Top 8 Machine Shop Cost Manufacturers & Suppliers List

1. Paragon Engines – Machine Shop Pricing

Domain: paragonengines.com

Registered: 2016 (9 years)

Introduction: Machine Shop Pricing:

Block Operations:

– Disassemble Engine: $220

– Hot Tank & Inspect Block: $125

– Bore Block – .030”: $315

– Bore Block – .060”: $375

– Sleeve (single cylinder): $220

– Hone w/torque plates: $440

– Line Bore Mains: $410

– Line Bore Cam: $440

– Install Steel Caps (each): $85

– Deck Block Parallel: $285

– Hone Lifter Bores: $160

– Bore lifter bores: $535

– Install Lifter bushing…

2. Reddit – Machine Shop Services for Engine Rebuilding

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the costs associated with machine shop services for engine rebuilding, specifically for a tired old 383 engine. Key services mentioned include hot tanking, honing, disassembly, cleaning, inspection, line honing, line boring, boring, honing, decking the block, final cleaning, detailing, installing plugs and cam bearings, crankshaft cleaning, grinding, polishing, con r…

3. Automotive Machine – Engine Size Guide

Domain: automotivemachine.com

Registered: 1996 (29 years)

Introduction: This company, Automotive Machine – Engine Size Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Practical Machinist – CNC Machine Shop Essentials

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: Starting a CNC machine shop involves various costs and equipment. Key details include: 1. Initial Equipment: A good CNC mill and CNC lathe are essential, with estimates around $300,000 for new machines like Haas. 2. Software: CAD and CAM software such as SolidWorks and MasterCAM are necessary, but pricing details were not provided. 3. Additional Costs: Real estate lease, electricity, and other too…

5. RidgeAP – Innovative Solutions

Domain: ridgeap.com

Registered: 1999 (26 years)

Introduction: This company, RidgeAP – Innovative Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. BES Racing – Engine Machine Shop Services

Domain: besracing.com

Registered: 2003 (22 years)

Introduction: BES Racing Engines offers a variety of machine shop services including:

– Balancing

– Crank Grinding

– Engine Dyno

– Flow Bench

– Head Porting

– Sheet Metal Intake Fabrication

**Block Work:**

– Bore & Hone Block:

– V8: $350

– V6: $305

– Inline 6: $295

– Inline 4: $225

– With torque plate add: $175

– Install cam bearings: $115

– Hot tank and install freeze plugs: $200

– Darton sleeves i…

7. Claysmith Cams – Cylinder Head Services

Domain: claysmithcams.com

Registered: 1997 (28 years)

Introduction: Machine Shop Services:

1. Cylinder Head Work:

– Disassemble V6 Cast Iron heads: $375

– Disassemble L6 Cast Iron head: $350

– Disassemble Cast Iron V8 heads: $450

– Disassemble Aluminum V8 heads: $475

– Disassemble Heads (32 Valves): $650

– Disassemble New V8 Heads: $200

– Inspect New V8 Heads: $125

– Blue Print Valve Job Only V8: $300

– CC One Chamber: $60

– CC Heads …

8. MGExp – MGB & GT Machine Shop Services

Domain: mgexp.com

Registered: 2011 (14 years)

Introduction: Machine shop services for MGB & GT components include: 1. Resizing, straightening, and bushing of rods. 2. Boring, boiling, beading, and decking of the block. 3. Installation of new cam bearings. 4. Grinding of the crank. 5. Blasting of rearend casing, front suspension bits, and heater box. 6. Additional services mentioned include cylinder bore/hone, installation of new freeze plugs, polishing cra…

Introduction: Navigating the Global Market for machine shop cost

In the ever-evolving global market, understanding machine shop costs is a pivotal challenge for B2B buyers. As companies in regions such as Africa, South America, the Middle East, and Europe—especially in nations like Brazil and Nigeria—seek reliable machining solutions, the complexities of pricing can be daunting. Whether you are looking to source precision components or large-scale production runs, knowing how to navigate the intricacies of machine shop costs is essential for making informed purchasing decisions.

This comprehensive guide delves into various facets of machine shop costs, offering insights into different types of machining services, their applications, and how to effectively vet suppliers. From the intricacies of engine block operations to the nuances of crankshaft machining, we cover the essential elements that impact pricing. Additionally, we provide actionable strategies to help buyers assess costs accurately, ensuring that you receive competitive quotes without compromising on quality.

By equipping international B2B buyers with the knowledge needed to navigate this complex landscape, this guide empowers you to make strategic decisions that enhance operational efficiency and cost-effectiveness. Understanding machine shop costs not only facilitates better negotiation but also fosters long-term partnerships with suppliers who align with your business objectives.

