Top 9 Lathe Machine Shop Manufacturers & Suppliers List

1. LittleMachineShop – Mini Lathes & Accessories

Domain: littlemachineshop.com

Registered: 2000 (25 years)

Introduction: This company, LittleMachineShop – Mini Lathes & Accessories, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Baileigh – Metal Lathes

Domain: baileigh.com

Registered: 2001 (24 years)

Introduction: Baileigh offers a range of metal lathes designed for precision and durability. Key features include:

– Heavy-duty construction for stability and longevity.

– Variable speed control for versatility in machining.

– Precision ground bedways for accurate cutting.

– Easy-to-use controls for enhanced operator efficiency.

– Various sizes and specifications to meet different machining needs.

– Optional ac…

3. Smithy – Premium Mill Drill Lathe Combo Machines

Domain: smithy.com

Registered: 1998 (27 years)

Introduction: Smithy Machine Tools offers premium mill drill lathe combo machines, including models such as FL300, FL300-II, FTL320, FTL400, SL280, SL6, STH6, and STL6. They provide various machine types including manual lathes, manual mills, and accessories for turning, threading, milling, drilling, and boring. The company is based in Washtenaw County, Michigan, and offers a 90-day hands-on trial, financing op…

4. Penn Tool Co – High-Precision Lathes

Domain: penntoolco.com

Registered: 1997 (28 years)

Introduction: Metal and Industrial Lathe Machines for Sale at Penn Tool Co. High-Precision Lathes: Birmingham Precision Gear Head Lathe (12″ x 36″, inclining spindle, 9 spindle speeds 70-1400ppm), Birmingham Precision Gear Head Lathe (14″ x 40″, diametric and module cutting threads, metric and imperial units), GMC High Speed Precision Engine Lathe (14″ x 40″, 3 horsepower, SINO digital readout, taper attachment…

5. Star – SW-7R Swiss Lathe

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Star SW-7R Swiss lathe with Fanuc 16i-T controls, offered for about $18,000, includes a lot of tooling and add-ons, immaculately maintained, previously used for producing batches of around 2,000 highly precise but low-complexity parts per month.

6. Rockwell – 14 Lathe

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: Lathe size: 12-14 inch, 36-48 inches between centers; Brands/models mentioned: Rockwell 14″, South Bend 13″, Cincinnati 15″ tray top; Features desired: Quick change gear box for threading; Budget: Variable, ideally under $3500; Previous lathe: Atlas/Craftsman 101; Other recommended brands: Precision Matthews, LeBlond, American, Monarch, Sheldon, Cincinnati; Popular size: 13 x 40; Recommended model…

7. Grizzly – Metal Lathes

Domain: grizzly.com

Registered: 1991 (34 years)

Introduction: This company, Grizzly – Metal Lathes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Turret Lathe Specialists – Precision Machining Services

Domain: turretlathespecialists.com

Registered: 2002 (23 years)

Introduction: Turret Lathe Specialists, Inc offers precision machining services since 1973, serving aerospace, defense, cryogenic, and commercial industries. Key features include:

– Over 15 CNC machines in the CNC department

– ISO 9001:2015 certified quality management system

– 20,000+ square foot full-service machining facility

– Extensive network of over 150 approved suppliers

– Services include prototyp…

9. Morgan Performance – CNC Turning & Milling Services

Domain: morganperformance.com

Registered: 1999 (26 years)

Introduction: Lathe Turning & Milling services for metals, plastics, composites, and other materials. CNC lathes with capabilities to turn parts up to 50″ diameter by 156″ long. Services include precision turning, milling (metal removal), threading, drilling, boring, splining & gearing, reaming, tapping, and countersinking. Design assistance available for all standard modeling and design file types. Turn-key pr…

Introduction: Navigating the Global Market for lathe machine shop

In today’s rapidly evolving manufacturing landscape, sourcing reliable lathe machine shops can pose significant challenges for international B2B buyers. Whether you’re a business in Nigeria looking to enhance your production capabilities or a Brazilian manufacturer seeking precision components, understanding the global market dynamics of lathe machine services is crucial. This comprehensive guide aims to demystify the complexities of selecting the right lathe machine shop by covering essential aspects such as types of lathes, their applications across various industries, and strategies for effective supplier vetting.

As you navigate this guide, you’ll gain insights into the diverse offerings available, from traditional manual lathes to advanced CNC systems, tailored to meet specific operational needs. We will also delve into cost considerations, helping you identify budget-friendly options without compromising on quality. Furthermore, the guide emphasizes the importance of building long-term relationships with suppliers who understand the unique challenges of your market, ensuring that you receive not just machines, but solutions that drive your business forward.

By equipping you with actionable knowledge and best practices, this guide empowers international B2B buyers to make informed purchasing decisions that align with their operational goals. Together, we can streamline your sourcing process and foster growth in your manufacturing endeavors, regardless of your geographic location.

