Top 8 Custom Parts Manufacturer Manufacturers & Suppliers List

1. MW Components – Custom Springs

Domain: mwcomponents.com

Registered: 2017 (8 years)

Introduction: MW Components offers a variety of custom components including:

– Custom Springs: Hot Wound Springs, Coiled Springs, Compression Springs, Extension Springs, Torsion Springs, Automotive Springs, Drawbar Springs, Constant Force Springs, Belleville Washers/Disc Springs, Flat Springs, Machined Springs.

– Custom Fasteners: API B7 Studs & Nuts, Bolts, Rivets, Screws, Captive Screws & Assemblies, Sock…

2. WMBerg – Custom Precision Parts & Components

Domain: wmberg.com

Registered: 1996 (29 years)

Introduction: Custom Precision Parts & Components Manufacturing including: Assemblies, Cams, Gearboxes, Geneva Mechanisms, Lead Screw Assemblies, Linear Ball Slides, Linear Roller Slides, Ratchets & Pawls, Belts & Chains, Aircraft Cables, various Flex-E products, O-Ring Belts & Cords, Sprockets (3D, Belt, Chain, Double, Roller Chain), Pulleys (Friction Drive, Grooved, Timing), Shafting, Hubs, Shafts, Shaft Acce…

3. SendCutSend – Custom Sheet Metal Fabrication Services

Domain: sendcutsend.com

Registered: 2015 (10 years)

Introduction: SendCutSend offers custom sheet metal fabrication services, including laser cutting, CNC routing, and waterjet cutting. Key features include:

– Fast turnaround: Custom sheet metal parts can be produced in as little as 2 days.

– Instant pricing: Users can upload STEP, DXF, or EPS files for immediate pricing.

– No minimum quantities: Customers can order as few or as many parts as needed.

– Free US s…

4. Misumi – Custom Component Manufacturing

Domain: us.misumi-ec.com

Registered: 2007 (18 years)

Introduction: Custom Component Manufacturing including CNC Machining, Die Mold, and Sheet Metal Fabrication. Key features include: CNC Milling with 3, 4, and 5 axis capabilities, tolerances of ±0.05 mm (±0.002 in) and as tight as ±0.005 mm (±0.0002 in); CNC Turning with diameters as small as 65 mm (2.75 in) and length tolerances of ±0.05 mm (±0.002 in) and as tight as ±0.003 mm (±0.0001 in); Sheet Metal Fabrica…

5. eMachineShop – Custom Manufacturing Services

Domain: emachineshop.com

Registered: 1999 (26 years)

Introduction: eMachineShop offers custom manufacturing services including CNC Machining, Injection Molding, 3D Printing, and Sheet Metal Fabrication. Key features include:

– Fast quotes and free CAD software.

– Custom sheet metal parts available in as little as 3 days.

– Supports various CAD file formats such as STEP, IGES, DXF, SLDPRT, STL, and more.

– Rapid prototyping and full production runs.

– Free shippin…

6. PCBWay – CNC Machining & 3D Printing Services

Domain: pcbway.com

Registered: 2012 (13 years)

Introduction: CNC Machining Service: Includes CNC Milling (3-axis, 4-axis, 5-axis), CNC Turning. 3D Printing Service: Offers Stereolithography (SLA), Digital Light Processing (DLP), Fused Deposition Modeling (FDM), Selective Laser Melting (SLM), Selective Laser Sintering (SLS), PolyJet (PJ), and Vacuum Casting (VC). Sheet Metal Fabrication: Services include Laser Cutting and Bending. Injection Molding Service: …

7. Norck – Custom Components Manufacturing

Domain: norck.com

Registered: 2016 (9 years)

Introduction: Custom Components Manufacturing services include CNC Machining, 3D Printing, Sheet Metal Fabrication, and Injection Molding. Key capabilities are: CNC Machining (tight tolerances, complex shapes), Sheet Metal Fabrication (enclosures, brackets, structural parts), and 3D Printing (FDM, SLA, MJF, PolyJet). Norck specializes in precision-engineered parts for industries such as aerospace, automotive, r…

8. MFG – Custom Manufacturing Services

Domain: mfg.com

Registered: 1991 (34 years)

Introduction: The World’s Largest Custom Manufacturing Marketplace – MFG offers a variety of custom part manufacturing services including 3D Printing, CNC Machining, Engineering and Design Services, Injection Molding, Sheet Metal Fabrication, and Stamping. Users can submit a Request for Quote to receive estimates from manufacturers, compare quotes, choose a manufacturer, and manage orders all in one platform. M…