Understanding machine shop cost Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Block Operations | Focus on disassembly, cleaning, and machining of engine blocks. | Automotive repair and remanufacturing. | Pros: Essential for engine performance; Cons: Can be costly due to labor and equipment. |

| Crankshaft Services | Specialization in grinding, polishing, and welding crankshafts. | High-performance engine builds and repairs. | Pros: Enhances engine efficiency; Cons: Requires specialized skills and equipment. |

| Cylinder Head Services | Involves valve jobs, resurfacing, and modifications for cylinder heads. | Automotive, aerospace, and industrial engines. | Pros: Critical for engine power; Cons: Complex processes can lead to higher costs. |

| Piston & Rod Operations | Services include fitting, reconditioning, and assembly of pistons and rods. | Engine manufacturing and overhaul. | Pros: Improves engine reliability; Cons: Labor-intensive, impacting turnaround times. |

| Assembly Operations | Comprehensive assembly of engine components, ensuring precision and quality. | Complete engine builds and remanufacturing. | Pros: Guarantees quality control; Cons: Higher initial investment may be needed. |

What Are Block Operations and Their Importance in B2B Transactions?

Block operations encompass the disassembly, cleaning, and machining of engine blocks. This service is crucial for automotive repair and remanufacturing, as it ensures the foundational component of an engine is in optimal condition. Buyers should consider the reputation and capabilities of the machine shop, as quality block work can directly affect engine performance and longevity. However, the costs can escalate due to labor intensity and the need for specialized equipment.

How Do Crankshaft Services Enhance Engine Performance?

Crankshaft services involve grinding, polishing, and sometimes welding crankshafts to restore or enhance their functionality. These services are particularly relevant for high-performance engine builds and repairs, where precision is key. B2B buyers should evaluate the machine shop’s expertise and machinery, as the accuracy of crankshaft work can significantly impact engine efficiency. While these services can lead to improved performance, they often require a significant investment in specialized skills and equipment.

What Do Cylinder Head Services Entail for Engine Efficiency?

Cylinder head services include valve jobs, resurfacing, and modifications necessary for optimal engine performance. This type of service is vital in sectors such as automotive, aerospace, and industrial engines, where high efficiency is paramount. When selecting a machine shop, buyers should assess the range of services offered and the quality of workmanship. Although cylinder head work can be costly and complex, the benefits in terms of power output and engine reliability are often worth the investment.

Why Are Piston & Rod Operations Critical for Engine Reliability?

Piston and rod operations focus on fitting, reconditioning, and assembling these critical engine components. These services are essential for both engine manufacturing and overhauls, ensuring that pistons and rods perform reliably under stress. Buyers should prioritize machine shops with a proven track record and the necessary equipment for these operations. While these services can improve engine reliability, they are labor-intensive, which may lead to longer turnaround times and higher costs.

What Are the Benefits of Comprehensive Assembly Operations?

Assembly operations involve the precise assembly of engine components, ensuring that all parts fit and function together correctly. This service is crucial for complete engine builds and remanufacturing projects. B2B buyers benefit from working with machine shops that emphasize quality control during assembly, which can lead to enhanced engine performance and reduced failure rates. However, the initial investment might be higher due to the labor and expertise required to achieve a high-quality assembly.

Key Industrial Applications of machine shop cost

| Industry/Sector | Specific Application of machine shop cost | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine Rebuilding and Performance Enhancements | Improved engine performance and longevity | Quality of machine work, turnaround time, and warranty terms |

| Aerospace | Precision Component Manufacturing | Compliance with stringent safety and performance standards | Certification of processes, material traceability, and quality assurance |

| Oil & Gas | Custom Tooling and Equipment Fabrication | Enhanced operational efficiency and reduced downtime | Material availability, custom machining capabilities, and lead times |

| Heavy Machinery | Repair and Maintenance of Industrial Equipment | Cost-effective solutions for equipment longevity | Expertise in heavy machinery, availability of spare parts, and service support |

| Marine Engineering | Engine and Component Overhaul | Increased reliability and performance in harsh environments | Specialized knowledge in marine applications and regulatory compliance |

How is machine shop cost applied in the automotive industry?

In the automotive sector, machine shop costs are primarily associated with engine rebuilding and performance enhancements. This involves precision machining of engine components to improve performance and extend the lifespan of vehicles. International buyers, especially from regions like Africa and South America, must consider the quality of the machine work and the availability of parts when sourcing services. The ability to provide warranties and quick turnaround times can significantly influence purchasing decisions.

What role does machine shop cost play in the aerospace industry?

The aerospace industry relies heavily on machine shop costs for the manufacturing of precision components that meet stringent safety and performance standards. The complexity of aerospace parts necessitates advanced machining capabilities and thorough quality assurance processes. For international buyers, particularly in Europe and the Middle East, ensuring that suppliers have the necessary certifications and can provide material traceability is critical for compliance with industry regulations.

How does machine shop cost impact the oil and gas sector?

In the oil and gas industry, machine shop costs are integral to custom tooling and equipment fabrication. The need for specialized tools that enhance operational efficiency can lead to significant cost savings and reduced downtime. For international buyers, especially in regions like Nigeria and Brazil, sourcing considerations should focus on the availability of materials and the supplier’s ability to handle custom machining requests within reasonable lead times.

Why is machine shop cost crucial for heavy machinery maintenance?

Heavy machinery requires regular repair and maintenance, which often involves machine shop services. The associated costs can be justified by the extended lifespan and reliability of equipment, leading to lower overall operational costs. Buyers in this sector should prioritize suppliers with expertise in heavy machinery, ensuring they have access to necessary spare parts and robust service support to minimize downtime.

How is machine shop cost utilized in marine engineering?

