Top 9 Industrial Machinery Suppliers Manufacturers & Suppliers List

1. Moog – Innovative Industrial Machinery Solutions

Domain: moog.com

Registered: 1990 (35 years)

Introduction: Moog offers innovative industrial machinery solutions that combine electric, hydraulic, and hybrid technologies. Key product categories include: Slip Rings, Motors, Servo Valves, Actuators and Servoactuators, Electrohydrostatic Pump Unit, Manifolds, Radial Piston Pumps, and Drives and Servo Drives. The company addresses challenges in various sectors such as Material Handling, Metal Forming and Pre…

2. Industrial Machine Corporation – Custom Machining Services

Domain: industrialmachinecorp.com

Registered: 2009 (16 years)

Introduction: This company, Industrial Machine Corporation – Custom Machining Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. 3M – Advanced Technical Ceramics

Domain: 3m.com

Registered: 1988 (37 years)

Introduction: 3M™ Nextel™ Ceramic Fibers and Fabrics, 3M Silicon Nitride, 3M Silicon Carbide, 3M Technical Ceramics for pumps and compressors, seals & gaskets including wet seals, mechanical seals, and dry gas seal faces.

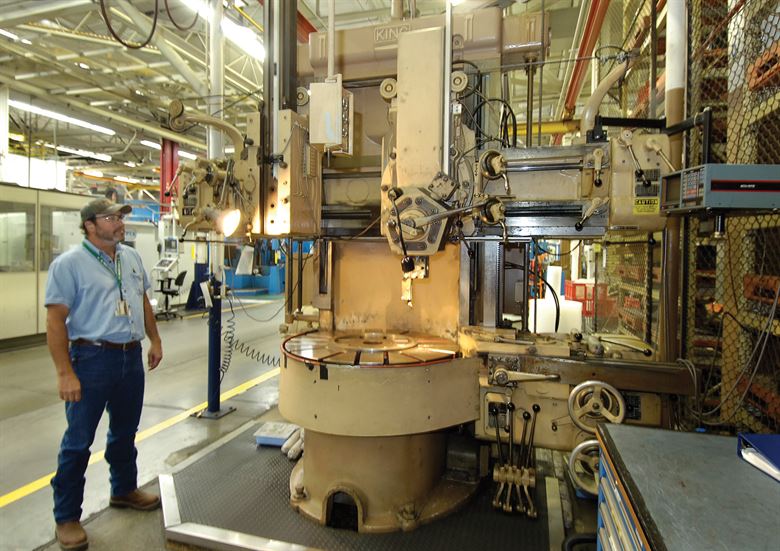

4. Prestige Equipment – CNC Boring Mill

Domain: prestigeequipment.com

Registered: 1996 (29 years)

Introduction: Used machinery for sale including CNC and conventional machine tools, fabricating equipment, and complete manufacturing facilities. Popular categories include brakes, hydraulic presses, boring mills, lathes, and CNC machining centers. Featured products include Giddings & Lewis RT1250 CNC Boring Mill, Poreba TCG 160/6M Lathe, and Bystronic Xcite 80E CNC Electric Servo Press Brake. The company speci…

5. Industrial Machinery – Machine Tools & Accessories

Domain: industrialmachinery.com

Registered: 1997 (28 years)

Introduction: Industrial Machinery offers new and used machine tools for sale, including parts and service for Bridgeport mills, CNC mills, lathes, shears, press brakes, ironworkers, and fabrication machinery. Key product categories include: 1. Machine Tooling & Accessories 2. Air Compressors – New & Used 3. Blast Cabinets – New & Used 4. Brakes – New and Used 5. Deburring & Beveling Machines 6. Drills – New & …

6. All Industrial – Machine Shop Supplies & Tools

Domain: allindustrial.com

Registered: 2003 (22 years)

Introduction: Machine Shop Supplies & Industrial Tools, including: Abrasives (Brushes, Files, Discs, Wheels), Deburring Tools, Dressing Tools, Grinding & Cutoff Wheels, Honing & Lapping, Fasteners (Bolts, Screws, Nuts), Hydraulic Systems & Pumps, Air Tools (Compressors, Wrenches), Hand & Power Tools (Drills, Saws, Wrenches), Holemaking Tools (Broaches, Drills, Countersinks), Coolants & Lubricants, Industrial Ch…

7. TMG – Pro Series Dual Truss Storage Shelters

Domain: tmgindustrial.com

Registered: 2015 (10 years)

Introduction: TMG-DT3081-PRO Pro Series 30′ x 80′ Dual Truss Storage Shelter – Current price: $21,999.00, Original price: $27,999.00. Durable outdoor storage solution or workshop for farms.

TMG-DT2064-PRO Pro Series 20′ x 63′ Dual Truss Storage Shelter – Current price: $11,999.00, Original price: $13,649.00. Easy to assemble, durable outdoor storage solution or workshop for farms.

TMG-ST3041CG 30′ x 40′ Conta…

8. Productivity – CNC Machine Tools & Equipment

Domain: productivity.com

Registered: 1991 (34 years)

Introduction: Productivity is a supplier and distributor of metalworking CNC machine tools and equipment. They offer a wide range of products and services including: CNC machine tools (new and used), fabrication equipment, machine parts, tooling and industrial supplies, automation and robotics solutions (including RoboFlex™), and services such as machine service and repair, preventive maintenance, and training….

9. PEKO Precision – Turnkey Machinery Solutions

Domain: pekoprecision.com

Registered: 1998 (27 years)

Introduction: PEKO Precision offers comprehensive machinery manufacturing and turnkey industrial equipment services, including contract manufacturing, contract assembly, NPI & engineering, sheet metal fabrication, and test development. Key offerings include:

– Turnkey machine build

– Custom machinery

– Automation equipment

– Custom ATE systems

– Capital equipment

– High-level assembly

– Precision assembl…

Introduction: Navigating the Global Market for industrial machinery suppliers

Navigating the complex landscape of industrial machinery suppliers presents a significant challenge for international B2B buyers, particularly when sourcing high-performance equipment that meets stringent quality and operational standards. As global industries strive for enhanced productivity and sustainability, understanding the nuances of industrial machinery—from types and applications to supplier vetting and cost considerations—becomes essential. This guide offers a comprehensive overview of the industrial machinery market, providing insights into various machinery types, such as CNC machines, hydraulic systems, and custom fabrication solutions.