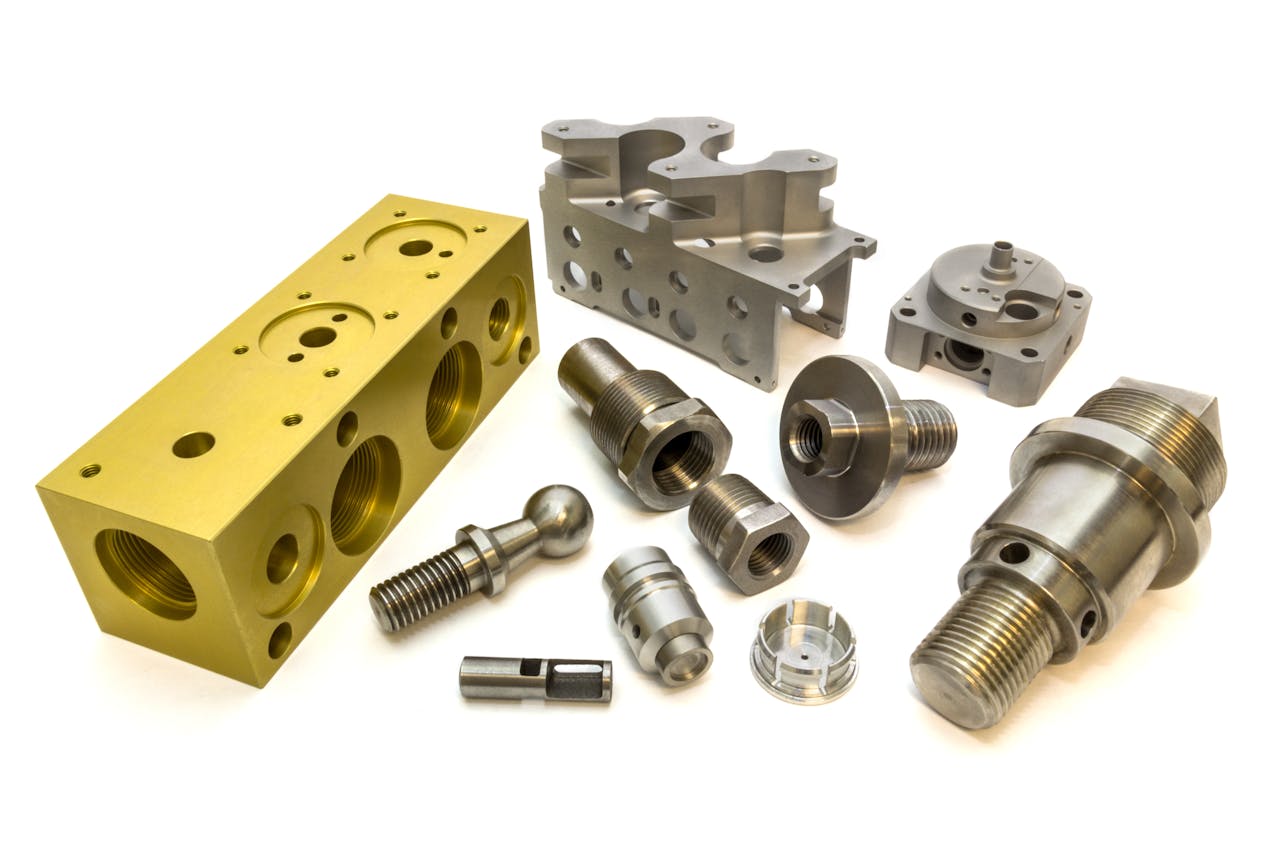

Introduction: Navigating the Global Market for custom parts manufacturer

In today’s competitive landscape, sourcing custom parts manufacturers can be a daunting task for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The challenge lies not just in finding suppliers but in ensuring they meet specific quality standards and can deliver on time without breaking the budget. This comprehensive guide will navigate you through the intricate world of custom parts manufacturing, covering a wide range of topics including types of manufacturing processes, applications across various industries, supplier vetting techniques, and cost considerations.

By delving into this guide, you will gain actionable insights to empower your purchasing decisions. You will learn how to identify reputable suppliers who can meet your unique specifications, whether you require low-volume production for prototypes or high-volume manufacturing for mass production. Additionally, the guide will highlight the importance of certifications such as ISO and ITAR, ensuring you choose manufacturers who adhere to international quality standards.

With a focus on practical solutions and expert advice, this guide is designed to equip you with the knowledge needed to confidently select custom parts manufacturers that align with your business goals. Whether you are in Nigeria, Vietnam, or elsewhere, understanding the global market for custom parts will help streamline your procurement processes, reduce lead times, and ultimately enhance your product offerings.

Understanding custom parts manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Machining | Precision machining using computer-controlled tools | Aerospace, automotive, electronics | Pros: High precision, scalability. Cons: Higher initial costs. |

| Injection Molding | Molding process for producing parts in high volumes | Consumer products, automotive, medical devices | Pros: Cost-effective for large quantities. Cons: High setup costs. |

| 3D Printing | Layer-by-layer additive manufacturing | Prototyping, complex geometries | Pros: Rapid prototyping, design flexibility. Cons: Limited material options. |

| Sheet Metal Fabrication | Cutting, bending, and assembling metal sheets | Construction, HVAC, automotive | Pros: Versatile, strong materials. Cons: May require additional finishing. |

| Custom Assemblies | Integration of multiple components into a complete product | Electronics, machinery, automotive | Pros: Streamlined production, tailored solutions. Cons: Complexity in logistics and sourcing. |

What are the Characteristics and Suitability of CNC Machining for B2B Buyers?

CNC machining is characterized by its ability to produce high-precision parts through the use of computer-controlled tools. It is particularly suitable for industries requiring tight tolerances, such as aerospace and automotive. B2B buyers should consider factors such as the complexity of the part, the required tolerances, and the volume of production when opting for CNC machining. While it provides excellent precision and repeatability, the initial setup costs can be higher compared to other manufacturing methods.

How Does Injection Molding Serve B2B Needs?

Injection molding is a manufacturing process that involves creating parts by injecting molten material into a mold. This method is ideal for producing large quantities of identical parts, making it popular in industries like consumer products and medical devices. B2B buyers should evaluate their production volume and material requirements, as the initial costs for mold creation can be significant. However, once the mold is created, the cost per part decreases substantially, making it a cost-effective option for high-volume production.

What Advantages Does 3D Printing Offer for Custom Parts Manufacturing?

3D printing, or additive manufacturing, allows for the creation of parts layer by layer, providing significant design flexibility. It is particularly beneficial for rapid prototyping and producing complex geometries that would be difficult or impossible to achieve with traditional methods. B2B buyers should consider their material needs and production timelines, as 3D printing can often expedite the development process. However, the range of materials available is more limited compared to traditional manufacturing methods, which may constrain some applications.

Why is Sheet Metal Fabrication a Versatile Choice for B2B Applications?