In marine engineering, machine shop costs are essential for engine and component overhauls. Given the challenging conditions faced by marine equipment, ensuring reliability and performance is paramount. International buyers need to focus on suppliers that possess specialized knowledge in marine applications and adhere to regulatory compliance to ensure the longevity and efficiency of their marine operations.

3 Common User Pain Points for ‘machine shop cost’ & Their Solutions

Scenario 1: Unexpected Cost Overruns in Machine Shop Services

The Problem:

B2B buyers often encounter the issue of unexpected cost overruns when sourcing machine shop services. This can occur due to a variety of factors, including unanticipated complexities in the machining process, inadequate initial assessments, or fluctuating market prices. For instance, a buyer may request a routine engine reconditioning service, only to find that additional repairs or modifications are necessary, leading to a significant increase in the final bill. This situation not only strains the budget but can also disrupt project timelines and overall business operations.

The Solution:

To mitigate the risk of unexpected cost overruns, it is crucial for buyers to engage in thorough pre-project consultations with machine shop providers. Start by requesting detailed quotes that outline all potential costs associated with the machining services. Ensure that these quotes include line-item breakdowns for different operations, such as cleaning, boring, and assembly. Additionally, ask about potential contingencies—what situations could arise that might lead to increased costs? Establishing a clear communication channel with the machine shop and setting expectations can help in anticipating challenges before they escalate. Consider negotiating a fixed-price contract for well-defined projects, as this can safeguard against fluctuating costs.

Scenario 2: Difficulty Understanding Complex Pricing Structures

The Problem:

Many B2B buyers struggle to comprehend the complex pricing structures of machine shop services. The pricing can vary widely based on the type of machine work required, the materials involved, and the specific machinery used. This complexity can lead to confusion and difficulty in budgeting for projects, particularly for buyers who may not have a technical background in machining. Consequently, misinterpretations can result in selecting a less suitable service provider or failing to allocate adequate resources for the project.

The Solution:

To navigate the intricacies of machine shop pricing, buyers should take proactive steps to educate themselves about common pricing practices in the industry. Begin by creating a glossary of terms related to machining and pricing to familiarize yourself with common operations and their associated costs. Reach out to multiple machine shops to request quotes and ask for explanations regarding their pricing structures. This not only helps in comparing services but also aids in understanding the rationale behind costs. Additionally, consider consulting with a knowledgeable industry expert or a procurement specialist who can offer insights into typical pricing benchmarks and help clarify any ambiguities.

Scenario 3: Inconsistent Quality of Machine Shop Work

The Problem:

Inconsistent quality of work from machine shops is a significant concern for B2B buyers. Variability in machining quality can lead to defective parts or inadequate repairs, which can compromise the performance of machinery or vehicles. This inconsistency may stem from various factors, including a lack of skilled labor, outdated equipment, or insufficient quality control processes. For international buyers, particularly from regions like Africa and South America, sourcing reliable machine shops can be even more challenging due to varying standards and practices.

The Solution:

To ensure consistent quality, buyers should prioritize building long-term relationships with reputable machine shops that have a proven track record of delivering high-quality work. Start by conducting thorough due diligence, which includes checking references, reviewing past projects, and assessing the shop’s certifications and quality assurance processes. Consider establishing a pilot project with the machine shop to evaluate their capabilities before committing to larger orders. Additionally, implementing a quality control protocol that includes regular inspections and performance reviews can help maintain standards throughout the duration of the partnership. Engaging in open communication regarding quality expectations and feedback can further enhance the reliability of the machine shop’s output.

Strategic Material Selection Guide for machine shop cost

What Are the Key Materials Impacting Machine Shop Costs?

When selecting materials for machine shop operations, understanding their properties, advantages, and limitations is crucial for international B2B buyers. This section explores four common materials—aluminum, steel, titanium, and cast iron—highlighting their relevance to machine shop costs and applications.

How Does Aluminum Affect Machine Shop Costs?

Aluminum is renowned for its lightweight and excellent corrosion resistance, making it a popular choice in various applications, especially in the automotive and aerospace sectors. Its high thermal conductivity is advantageous for heat dissipation in engine components. However, aluminum can be more expensive than steel, and its lower strength limits its use in high-stress applications.

For international buyers, aluminum’s compliance with standards such as ASTM and EN is essential. Additionally, the sourcing of aluminum can vary significantly by region, affecting costs and availability. Countries like Brazil and Nigeria may face challenges in sourcing quality aluminum, impacting overall project timelines and budgets.

What Are the Benefits and Drawbacks of Steel?

Steel is one of the most widely used materials in machine shops due to its strength, durability, and cost-effectiveness. It can withstand high temperatures and pressures, making it suitable for a variety of applications, including structural components and engine parts. The main drawback is its susceptibility to corrosion, which may require additional treatments or coatings, increasing overall costs.

For B2B buyers, understanding the different grades of steel (e.g., stainless, carbon) is vital, as these grades adhere to various international standards like ASTM and ISO. Buyers from Europe and the Middle East should be aware of local regulations regarding material sourcing and environmental compliance.

Why Choose Titanium for High-Performance Applications?

