Top 8 Cnc Routers China Manufacturers & Suppliers List

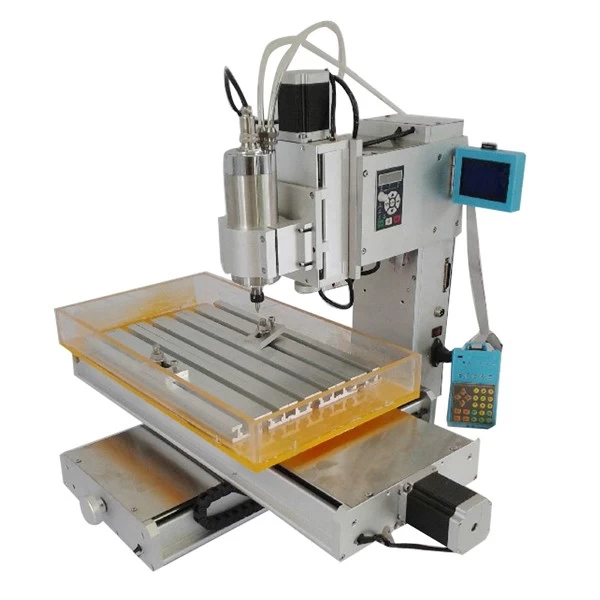

1. China CNC Router – 6040, 6090 & 3040 Models

Domain: china-cncrouter.com

Registered: 2015 (10 years)

Introduction: China CNC 6040 Router: Small CNC Machine with USB Controller, available in 1500W or 2200W options. China NC 6090 CO2 Laser Engraving Machine: 100W, 1000 x 600mm cutting area. China CNC Router 3040: 4 Axis with 500W DC Spindle and USB Controller. China Desktop Small Mini 5 Axis CNC Router Machine HY 6040: New with 2.2KW and USB. ChinaCNCzone Metal Engraving Machine: Steel Body 3040 5 Axis CNC Mill….

2. STYLECNC – CNC Machines

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: STYLECNC is a leading CNC machine manufacturer from China, offering a wide range of products including CNC routers, CNC milling machines, CNC laser machines, CNC plasma cutters, CNC wood lathes, and CNC knife cutters. Their product lineup includes: 1. CNC Router Machines for woodworking, metal fabrication, foam molding, stone carving, and plastic cutting. 2. CNC Milling Machines for precision meta…

3. OMNI CNC – CNC Cutting Machines

Domain: omni-cnc.com

Registered: 2009 (16 years)

Introduction: OMNI CNC is a leading manufacturer of CNC cutting machines in China, offering a wide range of products including CNC routers, fiber lasers, digital cutters, plasma cutters, and water jet cutters. Key product details include: 1. CNC Routers: Available in various configurations such as 5-axis, 3-axis, 4-axis, and custom models, designed for woodworking, mold making, stone carving, and cutting plasti…

4. FORSUN CNC – Wood CNC Router FS1325ATC

Domain: forsuncnc.com

Registered: 2020 (5 years)

Introduction: Product Name: Wood CNC Router FS1325ATC

Brand: FORSUN CNC

Price: $5,000.00 / Set

Price Range: $5,000.00 to $10,000.00 / Set based on configuration

Payment Terms: T/T, Visa, Mastercard, American Express, Discover

Warranty: 2 Years

Supply Ability: 30 Sets / Month

Model: FS1325ATC

Dimensions: X, Y-Axis Travel 1300X2500mm (4X8ft), Options for larger sizes available

Z-Axis Travel: 200mm, Options availa…

5. Elephant CNC – Professional Furniture CNC Machines

Domain: elephant-cnc.com

Registered: 2013 (12 years)

Introduction: Top #1 Professional CNC Machine Manufacturer in China. Products include: Furniture CNC Machine, Panel Furniture Production Line, CNC Nesting Machine, Wood Door Making Machine, Door Lock Drilling Machine, 4 Sides Wood Door Cutting Machine, Door, Wall and Cabinet Integrated Machine, Edge Banding Machine (Automatic, Manual, Semi-Automatic), Profiling Corner Trimming Machine, Panel Saw (Sliding Table …

6. Wattsan – CNC Router Machines

Domain: wattsan.com

Registered: 2016 (9 years)

Introduction: This company, Wattsan – CNC Router Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. EagleTec – CNC Routers and Router Bits