Understanding lathe machine shop Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Lathe | Computer-controlled, high precision | Mass production, complex parts | Pros: High accuracy, repeatability; Cons: Higher initial investment, requires skilled operators. |

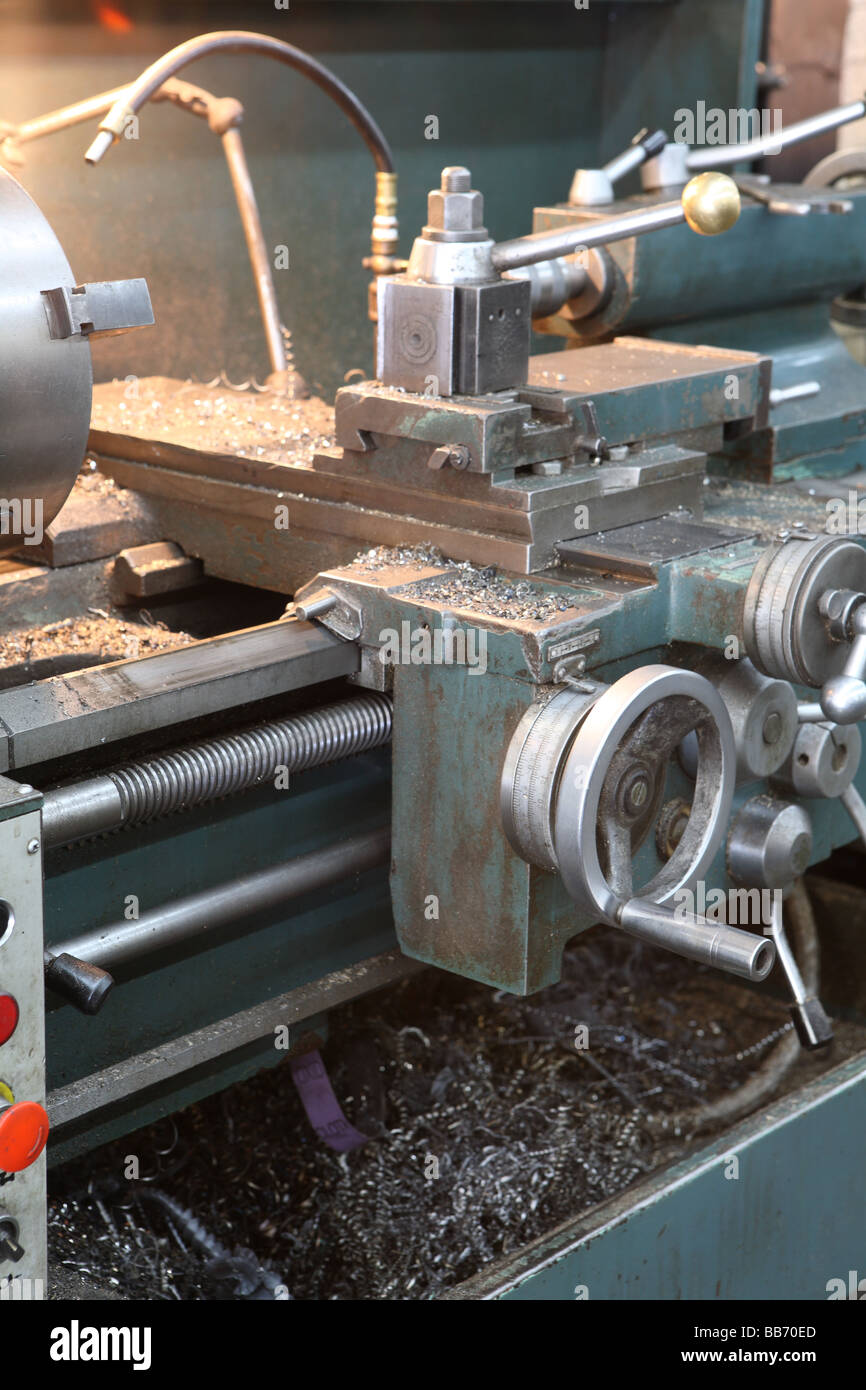

| Manual Lathe | Operated by hand, versatile | Small-scale machining, prototyping | Pros: Lower cost, easier maintenance; Cons: Slower production speed, less precision. |

| Turret Lathe | Multiple cutting tools on a rotating turret | High-volume production, repetitive tasks | Pros: Increased efficiency, quick tool changes; Cons: Limited flexibility for complex designs. |

| Vertical Lathe | Vertical spindle orientation | Large, heavy workpieces | Pros: Better for heavy materials, space-efficient; Cons: Limited to specific applications, higher cost. |

| Swiss Lathe | High-speed, precision machining capabilities | Precision parts, small components | Pros: Excellent for small, complex parts; Cons: Expensive, requires specialized knowledge. |

What Are the Characteristics of CNC Lathes and Their B2B Suitability?

CNC lathes are known for their computer-controlled operation, allowing for high precision and repeatability in machining processes. These machines are particularly suitable for mass production and the manufacturing of complex parts, making them a preferred choice for industries such as automotive and aerospace. When considering a CNC lathe, B2B buyers should evaluate the machine’s software compatibility, the availability of skilled operators, and the total cost of ownership, which includes maintenance and potential downtime.

How Do Manual Lathes Serve Small-Scale Machining Needs?

Manual lathes are versatile machines operated by hand, making them ideal for small-scale machining and prototyping tasks. These lathes offer a lower initial investment and simpler maintenance, appealing to startups and smaller workshops. However, buyers should be aware that manual lathes typically have slower production speeds and may lack the precision of CNC models. When purchasing, consider the machine’s condition, availability of parts, and the skill level required for operation.

What Advantages Do Turret Lathes Offer for High-Volume Production?

Turret lathes feature a rotating turret that holds multiple cutting tools, allowing for efficient high-volume production and repetitive tasks. This design significantly enhances productivity by enabling quick tool changes and reducing setup times. While they are efficient, turret lathes may not be as flexible for complex designs compared to other lathe types. Buyers should assess their production needs, the types of materials processed, and the cost-benefit ratio of investing in a turret lathe.

In What Scenarios Are Vertical Lathes Most Beneficial?

Vertical lathes are characterized by their vertical spindle orientation, which is particularly advantageous for machining large and heavy workpieces. They are space-efficient and can handle heavy materials effectively, making them suitable for industries such as heavy manufacturing and construction. However, vertical lathes are generally limited to specific applications. B2B buyers should consider the machine’s load capacity, the types of materials it can process, and the floor space available in their facilities.