International buyers, especially those from Africa, South America, the Middle East, and Europe, will find valuable information on how to assess potential suppliers, ensuring they align with their specific operational needs and budget constraints. The guide also delves into critical aspects such as the latest technological advancements, environmental regulations, and best practices for negotiating contracts. By equipping B2B buyers with the knowledge and tools needed to make informed purchasing decisions, this resource aims to facilitate successful partnerships and drive operational excellence across diverse industries. Whether you are a manufacturer seeking to upgrade your production line or a project manager looking for reliable machinery, this guide is designed to empower your sourcing strategy in the global market.

Understanding industrial machinery suppliers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Original Equipment Manufacturers (OEMs) | Design and manufacture machinery components and systems. | Automotive, Aerospace, Electronics | Pros: High-quality standards, custom solutions. Cons: Longer lead times, potentially higher costs. |

| Machinery Repair and Restoration Services | Specialize in refurbishing and maintaining existing machinery. | Food Processing, Pharmaceutical, Chemical Industries | Pros: Cost-effective, extends machinery life. Cons: Limited to existing equipment capabilities. |

| Industrial Equipment Distributors | Provide a wide range of new and used machinery and parts. | Manufacturing, Construction, Mining | Pros: Diverse inventory, competitive pricing. Cons: Variable quality, may lack specialized knowledge. |

| Custom Machine Shops | Focus on bespoke machinery design and fabrication. | Aerospace, Medical Devices, Specialty Manufacturing | Pros: Tailored solutions, flexibility in design. Cons: Higher costs, longer project timelines. |

| Auction and Liquidation Services | Specialize in selling surplus or used machinery through auctions. | Manufacturing, Distribution, Retail | Pros: Potential for significant savings, diverse options. Cons: Risk of purchasing equipment with unknown condition. |

What Are Original Equipment Manufacturers (OEMs) in Industrial Machinery?

OEMs are pivotal players in the industrial machinery landscape, focusing on designing and manufacturing original machinery components and systems. They cater to industries such as automotive, aerospace, and electronics, where precision and quality are paramount. B2B buyers often consider OEMs for their high-quality standards and ability to provide custom solutions tailored to specific operational needs. However, the trade-off may include longer lead times and higher costs, making it essential for buyers to assess their budget and timeline.

How Do Machinery Repair and Restoration Services Benefit B2B Buyers?

Machinery repair and restoration services specialize in refurbishing and maintaining existing machinery, making them a valuable resource for industries like food processing and pharmaceuticals. By opting for these services, businesses can extend the life of their machinery, which often results in significant cost savings compared to purchasing new equipment. However, buyers should be aware that these services are limited to the capabilities of existing machinery, which may restrict operational upgrades and efficiency improvements.

What Role Do Industrial Equipment Distributors Play in the Market?

Industrial equipment distributors serve as intermediaries that provide a vast array of new and used machinery and parts across various sectors, including manufacturing, construction, and mining. Their diverse inventory allows B2B buyers to find cost-effective solutions for their operational needs. However, the quality of equipment can vary significantly among distributors, and they may lack specialized knowledge about certain machinery, which can pose risks for buyers who require specific expertise.

Why Choose Custom Machine Shops for Specialized Needs?

Custom machine shops are essential for businesses requiring bespoke machinery designs and fabrication, particularly in sectors like aerospace and medical devices. These shops offer tailored solutions that meet unique operational demands, providing flexibility in design and functionality. However, buyers should consider that such customization often comes at a higher cost and may involve longer project timelines, making it crucial to plan accordingly.

What Are the Advantages and Disadvantages of Auction and Liquidation Services?

Auction and liquidation services specialize in selling surplus or used machinery, providing an opportunity for businesses to acquire equipment at potentially significant savings. These services can be particularly beneficial for manufacturing, distribution, and retail sectors looking to optimize costs. However, buyers must exercise caution, as there is a risk of purchasing equipment with unknown conditions, which could lead to unforeseen maintenance costs and operational downtime.

Key Industrial Applications of industrial machinery suppliers

| Industry/Sector | Specific Application of Industrial Machinery Suppliers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Machining and Fabrication | Increased precision and efficiency in production | Quality of machinery, technical support, and spare parts availability |

| Food Processing | Automated Packaging Solutions | Enhanced productivity and reduced labor costs | Compliance with food safety regulations, reliability of machinery |

| Pharmaceuticals | Custom Machinery for Drug Production | Streamlined production processes and improved quality | Expertise in handling sensitive materials, certification standards |

| Construction | Heavy Equipment for Material Handling | Improved project timelines and operational efficiency | Equipment durability, local service availability, and logistics |

