Top 9 Best Cnc Router For Small Shop Manufacturers & Suppliers List

1. Sainsmart – Genmitsu 3018 PROver

Domain: cncsourced.com

Registered: 2020 (5 years)

Introduction: [{‘name’: ‘Sainsmart Genmitsu 3018 PROver’, ‘price’: ‘$345’, ‘working_area’: ‘300 x 180 x 45 mm’, ‘precision’: ‘Around 0.003″‘, ‘material_compatibility’: ‘Wood, MDF, acrylic, polycarbonate, and PCB’, ‘pros’: [‘Easy to set up’, ‘Very affordable’, ‘Works with a variety of materials’, ‘Optional laser engraver upgrade option’], ‘cons’: [‘More expensive brands are sturdier and more powerful’, ‘Limited …

2. Carbide 3D – Shapeoko CNC

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Shapeoko CNC by Carbide 3D: Recommended for beginners, excellent support, large community, good learning resources, free starter software, common in the market, potential for used options.

2. Onefinity CNC: Newer option, claims to be lower maintenance, slightly higher price point, good support, active community.

3. Openbuilds machines: Easily modifiable to various sizes, suitable for customiz…

3. Wood Magazine – Benchtop CNC Machines

Domain: woodmagazine.com

Registered: 1996 (29 years)

Introduction: Benchtop CNC machines are suitable for hobbyist and small-shop woodworkers, offering a range of features and capacities. Prices range from $1,500 to $6,000, influenced by precision, durability, and technology. Key considerations include: 1. **Budget**: Determine how much to spend based on required capabilities. 2. **Envelope Size**: Understand the workpiece capacity in X, Y, and Z axes. For exampl…

4. Avid – CNC Router for Custom Furniture

Domain: woodweb.com

Registered: 1995 (30 years)

Introduction: CNC routers recommended for a small custom furniture shop, specifically for cutting sheet goods and solid wood parts (up to 2″ thick). Recommendations include brands like Avid, CAMaster, DB CNC, and Shop Sabre. Desired size is 4′ x 8′ with a small footprint. Emphasis on the need for a rigid machine for machining solid wood and the importance of quality over initial cost.

5. Omio – X8

Domain: chiefdelphi.com

Registered: 1998 (27 years)

Introduction: 1. Omio X8: Highly recommended for its ease of use, robust design, and reliability. Price: under $5000. Available from suppliers like OmioCNC and West Coast Products. 2. Shapeoko 3: A well-regarded machine for polycarbonate and aluminum, though slower for aluminum. Easy-to-use software. 3. Shapeoko 5 Pro: Features a 4′ x 4′ bed, priced around $5,400. Known for its out-of-the-box potential and larg…

6. Carbide 3D – Shapeoko 5 Pro CNC Router

Domain: shop.carbide3d.com

Registered: 2013 (12 years)

Introduction: Product Name: Shapeoko 5 Pro CNC Router

Sizes Available: 2×2, 4×4

Working Area: 4×4 feet

Price: Starting from $3,250.00

Features:

– Capable of passing larger materials through the machine (e.g., 4×8′ plywood)

– X travel just over 48 inches for cutting around 4-foot parts

– User-friendly design and advanced software compatibility

– Suitable for woodworking, sign-making, plastic fabrication, etc.

S…

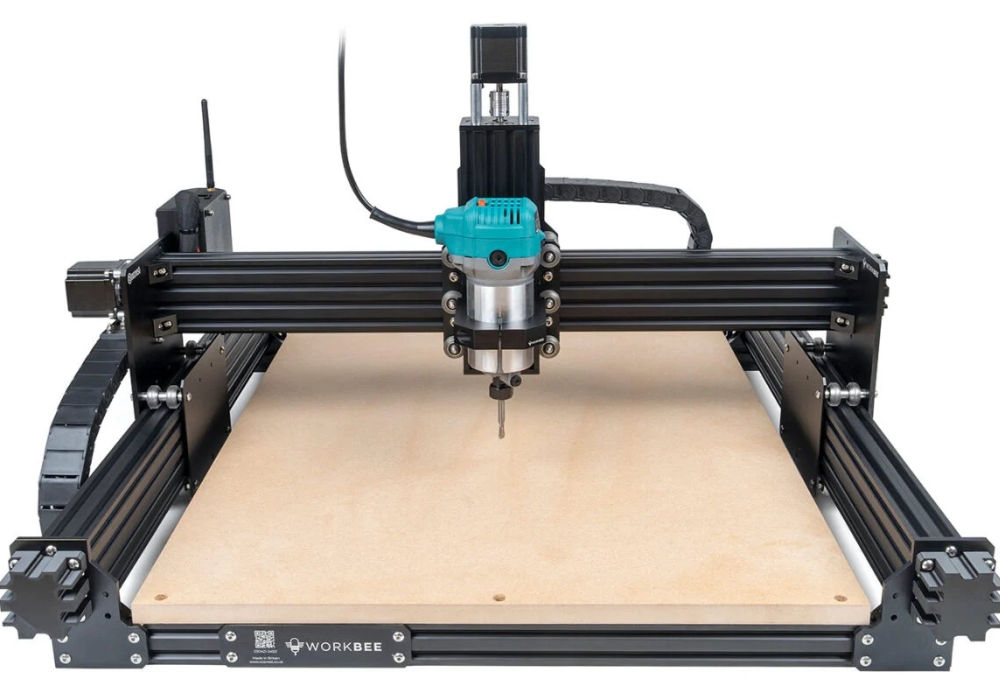

7. Onefinity – Foreman CNC Machine

Domain: forum.onefinitycnc.com

Registered: 2020 (5 years)