Domain: eaglecnctec.com

Registered: 2016 (9 years)

Introduction: This company, EagleTec – CNC Routers and Router Bits, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Chinese CNC Routers – Reliability and Support Insights

Domain: woodweb.com

Registered: 1995 (30 years)

Introduction: Chinese CNC routers are discussed in terms of their reliability, customer support, and cost-effectiveness. Key points include: 1. Importance of researching the company behind the CNC machine, especially if they have limited online presence. 2. Consideration of customer support and availability of spare parts. 3. The potential trade-off between initial cost and long-term reliability, suggesting tha…

Introduction: Navigating the Global Market for cnc routers china

The global market for CNC routers from China presents a wealth of opportunities for international B2B buyers, but navigating this landscape can be daunting. One of the key challenges faced by businesses, particularly in regions like Africa, South America, the Middle East, and Europe, is sourcing reliable and high-quality CNC routers that meet specific operational needs while remaining within budget. This guide aims to demystify the procurement process for CNC routers by offering a comprehensive overview of various types available, their applications across industries, and essential strategies for supplier vetting.

From wood and metal fabrication to intricate engraving and cutting tasks, CNC routers serve a multitude of functions that can significantly enhance production efficiency. Understanding the nuances of each machine type, along with their cost structures, is crucial for making informed purchasing decisions. This guide empowers buyers by providing actionable insights into the features and benefits of different CNC routers, as well as practical tips for selecting reputable suppliers.

By leveraging the information contained within this guide, B2B buyers can confidently navigate the complexities of sourcing CNC routers from China, ensuring they make choices that align with their business goals and operational requirements. Whether you are a startup in Nigeria or an established manufacturer in Germany, this resource will equip you with the knowledge necessary to optimize your CNC router investments and drive your business forward.

Understanding cnc routers china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3 Axis CNC Router | Simple operation, suitable for flat materials | Woodworking, plastic cutting | Pros: Cost-effective, easy to use. Cons: Limited in complex shapes. |

| 4 Axis CNC Router | Added rotational axis for more complex machining | Sign making, intricate designs | Pros: Greater flexibility, improved detail. Cons: Higher cost and complexity. |

| 5 Axis CNC Router | Multidimensional movement for complex geometries | Aerospace components, advanced engineering | Pros: High precision, versatile applications. Cons: Expensive, requires skilled operation. |

| Laser CNC Router | Uses laser technology for cutting and engraving | Custom signage, intricate designs | Pros: High detail, clean edges. Cons: Limited material types, maintenance-intensive. |

| Plasma CNC Cutter | Utilizes plasma for cutting metal sheets | Metal fabrication, automotive parts | Pros: Fast cutting speeds, effective for thick materials. Cons: Limited to metal, requires ventilation. |

What Are the Characteristics of a 3 Axis CNC Router?

The 3 Axis CNC router is the most basic type, featuring three axes of movement: X, Y, and Z. This machine is ideal for straightforward tasks such as cutting and engraving flat materials like wood and plastics. For B2B buyers, its cost-effectiveness and ease of use make it a popular choice for small businesses and hobbyists looking to enter the CNC market without a significant upfront investment. However, its limitations in creating complex shapes may not meet the needs of all applications.

How Does a 4 Axis CNC Router Enhance Machining Capabilities?

A 4 Axis CNC router introduces an additional rotational axis, allowing for more intricate machining and the ability to work on cylindrical objects. This variation is particularly beneficial in industries such as sign making and custom design work, where detail is crucial. B2B buyers should consider the increased flexibility and improved detail it offers, although the higher cost and complexity may require additional training and expertise.

Why Choose a 5 Axis CNC Router for Advanced Applications?

The 5 Axis CNC router is designed for high-precision machining, capable of executing complex geometries and intricate designs. This machine is essential for sectors like aerospace and advanced engineering, where accuracy and versatility are paramount. For businesses looking to invest in cutting-edge technology, the 5 Axis option provides significant advantages, but buyers must weigh the substantial investment and the need for skilled operators against their specific production requirements.

What Are the Benefits of Using a Laser CNC Router?

Laser CNC routers utilize laser technology for cutting and engraving, making them ideal for applications that require high detail, such as custom signage and intricate designs. They offer clean edges and minimal material waste, appealing to businesses focused on precision. However, B2B buyers should be aware of the limitations in the types of materials that can be processed and the potential for higher maintenance costs associated with these machines.