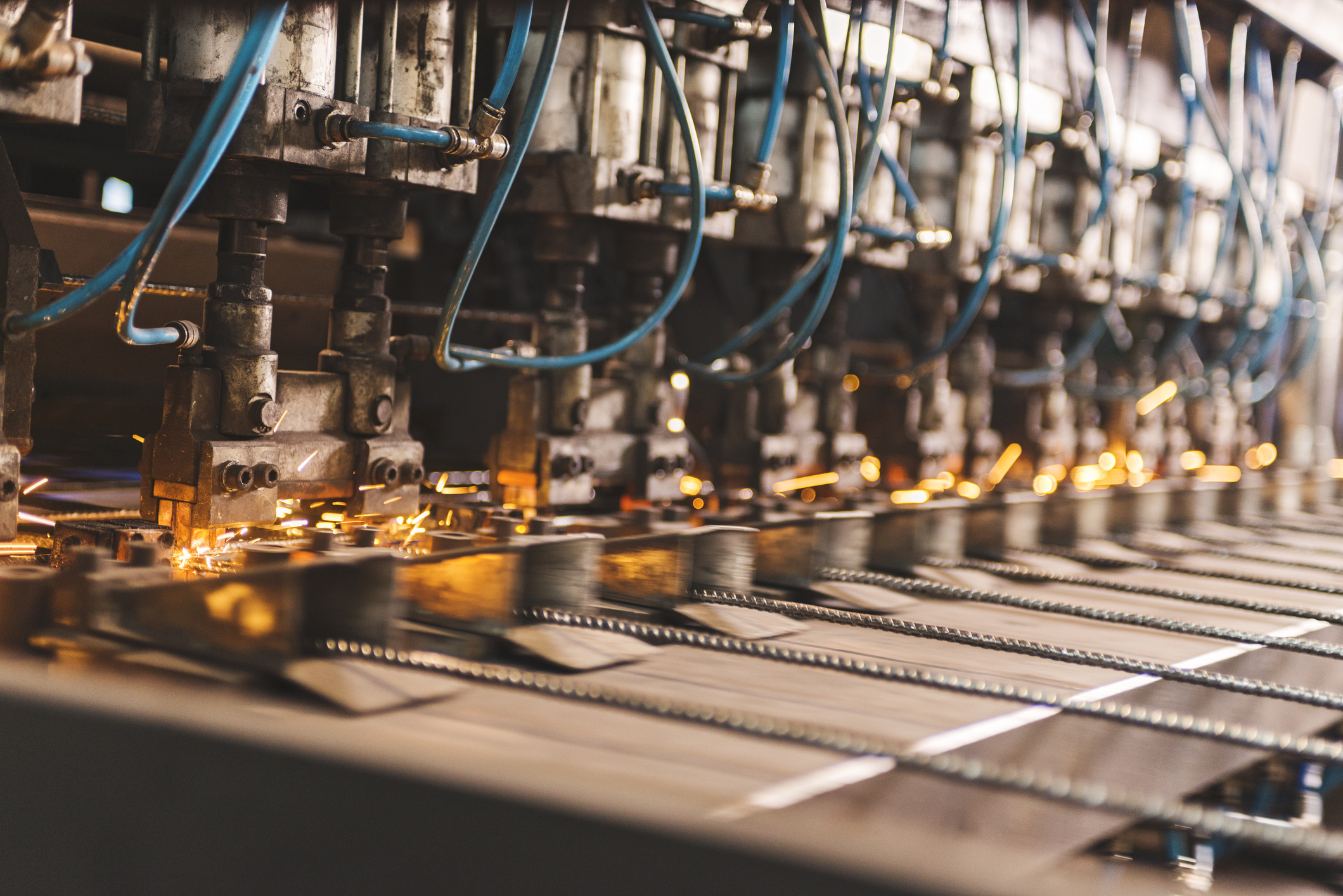

| Metalworking | Precision Cutting and Welding Equipment | Enhanced product quality and reduced waste | Availability of parts, after-sales service, and technology integration |

How Are Industrial Machinery Suppliers Integral to Manufacturing Operations?

In the manufacturing sector, industrial machinery suppliers provide CNC machining and fabrication services that enhance precision and efficiency. These suppliers offer advanced machinery capable of producing complex components with tight tolerances, reducing material waste and increasing throughput. For international buyers, particularly from regions like Africa and South America, sourcing reliable and high-quality machinery is critical to maintaining competitive production rates while ensuring compliance with local manufacturing standards.

What Role Do Industrial Machinery Suppliers Play in Food Processing?

In the food processing industry, automated packaging solutions from industrial machinery suppliers significantly enhance productivity and minimize labor costs. These systems ensure that products are packaged quickly and consistently, which is vital for maintaining freshness and compliance with safety regulations. Buyers must consider the supplier’s ability to meet food safety standards and provide reliable machinery that can withstand the demands of high-volume production, especially in regions with varying regulations.

How Do Industrial Machinery Suppliers Support the Pharmaceutical Industry?

Industrial machinery suppliers play a crucial role in the pharmaceutical sector by providing custom machinery for drug production. These machines are designed to handle sensitive materials and complex processes, ensuring high-quality output and compliance with stringent regulatory standards. For international B2B buyers, particularly from Europe and the Middle East, it is essential to partner with suppliers who have a deep understanding of pharmaceutical manufacturing protocols and can deliver machinery that meets rigorous certification requirements.

What Are the Benefits of Heavy Equipment from Industrial Machinery Suppliers in Construction?

In the construction industry, heavy equipment sourced from industrial machinery suppliers is vital for efficient material handling. This equipment allows for quicker project timelines and improved operational efficiency, enabling businesses to complete projects on schedule. Buyers should focus on the durability of the equipment, the availability of local service support, and the supplier’s logistics capabilities to ensure timely delivery and maintenance, especially in regions with challenging infrastructure.

How Do Industrial Machinery Suppliers Enhance Metalworking Processes?

In metalworking, precision cutting and welding equipment from industrial machinery suppliers are essential for producing high-quality components. These machines enhance product quality by allowing for intricate designs and reducing production waste. Buyers must assess the availability of parts and after-sales service, as well as the supplier’s ability to integrate new technologies, to ensure sustained operational efficiency and competitiveness in the market.

3 Common User Pain Points for ‘industrial machinery suppliers’ & Their Solutions

Scenario 1: Difficulty in Ensuring Machinery Compatibility with Existing Systems

The Problem:

Many B2B buyers face the challenge of integrating new industrial machinery with their existing systems. This often arises from a lack of clear specifications or understanding of the compatibility requirements. For instance, when purchasing a new CNC machine, buyers may discover that the machine does not interface well with their current software or control systems, leading to costly downtime and operational inefficiencies. This scenario is particularly critical for industries in regions like Africa or South America, where technological disparities can exacerbate integration issues.

The Solution:

To mitigate these compatibility issues, buyers should prioritize thorough consultations with suppliers before finalizing any purchase. Engaging in detailed discussions about system requirements, including software, control interfaces, and operational processes, is essential. Create a checklist of compatibility criteria tailored to your operations and ensure that the supplier can meet these requirements. Additionally, request detailed technical documentation and, if possible, arrange for a site visit or demonstration to evaluate how the new machinery can be integrated into your existing setup. This proactive approach not only aids in making informed purchasing decisions but also establishes a collaborative relationship with suppliers that can facilitate smoother integration.