Introduction: The user is considering purchasing a CNC machine, specifically the Onefinity Foreman model, for their small business that produces knives. They have no prior CNC experience but currently use a laser for engraving. Their primary use for the CNC will be cutting different sized pieces of wood (walnut, cherry, oak, maple) for bread knives. They plan to spend between $5,000 and $6,000 on the CNC. They …

8. STYLECNC – 2025 Top Rated Mini Desktop CNC Router

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: {“Product Name”: “2025 Top Rated Mini Desktop CNC Router for Small Business”, “Brand”: “STYLECNC”, “Model”: “STG6090”, “Table Size”: “2′ x 3′ (24″ x 36″, 600mm x 900mm)”, “Price”: {“Standard Edition”: “$2,580”, “Pro Edition”: “$3,200”}, “Stock Availability”: “360 Units in Stock Available for Sale Every Month”, “Warranty”: “One-Year Limited Warranty for Entire Machine (Extended Warranties Available…

9. Carbide 3D – Shapeoko 4 and 4 Pro

Domain: community.carbide3d.com

Registered: 2013 (12 years)

Introduction: This company, Carbide 3D – Shapeoko 4 and 4 Pro, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Introduction: Navigating the Global Market for best cnc router for small shop

In the competitive landscape of small-scale manufacturing, sourcing the best CNC router for small shops can be a daunting challenge for international B2B buyers. With the rise of digital fabrication, businesses across Africa, South America, the Middle East, and Europe are increasingly reliant on CNC technology to enhance productivity and precision. This guide provides a comprehensive overview of CNC routers tailored to small enterprises, addressing key considerations such as machine types, material compatibility, and practical applications.

From budget-friendly options ideal for hobbyists to advanced models suitable for professional prototyping and production, this resource ensures that buyers can navigate the diverse offerings in the global market. We delve into essential factors like supplier vetting, cost analysis, and maintenance requirements, empowering businesses to make informed purchasing decisions.

Whether you’re a startup in Nigeria seeking to create custom furniture or a workshop in Saudi Arabia aiming to expand your capabilities, understanding the nuances of CNC technology is vital. This guide not only highlights the best options available but also equips B2B buyers with the knowledge to evaluate their choices effectively, ensuring they invest in a CNC router that aligns with their operational needs and growth ambitions. By leveraging this information, businesses can enhance their competitive edge and drive innovation in their respective markets.

Understanding best cnc router for small shop Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Benchtop CNC Routers | Compact design, affordable, limited work area | Hobby projects, small-scale production | Pros: Cost-effective, easy to use. Cons: Limited capacity, less durable. |

| Large Format CNC Routers | Extensive work area (up to 4×8 ft), robust build | Furniture making, large signage | Pros: Versatile, high precision. Cons: Higher investment, requires space. |

| Hybrid CNC Routers | Multi-functionality (cutting, engraving, 3D printing) | Prototyping, diverse material handling | Pros: All-in-one solution, saves time. Cons: Complex setup, higher cost. |

| Entry-Level CNC Kits | DIY assembly, budget-friendly | Educational purposes, beginner projects | Pros: Affordable, customizable. Cons: Assembly required, may lack features. |

| Professional CNC Routers | High precision, industrial-grade components | Mass production, complex designs | Pros: Exceptional quality, longevity. Cons: Significant investment, requires expertise. |

What are the Characteristics of Benchtop CNC Routers?

Benchtop CNC routers are designed for small workshops and are ideal for hobbyists or small businesses looking to explore CNC technology without a hefty investment. They typically feature a compact footprint and a limited work area, making them suitable for smaller projects like signs or decorative items. B2B buyers should consider their specific needs, as these machines often come with fewer features and lower durability compared to larger models, which may lead to buyer’s remorse if the machine cannot handle more demanding tasks.

How Do Large Format CNC Routers Benefit Businesses?

Large format CNC routers stand out due to their extensive work area, often measuring up to 4×8 feet, allowing for the creation of larger items such as furniture and signage. Their robust build quality ensures they can handle tougher materials, including hardwoods and metals. Businesses in sectors such as woodworking and sign-making will find these machines invaluable. However, the higher initial investment and the need for adequate space can be drawbacks, necessitating careful consideration of the shop’s layout and budget.

What Makes Hybrid CNC Routers a Versatile Choice?

Hybrid CNC routers combine multiple functionalities, such as cutting, engraving, and even 3D printing, into a single machine. This versatility is particularly appealing for businesses that require diverse capabilities without the need to invest in separate machines. They are especially useful for prototyping and can handle various materials. However, the complexity of setup and the higher cost can deter some buyers, making it essential to evaluate whether the additional features justify the investment.

Why Consider Entry-Level CNC Kits for Educational Purposes?

Entry-level CNC kits are an excellent option for educational institutions or hobbyists entering the CNC world. These kits are budget-friendly and allow users to assemble the machine themselves, providing valuable hands-on experience. While they are often less powerful and feature-limited, they can still perform basic tasks effectively. For B2B buyers, the primary consideration should be the machine’s capability to meet specific project needs versus the learning opportunity it presents.

What Are the Advantages of Professional CNC Routers?

Professional CNC routers are engineered for high precision and durability, making them suitable for mass production and complex designs. These machines often feature advanced technology and robust components, ensuring consistent performance over time. While the investment is significant, businesses in manufacturing or specialized crafting will benefit from the exceptional quality and longevity these routers offer. However, the requirement for skilled operation and maintenance may necessitate additional training for staff, impacting overall operational costs.