Sheet metal fabrication involves processes like cutting, bending, and assembling metal sheets to create parts. It is widely used across various sectors, including construction and automotive, due to its strength and versatility. Buyers should assess the specific requirements of their projects, such as material type and thickness, as well as any finishing needs. While sheet metal parts are durable and can be produced quickly, additional finishing processes may be necessary to achieve the desired aesthetics or functionality.

How Do Custom Assemblies Enhance Production Efficiency for Businesses?

Custom assemblies integrate multiple components into a single product, streamlining the manufacturing process. This approach is particularly useful in industries such as electronics and machinery, where complex systems are common. B2B buyers should consider the logistics of sourcing various components and the potential need for specialized assembly processes. While custom assemblies can improve efficiency and reduce overall production time, they may introduce complexity in terms of supply chain management and quality control.

Key Industrial Applications of custom parts manufacturer

| Industry/Sector | Specific Application of custom parts manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision components for aircraft systems | Enhanced safety and performance in flight operations | Compliance with industry certifications (e.g., AS9100) |

| Automotive | Custom fasteners and brackets | Improved assembly efficiency and vehicle reliability | Material specifications and lead time flexibility |

| Medical Devices | Customized surgical instruments | Higher precision and better patient outcomes | Regulatory compliance (e.g., ISO 13485) and traceability |

| Robotics | Parts for robotic arms and automation systems | Increased productivity and operational efficiency | Tolerance specifications and material durability |

| Consumer Electronics | Custom casings and enclosures | Enhanced product design and user experience | Aesthetic finishes and rapid prototyping capabilities |

How Are Custom Parts Manufacturers Used in Aerospace Applications?

In the aerospace industry, custom parts manufacturers produce precision components essential for aircraft systems, including brackets, housings, and intricate assemblies. These parts must meet stringent safety and performance standards, necessitating compliance with certifications like AS9100. International buyers, particularly from Africa and South America, should consider lead times, material certifications, and the manufacturer’s ability to scale production to meet fluctuating demand.

What Role Do Custom Parts Play in the Automotive Sector?

Custom fasteners and brackets are vital in the automotive sector, where they contribute to vehicle assembly and overall reliability. Manufacturers can provide tailored solutions that improve assembly efficiency, reduce weight, and enhance vehicle performance. B2B buyers in regions like the Middle East and Europe must ensure that suppliers can deliver parts within tight timelines and meet specific material requirements to support their production schedules.

How Are Custom Parts Essential for Medical Devices?

In the medical device sector, customized surgical instruments are crucial for ensuring high precision and improved patient outcomes. These parts often require compliance with strict regulatory standards such as ISO 13485, which governs quality management systems in medical device manufacturing. Buyers from various global markets, including Africa and Europe, must prioritize manufacturers that offer traceability and documentation to support regulatory compliance.

Why Are Custom Parts Important for Robotics?

Custom parts are integral to the design and functionality of robotic arms and automation systems. These components must be engineered for high durability and precision to ensure operational efficiency and reliability. Buyers should consider manufacturers that can provide detailed specifications on tolerances and materials, particularly those sourcing from regions like South America and the Middle East, where advanced robotics applications are growing.

How Do Custom Parts Enhance Consumer Electronics?

In the consumer electronics industry, custom casings and enclosures are critical for product design and user experience. Manufacturers can offer various aesthetic finishes and rapid prototyping capabilities to meet the fast-paced demands of the market. B2B buyers in Europe and Africa should focus on suppliers that can quickly adapt to design changes and provide high-quality materials to ensure both functionality and visual appeal in their products.

3 Common User Pain Points for ‘custom parts manufacturer’ & Their Solutions

Scenario 1: Navigating Long Lead Times for Custom Parts

The Problem: B2B buyers often face significant delays when sourcing custom parts, especially when working with manufacturers that have long lead times. This issue can arise from various factors, including limited production capacity, inefficient supply chain management, or complex manufacturing processes. For businesses that rely on timely delivery to maintain project schedules, these delays can lead to increased costs and missed deadlines, ultimately affecting their reputation and client satisfaction.

The Solution: To mitigate the risk of long lead times, buyers should prioritize manufacturers that offer instant quoting and rapid production capabilities. Using digital platforms that provide instant quotes can streamline the procurement process, allowing buyers to assess multiple manufacturers’ capacities and timelines quickly. Additionally, engaging with manufacturers that utilize advanced technologies, such as CNC machining and 3D printing, can significantly reduce production times. It is also advisable to establish clear communication about project timelines and requirements upfront, ensuring that the manufacturer understands the urgency of the order. Regular follow-ups and updates during the production process can further enhance transparency and help manage expectations.

Scenario 2: Quality Assurance and Consistency Challenges

The Problem: Ensuring the quality and consistency of custom parts is a major concern for B2B buyers. Variations in material properties, manufacturing processes, or even human error can lead to defects that compromise the functionality of the final product. This is particularly critical in industries such as aerospace, automotive, or medical, where even minor discrepancies can have serious repercussions. Buyers may find themselves in a situation where parts do not meet specifications, resulting in costly rework or project delays.

The Solution: To address quality assurance concerns, buyers should partner with manufacturers that are certified with relevant quality standards, such as ISO 9001 or AS9100. These certifications indicate that the manufacturer adheres to strict quality control protocols. Buyers should also request detailed documentation, including Certificates of Compliance (CoCs) and inspection reports, for all custom parts. Implementing a robust Design for Manufacturability (DFM) process can help identify potential issues early in the design phase, allowing for adjustments before production begins. Establishing a feedback loop with the manufacturer can also facilitate continuous improvement and ensure that quality expectations are consistently met.

Scenario 3: Complexity in Customization and Design Changes

The Problem: B2B buyers often struggle with the complexities involved in customizing parts to meet specific design requirements. Whether it’s adapting existing components or creating entirely new ones, the process can be cumbersome and fraught with challenges. Buyers may encounter difficulties in communicating their needs, leading to misinterpretations and unsatisfactory results. This can be particularly frustrating when design changes are required late in the production process, resulting in delays and increased costs.