Why Choose Swiss Lathes for Precision Parts Manufacturing?

Swiss lathes are designed for high-speed, precision machining, making them ideal for producing small, complex components. Their ability to operate with tight tolerances makes them invaluable in sectors requiring high precision, such as medical device manufacturing and electronics. However, the initial investment for Swiss lathes can be significant, and they require specialized knowledge for operation. When evaluating Swiss lathes, buyers should focus on the machine’s capabilities, available support, and potential return on investment based on production needs.

Key Industrial Applications of lathe machine shop

| Industry/Sector | Specific Application of lathe machine shop | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision component manufacturing for aircraft engines | High accuracy and reliability in critical components | Certifications (e.g., AS9100), material specifications, lead times |

| Automotive | Production of engine parts and transmission components | Enhanced performance and durability of vehicles | OEM standards, parts traceability, and quality assurance processes |

| Oil & Gas | Fabrication of drilling and extraction equipment | Improved operational efficiency and safety | Compliance with industry regulations, material quality, and sourcing reliability |

| Medical Devices | Manufacturing of surgical instruments and implants | Critical for patient safety and regulatory compliance | Sterilization standards, biocompatibility, and precision requirements |

| Heavy Machinery & Equipment | Production of shafts, gears, and housings | Increased machine uptime and performance | Customization capabilities, robust machinery, and after-sales support |

How is Lathe Machine Shop Used in Aerospace Manufacturing?

In the aerospace industry, lathe machine shops are integral for producing high-precision components such as turbine blades and engine casings. The need for accuracy in these parts is paramount, as they directly affect the safety and performance of aircraft. Buyers in this sector must ensure that suppliers hold relevant certifications like AS9100, which confirms adherence to quality management systems specific to aerospace. Furthermore, they should consider the sourcing of specialized materials that can withstand extreme conditions.

What Role Does Lathe Machine Shop Play in Automotive Production?

Lathe machines are vital in automotive manufacturing for creating engine parts, transmission components, and other precision elements. These components require tight tolerances to enhance vehicle performance and longevity. B2B buyers must focus on suppliers that can meet OEM standards and provide traceability for parts. Additionally, understanding the lead times and the ability to scale production to meet demand fluctuations is crucial for maintaining a competitive edge in this fast-paced industry.

How Do Lathe Machine Shops Support the Oil & Gas Sector?

In the oil and gas industry, lathe machine shops are used to fabricate essential drilling and extraction equipment, such as drill bits and casing. The ability to produce durable components that can withstand harsh environments is critical for operational efficiency and safety. Buyers should prioritize suppliers who comply with industry regulations and can provide high-quality materials. Reliability in sourcing is also essential, as delays can lead to significant operational downtime.

Why Are Lathe Machine Shops Important for Medical Device Manufacturing?

Lathe machine shops play a crucial role in the production of medical devices, including surgical instruments and implants. The precision required for these components is vital for patient safety and compliance with regulatory standards. Buyers in this field must ensure that their suppliers adhere to sterilization standards and biocompatibility requirements. Additionally, the ability to provide detailed documentation and quality assurance processes is critical for maintaining compliance with health regulations.

How Do Heavy Machinery and Equipment Manufacturers Utilize Lathe Machines?

In heavy machinery manufacturing, lathe machine shops are essential for producing components like shafts, gears, and housings. These parts must be robust and precisely engineered to ensure the machinery operates effectively and efficiently. B2B buyers should consider suppliers that offer customization capabilities to meet specific project requirements. Furthermore, robust machinery and strong after-sales support are crucial for minimizing downtime and maximizing productivity in demanding operational environments.

3 Common User Pain Points for ‘lathe machine shop’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Lathe Machine Suppliers

The Problem:

B2B buyers often struggle to find trustworthy suppliers for lathe machines, especially in regions like Africa and South America, where the market may be less saturated with high-quality options. Many buyers report experiences with unreliable vendors, which can lead to delays in production, subpar machine quality, and increased operational costs. Additionally, language barriers and differing standards of service can complicate the procurement process, leaving buyers feeling overwhelmed and unsure about their choices.

The Solution:

To effectively source reliable lathe machine suppliers, buyers should start by conducting thorough research. Utilize platforms like industry-specific trade shows, online marketplaces, and B2B directories that list verified suppliers with customer reviews. Establish direct communication with potential suppliers, and don’t hesitate to ask for references or case studies. Building a relationship with suppliers who understand your local market’s needs and regulatory standards can help ensure that you receive high-quality machines and support. Additionally, consider engaging with local industry associations or chambers of commerce that can provide recommendations and insights about reputable suppliers in your region.

Scenario 2: Overcoming Equipment Downtime Due to Maintenance Issues

The Problem:

Lathe machine downtime can severely impact production schedules, leading to missed deadlines and lost revenue. Buyers frequently face challenges related to maintenance, such as difficulty in sourcing spare parts or understanding the maintenance requirements of their machines. This situation is exacerbated when machines are older or less common, making it challenging to find compatible parts or qualified technicians for repairs.

The Solution:

To mitigate downtime, buyers should implement a proactive maintenance strategy. Start by maintaining an inventory of critical spare parts that are prone to wear and tear. This approach minimizes delays when repairs are needed. Additionally, develop a relationship with a local technician or maintenance service that specializes in lathe machines; they can offer insights into preventative maintenance practices tailored to your specific equipment. Regular training for in-house staff on machine operation and basic troubleshooting can also empower your team to address minor issues before they escalate into significant problems.