Key Industrial Applications of best cnc router for small shop

| Industry/Sector | Specific Application of best cnc router for small shop | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking | Custom furniture production | High precision and customization of designs | Look for machines with large work envelopes and robust spindles. |

| Sign Making | Engraving and cutting of signage | Ability to produce intricate designs efficiently | Ensure compatibility with various materials like acrylic and wood. |

| Prototyping | Rapid prototyping of parts and components | Speed up product development cycles | Consider CNC routers with advanced software and high-speed capabilities. |

| Arts & Crafts | Personalized gifts and decorative items | Enhance product uniqueness and market appeal | Focus on machines that can handle a variety of materials and finishes. |

| Metal Fabrication | Cutting and engraving metal components | Expand service offerings and cater to diverse clients | Verify the machine’s capability for metal cutting and its durability. |

How Can the Best CNC Router Enhance Woodworking Operations?

In the woodworking industry, CNC routers are pivotal for custom furniture production. These machines allow for high precision, enabling artisans to create intricate designs that meet specific customer requirements. For international buyers, especially from regions like Africa and South America, sourcing a CNC router with a large work envelope is crucial, as it facilitates the production of larger pieces without the need for multiple setups. Additionally, robust spindles are necessary to handle various wood types, ensuring durability and consistent quality.

What Role Does CNC Routing Play in Sign Making?

In the sign-making sector, CNC routers are used for engraving and cutting signage from materials like acrylic and wood. The ability to produce intricate designs efficiently is a significant advantage, allowing businesses to fulfill custom orders quickly. For B2B buyers in the Middle East and Europe, it’s essential to select machines that offer versatility in material compatibility and precision. This ensures that the signage produced is not only visually appealing but also durable enough to withstand environmental conditions.

How Does CNC Technology Accelerate Prototyping?

CNC routers play a critical role in rapid prototyping across various industries. They enable businesses to produce parts and components quickly, significantly speeding up product development cycles. For international buyers, particularly in competitive markets, sourcing routers with advanced software and high-speed capabilities can enhance productivity. These machines should also support a variety of materials to accommodate diverse prototyping needs, ensuring that businesses can innovate without delays.

How Can Arts and Crafts Benefit from CNC Routers?

In the arts and crafts sector, CNC routers are invaluable for creating personalized gifts and decorative items. The ability to customize products enhances uniqueness, catering to consumer demand for one-of-a-kind items. For buyers from regions like Nigeria and Saudi Arabia, selecting routers that can handle multiple materials and finishes is crucial. This versatility allows artisans to explore various design possibilities, thereby increasing their market appeal and customer satisfaction.

What Advantages Do CNC Routers Offer in Metal Fabrication?

CNC routers are increasingly used in metal fabrication for cutting and engraving components. This capability allows businesses to expand their service offerings, catering to a diverse range of clients. For B2B buyers focused on this application, it is vital to verify the machine’s cutting capabilities for metal and its overall durability. Investing in a robust CNC router can facilitate precision work that meets industry standards, ultimately enhancing a company’s reputation and reliability in the market.

3 Common User Pain Points for ‘best cnc router for small shop’ & Their Solutions

Scenario 1: Limited Workspace in Small Shops

The Problem: Many B2B buyers operating small workshops face the challenge of limited physical space. As businesses strive to maximize productivity, they often find it difficult to fit larger CNC routers into their facilities. This constraint can lead to frustration, as smaller machines may not meet their production needs, forcing them to compromise on quality or efficiency. This is especially true for businesses looking to expand their offerings, such as custom furniture or intricate engravings, where a larger work area is necessary.

The Solution: When sourcing a CNC router for a small shop, prioritize models with a vertical design or those that are compact yet powerful, such as the MakerMade M2, which features a 4×8 ft work area while utilizing a space-saving vertical structure. Additionally, consider investing in a CNC router with a modular design, allowing you to expand its capabilities over time without needing additional floor space. Ensure the machine has a robust software solution that can handle tiling for larger projects, which enables users to work on extended pieces by breaking them down into manageable sections. This approach not only maximizes workspace efficiency but also allows businesses to take on larger projects without the need for additional equipment.

Scenario 2: Budget Constraints for Small Business Owners

The Problem: Budget limitations are a common pain point for small business owners looking to invest in a CNC router. With prices ranging from $1,500 to $6,000, finding a machine that balances cost and functionality can be daunting. Buyers often worry about making a poor investment that does not meet their needs or results in high operational costs due to inefficiencies.

The Solution: To navigate budget constraints, B2B buyers should conduct thorough market research to identify entry-level CNC routers that offer good functionality without breaking the bank. For example, the Sainsmart Genmitsu 3018 PROver is an affordable option that provides versatility for various materials, making it an excellent starting point for newcomers to CNC machining. To ensure you’re making a sound investment, create a list of required features based on your specific applications—such as material compatibility and cutting area size—and prioritize those that deliver the best value. Additionally, consider reaching out to manufacturers for possible financing options or warranties that can mitigate the risk of equipment failure, ultimately providing peace of mind in your investment.

Scenario 3: Complexity of Software Integration

The Problem: Many small shop owners encounter difficulties with the software that operates CNC routers. The learning curve associated with mastering CAD/CAM software can be steep, especially for those who are new to CNC machining. This complexity can lead to operational delays, increased training costs, and even mistakes in production, which can be costly for small businesses aiming for efficiency and quality.