The Solution: To navigate the complexities of customization, buyers should leverage manufacturers that offer comprehensive design and engineering consulting services. This collaboration can help clarify specifications and ensure that all parties have a mutual understanding of the project goals. Utilizing advanced technologies such as 3D CAD modeling can facilitate better communication of design intentions. Additionally, implementing agile manufacturing practices allows for more flexibility in accommodating design changes, enabling manufacturers to adapt quickly without significant downtime or cost penalties. Regular check-ins and collaborative project management tools can further enhance communication and streamline the customization process, leading to better outcomes and stronger partnerships.

Strategic Material Selection Guide for custom parts manufacturer

What Are the Key Properties of Common Materials Used in Custom Parts Manufacturing?

When selecting materials for custom parts, understanding the key properties of each material is crucial for ensuring optimal performance in specific applications. Here, we analyze four common materials used in custom parts manufacturing: Aluminum, Stainless Steel, Polycarbonate, and PEEK (Polyether Ether Ketone).

Aluminum: A Lightweight and Versatile Option

Aluminum is known for its excellent strength-to-weight ratio, corrosion resistance, and good thermal and electrical conductivity. It typically performs well in temperatures up to 150°C and is suitable for low to moderate pressure applications.

Pros: Aluminum is lightweight, making it ideal for applications where weight savings are critical, such as aerospace and automotive industries. It is also relatively inexpensive compared to other metals and can be easily machined or formed.

Cons: While durable, aluminum is softer than other metals and may not be suitable for high-stress applications. It can also be more susceptible to wear and tear over time.

Impact on Application: Aluminum is compatible with various media, including water and some chemicals, but may not perform well in highly acidic or alkaline environments.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local availability and compliance with standards such as ASTM B221 for aluminum extrusions. European buyers may prefer materials that meet EN standards.

Stainless Steel: The Durable Workhorse

Stainless steel is renowned for its exceptional corrosion resistance, strength, and durability, making it suitable for a wide range of applications, including food processing, medical devices, and industrial equipment. It can withstand temperatures up to 870°C, depending on the grade.

Pros: Its high strength and resistance to corrosion make stainless steel ideal for harsh environments. It also has a long lifespan, reducing the need for frequent replacements.

Cons: The cost of stainless steel can be higher than that of aluminum or plastics. Additionally, machining stainless steel can be more complex and may require specialized tools.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive chemicals, making it suitable for applications in the chemical and pharmaceutical industries.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM A240 and consider the availability of specific grades, such as 304 or 316, which are commonly used in various industries.

Polycarbonate: A Strong and Impact-Resistant Plastic

Polycarbonate is a thermoplastic known for its high impact resistance and optical clarity. It can withstand temperatures up to 120°C and is often used in applications requiring transparency, such as safety goggles and protective covers.

Pros: Polycarbonate is lightweight, shatter-resistant, and offers good thermal insulation. It is also easier to mold than metals, allowing for complex shapes.

Cons: While it has good impact resistance, polycarbonate can be prone to scratching and may degrade under prolonged exposure to UV light unless treated.

Impact on Application: It is suitable for applications involving low to moderate stresses and is often used in environments where visibility is important.

Considerations for International Buyers: Buyers should look for compliance with standards such as ISO 7391 for polycarbonate materials, especially in regions like Europe where material certification is crucial.

PEEK: The High-Performance Polymer

PEEK is a high-performance thermoplastic known for its exceptional mechanical properties and resistance to heat and chemicals. It can operate at temperatures up to 260°C and is often used in aerospace, automotive, and medical applications.

Pros: PEEK offers outstanding strength, chemical resistance, and dimensional stability, making it suitable for high-stress environments. It also has low friction properties, making it ideal for bearings and seals.

Cons: The cost of PEEK is significantly higher than that of metals and other plastics, which may limit its use to specialized applications.

Impact on Application: PEEK is compatible with a wide range of media, including harsh chemicals, making it suitable for demanding applications in industries like pharmaceuticals and aerospace.

Considerations for International Buyers: Buyers should ensure compliance with ASTM standards such as ASTM D638 for PEEK materials, particularly in regulated industries.

Summary Table of Material Selection for Custom Parts Manufacturing

| Material | Typical Use Case for custom parts manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and cost-effective | Softer than other metals | Medium |

| Stainless Steel | Food processing, medical devices | High strength and corrosion resistance | Higher cost and complex machining | High |

| Polycarbonate | Safety goggles, protective covers | Impact-resistant and lightweight | Prone to scratching and UV degradation | Medium |

| PEEK | Aerospace, automotive, medical applications | Exceptional mechanical properties | High cost | High |

This strategic material selection guide provides a comprehensive overview of common materials used in custom parts manufacturing, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for custom parts manufacturer

What Are the Key Stages in the Manufacturing Process for Custom Parts?

The manufacturing process for custom parts involves several critical stages that ensure high-quality outputs tailored to specific requirements. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting the appropriate materials based on the specific application and performance requirements. Common materials include metals, plastics, and composites. The selection often considers factors like strength, durability, and cost-effectiveness. Materials are then processed to ensure they meet the necessary specifications, which may involve cutting, bending, or other pre-forming treatments.

-

Forming: This stage encompasses various techniques used to shape the material into the desired form. Common forming methods include CNC machining, injection molding, and sheet metal fabrication. CNC machining allows for precise shaping and is ideal for complex geometries, while injection molding is used for high-volume production of plastic parts. Each technique has its advantages and is selected based on the part’s design and production volume.

-

Assembly: After forming, parts may need to be assembled into more complex structures. This could involve welding, fastening, or adhesive bonding. The assembly process must ensure that all components fit together accurately to maintain the integrity of the final product. Depending on the complexity, automated assembly systems may be utilized to enhance efficiency and precision.