Titanium is prized for its exceptional strength-to-weight ratio and corrosion resistance, making it ideal for high-performance applications in aerospace and medical fields. However, titanium is significantly more expensive than aluminum and steel, and its machining can be complex, requiring specialized tools and techniques.

International buyers must consider the availability of titanium and its compliance with standards like ASTM and JIS. In regions such as Africa and South America, sourcing titanium may be limited, potentially leading to increased costs and longer lead times.

How Does Cast Iron Fit into Machine Shop Operations?

Cast iron is commonly used for engine blocks and heavy machinery due to its excellent wear resistance and ability to dampen vibrations. It is cost-effective and readily available, making it a staple in many machine shops. However, cast iron is brittle, which can lead to cracking under excessive stress.

For B2B buyers, understanding the different types of cast iron (e.g., gray, ductile) and their respective applications is crucial. Compliance with international standards is also necessary, especially for buyers in Europe and the Middle East, where stringent regulations may apply.

Summary of Material Properties and Considerations

| Material | Typical Use Case for machine shop cost | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine components, aerospace parts | Lightweight, corrosion-resistant | Higher cost, lower strength | Medium |

| Steel | Structural components, engine parts | Strong, durable, cost-effective | Susceptible to corrosion | Low |

| Titanium | Aerospace, high-performance applications | Exceptional strength-to-weight ratio | High cost, complex machining | High |

| Cast Iron | Engine blocks, heavy machinery | Wear-resistant, cost-effective | Brittle, can crack under stress | Low |

This analysis provides B2B buyers with critical insights into material selection, enabling informed decisions that align with their operational needs and compliance requirements. Understanding the properties and implications of these materials can significantly impact machine shop costs and overall project success.

In-depth Look: Manufacturing Processes and Quality Assurance for machine shop cost

What Are the Main Stages in the Manufacturing Process of Machine Shop Costs?

Understanding the manufacturing processes in a machine shop is essential for B2B buyers looking to evaluate costs effectively. The typical stages involved include material preparation, forming, assembly, and finishing. Each stage has its own set of techniques and tools that influence the final cost of the products.

Material Preparation

The first step involves sourcing high-quality raw materials, which can include metals, plastics, and composites. The choice of material significantly affects both the cost and the performance of the final product. Materials are often inspected for quality and compliance with specifications before they enter the production line. Techniques such as cutting, shearing, or casting may be employed to shape the materials into manageable sizes.

Forming

This stage encompasses various techniques such as machining, welding, and forging. For instance, machining processes like turning and milling are commonly used to achieve precise dimensions and surface finishes. The complexity of the part being manufactured will dictate the methods used, which in turn affects labor and operational costs. Advanced technologies like CNC machining can improve precision and reduce waste, contributing to overall cost-effectiveness.

Assembly

Once the components are formed, they undergo assembly. This could involve manually fitting parts together or utilizing automated systems for larger-scale production. Quality assurance during assembly is crucial to ensure that all components meet design specifications. The use of jigs and fixtures can enhance accuracy and speed during this phase, impacting labor costs.

Finishing

Finishing processes such as coating, anodizing, or polishing enhance the product’s aesthetics and durability. These processes also serve to protect against corrosion and wear, thus extending the product’s lifespan. The choice of finishing techniques will influence the final cost, with more complex processes typically resulting in higher expenses.

How Is Quality Control Implemented in Machine Shops?

Quality Control (QC) is integral to the manufacturing process, ensuring that the final products meet international standards and client specifications. This involves various checkpoints and methodologies that B2B buyers should be familiar with.

International Standards and Certifications

Many machine shops adhere to international quality management standards such as ISO 9001. This certification indicates that the shop has established a robust quality management system that encompasses all processes from design to delivery. Other industry-specific certifications, like CE for products sold in Europe and API for oil and gas equipment, may also apply depending on the nature of the products.

Quality Checkpoints

Quality checks can occur at multiple stages, often categorized as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

IQC focuses on the quality of incoming materials and components. This is the first line of defense against defects, where materials are inspected and tested against specified standards.

-

IPQC occurs during the manufacturing process. Operators and quality inspectors monitor production to identify any deviations from the process and ensure that specifications are being met in real-time.

-

FQC is conducted after production but before delivery. This final inspection verifies that the finished product meets all quality and performance criteria.

What Testing Methods Are Commonly Used in Machine Shops?

Various testing methods are employed to ensure that products meet quality standards. Common techniques include:

- Dimensional Inspection: Using tools like calipers and micrometers to measure the physical dimensions of components.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic, magnetic particle, or dye penetrant testing are used to detect internal defects without damaging the product.

- Performance Testing: Simulating real-world conditions to assess how well a product performs under stress or load.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are some actionable steps:

Conducting Audits

Regular audits of potential suppliers can provide insights into their quality management practices. Buyers should look for comprehensive audits that cover all aspects of the manufacturing process, from material sourcing to final delivery.

Requesting Quality Reports

Suppliers should be able to provide documentation related to their quality control processes, including inspection reports, test results, and certifications. This documentation can help buyers assess whether the supplier meets their quality standards.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality processes. These services can conduct inspections at various stages of production and provide detailed reports that can inform purchasing decisions.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate several nuances when it comes to quality control. Different regions may have varying standards and expectations, which can complicate the procurement process. For instance, buyers from Brazil might prioritize compliance with local regulations, while those in Nigeria may focus on certifications relevant to the African market.