Scenario 2: Uncertainty About Machinery Performance and Reliability

The Problem:

Buyers often grapple with uncertainty regarding the performance and reliability of industrial machinery, especially when sourcing from international suppliers. For instance, a manufacturing firm in Europe might consider a new hydraulic press from a supplier in the Middle East but worry about its long-term durability and the supplier’s ability to provide timely maintenance and support. This concern can lead to indecision and hesitation in making purchases, ultimately affecting production timelines and profitability.

The Solution:

To address performance and reliability concerns, buyers should conduct thorough due diligence on potential suppliers. This includes researching the supplier’s history, customer reviews, and case studies of similar machinery in operation. Requesting references from other businesses that have used the same machinery can provide valuable insights into real-world performance. Additionally, consider negotiating trial periods or performance guarantees, which can offer reassurance about the machinery’s effectiveness. Establishing a clear communication line with the supplier for ongoing support and maintenance is also crucial. This ensures that any issues can be addressed swiftly, helping to maintain operational continuity.

Scenario 3: Challenges in After-Sales Support and Spare Parts Availability

The Problem:

Another significant pain point for B2B buyers is the lack of reliable after-sales support and the availability of spare parts. In many cases, suppliers may not have a robust network for providing service or spare parts, leading to extended downtimes when machinery fails. This issue is particularly pressing for buyers in regions with limited access to technical support or logistics challenges, such as those found in parts of Africa and South America.

The Solution:

Buyers should prioritize suppliers that offer comprehensive after-sales support and a clear spare parts availability plan. Before making a purchase, inquire about the supplier’s service network and their policies regarding spare parts supply. A good practice is to ask for a list of critical spare parts and their lead times, ensuring that you can maintain operations without lengthy delays. Additionally, consider forming a partnership with suppliers who are willing to provide training for in-house maintenance staff. This can empower your team to handle minor repairs and upkeep, reducing reliance on external support and enhancing operational resilience. Establishing a service contract that includes regular maintenance checks can also help prevent unexpected machinery failures, ensuring smooth operations.

Strategic Material Selection Guide for industrial machinery suppliers

What Are the Key Properties of Common Materials Used by Industrial Machinery Suppliers?

When selecting materials for industrial machinery, it is critical to understand their properties and how they affect performance. Here, we analyze four common materials: Steel, Aluminum, Stainless Steel, and Polycarbonate. Each material has unique characteristics that can significantly impact machinery performance and durability.

How Does Steel Perform in Industrial Applications?

Steel is one of the most widely used materials in industrial machinery due to its excellent strength and versatility. Key properties include high tensile strength, good temperature resistance, and the ability to withstand high pressures. However, steel is prone to corrosion, which can impact its longevity in certain environments.

Pros: Steel offers exceptional durability and is cost-effective for large-scale applications. Its manufacturing processes are well-established, making it easier to source and fabricate.

Cons: The primary drawback is its susceptibility to rust and corrosion, especially in humid or chemically aggressive environments. Additionally, the weight of steel can be a disadvantage in applications where weight savings are critical.

Impact on Application: Steel is suitable for heavy-duty applications such as structural components and machine frames, but care must be taken regarding environmental conditions.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Europe and the Middle East should ensure that the steel grades meet local regulations.

What Are the Advantages of Using Aluminum in Machinery?

Aluminum is favored for its lightweight and corrosion-resistant properties. It typically has a lower density than steel, making it advantageous for applications where weight is a concern. Key properties include good thermal and electrical conductivity and a relatively high strength-to-weight ratio.

Pros: The primary advantage of aluminum is its resistance to corrosion, which extends the life of machinery in harsh environments. Its lightweight nature also allows for easier handling and transportation.

Cons: Aluminum is generally more expensive than steel and may not provide the same level of strength under extreme conditions. Additionally, its lower melting point can limit its use in high-temperature applications.

Impact on Application: Aluminum is ideal for components that require lightweight structures, such as frames and casings, particularly in the aerospace and automotive industries.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades and their compliance with international standards, particularly in regions like Germany, where quality assurance is paramount.

Why Choose Stainless Steel for Industrial Machinery?

Stainless steel is renowned for its excellent corrosion resistance and high strength. Key properties include the ability to withstand high temperatures and pressures, making it suitable for demanding environments. It is also easy to clean, which is essential in industries like food processing.

Pros: The primary advantage of stainless steel is its durability and resistance to corrosion, making it ideal for applications in harsh environments. It also provides a clean aesthetic, which is beneficial for visible components.

Cons: The cost of stainless steel is higher than that of carbon steel, which can impact budget considerations. Additionally, it can be more challenging to machine, leading to increased manufacturing complexity.

Impact on Application: Stainless steel is commonly used in applications requiring hygiene and durability, such as food processing machinery and medical devices.

Considerations for International Buyers: Compliance with standards such as ASTM and JIS is essential, especially in industries with strict hygiene requirements. Buyers should also consider the specific alloy grades suited for their applications.

What Role Does Polycarbonate Play in Industrial Machinery?

Polycarbonate is a versatile thermoplastic known for its impact resistance and transparency. Key properties include excellent strength-to-weight ratio and resistance to UV light, making it suitable for various applications.

Pros: Polycarbonate is lightweight and shatter-resistant, making it ideal for safety shields and protective covers. Its transparency allows for visibility in applications where monitoring is required.

Cons: While polycarbonate is durable, it is not as heat-resistant as metals and can deform under high temperatures. Additionally, it can be more expensive than traditional plastics.

Impact on Application: Polycarbonate is suitable for protective components, safety equipment, and transparent housings, particularly in environments where visibility is essential.

Considerations for International Buyers: Buyers should ensure that the polycarbonate grades meet international standards for safety and performance, particularly in regions with stringent regulations.