-

Finishing: The final stage involves applying surface treatments to enhance the part’s appearance, durability, and resistance to environmental factors. Techniques such as painting, anodizing, or polishing can be employed. Finishing not only improves aesthetics but also contributes to the functionality of the part, ensuring it meets specific operational demands.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance (QA) is paramount in custom parts manufacturing, particularly for international B2B buyers. Several internationally recognized standards and industry-specific certifications play a crucial role in ensuring product quality.

-

ISO 9001: This is a global standard that outlines requirements for a quality management system (QMS). Companies certified to ISO 9001 demonstrate their ability to consistently provide products and services that meet customer and regulatory requirements.

-

Industry-Specific Certifications: Depending on the application, additional certifications may be required. For example:

– ISO 13485 for medical devices

– AS9100D for aerospace components

– IATF 16949 for automotive parts

– CE Marking for products sold in the European Economic Area -

API Certification: For manufacturers producing parts for the oil and gas industry, API (American Petroleum Institute) certifications are essential to ensure compliance with industry-specific standards.

How Do Quality Control Checkpoints Function in Custom Parts Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects and ensure compliance with specifications. The main QC checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival. It ensures that materials meet specified standards before they enter the production process.

-

In-Process Quality Control (IPQC): This involves monitoring the manufacturing process itself. Operators conduct checks at various stages to ensure that production remains within tolerances and specifications. Techniques like statistical process control (SPC) may be employed to track quality metrics in real-time.

-

Final Quality Control (FQC): Once the manufacturing process is complete, FQC involves a comprehensive inspection of the finished products. This may include dimensional checks, functional testing, and visual inspections to ensure that all parts meet the required standards before shipment.

What Testing Methods Are Commonly Used in Custom Parts Manufacturing?

Testing methods vary depending on the material and application, but several common techniques ensure that the custom parts perform as intended:

-

Dimensional Inspection: This involves measuring the physical dimensions of a part to ensure it meets design specifications. Tools such as calipers, micrometers, and coordinate measuring machines (CMM) are commonly used.

-

Functional Testing: Parts may undergo functional tests to ensure they perform as required under operational conditions. This is particularly important for mechanical components that must withstand specific loads or stresses.

-

Material Testing: Techniques such as tensile testing, hardness testing, and fatigue testing assess the material properties to ensure they meet performance requirements.

-

Non-Destructive Testing (NDT): Methods such as ultrasonic testing, radiography, and dye penetrant testing are used to detect internal flaws without damaging the part. This is crucial for components used in critical applications, such as aerospace and medical devices.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those sourcing from international suppliers, verifying quality control practices is essential to ensure product reliability. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and compliance with standards firsthand. This can provide insights into the supplier’s operational capabilities and commitment to quality.

-

Requesting Quality Documentation: Buyers should request certificates of compliance, inspection reports, and quality management system documentation. These documents provide a transparent view of the supplier’s quality assurance practices.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and the final products. This is particularly important for high-value or critical components.

-

Reviewing Customer Feedback: Assessing reviews and testimonials from other customers can provide insights into the supplier’s reliability and quality performance. This feedback can help inform purchasing decisions.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing custom parts internationally, B2B buyers must navigate several nuances in quality control:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. For instance, parts manufactured for the European market may require CE marking, while products for the U.S. market must meet FDA regulations for medical devices.

-

Cultural Differences: Understanding cultural attitudes towards quality and business practices can impact supplier relationships. Buyers should be aware of these differences to foster effective communication and collaboration.

-

Supply Chain Considerations: International shipping can introduce risks such as damage during transit or delays that affect quality. Establishing robust logistics and contingency plans can mitigate these risks.

-

Local Standards and Practices: Familiarity with local manufacturing standards and practices can help buyers set realistic expectations regarding quality and timelines. Engaging with local experts or consultants can provide valuable insights.

By understanding these manufacturing processes, quality assurance standards, and verification techniques, B2B buyers can make informed decisions when sourcing custom parts, ensuring they receive high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom parts manufacturer’

Introduction

Sourcing custom parts can be a complex process, particularly for international B2B buyers. This checklist serves as a practical guide to streamline your procurement journey, ensuring you select the right manufacturer to meet your specific needs efficiently and effectively. By following these steps, you can mitigate risks, enhance quality, and optimize costs.

Step 1: Define Your Technical Specifications

Before reaching out to manufacturers, it is essential to have a clear understanding of your technical requirements. Specify dimensions, tolerances, materials, and surface finishes that your custom parts must adhere to. This clarity helps manufacturers provide accurate quotes and timelines, reducing the likelihood of errors during production.

Step 2: Research and Identify Potential Manufacturers

Conduct thorough research to create a shortlist of potential custom parts manufacturers. Look for companies with experience in your industry, and ensure they have a robust portfolio of similar projects. Utilize platforms that connect you with vetted manufacturers, allowing you to compare capabilities and customer reviews.

Step 3: Evaluate Supplier Certifications

Verify that the manufacturers you are considering hold relevant industry certifications, such as ISO 9001 or AS9100. These certifications are indicators of a company’s commitment to quality management and operational excellence. Additionally, inquire about any specific certifications related to your industry, such as ITAR for defense-related parts.

Step 4: Request and Compare Quotes

Once you have narrowed down your list, request quotes from multiple suppliers. Ensure that each quote includes detailed pricing, lead times, and any additional costs such as shipping or tooling fees. Comparing these aspects will help you identify the most cost-effective solution while ensuring quality and timely delivery.

Step 5: Conduct Supplier Audits

If feasible, arrange for site visits or virtual audits of potential suppliers. This step allows you to assess their production capabilities, quality control processes, and overall working conditions. A direct assessment can provide insights that are not visible through documentation alone, helping to gauge reliability and professionalism.