Scenario 3: Navigating the Complexity of Customization and Specifications

The Problem:

Many B2B buyers require lathes that can be customized to fit specific production needs, but navigating the complexities of machine specifications can be daunting. Buyers often find themselves unsure of what features are necessary for their operations, leading to the risk of over-specifying (and overspending) or under-specifying (and compromising quality). This challenge is particularly prevalent in industries with unique requirements, such as aerospace or automotive manufacturing.

The Solution:

To effectively navigate customization challenges, buyers should engage in a detailed requirements analysis before beginning the procurement process. This involves assessing current production workflows and identifying specific needs—like material types, tolerances, and expected output rates. Collaborating with a knowledgeable consultant or a technical sales representative from a lathe machine supplier can provide valuable insights into machine capabilities and features. Additionally, consider requesting demonstrations or trial periods for machines to evaluate their performance in real-world conditions before making a significant investment. This hands-on approach can help ensure that the machine’s specifications align perfectly with your operational requirements.

Strategic Material Selection Guide for lathe machine shop

What Are the Key Materials Used in Lathe Machine Shops?

In the context of lathe machine shops, the selection of materials is crucial for ensuring optimal performance, durability, and cost-effectiveness. The following analysis outlines four common materials used in lathe applications, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Steel

Key Properties:

Steel is known for its high tensile strength and durability. It has excellent wear resistance and can withstand high temperatures, making it suitable for heavy-duty applications. Different grades of steel, such as carbon steel and alloy steel, offer varying levels of hardness and corrosion resistance.

Pros & Cons:

Steel is highly durable and can be machined to precise tolerances. However, it is more expensive than other materials like aluminum. The manufacturing complexity can also increase depending on the specific steel grade used, which may require specialized tooling.

Impact on Application:

Steel is compatible with a wide range of media, including oils and coolants commonly used in machining operations. Its strength makes it ideal for parts that undergo significant stress.

Considerations for International Buyers:

Buyers should be aware of compliance with international standards such as ASTM and DIN. The availability of specific steel grades may vary by region, impacting lead times and costs.

2. Aluminum

Key Properties:

Aluminum is lightweight and has excellent corrosion resistance. It can be easily machined and is known for its thermal conductivity, making it suitable for applications requiring heat dissipation.

Pros & Cons:

Aluminum is less expensive than steel and is easier to machine, which can reduce manufacturing costs. However, it has lower tensile strength compared to steel, making it less suitable for high-stress applications.

Impact on Application:

Aluminum is ideal for components that require lightweight characteristics and good corrosion resistance, such as housings and brackets. It is compatible with various media, including water-based coolants.

Considerations for International Buyers:

Buyers should consider regional preferences for aluminum alloys, which can vary significantly. Compliance with standards like JIS may also be important, particularly in Asian markets.

3. Cast Iron

Key Properties:

Cast iron is known for its excellent machinability and vibration-damping properties. It has good wear resistance and can withstand high temperatures, making it a preferred choice for lathe beds and frames.

Pros & Cons:

Cast iron is generally less expensive than steel and offers good stability. However, it is brittle and can fracture under extreme stress, limiting its use in high-stress applications.

Impact on Application:

Cast iron is particularly suitable for components that require stability and precision, such as lathe beds. Its ability to dampen vibrations enhances machining accuracy.

Considerations for International Buyers:

Buyers should ensure that cast iron components meet regional quality standards, as variations in composition can affect performance. Compliance with ASTM standards is often required in North America.

4. Composite Materials

Key Properties:

Composite materials, such as fiberglass-reinforced plastics, offer a unique combination of lightweight and strength. They exhibit excellent resistance to corrosion and can be engineered for specific applications.

Pros & Cons:

Composites can be tailored to meet specific performance criteria, making them versatile. However, they can be more expensive than traditional materials and may require specialized manufacturing processes.

Impact on Application:

Composites are suitable for applications requiring lightweight components that resist chemical exposure. They can be used in environments with aggressive media, such as certain acids or solvents.

Considerations for International Buyers:

Understanding the local availability of composite materials and their compliance with international standards is essential. Buyers should also evaluate the long-term durability and performance of composites in their specific applications.

Summary Table

| Material | Typical Use Case for lathe machine shop | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Precision parts and heavy-duty applications | High tensile strength | More expensive than alternatives | High |

| Aluminum | Lightweight components and housings | Excellent corrosion resistance | Lower tensile strength | Medium |

| Cast Iron | Lathe beds and frames | Good stability and vibration damping | Brittle under extreme stress | Low |

| Composite Materials | Chemical-resistant components | Tailored performance | Higher manufacturing complexity | High |

This guide provides a comprehensive overview of materials commonly used in lathe machine shops, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for lathe machine shop

What Are the Main Stages of Manufacturing in a Lathe Machine Shop?

Manufacturing in a lathe machine shop involves several critical stages that ensure high-quality output. Each stage is designed to transform raw materials into finished components while maintaining precision and efficiency.

1. Material Preparation: What Steps Are Involved?

The first step in the manufacturing process is material preparation. This involves selecting the appropriate raw materials, which may include metals such as aluminum, steel, or brass, depending on the specifications of the final product. The materials are then cut into manageable sizes, often using saws or shears.

Once cut, the materials undergo cleaning to remove any contaminants that may affect the machining process. This may involve chemical cleaning or abrasive methods. Proper material preparation is essential as it ensures uniformity and quality in the finished product.

2. Forming: How Is the Material Shaped?

In the forming stage, the prepared materials are shaped using a lathe machine. This is where the actual machining occurs, and it can involve various techniques such as turning, facing, and threading.

- Turning involves rotating the workpiece against a cutting tool to remove material, creating cylindrical shapes.

- Facing is used to create flat surfaces on the ends of the workpiece.