The Solution: To alleviate the challenges of software integration, buyers should prioritize CNC routers that come with user-friendly software or those that are compatible with widely-used programs. Look for routers that offer comprehensive training resources, such as tutorials, webinars, and customer support. For instance, machines that utilize open-source software like GRBL allow for a customizable experience that can be tailored to your specific needs. Additionally, investing in training programs for staff can dramatically reduce the learning curve. Consider partnering with local technical schools or online platforms that offer courses tailored to CNC machining, which can enhance your team’s skills and confidence, ultimately improving production quality and efficiency.

Strategic Material Selection Guide for best cnc router for small shop

What Are the Key Materials for CNC Routers in Small Shops?

When selecting a CNC router for a small shop, the choice of material is crucial for achieving optimal performance and product quality. Below, we analyze four common materials used in CNC machining, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Wood

Key Properties:

Wood is a versatile material with a wide range of densities and hardness levels. Its natural composition allows for easy cutting and shaping, making it ideal for various applications. However, wood can be sensitive to moisture and temperature changes, which may affect its stability.

Pros & Cons:

Wood is relatively inexpensive and widely available, making it a popular choice for small businesses. It offers excellent aesthetic qualities and can be finished in numerous ways. However, its durability is lower compared to metals and plastics, and it may require additional treatments to prevent warping or decay.

Impact on Application:

Wood is suitable for furniture, signage, and decorative items. Its compatibility with various CNC router bits allows for intricate designs and carvings.

Considerations for International Buyers:

Buyers in regions like Africa and South America should consider local wood species and sustainability practices. Compliance with environmental standards may also be necessary, depending on the specific type of wood used.

2. Acrylic

Key Properties:

Acrylic is a transparent thermoplastic known for its clarity and UV resistance. It has a lower temperature resistance compared to other materials but can be easily machined and polished.

Pros & Cons:

Acrylic is lightweight and offers a high-quality finish, making it ideal for displays and signage. However, it can be more expensive than wood and may scratch easily, requiring careful handling during production.

Impact on Application:

Acrylic is commonly used for creating signage, displays, and protective covers. Its ability to be laser cut and engraved enhances its versatility in design.

Considerations for International Buyers:

Compliance with local regulations regarding plastic use is essential, especially in Europe, where restrictions on certain plastics are becoming more stringent. Buyers should also consider the availability of acrylic in their region.

3. Aluminum

Key Properties:

Aluminum is a lightweight metal with excellent corrosion resistance and thermal conductivity. It can withstand higher temperatures and pressures compared to wood and acrylic.

Pros & Cons:

Aluminum is durable and suitable for various applications, including mechanical parts and structural components. However, it is more challenging to machine than softer materials, requiring specialized tools and skills, which can increase manufacturing complexity.

Impact on Application:

Aluminum is ideal for precision parts, frames, and custom enclosures. Its strength-to-weight ratio makes it a preferred choice for applications requiring durability without excessive weight.

Considerations for International Buyers:

Buyers should be aware of material standards such as ASTM or DIN when sourcing aluminum. Additionally, understanding local machining capabilities is vital, as not all shops may be equipped to handle aluminum effectively.

4. MDF (Medium Density Fiberboard)

Key Properties:

MDF is an engineered wood product made from wood fibers, wax, and resin. It offers a smooth surface for machining and is less prone to warping compared to solid wood.

Pros & Cons:

MDF is cost-effective and easy to work with, making it ideal for prototypes and temporary fixtures. However, it is less durable than solid wood or metal and can be susceptible to moisture damage.

Impact on Application:

MDF is commonly used for cabinetry, furniture, and decorative items. Its smooth surface allows for detailed carvings and paint finishes.

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding formaldehyde emissions from MDF. Understanding the sourcing of MDF and its environmental impact is also crucial for sustainable practices.

Summary Table

| Material | Typical Use Case for best cnc router for small shop | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture, signage, decorative items | Inexpensive and widely available | Lower durability compared to metals | Low |

| Acrylic | Signage, displays, protective covers | High-quality finish and clarity | Scratches easily, more expensive than wood | Medium |

| Aluminum | Precision parts, frames, custom enclosures | Durable with excellent strength-to-weight ratio | More challenging to machine, requires specialized tools | High |

| MDF | Cabinetry, furniture, decorative items | Cost-effective and easy to work with | Susceptible to moisture damage | Low |

This strategic material selection guide provides B2B buyers with essential insights into the materials best suited for CNC routers in small shops, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for best cnc router for small shop

What Are the Typical Manufacturing Processes for CNC Routers Designed for Small Shops?

The manufacturing of CNC routers tailored for small businesses involves a systematic approach to ensure quality, durability, and performance. The process typically encompasses several key stages: material preparation, forming, assembly, and finishing. Each stage is critical for delivering a reliable machine that meets the diverse needs of small-scale operations.

How Is Material Prepared for CNC Router Manufacturing?

The first step in manufacturing CNC routers is material preparation. This stage often involves selecting high-quality raw materials, such as aluminum for structural components and high-grade steel for the spindle and other critical parts. Suppliers typically conduct a thorough inspection of materials to ensure they meet specified mechanical properties and tolerances.

After selecting the materials, they are cut to size using precision tools. This stage often involves laser cutting or water jet cutting, which guarantees high accuracy and minimizes waste. The prepared materials are then cleaned and treated to enhance their durability, such as applying corrosion-resistant coatings.

What Forming Techniques Are Commonly Used in CNC Router Production?

Once the materials are ready, the next stage is forming. This involves various machining processes, such as milling, turning, and drilling, to shape the components according to design specifications. CNC machining centers are commonly used in this phase to achieve high precision and repeatability.