Understanding the specific quality standards and certifications required in each region can help buyers mitigate risks and ensure compliance. It’s also advisable to establish clear communication with suppliers about quality expectations, deadlines, and documentation requirements.

Conclusion

In summary, a comprehensive understanding of manufacturing processes and quality assurance is crucial for B2B buyers in the machine shop industry. By familiarizing themselves with the stages of production, QC methodologies, testing techniques, and verification processes, buyers can make informed decisions that align with their operational needs and quality standards. This diligence not only enhances the procurement process but also contributes to building long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘machine shop cost’

In the competitive landscape of B2B procurement, understanding the costs associated with machine shop services is crucial for making informed decisions. This guide serves as a practical checklist for international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe. By following these steps, you can navigate the complexities of machine shop costs effectively.

Step 1: Define Your Technical Specifications

Clearly outline your project requirements, including the type of machining services needed (e.g., milling, turning, grinding). This step is essential because precise specifications will help suppliers provide accurate quotes and ensure that the final product meets your expectations.

- Detail the materials you will be working with.

- Specify tolerances and any industry standards that must be adhered to.

Step 2: Research Potential Suppliers

Conduct thorough research to identify machine shops that specialize in the services you require. This is important as it helps to narrow down suppliers who have the necessary expertise and experience in your specific industry.

- Look for reviews and testimonials from other B2B clients.

- Utilize platforms like LinkedIn to connect with industry professionals and gather recommendations.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001 or industry-specific qualifications. Certifications are a testament to a supplier’s commitment to quality and compliance, which can significantly impact the reliability of the services they provide.

- Ask for documentation and check the validity of their certifications.

- Inquire about their quality control processes and how they ensure consistent output.

Step 4: Request Detailed Quotes

Obtain itemized quotes from multiple suppliers to compare pricing transparently. This step is crucial for understanding the cost structure and identifying any hidden fees that could affect your budget.

- Ensure that the quotes break down costs for labor, materials, and any additional services.

- Ask about lead times and payment terms to avoid surprises later in the procurement process.

Step 5: Assess Production Capabilities

Evaluate the production capabilities of the suppliers, including their equipment and technology. This is vital to ensure they can meet your project’s volume and complexity requirements.

- Inquire about the types of machinery they use and their maintenance practices.

- Assess whether they have the capacity to handle urgent orders or fluctuations in demand.

Step 6: Check for After-Sales Support

After-sales support is a critical component of the supplier relationship. Confirm that the supplier offers assistance post-delivery, such as warranty services or troubleshooting support.

- Ask about their process for handling defects or issues with the finished products.

- Ensure they have a clear communication channel for ongoing support.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful partnership with your machine shop supplier. Establishing clear channels for updates and inquiries can prevent misunderstandings and delays.

- Designate a point of contact from both your team and the supplier’s side.

- Schedule regular check-ins to discuss project progress and any potential issues.

By following this checklist, B2B buyers can ensure that they make informed decisions when sourcing machine shop services, ultimately leading to successful project outcomes and long-term partnerships.

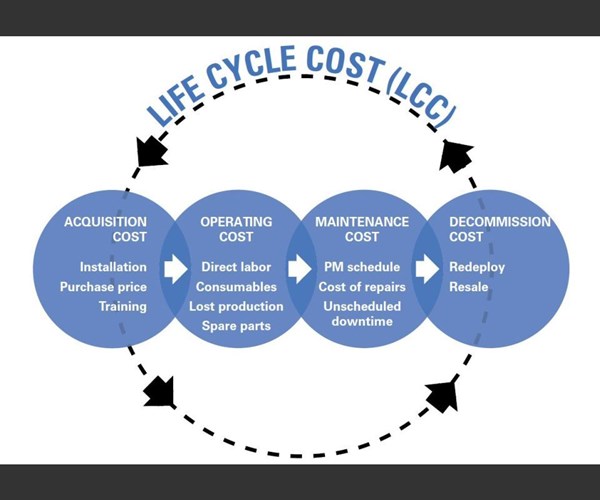

Comprehensive Cost and Pricing Analysis for machine shop cost Sourcing

What Are the Key Cost Components in Machine Shop Pricing?

Understanding the cost structure of machine shop pricing is essential for international B2B buyers. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: This includes raw materials required for machining operations, such as metals and alloys. The cost fluctuates based on global market prices and can vary significantly depending on the type of material specified.

-

Labor: Skilled labor is a significant cost driver. The complexity of the operations and the skill level required will affect labor costs. For instance, tasks that involve precision work, such as CNC machining or specialized assembly, typically incur higher labor charges.

-

Manufacturing Overhead: This encompasses indirect costs associated with running a machine shop, such as utilities, equipment maintenance, and facility costs. Efficient management of these overheads can lead to more competitive pricing.

-

Tooling: Tooling costs can be substantial, particularly for custom projects that require specific tools. These costs should be factored into the total pricing, especially if the tooling is unique to a specific order.

-

Quality Control (QC): Ensuring that the final product meets required specifications involves QC processes that add to the cost. Certifications and testing procedures will also influence pricing.