- Threading is critical for producing screw threads on the workpiece.

Each of these techniques requires precise control over speed, feed rate, and tool selection to ensure dimensional accuracy and surface finish.

3. Assembly: How Are Parts Joined Together?

Once individual components are machined, they may need to be assembled. This stage can involve various joining techniques, such as welding, soldering, or using fasteners. The choice of assembly method depends on the application and the materials used.

For instance, precision assemblies may require welding to ensure strong, permanent joints. In contrast, components intended for easy disassembly may use screws or bolts. This stage is crucial for ensuring that the final product functions as intended, particularly in applications where tight tolerances are essential.

4. Finishing: What Techniques Are Used to Achieve Quality?

The finishing stage enhances the aesthetic and functional properties of the product. This may involve processes such as grinding, polishing, or coating.

- Grinding is used to achieve high levels of precision and smoothness.

- Polishing enhances the visual appearance and can also reduce friction.

- Coating can provide protection against corrosion or wear.

Each finishing technique is selected based on the desired properties of the final product and the specific industry standards that must be met.

What Quality Assurance Processes Are Essential for Lathe Machine Shops?

Quality assurance (QA) is a critical aspect of manufacturing in a lathe machine shop. It ensures that products meet both customer specifications and regulatory standards.

1. What International Standards Should Be Followed?

Adhering to international standards is essential for maintaining quality and gaining trust in global markets. One of the most recognized standards is ISO 9001, which outlines criteria for a quality management system. This standard emphasizes continuous improvement, customer satisfaction, and process optimization.

In addition to ISO 9001, industry-specific certifications may be required. For example, CE marking is crucial for products sold in the European market, indicating compliance with safety, health, and environmental protection standards. In the oil and gas sector, certifications like API (American Petroleum Institute) standards are essential for components used in drilling and production equipment.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral throughout the manufacturing process. Key stages include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, minimizing waste and rework.

- Final Quality Control (FQC): A thorough inspection of the finished product ensures it meets all specifications before shipping.

Each checkpoint is designed to catch potential issues that could affect product quality, ensuring that only the best products reach the customer.

3. What Common Testing Methods Are Used?

Various testing methods are employed to verify the quality of machined components. Common methods include:

- Dimensional Inspection: Utilizing tools like calipers and micrometers to ensure that parts meet specified dimensions.

- Surface Roughness Testing: Measuring the surface finish to ensure it meets required standards.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle testing to identify internal flaws without damaging the product.

These testing methods are critical for verifying that components are fit for purpose and comply with industry standards.

How Can B2B Buyers Verify Supplier Quality Assurance?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying the quality assurance processes of suppliers is essential for mitigating risks.

1. What Role Do Audits and Reports Play?

Conducting supplier audits is a proactive approach to ensure that manufacturing processes and quality control measures meet industry standards. An audit may involve on-site inspections, reviewing quality management systems, and assessing compliance with international standards.

Additionally, suppliers should provide detailed quality assurance reports that outline their QC processes, inspection results, and any certifications they hold. This transparency helps build trust and ensures that buyers can make informed decisions.

2. How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing processes and quality assurance practices. These inspections can be particularly valuable when sourcing from international suppliers, as they provide an additional layer of assurance regarding product quality.

What Are the Nuances of Quality Control for International B2B Buyers?

B2B buyers operating in different regions must be aware of specific nuances in quality control. For instance, understanding local regulations and standards is critical when importing products. Additionally, language barriers and cultural differences may affect communication regarding quality expectations.

It is advisable for buyers to establish clear quality requirements in contracts and maintain open lines of communication with suppliers to address any concerns promptly. By prioritizing quality assurance and understanding the manufacturing processes involved, buyers can mitigate risks and ensure they receive high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lathe machine shop’

To assist international B2B buyers in procuring a lathe machine shop, this guide outlines essential steps to ensure a successful sourcing process. By following this checklist, buyers can make informed decisions that align with their operational needs and budget constraints.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications required for your lathe machines. Consider factors such as size, power, precision, and the types of materials you will be working with. A precise specification helps narrow down options and ensures that the machines you consider will meet your production needs effectively.

- Key considerations: Maximum turning diameter, length of workpiece, and spindle speed.

- Performance requirements: Determine if CNC (Computer Numerical Control) capabilities are necessary for your operations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a solid reputation in the lathe machine market. Look for companies that have experience serving businesses in your region or industry. This step is crucial to ensure you partner with reliable suppliers who can meet your specifications and timelines.

- Sources to consider: Industry trade shows, online marketplaces, and professional networks.

- Evaluate online presence: Supplier websites should provide comprehensive information about their products and services.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with industry standards. Certifications such as ISO 9001 can indicate a commitment to quality management and consistent performance.

- Importance of certifications: They ensure that the supplier adheres to international quality standards, which is critical for maintaining operational excellence.

- Request documentation: Ask for copies of certifications and any relevant quality assurance processes they follow.

Step 4: Request Detailed Quotations

Solicit detailed quotations from shortlisted suppliers, including pricing, delivery timelines, and payment terms. A well-structured quote provides clarity on what to expect and allows for easier comparison between suppliers.

- Include specifics: Ensure the quote covers all aspects, including installation, training, and after-sales support.

- Negotiation opportunities: Use the quotes to negotiate better terms, especially if you are considering bulk purchases.

Step 5: Assess After-Sales Support and Warranty

Investigate the after-sales support and warranty policies offered by potential suppliers. Robust support and warranty terms can save significant costs and downtime should any issues arise with the machinery.

- Key aspects to check: Availability of spare parts, service contracts, and response times for service requests.

- Long-term relationship: A supplier with strong after-sales support is often a better long-term partner.