Additionally, advanced forming techniques, including 3D printing for certain non-structural components, are becoming more prevalent. This allows for more complex designs and reduces lead times. The use of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software ensures that every component is manufactured to the exact specifications required for optimal performance.

How Are CNC Routers Assembled?

The assembly phase is where the individual components come together to form the complete CNC router. This process typically involves several sub-assemblies, including the frame, gantry, spindle, and control systems. Skilled technicians perform the assembly, ensuring that all parts fit correctly and are aligned to prevent operational issues.

During assembly, critical adjustments are made to optimize performance. For example, the alignment of the spindle is crucial for maintaining precision during machining. Technicians often use specialized tools to measure and adjust these components, ensuring that the machine operates within the specified tolerances.

What Finishing Processes Are Involved in CNC Router Manufacturing?

After assembly, the CNC router undergoes finishing processes to enhance its appearance and protect it from wear. This may include powder coating or anodizing the metal surfaces, which not only improves aesthetics but also adds a layer of protection against corrosion and scratches.

Furthermore, quality checks are performed throughout the finishing process to ensure that the final product meets all design and performance specifications. These checks include visual inspections and functional tests to verify that all features operate as intended.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is paramount in the manufacturing of CNC routers, especially for B2B buyers who require reliable machinery for their operations. International standards, such as ISO 9001, provide a framework for quality management systems and are widely recognized in the industry. Compliance with ISO 9001 indicates that the manufacturer adheres to rigorous quality control processes.

In addition to ISO standards, specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for machinery used in the oil and gas sector may be relevant. These certifications help ensure that the equipment meets stringent safety and performance criteria.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) is integrated into every stage of the CNC router manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This occurs at the initial stage when raw materials arrive. Suppliers must provide documentation that verifies material quality, and samples are often tested to confirm compliance with specifications.

-

In-Process Quality Control (IPQC): During the forming and assembly stages, ongoing inspections are conducted to monitor the manufacturing process. This includes measuring critical dimensions and testing the functionality of assembled components.

-

Final Quality Control (FQC): Once the CNC router is fully assembled, it undergoes rigorous testing to ensure all systems function correctly. This may involve running the machine under load and verifying precision cuts.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality assurance practices of their CNC router suppliers. This includes:

-

Conducting Audits: Regular audits of the manufacturing facility can provide insights into the quality control processes in place. Buyers should consider both on-site inspections and remote audits using digital tools.

-

Requesting Quality Reports: Suppliers should be willing to provide quality control reports that detail their inspection processes, results, and any corrective actions taken. This transparency can build trust and confidence in the supplier’s capabilities.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of the manufacturer’s compliance with quality standards. This is particularly important for international transactions where buyers may not have direct access to the manufacturing facility.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, face unique challenges when sourcing CNC routers. These include:

-

Understanding Local Regulations: Different countries may have specific regulations regarding machinery imports, including safety standards and certifications. Buyers should familiarize themselves with these requirements to avoid compliance issues.

-

Navigating Language Barriers: Communication can be a challenge in international transactions. It is essential to have clear, documented agreements that outline quality expectations and responsibilities.

-

Evaluating Supply Chain Risks: Political instability, economic fluctuations, and logistical challenges can affect supply chains. Buyers should assess these risks and consider establishing relationships with multiple suppliers to mitigate potential disruptions.

By understanding the manufacturing processes and quality assurance practices associated with CNC routers, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best cnc router for small shop’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking the best CNC router for small shops. It outlines essential steps to ensure you make an informed decision, maximizing your investment while meeting your operational needs. Whether you’re in Africa, South America, the Middle East, or Europe, following this guide will help streamline your procurement process.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is fundamental to selecting the right CNC router. Consider the types of materials you will work with, the size of your projects, and the precision needed.

– Work Area: Determine the maximum dimensions of the workpieces you’ll be handling.

– Spindle Speed and Power: Identify the necessary spindle speed and power based on material types (wood, metal, etc.).

Step 2: Set a Realistic Budget

Establishing a budget is critical to avoid overspending and to ensure you select a machine that meets your needs without compromising on quality.

– Price Range: CNC routers can range from $1,500 to over $6,000. Define your budget while considering the potential ROI.

– Total Cost of Ownership: Factor in additional costs such as maintenance, accessories, and software that may influence long-term expenditures.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it’s crucial to vet suppliers thoroughly. Look for reputable manufacturers with a track record of quality and service.

– Company Profiles: Request detailed information about their manufacturing processes and quality control measures.

– References and Reviews: Seek testimonials from other businesses in your region to gauge satisfaction and reliability.

Step 4: Verify Certifications and Compliance

Ensure that the CNC router and the supplier comply with international standards and safety regulations. This step safeguards your investment and guarantees operational reliability.

– ISO Certifications: Check for ISO certification or other relevant quality assurance standards.

– Local Compliance: Be aware of any local regulations that may affect machine operation in your region.

Step 5: Assess Support and Training Options

A reliable support system can significantly enhance your operational efficiency and reduce downtime. Investigate what training and after-sales support are available.

– Technical Support: Confirm the availability of technical assistance and warranty terms.

– Training Programs: Look for suppliers that offer training on equipment operation and software to enhance your team’s capabilities.

Step 6: Test the Equipment Before Purchase

Whenever possible, request a demonstration or a trial period before finalizing your purchase. This step allows you to evaluate the machine’s performance and suitability for your specific needs.

– Hands-On Experience: Ensure you can operate the machine with ease and that it meets your precision requirements.

– Material Compatibility: Test the router with the materials you plan to use to ensure optimal performance.