Summary Table of Material Selection for Industrial Machinery

| Material | Typical Use Case for industrial machinery suppliers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, machine frames | Exceptional durability and cost-effectiveness | Susceptible to corrosion | Medium |

| Aluminum | Lightweight frames, automotive parts | Corrosion resistance and lightweight | Higher cost and lower strength | High |

| Stainless Steel | Food processing machinery, medical devices | Excellent corrosion resistance | Higher manufacturing complexity | High |

| Polycarbonate | Safety shields, transparent housings | Lightweight and impact-resistant | Limited heat resistance | Medium |

This guide provides a comprehensive overview of material selection for industrial machinery suppliers, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for industrial machinery suppliers

What Are the Main Stages in the Manufacturing Process for Industrial Machinery?

The manufacturing process for industrial machinery encompasses several critical stages, each designed to ensure that the final product meets performance and quality expectations. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting the appropriate raw materials, which may include metals, plastics, and composites. Suppliers often conduct thorough inspections to verify material quality and specifications. Advanced technologies like laser scanning and automated measurement tools are increasingly used to ensure precision in material selection.

-

Forming: In this stage, raw materials are shaped into parts through various methods such as machining, molding, or casting. Techniques can vary widely depending on the machine’s design and intended application. For instance, CNC machining is favored for its accuracy and efficiency in producing complex components, while injection molding is used for high-volume plastic parts.

-

Assembly: Once parts are formed, they are assembled into sub-assemblies or the final product. This stage often employs methods like robotic assembly or manual techniques, depending on the complexity and volume of production. Precision in assembly is crucial; thus, many suppliers implement jigs and fixtures to ensure consistency.

-

Finishing: The final stage includes processes like painting, coating, and surface treatment to enhance durability and aesthetic appeal. Techniques such as anodizing or powder coating may be used to protect metal surfaces from corrosion. Quality checks are performed throughout this stage to confirm that the finishing meets specified standards.

How Do International Standards Influence Quality Assurance in Machinery Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process, particularly for industrial machinery suppliers looking to meet global market demands. International standards such as ISO 9001 play a significant role in shaping QA processes.

-

ISO 9001 Certification: This globally recognized standard outlines the requirements for a quality management system (QMS). It emphasizes a process-oriented approach to ensure that products consistently meet customer and regulatory requirements. Suppliers aiming for ISO 9001 certification must demonstrate their ability to enhance customer satisfaction through effective system implementation, including continuous improvement.

-

Industry-Specific Standards: Depending on the type of machinery, suppliers may also need to comply with industry-specific standards such as CE marking for products sold in Europe or API standards for oil and gas machinery. These certifications ensure that products meet safety, health, and environmental protection requirements.

What Are the Key Quality Control Checkpoints in Machinery Manufacturing?

Quality control (QC) is integrated into various checkpoints throughout the manufacturing process to catch defects early and ensure compliance with standards.

-

Incoming Quality Control (IQC): This checkpoint assesses the quality of raw materials before they enter the production line. Suppliers may utilize tools like statistical sampling and visual inspections to evaluate incoming materials against predefined criteria.

-

In-Process Quality Control (IPQC): During production, manufacturers perform IPQC to monitor and control processes. This may involve real-time inspections and testing of components to ensure they meet design specifications. Techniques such as Six Sigma and Lean Manufacturing are often employed to minimize defects.

-

Final Quality Control (FQC): After assembly and finishing, FQC checks the entire product against quality standards. This stage often includes functional testing, performance assessments, and final inspections to validate that the machinery operates as intended.

What Testing Methods Are Commonly Used to Ensure Quality in Industrial Machinery?

Various testing methods are employed to ensure that industrial machinery meets quality and safety standards. Common testing techniques include:

-

Functional Testing: This involves operating the machinery under normal and extreme conditions to ensure it performs as expected. Functional tests may simulate real-world scenarios to validate durability and reliability.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, magnetic particle inspection, and radiographic testing are used to detect internal and surface flaws without damaging the components. These methods are critical for ensuring the integrity of critical parts.

-

Performance Testing: Suppliers may conduct tests to measure performance metrics like speed, accuracy, and energy consumption. These assessments help identify areas for improvement and ensure compliance with industry standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

When sourcing industrial machinery, B2B buyers must evaluate the quality control processes of potential suppliers to ensure they can deliver reliable products. Here are effective strategies for verification:

-

Supplier Audits: Conducting on-site audits allows buyers to assess a supplier’s manufacturing processes, quality management systems, and adherence to international standards. Audits can reveal insights into a supplier’s commitment to quality and continuous improvement.

-

Quality Reports: Requesting detailed quality reports, including metrics from IQC, IPQC, and FQC, provides transparency into the supplier’s quality assurance efforts. These reports should outline testing results, defect rates, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality processes. These inspections can occur at various stages of production, ensuring that the machinery meets specified standards before delivery.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances regarding quality control in machinery manufacturing.

-

Cultural and Regulatory Differences: Understanding local regulations and cultural expectations is crucial. Buyers should familiarize themselves with compliance requirements in their region and how they align with international standards.

-

Supply Chain Considerations: Supply chain dynamics can affect quality control. Buyers should assess the reliability of suppliers’ logistics and material sourcing to mitigate risks related to delays or subpar materials.

-

Language and Communication Barriers: Effective communication is vital for ensuring quality. Buyers should establish clear lines of communication with suppliers, potentially employing bilingual staff or translation services to facilitate understanding.

By comprehensively understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing industrial machinery suppliers, ultimately enhancing their operational efficiency and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘industrial machinery suppliers’

This guide serves as a practical checklist for B2B buyers looking to procure industrial machinery suppliers. By following these steps, you can streamline your sourcing process and ensure you partner with reliable suppliers who meet your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical requirements of the machinery you need. This includes specifications such as size, capacity, power requirements, and any specific features essential for your operations. Having detailed specifications will enable you to communicate effectively with potential suppliers and ensure they can meet your needs.

Step 2: Conduct Market Research

Investigate the market landscape for industrial machinery suppliers. Look for suppliers that specialize in your required machinery type and have a proven track record. Consider factors such as geographic location, market reputation, and the range of products offered. This research will help you narrow down your options and identify the most suitable suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Pay attention to their experience in your specific machinery type and their ability to meet deadlines and quality standards. Don’t just rely on their website; seek feedback from other clients to gain insights into their reliability and service quality.