Step 6: Visit the Supplier’s Facility (if possible)

If feasible, arrange to visit the supplier’s facility to inspect their operations and machinery. This visit provides a firsthand look at the quality of their products and the professionalism of their operations.

- What to look for: The condition of the machines, cleanliness of the facility, and the expertise of their staff.

- Trust your instincts: Personal interactions can often reveal more than what is presented in a proposal.

Step 7: Finalize the Agreement

Once you have selected a supplier, finalize the agreement by clearly outlining all terms and conditions. Ensure that both parties understand the expectations regarding delivery, installation, and payment.

- Legal considerations: Involve legal counsel to review the contract, especially if it includes significant financial commitments.

- Maintain communication: Keep lines of communication open during the contract execution phase to address any concerns promptly.

By following these steps, international B2B buyers can effectively navigate the complexities of sourcing lathe machines and establish successful partnerships that enhance their operations.

Comprehensive Cost and Pricing Analysis for lathe machine shop Sourcing

What Are the Key Cost Components in Sourcing Lathe Machine Shops?

When engaging with lathe machine shops, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The raw materials used in production, such as metal alloys and plastics, significantly impact costs. Prices can fluctuate based on global market conditions, availability, and quality specifications. Opting for higher-quality materials may lead to increased upfront costs but can enhance durability and performance.

-

Labor: Labor costs encompass skilled machinists and operators. The wage rates can vary widely based on geographic location and expertise. For instance, labor costs in Europe may be higher than in Africa or South America, reflecting local economic conditions and labor market dynamics.

-

Manufacturing Overhead: This includes costs associated with maintaining machinery, facility expenses, and utilities. Efficient overhead management can lead to cost savings, making it essential for buyers to inquire about a supplier’s operational efficiencies.

-

Tooling: Tooling costs involve the equipment and fixtures necessary for machining operations. Custom tooling can increase initial costs but may be necessary for specialized projects. Buyers should evaluate the tooling requirements early in the sourcing process to avoid unexpected expenses.

-

Quality Control (QC): Investing in robust QC processes ensures that products meet specifications and standards. However, stringent QC measures can add to overall costs. It’s important to assess a supplier’s QC capabilities and certifications to ensure compliance without excessive costs.

-

Logistics: Transportation and shipping costs can be significant, especially for international transactions. Factors such as distance, shipping method, and Incoterms can influence logistics expenses. Buyers should consider these factors when comparing suppliers from different regions.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the industry standard margins can help buyers negotiate better deals.

What Influences Pricing in Lathe Machine Shop Sourcing?

Several factors can influence pricing when sourcing from lathe machine shops:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounted rates. Buyers should evaluate their needs and consider negotiating bulk purchase agreements to optimize costs.

-

Specifications and Customization: Custom projects that require specific tolerances or unique designs may incur higher costs. Clear communication of specifications upfront can help suppliers provide accurate quotes.

-

Material Quality and Certifications: The choice of materials and the presence of certifications (e.g., ISO, AS9100) can affect prices. Higher-grade materials or certified processes often justify a higher price point due to their enhanced reliability.

-

Supplier Factors: Supplier reputation, experience, and service quality can influence pricing. Established suppliers with a proven track record may charge premium rates, but their reliability can mitigate risks.

-

Incoterms: Understanding Incoterms is essential for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect pricing and responsibility for shipping costs, impacting the overall expense.

What Are Some Effective Buyer Tips for Negotiating Prices?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, here are some negotiation tips:

-

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and terms in your industry. Use this data to benchmark and negotiate effectively.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just the upfront price. Evaluate long-term factors like maintenance, durability, and operational efficiency when assessing supplier quotes.

-

Flexibility and Relationship Building: Establishing a good relationship with suppliers can lead to better terms and pricing. Being flexible in negotiations can foster goodwill and encourage suppliers to offer discounts.

-

Leverage Local Knowledge: Utilize local contacts and experts to navigate the sourcing landscape effectively. They can provide insights into regional pricing trends and supplier reputations.

-

Be Aware of Pricing Nuances: Understand that pricing can vary significantly based on region and economic conditions. Be prepared for fluctuations and factor these into your budget planning.

Disclaimer on Pricing Information

It is essential to note that the prices and costs outlined in this analysis are indicative and can vary based on market conditions, supplier capabilities, and specific project requirements. Always consult with multiple suppliers to obtain accurate quotes tailored to your needs.

Alternatives Analysis: Comparing lathe machine shop With Other Solutions

Understanding Alternative Solutions to Lathe Machine Shops

In the evolving landscape of manufacturing and machining, businesses often seek alternatives to traditional lathe machine shops. These alternatives can provide similar functionalities while potentially offering advantages in cost, efficiency, or implementation. This section explores several viable options, comparing them against the conventional lathe machine shop to assist B2B buyers in making informed decisions.

Comparison Table

| Comparison Aspect | Lathe Machine Shop | CNC Machining Center | 3D Printing |

|---|---|---|---|

| Performance | High precision in turning | Excellent for complex shapes | Good for prototyping and low-volume production |

| Cost | Moderate to high setup cost | Higher initial investment | Variable; low for small parts but can escalate |

| Ease of Implementation | Requires skilled operators | Steeper learning curve | User-friendly software available |

| Maintenance | Regular upkeep needed | High maintenance due to complexity | Minimal maintenance required |

| Best Use Case | Traditional machining tasks | Complex, high-volume production | Rapid prototyping, custom parts |

Detailed Breakdown of Alternatives

CNC Machining Center

CNC (Computer Numerical Control) machining centers are automated machines that can perform multiple machining tasks with high precision. They excel in producing complex geometries and are ideal for high-volume production runs. The primary advantage of CNC machining centers lies in their automation, which reduces labor costs and increases output efficiency. However, they come with a higher initial investment and a steeper learning curve, requiring operators to be trained in both machining and programming. For businesses that prioritize volume and complexity, CNC machining is often a superior choice.