Step 7: Plan for Future Scalability

As your business grows, your equipment needs may evolve. Consider the scalability of the CNC router you choose.

– Upgrade Options: Look for machines that allow for upgrades or expansions, such as larger work areas or additional features.

– Software Flexibility: Ensure the machine is compatible with future software updates or additional functionalities that may arise.

By following these steps, B2B buyers can navigate the complexities of sourcing a CNC router for their small shop effectively, ensuring they choose a machine that meets their present and future needs.

Comprehensive Cost and Pricing Analysis for best cnc router for small shop Sourcing

What Are the Key Cost Components of CNC Routers for Small Shops?

When evaluating CNC routers, understanding the cost structure is critical for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of materials used in the construction of CNC routers significantly impacts pricing. High-grade metals and durable plastics can increase the overall cost but contribute to longevity and performance.

-

Labor: Labor costs are influenced by the complexity of assembly and the skill level required. CNC routers that require more intricate assembly will likely incur higher labor costs.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and depreciation of equipment. Efficient manufacturing processes can help minimize these costs.

-

Tooling: The quality and type of tooling required can also affect pricing. High-precision tools may be more expensive but can result in better performance and reduced waste.

-

Quality Control (QC): Investing in robust QC processes ensures that machines meet specified standards. While this adds to the cost, it can prevent costly returns and repairs down the line.

-

Logistics: The costs of shipping, handling, and storage also play a role. International shipments may incur additional tariffs and freight charges, affecting the final price.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. The margin can vary based on market demand and competitive positioning.

How Do Price Influencers Affect CNC Router Costs?

Several factors can influence the pricing of CNC routers, particularly for international B2B buyers.

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Buyers should negotiate MOQs with suppliers to achieve better pricing.

-

Specifications and Customization: Custom-built CNC routers tailored to specific needs will generally cost more than standard models. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials: The choice of materials not only affects the cost but also the performance and durability of the CNC router. Buyers should consider the long-term implications of material choices.

-

Quality and Certifications: Machines with higher certifications (e.g., ISO) or those made by reputable manufacturers may come at a premium. However, this often translates into better reliability and support.

-

Supplier Factors: The supplier’s location, reputation, and service offerings can also influence pricing. Established suppliers may offer better warranties and support, justifying a higher cost.

-

Incoterms: Understanding shipping terms (Incoterms) is essential for international buyers. The chosen terms can affect the total landed cost of the router, including insurance and duties.

What Buyer Tips Can Help Optimize CNC Router Purchases?

To maximize value when sourcing CNC routers, consider the following tips:

-

Negotiate with Suppliers: Don’t hesitate to negotiate pricing and payment terms. Suppliers may offer discounts for repeat business or larger orders.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, assess maintenance, operational costs, and potential downtime. A lower-priced machine may lead to higher long-term costs if it requires frequent repairs.

-

Understand Pricing Nuances for International Transactions: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, local tariffs, and shipping costs that can affect pricing.

-

Research and Compare: Take the time to compare different models and suppliers. Online reviews, testimonials, and industry reports can provide valuable insights into performance and reliability.

-

Plan for Future Needs: Consider scalability and adaptability when selecting a CNC router. A slightly higher initial investment in a more capable machine can pay off if your business expands.

Disclaimer on Indicative Prices

The prices mentioned for CNC routers vary widely based on specifications, features, and regional market conditions. Always consult with suppliers for the most accurate and up-to-date pricing tailored to your specific requirements and location.

Alternatives Analysis: Comparing best cnc router for small shop With Other Solutions

Introduction to CNC Router Alternatives for Small Shops

When considering the best CNC router for small shops, it is essential to explore alternative solutions that can meet similar manufacturing needs. These alternatives may offer varying capabilities, costs, and operational complexities that might align better with specific business objectives or constraints. Understanding these options allows B2B buyers to make informed decisions that enhance productivity and efficiency in their operations.

Comparison Table of CNC Router Alternatives

| Comparison Aspect | Best CNC Router for Small Shop | Alternative 1: Laser Cutter | Alternative 2: Manual Router |

|---|---|---|---|

| Performance | High precision; versatile with various materials | Excellent precision for engraving and cutting | Moderate precision; limited to specific materials |

| Cost | $1,500 – $6,000 | $1,000 – $5,000 | $200 – $1,000 |

| Ease of Implementation | Moderate setup complexity; requires software knowledge | Generally easier; often plug-and-play | Simple setup; minimal training needed |

| Maintenance | Requires regular calibration and software updates | Low maintenance; mostly clean optics | Minimal maintenance; mainly blade replacement |

| Best Use Case | Prototyping, custom furniture, and intricate designs | Detailed engravings, signage, and thin materials | Basic shaping, trimming, and woodworking tasks |

Detailed Breakdown of Alternatives

Alternative 1: Laser Cutter

Laser cutters are an increasingly popular choice for small shops looking to achieve high precision in engraving and cutting. They excel in working with materials like wood, acrylic, and even some metals. The primary advantage of laser cutters is their ability to create intricate designs with minimal material waste. However, they may not be suitable for thicker materials and can require significant investment in safety measures and ventilation. Their cost-effectiveness increases when used for high-volume production, but the initial setup can be lower than a CNC router depending on the specific model.

Alternative 2: Manual Router

Manual routers are a traditional tool in woodworking that can still play a vital role in small shops. They are cost-effective and easy to operate, making them ideal for businesses with limited budgets or those just starting. While they lack the precision and versatility of CNC routers, manual routers can be effective for basic shaping and trimming tasks. The major downsides include the need for skilled labor to achieve the desired results and the limitations in production speed and complexity. They are best suited for small-scale projects or businesses that do not require high-volume production.