Step 6: Review Communication and Support Systems

Effective communication is critical in the custom parts manufacturing process. Evaluate how responsive and transparent potential suppliers are during your initial interactions. Ensure they have robust support systems in place, such as dedicated account managers or customer service teams, to assist you throughout the project lifecycle.

Step 7: Establish Clear Terms and Agreements

Once you have selected a manufacturer, formalize your partnership with a clear contract. Define terms regarding payment schedules, delivery timelines, and quality assurance protocols. This agreement will serve as a safeguard for both parties and help prevent misunderstandings during the manufacturing process.

By following these steps, you can enhance your sourcing strategy for custom parts manufacturing, ensuring a smoother procurement process and ultimately achieving better results for your projects.

Comprehensive Cost and Pricing Analysis for custom parts manufacturer Sourcing

What Are the Key Cost Components in Custom Parts Manufacturing?

When evaluating the costs associated with custom parts manufacturing, it is essential to understand the various components that contribute to the overall pricing structure. The primary cost components include:

-

Materials: The choice of materials significantly impacts the price. Options range from standard metals and plastics to specialized alloys, each with its associated costs. Understanding the material properties required for your application can help in making cost-effective decisions.

-

Labor: Labor costs vary based on the complexity of the manufacturing processes and the skill level required. For instance, intricate designs may necessitate skilled machinists, resulting in higher labor costs.

-

Manufacturing Overhead: This includes costs related to facility operation, equipment maintenance, and administrative expenses. Overhead is often distributed across all parts produced, making it a critical factor in pricing.

-

Tooling: Custom tooling can be a significant upfront investment, especially for parts that require unique molds or fixtures. This cost is amortized over the production run, influencing per-unit pricing.

-

Quality Control (QC): Ensuring that parts meet specified standards involves additional costs for inspections, testing, and certifications. This is particularly relevant for industries such as aerospace and medical, where compliance with strict regulations is mandatory.

-

Logistics: Shipping and handling costs can vary widely depending on the distance and method of transport. For international buyers, understanding Incoterms is crucial to determine who bears the cost and risk during transit.

-

Margin: Manufacturers typically add a profit margin to cover their risk and ensure sustainability. This margin can vary based on market competition and the perceived value of the service provided.

How Do Price Influencers Affect Custom Parts Manufacturing Costs?

Several factors can influence the pricing of custom parts, particularly for international buyers:

-

Volume and Minimum Order Quantities (MOQ): Higher volumes generally lead to lower per-unit costs due to economies of scale. However, many manufacturers set MOQs that might not align with the needs of smaller businesses.

-

Specifications and Customization: Highly customized parts or specific tolerances can lead to increased costs. It is advisable to clearly define specifications to avoid unnecessary modifications later.

-

Material Selection: Different materials not only vary in cost but also in availability and processing times. Understanding the trade-offs between material performance and cost can lead to better purchasing decisions.

-

Quality and Certifications: Parts requiring specific industry certifications (e.g., ISO, ITAR) may incur additional costs. Buyers should assess the necessity of these certifications against their project needs.

-

Supplier Factors: The reputation and reliability of suppliers can impact costs. Established manufacturers might charge more due to their quality assurance processes, while newer suppliers may offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms dictate the responsibilities of buyers and sellers in shipping logistics. Selecting the right terms can help mitigate unexpected costs in transportation and customs.

What Are the Best Negotiation Tips for B2B Buyers Sourcing Custom Parts?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can leverage several strategies to enhance cost-efficiency:

-

Conduct Thorough Market Research: Understand the market rates for the specific components you need. This knowledge can empower you in negotiations.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial price and consider long-term costs associated with maintenance, quality issues, and logistics. A cheaper part may lead to higher costs over time.

-

Build Relationships with Suppliers: Establishing a good rapport with suppliers can lead to better pricing, priority service, and increased flexibility.

-

Be Transparent About Needs: Clearly communicate your requirements, including budget constraints and timelines. This transparency can lead to tailored solutions that meet your needs without unnecessary costs.

-

Request Quotes from Multiple Suppliers: Obtaining quotes from various manufacturers not only provides pricing insights but also encourages competitive pricing among suppliers.

Disclaimer on Indicative Prices

It is important to note that pricing for custom parts can vary significantly based on specific project requirements, material choices, and market conditions. Therefore, all prices mentioned should be viewed as indicative and subject to change based on the aforementioned factors. Always seek updated quotes from suppliers to ensure accurate budgeting for your projects.

Alternatives Analysis: Comparing custom parts manufacturer With Other Solutions

Exploring Alternatives to Custom Parts Manufacturing

In the world of manufacturing, businesses often face the challenge of selecting the most effective method for producing custom components. While custom parts manufacturing offers unique advantages, exploring alternative solutions can provide additional options tailored to specific project needs. This section will compare custom parts manufacturing with two viable alternatives: 3D printing and off-the-shelf components.

Comparison Table

| Comparison Aspect | Custom Parts Manufacturer | 3D Printing | Off-the-Shelf Components |

|---|---|---|---|

| Performance | High precision and quality | Good for complex geometries | Limited by available designs |

| Cost | Moderate to high | Generally lower for low volumes | Lower due to mass production |

| Ease of Implementation | Requires detailed specs | Easy for rapid prototyping | Quick and straightforward |

| Maintenance | Varies by manufacturer | Minimal; requires printer upkeep | Minimal; dependent on application |

| Best Use Case | Complex, high-quality parts | Prototyping and low-volume runs | Standardized applications |

Understanding 3D Printing: Pros and Cons

3D printing, also known as additive manufacturing, allows for the creation of parts layer by layer. This method excels in producing intricate designs and prototypes quickly. One of its major advantages is cost-effectiveness for low-volume runs, making it ideal for startups and projects that require rapid iteration. However, 3D printing may not always meet the stringent quality and precision standards required for high-stakes industries, such as aerospace or medical. Additionally, the material choices can be limited compared to traditional manufacturing processes.