Step 4: Verify Certifications and Compliance

Ensure that the suppliers you consider have the necessary certifications and compliance with international standards. This includes ISO certifications, safety certifications, and any industry-specific regulations. Valid certifications indicate that the supplier adheres to quality management practices and can be trusted to deliver reliable machinery.

Step 5: Assess After-Sales Support and Services

Evaluate the after-sales support offered by potential suppliers. Reliable suppliers should provide maintenance services, spare parts availability, and technical support. Consider how quickly they can respond to service requests and whether they offer training for your staff on operating the machinery effectively.

Step 6: Request Quotes and Compare Pricing

Once you have identified potential suppliers, request quotes that detail not only the price of the machinery but also any additional costs such as shipping, installation, and warranties. Comparing these quotes will give you a clearer picture of the overall investment and help you make an informed decision based on value rather than just cost.

Step 7: Negotiate Terms and Finalize Agreement

Engage in discussions with your preferred suppliers to negotiate terms that are favorable for both parties. Discuss payment terms, delivery schedules, and warranty conditions. Once you reach an agreement, ensure all terms are documented in a formal contract to protect both parties and clarify expectations moving forward.

Following this checklist will help you navigate the complexities of sourcing industrial machinery suppliers, ensuring you make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for industrial machinery suppliers Sourcing

What Are the Key Cost Components in Industrial Machinery Pricing?

When sourcing industrial machinery, understanding the cost structure is essential for informed purchasing decisions. The main cost components include:

-

Materials: The choice of materials significantly impacts pricing. High-quality, durable materials often come at a premium but can lead to lower maintenance costs in the long run. Sourcing locally can also reduce material costs, especially in regions like Africa and South America, where transportation fees can escalate expenses.

-

Labor: Labor costs vary greatly depending on the manufacturing location. In regions with high labor costs, such as Western Europe, suppliers may pass these costs onto buyers. Conversely, sourcing from areas with lower labor costs can provide savings, though it’s crucial to evaluate the skill level and expertise of the workforce.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Suppliers often calculate overhead into their pricing, which can vary based on operational efficiency and scale.

-

Tooling: Custom tooling for specific machinery can be a significant upfront cost. Buyers should consider whether the investment in custom tooling is justified by the expected production volume and long-term usage.

-

Quality Control (QC): Implementing stringent QC processes can increase costs but is essential for ensuring reliability and performance. Machinery that meets international certifications may be priced higher but can mitigate risks associated with failures and downtime.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Understanding Incoterms is crucial as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and demand. Understanding the margin can help buyers gauge the reasonableness of the price.

How Do Price Influencers Affect Industrial Machinery Costs?

Several factors influence the pricing of industrial machinery, including:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to better pricing due to economies of scale. Buyers should negotiate for lower costs based on projected purchase volumes.

-

Specifications and Customization: Custom machinery tailored to specific needs can significantly impact costs. Detailed specifications can either inflate the price due to complexity or provide savings if they allow for standardization.

-

Material Quality and Certifications: Premium materials and certifications (e.g., ISO, CE) can increase costs but often result in better performance and compliance with international standards, particularly important for European buyers.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their experience and quality assurance processes.

-

Incoterms: Understanding the terms of shipment can lead to better pricing negotiations. Costs can vary widely based on whether the supplier or buyer is responsible for shipping, insurance, and customs duties.

What Buyer Tips Can Enhance Cost Efficiency in Industrial Machinery Procurement?

B2B buyers can implement several strategies to optimize costs when sourcing industrial machinery:

-

Effective Negotiation: Always approach negotiations with a clear understanding of the market prices and the supplier’s cost structure. Leverage bulk purchasing and long-term contracts to negotiate better terms.

-

Focus on Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term operational costs, including maintenance, energy consumption, and parts replacement. Investing in higher-quality machinery may lead to lower TCO.

-

Understand Pricing Nuances for International Transactions: Familiarize yourself with regional pricing differences and potential tariffs when importing machinery. This knowledge can aid in making informed decisions and avoiding unexpected costs.

-

Explore Local Suppliers: For buyers in Africa and South America, local suppliers may offer competitive pricing due to reduced logistics costs. Building relationships with local vendors can also enhance service responsiveness.

Disclaimer on Indicative Prices

Prices for industrial machinery can vary widely based on the aforementioned factors. It is advisable to obtain multiple quotes and conduct thorough market research to ensure you are getting a competitive deal.

Alternatives Analysis: Comparing industrial machinery suppliers With Other Solutions

Understanding Alternative Solutions to Industrial Machinery Suppliers

In the competitive landscape of industrial operations, B2B buyers must evaluate various solutions to optimize productivity and efficiency. While industrial machinery suppliers offer a comprehensive range of equipment and services tailored for specific manufacturing needs, alternative solutions can also provide effective results. This analysis compares industrial machinery suppliers with two viable alternatives: In-House Manufacturing and Outsourcing Production.

Comparison Table

| Comparison Aspect | Industrial Machinery Suppliers | In-House Manufacturing | Outsourcing Production |

|---|---|---|---|

| Performance | High, tailored solutions | Variable, dependent on expertise and equipment | High, but varies by partner quality |

| Cost | Higher initial investment, long-term savings | Potentially lower long-term costs, high upfront costs | Variable, often lower initial costs but can rise with hidden fees |

| Ease of Implementation | Moderate, requires training and integration | High complexity, requires skilled labor and training | Generally easier, relies on supplier expertise |

| Maintenance | Regular service contracts available | Ongoing, requires skilled maintenance teams | Minimal, handled by the supplier |

| Best Use Case | Custom solutions for specific industries | High-volume production with skilled labor | Cost-sensitive projects or those requiring specific expertise |

Analyzing In-House Manufacturing as an Alternative

In-house manufacturing allows companies to maintain direct control over production processes, ensuring quality and responsiveness to market demands. The primary advantage of this approach is the potential for lower long-term costs through economies of scale. However, it often requires significant upfront investment in machinery and skilled labor, which can be a barrier for smaller firms. Additionally, maintaining and upgrading equipment can lead to ongoing operational complexities.