Conclusion: Choosing the Right Solution for Your Small Shop

Selecting the appropriate solution for your small shop depends on various factors, including budget, production needs, and the types of materials you plan to work with. CNC routers offer exceptional versatility and precision, making them ideal for diverse applications, from prototyping to complex designs. However, if your focus is on engraving or working with thinner materials, a laser cutter may provide the best balance of cost and performance. For basic woodworking tasks, a manual router can be a practical choice, especially for startups or businesses operating on tight budgets. Ultimately, understanding your specific requirements and operational goals will guide you to the most effective solution for your business.

Essential Technical Properties and Trade Terminology for best cnc router for small shop

What Key Technical Properties Should You Consider for CNC Routers?

When evaluating CNC routers for small shops, several critical specifications can influence your purchasing decision and operational efficiency. Understanding these properties will help you align your choices with your business needs.

1. Working Area

The working area, often expressed in dimensions such as length, width, and height (e.g., 4×8 ft), indicates the maximum size of material that the CNC router can accommodate. For small shops, selecting a router with an appropriate working area is essential, as it directly impacts the types and sizes of projects you can undertake. A larger working area allows for more extensive projects, such as furniture, while a smaller area is suitable for detailed work like engraving or small components.

2. Spindle Speed

Spindle speed, measured in revolutions per minute (RPM), defines how quickly the router bit rotates during operation. Higher spindle speeds (e.g., up to 30,000 RPM) can enhance the router’s ability to cut through various materials, including wood, plastics, and metals. For B2B buyers, understanding spindle speed is crucial because it affects cutting efficiency, precision, and the types of materials the router can handle effectively.

3. Material Compatibility

Material compatibility refers to the range of materials the CNC router can effectively cut or engrave, such as wood, acrylic, aluminum, and composites. Different projects may require different materials, so it’s vital to choose a router that can handle the specific types of materials your business will use. This versatility can significantly impact your production capabilities and market offerings.

4. Tolerance and Precision

Tolerance indicates the degree of accuracy with which a CNC router can cut or engrave materials. This is often expressed in millimeters or inches (e.g., ±0.01 mm). High precision is essential for applications requiring detailed work, such as prototyping or intricate designs. For businesses aiming for high-quality outputs, investing in a router with tighter tolerances can reduce errors and improve overall production quality.

5. Build Quality and Durability

The build quality of a CNC router determines its longevity and ability to withstand rigorous use. Routers constructed from high-grade materials, such as aluminum or steel, tend to offer better stability and durability. For B2B buyers, this aspect is critical, as a robust machine can lead to lower maintenance costs and longer operational lifespans, ultimately resulting in better return on investment.

What Trade Terminology Should You Know When Buying CNC Routers?

Navigating the procurement process for CNC routers involves familiarizing yourself with industry-specific terminology. Understanding these terms can streamline your interactions with suppliers and enhance your purchasing decisions.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC routers, knowing whether a machine is OEM can indicate the quality and reliability of the components used, which is crucial for ensuring consistent performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is vital for budgeting and inventory management. A high MOQ can affect cash flow, especially for small shops that may not need large quantities of machinery or parts.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. Including detailed specifications in your RFQ can help ensure that you receive accurate and comparable quotations, facilitating better decision-making in the procurement process.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms can help you understand shipping costs, delivery timelines, and risk management, ensuring a smoother transaction process when sourcing CNC routers from international suppliers.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for planning production schedules and managing customer expectations, particularly in industries where timely delivery is critical.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting the best CNC router for their small shop, ultimately leading to enhanced productivity and profitability.

Navigating Market Dynamics and Sourcing Trends in the best cnc router for small shop Sector

What Are the Current Market Dynamics for CNC Routers in Small Shops?

The global CNC router market is experiencing robust growth, driven by increasing demand for precision manufacturing and custom fabrication across various sectors, including woodworking, metalworking, and prototyping. Particularly in regions like Africa, South America, the Middle East, and Europe, small shop owners are leveraging CNC technology to enhance productivity and diversify their offerings. The shift toward digital manufacturing solutions is becoming more pronounced as businesses seek cost-effective and scalable operations.

Emerging trends include the adoption of advanced automation technologies, such as AI and IoT, which facilitate smarter machining processes and real-time monitoring. This trend is particularly relevant for international buyers looking to optimize their production capabilities while minimizing labor costs. Additionally, the rise of e-commerce platforms is driving demand for custom, small-batch production, further solidifying the role of CNC routers in small shops. As manufacturers introduce more affordable and versatile models, even businesses with limited budgets can access high-quality machinery that meets their operational needs.

Buyers should also be aware of the competitive landscape, which is characterized by a mix of established manufacturers and innovative startups. This dynamic environment often leads to rapid advancements in technology and features, such as enhanced user interfaces, compatibility with various materials, and improved precision. For B2B buyers in emerging markets, understanding these dynamics is crucial to making informed purchasing decisions that align with their business goals.

How Does Sustainability Influence the Sourcing of CNC Routers for Small Shops?

Sustainability is increasingly becoming a vital consideration in the sourcing of CNC routers for small shops. Environmental impact concerns are prompting businesses to seek machines that utilize eco-friendly materials and processes. This includes routers that are energy-efficient, reducing power consumption during operation, and those that incorporate sustainably sourced components.