Evaluating Off-the-Shelf Components: Pros and Cons

Off-the-shelf components are pre-manufactured parts that can be quickly sourced and integrated into a project. The primary benefit of this approach is the cost savings associated with mass production, which leads to lower prices and faster delivery times. This solution is excellent for standard applications where customization is not critical. However, the downside is that businesses may find themselves limited by the available designs, which might not fit their specific requirements perfectly. Moreover, reliance on stock parts may lead to longer-term compatibility issues as product specifications evolve.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting a manufacturing solution, B2B buyers should consider their specific needs, including project complexity, budget constraints, and timelines. Custom parts manufacturing offers tailored solutions for complex requirements, while 3D printing is ideal for rapid prototyping and flexibility. Off-the-shelf components provide a cost-effective and quick option for standard needs. By carefully assessing these factors, buyers can make informed decisions that align with their project goals and enhance operational efficiency.

Essential Technical Properties and Trade Terminology for custom parts manufacturer

What Are the Key Technical Properties for Custom Parts Manufacturing?

When engaging with a custom parts manufacturer, understanding the technical specifications is essential for ensuring that the produced components meet your exact needs. Here are some critical specifications that every B2B buyer should be aware of:

-

Material Grade

Material grade refers to the specific classification of materials based on their physical and chemical properties. Different grades can significantly affect durability, weight, and resistance to environmental factors. Choosing the right material grade ensures that the parts will perform optimally in their intended application, thus reducing the risk of failure and costly downtime. -

Tolerance

Tolerance defines the allowable deviation from a specified dimension. In manufacturing, tight tolerances are crucial for parts that must fit together precisely, such as in machinery or automotive applications. Understanding tolerance specifications helps buyers ensure that parts will function as intended without unnecessary modifications or adjustments. -

Surface Finish

Surface finish refers to the texture and quality of a part’s surface after manufacturing. It can affect not only aesthetics but also functionality, such as friction and corrosion resistance. Different applications may require specific surface finishes, making it important for buyers to specify their needs clearly. -

Lead Time

Lead time is the total time taken from placing an order to receiving the finished product. In B2B environments, understanding lead times is critical for project planning and inventory management. Manufacturers often provide various lead times depending on the complexity of the part and the production process, so having clarity on this aspect can aid in supply chain efficiency. -

Minimum Order Quantity (MOQ)

MOQ refers to the smallest quantity of a product that a manufacturer is willing to produce. This specification can impact your purchasing strategy, especially for startups or companies looking to prototype products. Understanding MOQ helps in budgeting and inventory planning, ensuring you can meet demand without overcommitting resources.

What Are Common Trade Terms in Custom Parts Manufacturing?

Familiarity with industry terminology is vital for effective communication and negotiation with manufacturers. Below are some common terms that every B2B buyer should understand:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable sources for custom components that meet industry standards. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. This is a critical step in the procurement process, allowing buyers to compare options and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms helps buyers understand shipping, insurance, and customs responsibilities, thus mitigating risks associated with international trade. -

CNC (Computer Numerical Control)

CNC refers to automated machining processes controlled by computers. This technology allows for high precision and consistency in manufacturing, making it a key consideration for buyers seeking complex or high-tolerance parts. -

Prototype

A prototype is an initial model of a product used for testing and validation. In custom parts manufacturing, prototypes are crucial for assessing design viability and functionality before mass production, helping to minimize costly errors down the line. -

BOM (Bill of Materials)

A BOM is a comprehensive list of raw materials, components, and assemblies required to construct a product. Understanding the BOM is essential for accurate cost estimation and effective project management in custom parts manufacturing.

By grasping these essential technical properties and trade terms, B2B buyers can navigate the complexities of custom parts manufacturing more effectively, ensuring that their projects meet both budgetary and functional requirements.

Navigating Market Dynamics and Sourcing Trends in the custom parts manufacturer Sector

What Are the Key Trends Shaping the Custom Parts Manufacturing Market?

The custom parts manufacturing sector is currently experiencing a transformative phase driven by several global factors. A surge in demand for low-volume, high-precision parts has emerged, primarily fueled by advancements in technology and the shift towards just-in-time manufacturing. Businesses are increasingly adopting digital platforms that facilitate instant quoting and streamlined communication with manufacturers, enabling quicker decision-making processes. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the focus is on finding reliable partners who can provide high-quality parts with competitive pricing and reduced lead times.

Emerging technologies such as additive manufacturing, CNC machining, and advanced materials are redefining production capabilities. The rise of platforms that connect buyers directly with vetted manufacturers enhances transparency and fosters better collaboration, allowing for tailored solutions that meet specific project requirements. Furthermore, the integration of Industry 4.0 principles—such as IoT, data analytics, and AI—into manufacturing processes is becoming more prevalent, allowing companies to optimize their operations and improve product quality.

How Is Sustainability Impacting B2B Sourcing in Custom Parts Manufacturing?

Sustainability is becoming a critical concern for B2B buyers in the custom parts manufacturing sector. The environmental impact of manufacturing processes is under scrutiny, prompting organizations to prioritize ethical sourcing and sustainable practices. Buyers are increasingly seeking manufacturers that utilize eco-friendly materials and adhere to sustainable manufacturing processes. Certifications such as ISO 14001 for environmental management systems and the use of recycled or bio-based materials are becoming essential factors in supplier selection.

Moreover, the demand for transparency in supply chains is growing, as companies aim to ensure that their sourcing practices align with corporate social responsibility (CSR) goals. This shift not only enhances brand reputation but also mitigates risks associated with unethical practices in the supply chain. For international buyers, especially those in emerging markets, establishing partnerships with manufacturers that prioritize sustainability can lead to long-term benefits, including cost savings and improved customer loyalty.