Evaluating Outsourcing Production as an Alternative

Outsourcing production involves partnering with external manufacturers to fulfill production needs. This method can significantly reduce initial capital expenditure and allows companies to leverage specialized expertise, especially in complex manufacturing processes. However, the quality and reliability of the end product heavily depend on the chosen partner. Hidden costs can also emerge, such as shipping, tariffs, or fluctuations in service availability, potentially impacting overall project timelines.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between industrial machinery suppliers and alternative solutions like in-house manufacturing or outsourcing production, B2B buyers must carefully assess their specific requirements. Factors such as production volume, budget constraints, and the need for customization play crucial roles in decision-making. A thorough evaluation of each option’s pros and cons, alongside potential long-term impacts on productivity and cost, will enable buyers to make informed choices that align with their strategic goals.

Essential Technical Properties and Trade Terminology for industrial machinery suppliers

What Are the Critical Technical Properties for Industrial Machinery?

When evaluating industrial machinery, several key specifications are essential for ensuring the equipment meets performance and operational requirements. Understanding these properties aids B2B buyers in making informed decisions that align with their operational needs.

1. Material Grade

Material grade refers to the specific classification of the materials used in machinery construction, such as steel or aluminum alloys. Different grades possess varying characteristics like strength, corrosion resistance, and durability. Selecting the appropriate material grade is crucial for ensuring the machinery can withstand operational stresses and environmental conditions, thereby minimizing maintenance costs and extending equipment lifespan.

2. Tolerance

Tolerance defines the allowable deviation from a specified dimension in manufacturing processes. It is critical for ensuring parts fit together correctly and function as intended. In B2B contexts, tight tolerances can lead to higher manufacturing costs but are often necessary for precision applications. Buyers must balance the need for precision with budget constraints, considering how tolerance levels impact operational efficiency and product quality.

3. Load Capacity

Load capacity is the maximum weight or force that machinery can safely handle during operation. Understanding load capacities is vital for applications in sectors like construction, manufacturing, and logistics. Exceeding load limits can lead to equipment failure, safety hazards, and costly downtime. Buyers should assess their operational requirements and ensure that machinery specifications align with anticipated loads.

4. Cycle Time

Cycle time is the total time taken to complete one full cycle of operation, including processing, handling, and any necessary downtime. This metric is essential for determining productivity levels. Shorter cycle times can lead to higher throughput, making machinery more cost-effective in high-volume production environments. Buyers should evaluate cycle times in relation to their production goals to enhance operational efficiency.

5. Energy Efficiency Rating

Energy efficiency ratings indicate how much energy machinery consumes during operation compared to its output. With increasing pressure to reduce energy costs and environmental impact, selecting energy-efficient machinery can lead to significant savings. Buyers should consider machinery with higher energy efficiency ratings to optimize operational costs and align with sustainability initiatives.

What Are Common Trade Terms Used in Industrial Machinery Procurement?

Understanding industry jargon is essential for effective communication and negotiation in the B2B machinery market. Here are some common terms that buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the machinery sector, OEMs are crucial for ensuring compatibility and quality in replacement parts. Buyers often seek OEM components to guarantee reliability and maintain warranty coverage.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers looking to manage inventory costs while meeting production needs. Understanding MOQs helps buyers negotiate better terms and avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers for specific goods or services. This process enables buyers to compare pricing and terms across different suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for managing logistics, shipping costs, and risk during the procurement process.

5. Lead Time

Lead time refers to the period between the initiation of an order and its fulfillment. In machinery procurement, understanding lead times is critical for project planning and ensuring timely delivery of equipment. Buyers should factor in lead times when scheduling production to avoid delays.

By grasping these essential technical properties and industry terminology, B2B buyers can navigate the complexities of purchasing industrial machinery more effectively, ensuring they make decisions that enhance productivity and operational success.

Navigating Market Dynamics and Sourcing Trends in the industrial machinery suppliers Sector

What Are the Current Market Dynamics and Key Trends in the Industrial Machinery Suppliers Sector?

The industrial machinery sector is undergoing a significant transformation driven by technological advancements, shifting consumer demands, and global economic factors. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe evaluate their sourcing strategies, they must consider the integration of automation and smart technologies. Innovations such as IoT-enabled machinery and AI-driven analytics are becoming crucial for improving efficiency and productivity. These technologies facilitate predictive maintenance, reduce downtime, and enhance operational visibility, which are essential in competitive markets.

Another key trend is the growing emphasis on customization and flexibility. Suppliers are increasingly offering tailored solutions to meet specific client needs, moving away from one-size-fits-all approaches. This shift is particularly relevant for industries like food processing, pharmaceuticals, and automotive manufacturing, where unique operational requirements demand specialized machinery. Furthermore, the rise of e-commerce and digital marketplaces is reshaping how buyers interact with suppliers, enabling easier access to a global inventory of both new and used machinery.

Supply chain resilience is also a critical consideration as geopolitical tensions and disruptions from global events (e.g., pandemics) have highlighted vulnerabilities. Buyers are now seeking suppliers with diverse sourcing strategies and robust logistics capabilities to mitigate risks and ensure continuity. As a result, international partnerships and local sourcing options are gaining traction, enabling businesses to respond swiftly to market fluctuations.

How Are Sustainability and Ethical Sourcing Influencing B2B Transactions in Industrial Machinery?

Sustainability has emerged as a pivotal factor influencing procurement decisions in the industrial machinery sector. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their environmental impact. This trend is particularly relevant in regions like Europe, where regulatory frameworks and consumer expectations around sustainability are stringent. Buyers are looking for machinery that not only meets performance standards but also incorporates energy-efficient technologies and sustainable materials.

Ethical sourcing practices are equally important. Buyers are demanding transparency in supply chains to ensure that the materials used in machinery production are ethically sourced and that suppliers uphold fair labor practices. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential for suppliers to demonstrate their commitment to sustainability and ethical standards.