In What Scenarios Is a Plasma CNC Cutter Most Effective?

Plasma CNC cutters are engineered for speed and efficiency in cutting metal sheets, making them invaluable in the metal fabrication and automotive industries. They can handle thicker materials quickly, which is essential for high-volume production environments. While they offer impressive cutting capabilities, buyers should consider the limitations regarding material types and the need for adequate ventilation during operation.

Key Industrial Applications of cnc routers china

| Industry/Sector | Specific Application of cnc routers china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking | Custom furniture manufacturing | Enhanced precision and reduced material waste | Machine size, spindle power, and software compatibility |

| Metal Fabrication | Precision metal part production | Increased efficiency and reduced labor costs | Material compatibility, cutting speed, and machine durability |

| Signage and Advertising | Custom signage production | Ability to create intricate designs and prototypes | Versatility in materials, engraving capabilities, and software support |

| Aerospace and Automotive | Component machining and prototyping | High precision and repeatability for critical parts | Tolerance requirements, material types, and post-processing capabilities |

| Arts and Crafts | Personalized crafts and artistic creations | Customization potential for unique products | Size of the work area, tooling options, and ease of use |

How Are CNC Routers Used in the Woodworking Industry?

In the woodworking industry, CNC routers from China are used for custom furniture manufacturing, allowing for intricate designs and precise cuts. These machines help businesses reduce material waste and improve production efficiency by automating repetitive tasks. International buyers, especially from regions like Africa and Europe, should consider the machine’s size, spindle power, and compatibility with design software to ensure it meets their specific production needs.

What Role Do CNC Routers Play in Metal Fabrication?

CNC routers are essential in the metal fabrication sector for producing precision parts used in various industries, including automotive and aerospace. They enhance efficiency by automating processes that would typically require manual labor, thus cutting down on labor costs and errors. Buyers must evaluate the machines for material compatibility, cutting speed, and durability, especially when sourcing from China, to ensure they can handle the specific metals they work with.

How Are CNC Routers Transforming Signage and Advertising?

In signage and advertising, CNC routers facilitate the creation of custom signs, allowing for intricate designs and rapid prototyping. This capability enables businesses to offer unique products that stand out in a competitive market. When sourcing CNC routers, buyers should focus on the machine’s versatility in handling various materials, engraving capabilities, and the availability of software support to streamline the design process.

Why Are CNC Routers Important in Aerospace and Automotive Industries?

CNC routers play a critical role in the aerospace and automotive industries, where high precision and repeatability are paramount for component machining and prototyping. These machines help ensure that parts meet stringent quality standards while reducing production lead times. International buyers should pay attention to tolerance requirements, material types, and the machine’s post-processing capabilities when selecting a CNC router for these demanding applications.

How Do CNC Routers Benefit Arts and Crafts?

CNC routers are increasingly popular in the arts and crafts sector for creating personalized items and artistic creations. They provide artisans and small businesses with the ability to customize products, thereby enhancing their market appeal. Buyers should consider the size of the work area, tooling options, and user-friendliness of the machine when sourcing from China to ensure it aligns with their creative processes and project requirements.

3 Common User Pain Points for ‘cnc routers china’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality CNC Routers from China

The Problem: International buyers often face challenges in sourcing high-quality CNC routers from China. With numerous manufacturers claiming to offer the best products, it can be overwhelming to discern which ones meet rigorous quality standards. Additionally, language barriers, cultural differences, and time zone disparities can complicate communication, leading to misunderstandings regarding specifications, pricing, and delivery timelines.

The Solution: To effectively navigate the sourcing process, B2B buyers should conduct thorough research before engaging with manufacturers. Utilize platforms like Alibaba or Made-in-China, which allow for reviews and ratings of suppliers. Buyers should request samples and conduct quality inspections before placing large orders. Engaging a local sourcing agent familiar with the Chinese market can also bridge communication gaps and facilitate smoother transactions. Establishing clear specifications and expectations upfront will mitigate potential issues down the line.

Scenario 2: Managing Installation and Training Challenges for CNC Routers

The Problem: Many buyers, especially those new to CNC technology, struggle with the installation and operation of their newly purchased routers. Without proper training, teams may be unable to utilize the machines effectively, leading to operational inefficiencies and increased downtime. This is particularly concerning for businesses aiming to maximize productivity and minimize labor costs.