3D Printing

3D printing, or additive manufacturing, has emerged as a revolutionary alternative to traditional machining methods. It allows for the creation of intricate designs directly from digital models, making it exceptionally useful for prototyping and custom parts production. One of the main benefits of 3D printing is its flexibility; it can produce low volumes of parts economically and with minimal setup time. However, the material options can be limited compared to metal machining, and the cost can escalate for larger or more complex components. This method is best suited for industries focused on rapid prototyping or requiring customized solutions.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between a lathe machine shop and its alternatives, B2B buyers should consider several factors, including the complexity of the parts, volume of production, available budget, and required precision. For traditional manufacturing needs, a lathe machine shop may provide the best results. Conversely, for businesses needing intricate designs or rapid prototyping capabilities, CNC machining or 3D printing may be more advantageous. Evaluating these aspects will help buyers align their choice with operational goals, ensuring a solution that meets both immediate and long-term manufacturing needs.

Essential Technical Properties and Trade Terminology for lathe machine shop

What Are the Key Technical Properties of Lathe Machines in a Machine Shop?

When assessing lathe machines for your operations, understanding their technical specifications is crucial for making informed purchasing decisions. Here are several key specifications to consider:

-

Material Grade: The material used in the construction of a lathe significantly affects its durability and performance. Common materials include cast iron and steel, which provide the necessary rigidity and vibration dampening. For B2B buyers, selecting machines made from high-grade materials ensures longevity and reliability in high-volume production environments.

-

Tolerance Levels: Tolerance refers to the permissible limit of variation in a physical dimension. In lathe machining, tight tolerances are critical for ensuring parts fit and function correctly. For businesses in sectors such as aerospace or automotive, where precision is paramount, understanding the tolerance levels that a lathe can achieve is essential for quality assurance.

-

Spindle Speed: This specification indicates the rotational speed of the spindle and is measured in revolutions per minute (RPM). Different materials and operations require varying spindle speeds; for example, softer materials can be machined at higher speeds. B2B buyers must consider the range of spindle speeds available to ensure versatility in their machining capabilities.

-

Bed Length and Swing Over Bed: The bed length determines the maximum length of the workpiece that can be machined, while the swing over bed refers to the maximum diameter of the workpiece that can be accommodated. Understanding these dimensions is vital for companies that deal with large or long components, as they dictate the types of jobs the lathe can handle.

-

Quick Change Gearbox: This feature allows operators to change spindle speeds and feeds rapidly, facilitating a variety of machining operations without extensive downtime. For businesses that require flexibility in their production processes, a lathe with a quick change gearbox can significantly enhance productivity.

What Are Common Trade Terms Used in the Lathe Machine Industry?

Familiarizing yourself with industry jargon can streamline communication and enhance negotiation processes with suppliers. Here are some common terms relevant to lathe machine operations:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers to ensure they are sourcing quality components that meet industry standards.

-

MOQ (Minimum Order Quantity): This is the smallest amount of product that a supplier is willing to sell. For buyers, knowing the MOQ can help in budgeting and inventory management, particularly when purchasing lathes or related components in bulk.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing for specific items or services. Using RFQs effectively can help businesses compare costs and negotiate better deals, ensuring they are getting the best value for their investments.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers in shipping and logistics. Familiarity with Incoterms can help B2B buyers manage shipping costs and responsibilities more effectively, particularly when sourcing machines globally.

-

CNC (Computer Numerical Control): CNC refers to automated control of machining tools through a computer. Understanding the capabilities of CNC lathes versus traditional lathes is essential for businesses looking to enhance precision and efficiency in their machining operations.

-

Surplus Asset Management: This term refers to the process of selling excess machinery or equipment. For companies looking to upgrade their equipment, understanding surplus asset management strategies can maximize their return on investment when disposing of old lathes.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right lathe machines and negotiate favorable terms in their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the lathe machine shop Sector

What Are the Key Market Dynamics and Sourcing Trends for Lathe Machine Shops?

The lathe machine shop sector is experiencing significant shifts driven by technological advancements, evolving customer needs, and global market dynamics. Key trends include the increasing adoption of CNC (Computer Numerical Control) lathes, which enhance precision and efficiency in machining operations. As industries seek to optimize production processes, the demand for automation and smart manufacturing solutions is rising, particularly in regions like Africa and South America, where industrialization is accelerating. International B2B buyers from these regions should focus on suppliers that offer advanced technology integrations, such as IoT-enabled machines that facilitate real-time monitoring and predictive maintenance.

Moreover, the trend towards digital sourcing platforms is reshaping how buyers connect with suppliers. Online auctions and surplus machinery marketplaces are becoming popular avenues for procuring both new and used equipment, allowing buyers to access a broader inventory and competitive pricing. These platforms not only facilitate price comparison but also enable buyers to evaluate the condition and specifications of machines before making purchasing decisions.

Additionally, geopolitical factors, such as trade agreements and tariffs, are influencing sourcing strategies. Buyers must remain vigilant about market volatility and consider diversifying their supplier base to mitigate risks associated with dependence on a single region or supplier.

How Can Sustainability and Ethical Sourcing Impact Lathe Machine Shop Operations?

Sustainability is becoming a critical consideration in the lathe machine shop sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt more sustainable practices. This includes using energy-efficient machinery, reducing waste, and implementing recycling programs for scrap metal and used parts. For international buyers, especially in emerging markets, sourcing from suppliers that prioritize sustainability can enhance their brand reputation and compliance with global regulations.