Moreover, the adoption of “green” materials—such as recycled metals and biodegradable components—is gaining momentum. Buyers are encouraged to inquire about the sustainability credentials of potential suppliers, including their waste management practices and carbon footprint. This focus on sustainability not only aligns with corporate social responsibility goals but also helps in enhancing brand reputation and customer loyalty in an increasingly eco-conscious market.

What Historical Developments Have Shaped the Industrial Machinery Suppliers Sector?

The industrial machinery sector has evolved significantly over the past century, influenced by technological advancements and changing market needs. Initially, the industry was dominated by manual processes, which limited production efficiency and scalability. The introduction of mechanization in the early 20th century marked a turning point, enabling manufacturers to increase output and reduce labor costs.

Post-World War II, the sector experienced a technological boom, with the advent of computer numerical control (CNC) machines revolutionizing precision engineering. This innovation allowed for higher accuracy and the ability to produce complex parts with minimal human intervention. The globalization of trade in the late 20th century further transformed the landscape, as manufacturers sought cost-effective solutions by sourcing machinery from various international suppliers.

Today, the industrial machinery sector continues to evolve with the integration of smart technologies and a focus on sustainability. As buyers navigate this dynamic landscape, understanding the historical context provides valuable insights into current trends and future opportunities within the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of industrial machinery suppliers

-

How do I solve challenges related to sourcing industrial machinery?

To effectively address sourcing challenges, first, define your specific machinery needs based on your production requirements. Research potential suppliers by reviewing their product offerings, industry experience, and customer testimonials. Utilize trade shows, industry publications, and online platforms to identify reputable suppliers. Establish direct communication to discuss your requirements, inquire about customization options, and evaluate their responsiveness. Finally, consider starting with a small order to assess the quality and reliability before committing to larger purchases. -

What is the best type of industrial machinery for my manufacturing process?

The best type of industrial machinery for your manufacturing process depends on several factors, including the materials you work with, production volume, and specific application needs. Conduct a thorough analysis of your production workflow to identify bottlenecks or inefficiencies. Consult with suppliers who specialize in your industry to gain insights into the latest technologies and equipment that can enhance productivity and quality. Consider both new and used machinery options to find the best fit for your budget and operational goals. -

How can I ensure the quality of machinery from international suppliers?

To ensure quality, start by vetting suppliers through their certifications and compliance with international standards. Request samples or arrange for factory visits to assess manufacturing processes firsthand. Utilize third-party inspection services to conduct quality checks before shipment. Additionally, review customer feedback and case studies that highlight the supplier’s track record. Establish a clear agreement on quality assurance protocols, including warranty terms and after-sales support. -

What are the common payment terms for industrial machinery purchases?

Payment terms can vary widely among suppliers, but common practices include upfront deposits, progress payments, and balance upon delivery. For international transactions, letters of credit and escrow services can provide additional security. Always clarify payment terms in the purchase agreement and ensure they align with your cash flow and financial planning. Consider negotiating terms that allow for partial payments based on milestones, which can mitigate risk for both parties. -

What is the minimum order quantity (MOQ) for industrial machinery?

Minimum order quantities (MOQ) can differ significantly based on the type of machinery and supplier. Some suppliers may have flexible MOQs, especially for custom machinery, while others may require larger orders to justify production costs. It is advisable to communicate your needs directly with suppliers to explore possibilities. If MOQs are higher than your immediate requirements, consider forming a consortium with other buyers to meet the MOQ collectively. -

How do I vet international suppliers for reliability and trustworthiness?

Vetting international suppliers involves researching their business history, financial stability, and reputation within the industry. Utilize platforms like LinkedIn to connect with current or past customers for references. Verify their registration and certifications through relevant trade bodies or governmental organizations. Additionally, consider visiting their facility or engaging a local agent to conduct on-the-ground assessments to ensure they meet your quality and operational standards. -

What logistics considerations should I keep in mind when importing machinery?

When importing machinery, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner experienced in handling industrial equipment to manage the shipping process. Ensure that all required documentation, such as commercial invoices and packing lists, is accurate and complete to avoid delays at customs. Additionally, factor in lead times for production and shipping to align with your project timelines. -

How can I customize industrial machinery to suit my specific needs?

Customizing industrial machinery often involves collaboration with the supplier to align the equipment with your operational requirements. Begin by providing detailed specifications of your needs, including dimensions, materials, and performance criteria. Many suppliers offer design services to modify existing models or create bespoke machinery. Be prepared to discuss budget constraints and timelines, and consider prototyping to validate the design before full-scale production. Regular communication throughout the customization process is key to achieving the desired outcomes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for industrial machinery suppliers

What Are the Key Insights for B2B Buyers in Industrial Machinery Sourcing?

In today’s rapidly evolving industrial landscape, strategic sourcing is paramount for B2B buyers seeking to enhance operational efficiency and reduce costs. By leveraging innovative solutions from established suppliers, businesses can achieve greater productivity and ensure high-quality output while adhering to environmental standards. The integration of advanced technologies—such as electric, hydraulic, and hybrid systems—enables suppliers to meet diverse application requirements, providing a competitive edge in various sectors, from plastics to steel production.

Furthermore, as global supply chains become increasingly interconnected, buyers from Africa, South America, the Middle East, and Europe must prioritize suppliers who demonstrate agility and responsiveness. Engaging with suppliers that offer extensive customization, rapid prototyping, and a robust service network can significantly reduce lead times and enhance project outcomes.

How Can International Buyers Prepare for Future Trends in Industrial Machinery?

Looking ahead, international B2B buyers should remain vigilant about emerging trends in automation and digitalization within the industrial machinery sector. Embracing these advancements not only fosters innovation but also positions companies to respond proactively to market shifts. By establishing strategic partnerships with forward-thinking suppliers, businesses can navigate the complexities of the global marketplace more effectively.

As you explore potential suppliers, consider initiating conversations that delve into their technological capabilities and service offerings. This proactive approach will empower your organization to make informed decisions that drive growth and sustainability in an increasingly competitive environment.