How Has the Custom Parts Manufacturing Sector Evolved Over Time?

The custom parts manufacturing sector has undergone significant evolution over the decades, transitioning from traditional manufacturing methods to more advanced technologies. Initially dominated by mass production techniques, the industry began to embrace customization in response to the increasing demand for personalized products. The advent of computer-aided design (CAD) and computer numerical control (CNC) machining in the late 20th century revolutionized the way parts were manufactured, enabling higher precision and efficiency.

In recent years, the rise of digital manufacturing platforms has transformed the landscape, allowing businesses to source parts from a global network of suppliers seamlessly. The integration of advanced technologies, such as additive manufacturing and smart automation, continues to drive innovation, making it possible for manufacturers to respond quickly to changing market demands. This evolution not only enhances the capabilities of custom parts manufacturers but also empowers B2B buyers to access a broader range of solutions tailored to their specific needs.

In summary, understanding the dynamics and trends in the custom parts manufacturing sector is essential for international B2B buyers. By leveraging technology, prioritizing sustainability, and staying attuned to market changes, businesses can navigate this evolving landscape effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of custom parts manufacturer

-

How do I choose the right custom parts manufacturer for my needs?

Choosing the right custom parts manufacturer involves assessing several key factors. Start by evaluating their expertise in your industry, particularly their experience with similar parts and materials. Check for relevant certifications such as ISO standards, which indicate quality assurance. Additionally, examine their production capabilities, including technologies used, lead times, and flexibility in meeting your design specifications. Finally, consider their communication practices and customer support, as strong collaboration is vital for successful project execution. -

What are the common minimum order quantities (MOQs) for custom parts?

Minimum order quantities for custom parts can vary significantly depending on the manufacturer and the complexity of the part. Typically, MOQs range from as low as 10 units for simple components to several hundred for more intricate designs or specialized materials. It’s essential to discuss your project’s requirements with potential suppliers to understand their specific MOQs. Some manufacturers may offer flexibility for prototyping or pilot runs, allowing you to test designs without committing to large quantities upfront. -

What customization options are available when sourcing custom parts?

When sourcing custom parts, manufacturers often provide a range of customization options, including material selection, dimensions, finishes, and tolerances. Many suppliers also offer design consultation services to optimize your part for manufacturability and cost-effectiveness. Advanced technologies such as 3D printing allow for intricate designs and rapid prototyping. Ensure you communicate your specific requirements clearly to the manufacturer, as this will help them tailor their offerings to meet your needs effectively. -

How do I ensure quality assurance in custom parts manufacturing?

To ensure quality assurance in custom parts manufacturing, verify that the manufacturer adheres to recognized quality standards, such as ISO 9001 or industry-specific certifications. Request detailed inspection reports and Certificates of Compliance (CoC) for materials used. Inquire about their quality control processes, including in-process inspections and final testing protocols. Establish clear communication regarding quality expectations and consider implementing a quality audit to evaluate their practices before committing to large orders. -

What payment terms should I expect when working with international suppliers?

Payment terms can vary based on the supplier and your negotiation. Common terms include full payment upfront, a deposit with the balance due upon delivery, or net payment terms (e.g., 30 or 60 days post-delivery). Ensure to clarify these terms early in negotiations to avoid misunderstandings. Additionally, consider using secure payment methods and trade finance options to mitigate risks, especially when dealing with international transactions. Always ensure that the payment terms align with your cash flow needs. -

What are the logistics considerations for sourcing custom parts internationally?

Logistics for sourcing custom parts internationally involve several key considerations. First, factor in shipping times and costs, which can vary based on your supplier’s location and the shipping method chosen. Understand import/export regulations and tariffs in your country, as these can impact overall costs and lead times. Additionally, ensure that the manufacturer has robust logistics capabilities, including reliable shipping partners and tracking systems. Clear communication regarding delivery schedules is crucial to avoid production delays. -

How can I vet potential suppliers for custom parts manufacturing?

Vetting potential suppliers involves several steps to ensure reliability and capability. Start by checking their industry experience and client references. Request information about their certifications and quality assurance processes. Conduct site visits or virtual tours to assess their facilities and production capabilities. Additionally, consider using third-party platforms that offer supplier ratings and reviews. Establishing a clear communication channel during the vetting process can also help gauge their responsiveness and willingness to collaborate. -

What should I do if I encounter issues with a custom parts order?

If you encounter issues with a custom parts order, promptly communicate with your supplier to address the problem. Document specific concerns, such as quality discrepancies or delays, and provide supporting evidence, like photos or inspection reports. Most reputable manufacturers will have processes in place for handling disputes or complaints. Depending on the situation, you may negotiate for a replacement, a refund, or adjustments to the order. Maintaining a professional tone and open communication can help facilitate a positive resolution.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for custom parts manufacturer

As the global market for custom parts continues to evolve, strategic sourcing emerges as a pivotal factor for international B2B buyers seeking to optimize their supply chains. By leveraging advanced platforms that connect businesses with a vast network of vetted manufacturers, companies can access a diverse array of manufacturing processes and materials tailored to their unique specifications. This flexibility not only facilitates rapid prototyping but also ensures high-quality production at competitive pricing, essential for maintaining a competitive edge in today’s fast-paced environment.

Investing in strategic sourcing allows organizations to streamline their operations, reduce lead times, and enhance collaboration with suppliers. Furthermore, with growing capabilities in digital manufacturing, including instant quoting and real-time project management, buyers can make informed decisions that align with their operational goals and budgetary constraints.

Looking ahead, it is vital for B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, to embrace these advancements. By actively engaging in strategic sourcing practices, businesses can position themselves for success in a dynamic global market. Now is the time to explore these opportunities and build partnerships that will drive innovation and growth.