Ethical sourcing is equally important, as buyers increasingly demand transparency in supply chains. This involves ensuring that materials are sourced responsibly, with attention to labor practices and environmental stewardship. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a supplier’s commitment to ethical practices.

Moreover, as the demand for ‘green’ materials grows, buyers should consider suppliers that offer alternative materials with lower environmental footprints. This not only aligns with global sustainability goals but also appeals to environmentally conscious customers.

How Has the Lathe Machine Shop Sector Evolved Over Time?

The lathe machine shop sector has undergone significant evolution since its inception in the 18th century. Initially, lathes were manually operated, requiring skilled craftsmen to produce precision parts. With the advent of industrialization, mechanization led to increased production capabilities and the introduction of electric lathes, which enhanced efficiency.

The late 20th century marked a pivotal shift with the introduction of CNC technology, revolutionizing machining processes. This advancement allowed for greater precision and automation, enabling manufacturers to produce complex components with minimal human intervention. Today, the sector is witnessing the integration of Industry 4.0 technologies, including artificial intelligence and machine learning, to further optimize operations and enhance product quality.

As a result, international B2B buyers must stay informed about technological advancements and industry trends to ensure they are sourcing from suppliers that align with current and future market demands. Understanding this evolution can provide valuable insights into making informed purchasing decisions and fostering long-term partnerships within the lathe machine shop sector.

Frequently Asked Questions (FAQs) for B2B Buyers of lathe machine shop

-

How do I select the right lathe machine for my business needs?

Selecting the right lathe machine involves understanding your specific application requirements, such as the types of materials you will be machining and the precision levels needed. Assess the machine’s size, power, and capabilities, including whether you require CNC (Computer Numerical Control) or manual lathes. Additionally, consider the machine’s versatility for future projects. Consulting with manufacturers or suppliers can also provide insights into the best options for your operational needs. -

What are the key features to look for in a lathe machine?

When evaluating lathe machines, focus on features such as spindle speed, bed length, and the machine’s ability to handle various materials. A quick-change gearbox is essential for threading applications, while a robust construction ensures durability and stability during operations. Look for additional features like digital readouts for precision and automatic tool changers for efficiency. Understanding these specifications will help you make an informed choice that aligns with your production goals. -

What are the typical payment terms for purchasing lathe machines internationally?

Payment terms can vary widely based on the supplier and the buyer’s location. Common options include advance payment, letters of credit, or payment upon delivery. For international transactions, it is crucial to establish clear terms regarding currency, payment method, and potential escrow services to protect both parties. Always ensure that the terms are documented in the purchase agreement to avoid misunderstandings and facilitate smoother transactions. -

What is the minimum order quantity (MOQ) for lathe machines, and how does it affect my purchase?

The MOQ for lathe machines typically depends on the manufacturer or supplier. Many suppliers may have a minimum order requirement for bulk purchases, which could be a single unit or several machines. Understanding the MOQ is vital, as it impacts your initial investment and inventory management. If you are starting small, seek suppliers that accommodate lower quantities or offer financing options to ease the financial burden. -

How can I ensure the quality of lathe machines from international suppliers?

To ensure quality when sourcing lathe machines internationally, conduct thorough supplier vetting. This includes checking certifications, reviewing past customer feedback, and requesting product samples if feasible. Consider visiting the manufacturing facility or utilizing third-party inspection services to assess the machines before purchase. Establishing a relationship with a reputable supplier will also increase the likelihood of receiving high-quality equipment that meets your specifications. -

What logistics considerations should I keep in mind when importing lathe machines?

Logistics is crucial when importing lathe machines, as it involves transport, customs clearance, and delivery timelines. Ensure you understand the shipping methods available (e.g., sea or air freight) and the associated costs. Additionally, factor in customs duties and taxes that may apply to your shipment. Collaborating with experienced logistics providers can help streamline the process and mitigate potential delays in delivery. -

What customization options are available for lathe machines?

Many manufacturers offer customization options for lathe machines to better suit specific operational needs. This may include modifications to the machine’s size, tooling options, or software features for CNC machines. Discuss your requirements with suppliers to explore available options, ensuring they align with your production processes. Customization can enhance efficiency and productivity, making it a worthwhile investment for your business. -

How do I handle after-sales support and maintenance for lathe machines?

After-sales support is critical for the longevity and performance of your lathe machines. Ensure that the supplier provides comprehensive support, including installation, training, and maintenance services. Inquire about warranty terms and the availability of spare parts for future repairs. Establishing a relationship with a local service provider can also facilitate timely maintenance and minimize downtime, ultimately supporting your operational efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lathe machine shop

In today’s competitive landscape, strategic sourcing is vital for lathe machine shops aiming to optimize operations and enhance profitability. By leveraging a diverse range of suppliers, businesses can ensure access to the latest technologies and high-quality equipment, which is essential for meeting the growing demands of international markets. Investing in both new and used machinery, alongside effective surplus asset management, enables buyers to maximize their operational efficiency while minimizing costs.

For international B2B buyers, especially those in emerging markets across Africa, South America, the Middle East, and Europe, the opportunity to capitalize on strategic sourcing cannot be overstated. Engaging with reputable suppliers who understand local market dynamics can yield significant advantages, from improved supply chain resilience to better pricing strategies.

As you navigate the complexities of sourcing for your lathe machine shop, consider the long-term benefits of building strong partnerships with suppliers. Embrace innovative sourcing solutions and stay informed about market trends to position your business for success. The future of your operations depends on the strategic decisions you make today—seize the opportunity to enhance your competitive edge.