact of manufacturing processes is under scrutiny, leading to increased demand for ‘green’ materials and practices. Suppliers that utilize recyclable materials, such as aluminum and certain steel grades, and implement energy-efficient production methods are gaining a competitive edge. The adoption of sustainable practices is not just about compliance; it is increasingly viewed as a brand differentiator that appeals to environmentally-conscious consumers and businesses.

Ethical sourcing is equally critical, particularly in regions with complex supply chains. Buyers are prioritizing suppliers that maintain transparency and adhere to ethical labor practices, as well as those that can provide certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety. These certifications assure buyers that their suppliers are committed to minimizing their ecological footprint and promoting responsible sourcing.

Moreover, many companies are now integrating sustainability into their product design processes, considering factors like end-of-life recyclability and the overall lifecycle impact of their products. By selecting suppliers that share their commitment to sustainability, B2B buyers can enhance their own corporate social responsibility (CSR) profiles while fostering long-term partnerships.

What Is the Historical Context of the Sheet Metal Bending Service Sector?

The evolution of the sheet metal bending service sector has been marked by significant technological advancements and shifts in market demand. Historically, metal bending relied heavily on manual processes, which limited precision and scalability. However, the introduction of hydraulic and pneumatic press brakes in the mid-20th century revolutionized the industry, allowing for more complex and precise bending operations.

The late 20th and early 21st centuries saw the rise of CNC technology, which automated many aspects of the bending process. This innovation led to greater accuracy, repeatability, and efficiency, enabling manufacturers to meet the growing demands of various industries. As global trade expanded, the sheet metal bending service sector began to cater to international markets, necessitating compliance with diverse regulations and standards.

Today, the industry continues to evolve with the integration of digital technologies, such as 3D modeling and cloud-based project management tools, which facilitate better collaboration between buyers and suppliers. This historical context underscores the importance of adaptability and innovation in meeting the changing needs of B2B buyers in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of sheet metal bending service

-

How do I prevent corner flanges from colliding in my designs?

To avoid issues with corner flanges colliding during the bending process, it’s crucial to incorporate sufficient clearance in your design. This involves ensuring that the flanges meeting at a corner have enough space between them to accommodate the bending machinery. Utilize design software to simulate the bending process and identify potential collisions. Consulting with your bending service provider can also help you optimize your design for better manufacturability, ensuring that your parts are fabricated accurately and efficiently. -

What are the key bending specifications I should consider?

When sourcing sheet metal bending services, it’s essential to understand the bending specifications relevant to your project. Key factors include material thickness, bend radius, K factor, and tolerances. Different materials may require specific bending guidelines, so refer to the provider’s material catalog or bending calculator for precise information. Additionally, consider the minimum flange length required for effective bending, as this can affect the overall design and functionality of the finished product. -

What is the best material for my sheet metal bending project?

The best material for your bending project depends on the application and desired properties. Common materials used in sheet metal bending include aluminum, stainless steel, and mild steel. For lightweight applications, aluminum alloys like 5052 or 6061 are preferred. If corrosion resistance is critical, stainless steel grades such as 304 or 316 are ideal. Consult with your supplier to evaluate the material’s mechanical properties, availability, and cost-effectiveness to ensure it meets your project requirements. -

What are typical lead times for sheet metal bending services?

Lead times for sheet metal bending can vary significantly based on the complexity of the design and the workload of the fabricator. Generally, you can expect standard lead times to start at around 3 to 7 business days for simple projects. For more complex or custom orders, lead times may extend to several weeks. Always confirm lead times with your supplier upfront and factor in any potential delays in logistics, especially when sourcing from international suppliers. -

What are the minimum order quantities (MOQs) for sheet metal bending services?

Minimum order quantities for sheet metal bending services can vary widely among providers. Some companies offer no minimum quantity, allowing you to order single prototypes or small batches, which is ideal for testing and development phases. Others may have MOQs based on production efficiency and material costs. When engaging with suppliers, inquire about their MOQ policies and how they can accommodate your specific project needs, especially if you are operating on a tight budget or timeline. -

How do I ensure quality assurance in my sheet metal bending projects?

To ensure quality assurance, select a bending service provider with established certifications (e.g., ISO 9001) that demonstrate their commitment to quality management. Request detailed information about their quality control processes, including inspection methods and tolerances they adhere to. Additionally, consider requesting samples or prototypes before committing to larger orders. Clear communication about your quality requirements and expectations will also help align with your supplier’s capabilities. -

What payment terms should I expect when sourcing sheet metal bending services internationally?

Payment terms can vary based on the supplier and the nature of your business relationship. Common terms include upfront payments, net 30, or net 60 days after delivery. It’s essential to clarify payment methods accepted, such as credit cards, bank transfers, or letters of credit, especially when dealing with international transactions. Always negotiate terms that ensure both parties are comfortable, and consider using escrow services for added security in larger transactions. -

What logistics considerations should I keep in mind when ordering sheet metal bending services?

When ordering sheet metal bending services, logistics play a crucial role in timely delivery. Assess shipping options, including air freight for expedited needs or sea freight for cost-effective solutions, particularly for larger orders. Additionally, understand the customs regulations and potential tariffs involved in importing goods into your country. Work closely with your supplier to ensure they provide accurate documentation for smooth customs clearance, and factor in lead times for shipping when planning your project timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for sheet metal bending service

In today’s competitive landscape, strategic sourcing of sheet metal bending services is essential for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By collaborating with experienced suppliers who leverage advanced CNC technology and offer a range of materials and finishes, companies can achieve high precision and efficiency in their projects. The importance of understanding material specifications, tolerances, and design guidelines cannot be overstated, as these factors directly influence the quality and cost-effectiveness of the final products.

Furthermore, the ability to access instant quotes and rapid turnaround times is a significant advantage, enabling businesses to respond swiftly to market demands and reduce lead times. Buyers are encouraged to utilize online platforms that facilitate seamless communication and order management, ensuring a streamlined process from design to delivery.

As we look to the future, the demand for custom sheet metal solutions will continue to rise. International buyers are urged to prioritize strategic partnerships with reputable service providers that can meet their unique needs while adhering to quality standards. By investing in these relationships, businesses can not only enhance their product offerings but also strengthen their market position in a dynamic global economy.