-

Logistics: Shipping and handling charges are critical, especially for international shipments. These costs vary based on the destination, shipment method, and Incoterms.

-

Margin: Suppliers add a profit margin to cover their costs and provide a return on investment. This margin can vary based on competition and market demand.

How Do Price Influencers Impact Machine Shop Costs?

Several factors influence the pricing of machine shop services, particularly for international B2B buyers.

-

Volume/MOQ: Bulk orders often result in reduced unit costs. Suppliers may offer discounts for larger quantities, making it essential for buyers to evaluate their needs carefully.

-

Specifications and Customization: Custom projects typically incur higher costs due to the additional design and production complexities. Clear communication of specifications can help manage these costs.

-

Materials: The choice of materials significantly impacts the overall price. High-quality or specialized materials may lead to increased costs, but they can also enhance the durability and performance of the final product.

-

Quality and Certifications: Suppliers with industry certifications (e.g., ISO, AS9100) may charge more due to their commitment to quality. Buyers should weigh the benefits of certified suppliers against their budgets.

-

Supplier Factors: The supplier’s location, reputation, and operational efficiency can affect pricing. Established suppliers may charge a premium for their reliability and expertise.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk.

What Are the Best Buyer Tips for Cost-Efficiency in Machine Shop Sourcing?

When sourcing machine shop services, especially for international projects, buyers should consider the following strategies to enhance cost-efficiency:

-

Negotiation: Engage in negotiations to secure better pricing, particularly for larger orders. Understanding the supplier’s cost structure can provide leverage in discussions.

-

Total Cost of Ownership (TCO): Assess the TCO rather than just the initial price. Consider factors like maintenance, longevity, and performance, which can impact overall expenses.

-

Pricing Nuances for International Buyers: Be aware of additional costs associated with customs, tariffs, and taxes when importing goods. These can significantly alter the final price.

-

Supplier Relationship Management: Building strong relationships with suppliers can lead to better pricing and service. Regular communication and feedback can foster collaboration and trust.

-

Research and Comparison: Conduct thorough research and compare prices from multiple suppliers. This helps in identifying competitive pricing and understanding market trends.

Conclusion

Machine shop pricing is influenced by a multitude of factors that require careful consideration by international B2B buyers. By understanding the cost components, price influencers, and employing strategic sourcing techniques, buyers can make informed decisions that optimize their procurement processes. Keep in mind that the prices mentioned are indicative and can fluctuate based on market conditions and specific project requirements.

Alternatives Analysis: Comparing machine shop cost With Other Solutions

Exploring Alternatives to Machine Shop Costs

In the realm of manufacturing and maintenance, machine shops are a cornerstone for precision machining and repairs. However, B2B buyers are increasingly seeking alternatives that may provide similar benefits at different cost points or operational efficiencies. This analysis compares machine shop costs with other viable solutions, enabling businesses to make informed decisions tailored to their needs.

| Comparison Aspect | Machine Shop Cost | 3D Printing Technology | CNC Machining Services |

|---|---|---|---|

| Performance | High precision and quality control for complex parts | Capable of creating intricate designs with less waste | High precision and flexibility in part design |

| Cost | Varies widely ($20-$960 per job) | Generally lower for small to medium runs; setup costs can be high | Higher upfront costs but cost-effective for large runs |

| Ease of Implementation | Requires skilled labor and specialized equipment | Requires technical knowledge for design and operation | Requires skilled operators and setup time |

| Maintenance | Regular maintenance of machinery required | Minimal maintenance; focus on printer upkeep | Regular maintenance of CNC machines necessary |

| Best Use Case | Traditional machining, automotive parts, and repairs | Prototyping, custom parts, and low-volume production | Mass production and complex part manufacturing |

What Are the Advantages and Disadvantages of 3D Printing Technology?

3D printing, or additive manufacturing, has emerged as a revolutionary alternative to traditional machining. Its primary advantage lies in its ability to produce highly complex geometries that are often impossible to achieve through conventional methods. Additionally, 3D printing typically results in lower material waste, making it environmentally friendly. However, the initial setup costs for 3D printers can be significant, and the technology may not be suitable for all materials, particularly metals that require high strength and durability.

Why Consider CNC Machining Services?

CNC (Computer Numerical Control) machining services offer high precision and flexibility, making them ideal for producing complex parts in larger quantities. The technology allows for automated production, which increases efficiency and reduces labor costs over time. However, like machine shops, CNC machining requires skilled operators and can have high initial setup costs, particularly for custom jobs. This method is best suited for businesses needing consistent, high-quality outputs across large production runs.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When considering alternatives to machine shop costs, B2B buyers must assess their specific requirements, including production volume, part complexity, and budget constraints. For low-volume, complex parts, 3D printing may be the most cost-effective and efficient choice. In contrast, for high-volume production with consistent quality, CNC machining is likely the better option. Ultimately, the right solution will depend on the unique needs of the business, including the desired balance between cost, quality, and operational efficiency. By conducting thorough research and weighing the pros and cons of each alternative, buyers can make informed decisions that align with their strategic goals.

Essential Technical Properties and Trade Terminology for machine shop cost

What Are the Key Technical Properties Impacting Machine Shop Costs?