Ethical sourcing practices are essential for building a responsible supply chain. B2B buyers should prioritize manufacturers that demonstrate a commitment to sustainability through certifications such as ISO 14001, which indicates effective environmental management systems. Moreover, the use of recyclable materials in the construction of CNC routers can greatly reduce waste and promote a circular economy.

The demand for “green” certifications and materials is also on the rise among consumers, influencing small businesses to adopt more sustainable practices. By sourcing CNC routers from environmentally responsible manufacturers, businesses not only enhance their brand reputation but also appeal to a growing customer base that values sustainability. This alignment with ethical standards can also lead to potential cost savings through energy efficiency and reduced waste.

How Has the CNC Router Industry Evolved to Meet B2B Needs?

The evolution of the CNC router industry has been marked by significant technological advancements that have transformed manufacturing processes. Initially, CNC routers were primarily used in large-scale operations, but as technology progressed, smaller, more affordable models emerged, making them accessible to small shops and hobbyists.

Over the past decade, innovations such as improved software for easier operation, enhanced precision capabilities, and the ability to work with a broader range of materials have significantly increased the utility of CNC routers. The introduction of modular systems has also allowed small businesses to customize their machines according to specific needs, thus optimizing their investments.

As the industry continues to evolve, B2B buyers must stay informed about the latest advancements and trends to make strategic purchasing decisions. This knowledge not only helps businesses remain competitive but also positions them to leverage new technologies for improved efficiency and productivity in their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of best cnc router for small shop

-

How do I choose the right CNC router for my small shop?

Choosing the right CNC router involves assessing your specific needs, including the materials you plan to work with, the size of your projects, and your budget. Start by determining the machine’s working area, spindle speed, and material compatibility. For example, if you primarily work with wood and plastics, a machine like the Sainsmart Genmitsu 3018 PROver could be ideal due to its affordability and versatility. Additionally, consider the ease of assembly, software compatibility, and after-sales support from suppliers. -

What is the best CNC router for small businesses on a budget?

For small businesses operating on a budget, the Sainsmart Genmitsu 3018 PROver is often recommended. Priced at around $200, it offers a user-friendly setup and can handle a variety of materials, including wood, acrylic, and soft metals. While it may lack the robustness of higher-end models, it provides an excellent entry point for hobbyists and small shops looking to explore CNC technology without significant investment. -

What are the typical payment terms for international CNC router purchases?

Payment terms for international purchases can vary widely by supplier, but common practices include a deposit of 30-50% upfront with the balance due prior to shipment. Some suppliers may offer payment via letter of credit for larger transactions, providing additional security. Always clarify payment methods accepted (like bank transfers or credit cards) and ensure that terms are documented in your purchase agreement to avoid misunderstandings. -

How can I vet suppliers when purchasing CNC routers internationally?

Vetting suppliers is crucial for ensuring quality and reliability. Start by checking their business credentials and customer reviews online. Request references from previous clients and inquire about their experience with the supplier. Additionally, consider visiting the supplier’s facility if possible or utilizing third-party inspection services to assess the quality of the machinery before purchase. Platforms like Alibaba or industry-specific trade shows can also provide insights into supplier reputations. -

What customization options are available for CNC routers?

Many suppliers offer customization options for CNC routers, including modifications in working size, spindle type, and software compatibility. Depending on your needs, you might also request specific features such as enhanced dust collection systems or integrated laser engravers. Always discuss your requirements with the supplier during the inquiry process to ensure that the machine meets your operational specifications. -

What is the minimum order quantity (MOQ) for CNC routers?

The minimum order quantity (MOQ) for CNC routers can vary by supplier and the type of machine. Some manufacturers may allow single-unit purchases, especially for entry-level models, while others might set MOQs for bulk orders or customized machines. It’s essential to communicate your needs with the supplier to understand their policies and negotiate terms that align with your business goals. -

What logistics should I consider when importing CNC routers?

When importing CNC routers, consider shipping costs, customs duties, and lead times. Ensure that you have a clear understanding of the incoterms (International Commercial Terms) used in your agreement, as they dictate responsibilities for shipping, insurance, and tariffs. Additionally, partner with a reliable freight forwarder experienced in handling machinery imports to streamline the process and mitigate potential delays. -

How do I ensure quality assurance when purchasing CNC routers?

To ensure quality assurance when purchasing CNC routers, request detailed specifications and certifications for the machines you’re considering. Many reputable suppliers will provide documentation proving compliance with international standards. Additionally, consider implementing a quality control process, such as pre-shipment inspections, to verify the machine’s condition and functionality before it arrives at your facility. Building a strong relationship with your supplier can also facilitate ongoing support and quality assurance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for best cnc router for small shop

As we conclude our exploration of the best CNC routers for small shops, it is crucial to underscore the significance of strategic sourcing in making informed purchasing decisions. Understanding the diverse range of CNC routers available—such as the budget-friendly Sainsmart Genmitsu 3018 PROver and the more robust MakerMade M2—enables businesses to align their equipment choices with specific project needs and financial constraints. By evaluating machine capabilities, work area dimensions, and material compatibility, B2B buyers can avoid costly mistakes and ensure that their investment enhances productivity and efficiency.

For international buyers from regions like Africa, South America, the Middle East, and Europe, this is an opportune moment to leverage the expanding market for CNC technology. Emphasizing quality, durability, and after-sales support in your sourcing strategy will yield long-term benefits. As the industry continues to evolve, staying informed about technological advancements and market trends will empower your business to adapt and thrive.

Take the next step in your CNC journey by assessing your unique requirements and engaging with suppliers who can meet your operational goals. The right CNC router can be a transformative asset for your small shop, driving innovation and growth in your business.