Understanding the technical properties involved in machine shop operations is crucial for B2B buyers, especially when evaluating costs and ensuring quality. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the quality and specifications of the raw materials used in machining processes. Common grades include stainless steel, aluminum, and various alloys. The choice of material affects not only the durability and performance of the final product but also the cost. Higher-grade materials typically incur higher prices due to their superior properties and sourcing challenges.

2. Tolerance

Tolerance indicates the permissible limits of variation in a physical dimension. It is essential in precision engineering as it determines how closely parts fit together. Tight tolerances require more sophisticated machinery and skilled labor, which can increase costs. Understanding tolerances is vital for buyers to ensure that the machined components meet their operational requirements without unnecessary expenditure.

3. Surface Finish

The surface finish specification indicates the texture of the finished surface. It can significantly impact the performance of a component, especially in terms of wear resistance and friction. Different finishing processes, such as grinding, polishing, or anodizing, can vary widely in cost. Buyers should assess the required finish to align with their performance needs and budget constraints.

4. Heat Treatment

Heat treatment processes, such as annealing or quenching, enhance the properties of materials, including strength and hardness. While these processes add to the overall cost, they can be essential for specific applications. Understanding the necessity and implications of heat treatment can help buyers make informed decisions about their machining needs.

5. Machining Time

Machining time refers to the duration required to complete the machining process. It is directly linked to labor costs and the operational efficiency of the machine shop. Buyers should evaluate the complexity of their projects, as intricate designs may require longer machining times and, subsequently, higher costs.

What Are Common Terms Used in Machine Shop Cost Discussions?

Familiarity with industry jargon can facilitate smoother negotiations and clearer communication between buyers and machine shop operators. Here are some common terms to understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM standards is crucial for ensuring that components meet original specifications, which can affect product quality and warranty considerations.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers looking to manage inventory costs and minimize financial risk. Knowing the MOQ helps buyers plan their orders effectively, especially when dealing with custom parts.

3. RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on supplying products or services. It outlines specific requirements, including technical specifications and quantities. For B2B buyers, crafting a detailed RFQ can lead to more accurate quotations and better supplier selection.

4. Incoterms

Incoterms (International Commercial Terms) are a series of predefined commercial terms published by the International Chamber of Commerce that are widely used in international transactions. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers to avoid unexpected costs and ensure smooth transactions.

5. Lead Time

Lead time refers to the amount of time from the initiation of a process until its completion. In the context of machine shops, it includes the time taken for production, shipping, and delivery. Recognizing lead times is essential for buyers to manage project timelines and plan for delays effectively.

By understanding these technical properties and industry terms, B2B buyers can make more informed decisions that align with their operational needs and budget constraints. This knowledge not only aids in cost management but also enhances the overall efficiency of procurement processes.

Navigating Market Dynamics and Sourcing Trends in the machine shop cost Sector

What are the Key Trends Shaping the Machine Shop Cost Sector?

The machine shop cost sector is experiencing significant transformations driven by various global factors. One of the most influential drivers is the rising demand for precision-engineered components across industries such as automotive, aerospace, and energy. This demand is pushing machine shops to adopt advanced technologies such as CNC machining, additive manufacturing, and automation, which enhance productivity and reduce operational costs. Moreover, international B2B buyers are increasingly seeking suppliers that can offer not only competitive pricing but also shorter lead times and high-quality outputs.

Emerging trends in sourcing indicate a shift towards digital procurement platforms that facilitate real-time price comparisons and supplier evaluations. This trend is particularly pertinent for international buyers from regions like Africa and South America, where accessing reliable information can be challenging. Additionally, machine shops are leveraging data analytics to optimize their pricing strategies, allowing them to remain agile in a fluctuating market.

Another significant market dynamic is the increasing emphasis on local sourcing. Buyers are recognizing the benefits of reducing supply chain risks associated with long-distance shipping and geopolitical instability. This focus on local suppliers can lead to cost savings and improved delivery times, particularly vital for buyers in regions like Nigeria and Brazil, where infrastructure can pose challenges.

How Can Sustainability and Ethical Sourcing Impact Machine Shop Costs?

Sustainability is becoming a critical consideration in the machine shop cost sector. Environmental impacts from manufacturing processes, such as waste generation and energy consumption, are under scrutiny. International B2B buyers are increasingly prioritizing suppliers with sustainable practices, not only to comply with regulations but also to enhance their brand image. This shift necessitates that machine shops invest in greener technologies and processes, which may initially increase costs but can lead to long-term savings through efficiency improvements and reduced waste.

Ethical sourcing is also gaining prominence. Buyers are becoming more aware of the importance of supply chain transparency and the ethical implications of sourcing materials. This includes ensuring that suppliers adhere to fair labor practices and environmental standards. Certifications such as ISO 14001 for environmental management systems and ISO 45001 for occupational health and safety are becoming essential for machine shops aiming to attract international clients.

Moreover, the use of recycled materials and eco-friendly processes can differentiate suppliers in a competitive market. For instance, machine shops that utilize sustainable materials in their operations can appeal to environmentally conscious buyers, potentially allowing them to command higher prices for their services.

What is the Historical Context of Machine Shop Costs?

The evolution of machine shop costs reflects broader changes in manufacturing practices and technology. Historically, machine shops operated on a labor-intensive basis, relying heavily on skilled machinists to produce components. This traditional model often resulted in inconsistent pricing due to variations in labor costs and material availability.

The introduction of CNC technology in the late 20th century marked a turning point. Automation not only increased precision and efficiency but also standardized production processes, leading to more predictable costing structures. This evolution has continued into the 21st century with the rise of digital technologies and the internet, enabling machine shops to optimize their operations further and respond more adeptly to market demands.

Today, machine shop costs are influenced by a complex interplay of technology, global supply chains, and evolving customer expectations. As international B2B buyers seek cost-effective and reliable solutions, understanding these historical trends can provide valuable insights into current market dynamics and sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of machine shop cost

-

How do I determine the cost of machine shop services for my specific needs?

To accurately determine the cost of machine shop services, start by identifying the specific operations you require, such as engine disassembly, block boring, or cylinder head milling. Request quotes from multiple machine shops, ensuring you provide detailed specifications about your project. Be aware that costs can vary significantly based on the complexity of the job, the materials used, and the shop’s location. Additionally, consider factors like turnaround time and the shop’s reputation, as these can impact overall value. -

What factors influence machine shop pricing for B2B buyers?

Machine shop pricing is influenced by several factors, including labor costs, material prices, overhead expenses, and the complexity of the services rendered. Geographic location can also play a role, as labor rates and shipping costs differ across regions. Customization requirements, such as specific tolerances or unique materials, may lead to higher prices. Lastly, bulk orders or long-term contracts can often result in discounted rates, making it beneficial to negotiate pricing based on volume. -

What are the typical payment terms for international machine shop services?

Payment terms for international machine shop services can vary widely but often include options such as upfront deposits, net 30/60/90 days, or letters of credit. It’s essential to clarify payment expectations before engaging in a contract. Many shops may require a percentage of the total cost upfront, particularly for custom or large orders. Additionally, consider any currency conversion fees and the potential for tariffs or duties that may affect the overall cost. -

How can I vet machine shop suppliers for quality and reliability?

When vetting machine shop suppliers, assess their reputation through customer reviews and testimonials. Request references from previous clients and evaluate their experience with similar projects. Additionally, check for certifications or compliance with international quality standards, such as ISO 9001. Visiting the facility, if feasible, can provide insight into their operations and equipment. Engaging in a trial order can also help gauge their reliability before committing to larger projects. -

What are the minimum order quantities (MOQs) for machine shop services?

Minimum order quantities (MOQs) for machine shop services can vary based on the type of work and the supplier’s capabilities. Some shops may have flexible MOQs for standard services, while custom projects might require higher quantities to justify setup costs. It’s crucial to discuss MOQs during initial negotiations, as some suppliers may be willing to accommodate smaller orders for new clients or ongoing partnerships. Understanding these terms can help you plan your project budget effectively. -

How do I handle logistics and shipping for machine shop orders?

To manage logistics for machine shop orders, consider the shipping options available, including air freight for urgent needs or sea freight for cost-effective solutions. Evaluate the supplier’s ability to package and label items correctly to prevent damage during transit. Additionally, factor in customs clearance and duties when shipping internationally, as these can affect delivery timelines and costs. Establishing a reliable logistics partner can streamline the process and ensure timely delivery. -

What should I expect during the quality assurance (QA) process with machine shops?

During the quality assurance (QA) process, machine shops typically perform inspections at various stages of production to ensure compliance with specifications. Expect documentation, such as inspection reports and certificates of conformity, to be provided. Discuss the QA protocols upfront, including any specific tests or measurements you require. A reputable shop will be transparent about their QA processes and willing to accommodate additional requests to meet your quality standards. -

Can machine shops accommodate custom specifications for my projects?

Yes, many machine shops specialize in accommodating custom specifications to meet the unique needs of B2B buyers. When discussing your project, provide detailed drawings or specifications, and be open to discussing adjustments based on the shop’s capabilities. Customization can impact pricing and lead times, so it’s essential to communicate clearly and establish expectations early in the process. Collaborating closely with the shop can help achieve the desired outcomes while ensuring quality and efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for machine shop cost

In the competitive landscape of machine shop services, understanding cost structures is paramount for international B2B buyers. Key insights reveal that pricing can vary significantly based on geographical location, service complexity, and material requirements. For instance, machine operations such as engine disassembly, block honing, and cylinder head services often have a wide range of costs, from as low as $20 for basic tasks to several thousand dollars for comprehensive engine rebuilds.

Strategic sourcing is essential for optimizing these costs. By fostering relationships with reliable suppliers and understanding regional pricing nuances, buyers can negotiate better terms and ensure they receive high-quality services. This not only enhances operational efficiency but also strengthens supply chain resilience, especially for businesses in emerging markets across Africa, South America, the Middle East, and Europe.

As we look to the future, the machine shop industry is poised for growth, driven by technological advancements and evolving buyer needs. International B2B buyers should leverage these insights to strategically source their machine shop requirements, ensuring they stay ahead of the curve. Engage with local experts, explore potential partnerships, and take proactive steps to secure competitive pricing and quality service.