The Solution: Buyers should prioritize manufacturers that offer comprehensive installation and training services as part of their purchase agreement. This can include on-site training sessions or detailed online tutorials tailored to the specific machine model. Additionally, buyers should consider investing in a maintenance contract that provides ongoing technical support. Establishing a relationship with the supplier can ensure that your team has access to assistance whenever needed, ultimately enhancing operational capabilities and confidence in using the equipment.

Scenario 3: Addressing After-Sales Support and Parts Availability

The Problem: After purchasing a CNC router, many businesses find themselves facing challenges related to after-sales support and the availability of replacement parts. Delays in obtaining essential components can halt production, leading to lost revenue and frustrated clients. This issue is particularly critical for companies that rely on just-in-time manufacturing processes.

The Solution: Before finalizing a purchase, it is crucial for buyers to inquire about the manufacturer’s after-sales support policies and the availability of spare parts. Opt for suppliers that have a proven track record of reliable support and a robust supply chain for parts. Establishing a clear agreement regarding warranty terms, response times for support inquiries, and parts sourcing can significantly reduce downtime. Buyers should also consider investing in spare parts upfront to maintain operational continuity, thus ensuring that production schedules remain uninterrupted.

Strategic Material Selection Guide for cnc routers china

What Are the Key Materials Used in CNC Routers from China?

When selecting a CNC router from China, understanding the materials that can be processed is crucial for optimizing performance and ensuring product suitability. Below, we analyze four common materials—wood, aluminum, acrylic, and steel—highlighting their properties, advantages, disadvantages, and specific considerations for international buyers.

Wood: The Versatile Choice for CNC Routing

Key Properties: Wood is a natural material with varying density and grain patterns. It is generally easy to cut and engrave, making it a popular choice for CNC routers.

Pros & Cons: The primary advantage of wood is its availability and cost-effectiveness. It is lightweight and can be easily shaped, making it suitable for a wide range of applications from furniture to decorative items. However, wood can be susceptible to warping and moisture, which may affect the final product’s durability.

Impact on Application: Wood is ideal for projects requiring intricate designs and fine details. Its compatibility with various finishes allows for customization, but care must be taken to avoid splintering during machining.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local wood regulations and sustainability practices. Compliance with standards such as the Forest Stewardship Council (FSC) certification is essential for responsible sourcing.

Aluminum: The Lightweight Metal with Strength

Key Properties: Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. It can withstand high temperatures, making it suitable for various machining processes.

Pros & Cons: The key advantage of aluminum is its strength-to-weight ratio, which allows for robust designs without adding excessive weight. However, machining aluminum can be complex, requiring specialized tools and techniques to prevent issues like burr formation.

Impact on Application: Aluminum is widely used in industries such as aerospace, automotive, and construction. Its compatibility with anodizing and other finishing processes enhances its aesthetic appeal but may increase production costs.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should ensure compliance with DIN standards for aluminum products. Understanding the alloy specifications and machining requirements is crucial for successful implementation.

Acrylic: The Clear Choice for Precision Cutting

Key Properties: Acrylic is a transparent thermoplastic known for its clarity and impact resistance. It is easily machinable and can be cut into intricate shapes with high precision.

Pros & Cons: The primary advantage of acrylic is its versatility in applications ranging from signage to display cases. It offers an excellent finish and can be polished to enhance clarity. However, acrylic can be prone to scratching and may require protective coatings.

Impact on Application: Acrylic is suitable for projects requiring visual appeal, such as retail displays and decorative items. Its compatibility with various adhesives and paints allows for creative applications.

Considerations for International Buyers: Buyers from the Middle East should be aware of the local climate’s impact on acrylic products, as extreme temperatures can affect material performance. Compliance with international standards for plastics is also essential.

Steel: The Heavy-Duty Material for Industrial Applications

Key Properties: Steel is a robust material with high tensile strength and durability. It is suitable for heavy-duty applications and can withstand significant wear and tear.

Pros & Cons: The key advantage of steel is its strength, making it ideal for structural applications. However, it is heavier and more challenging to machine compared to other materials, which can increase manufacturing complexity and costs.

Impact on Application: Steel is commonly used in industrial settings for components that require high durability, such as machinery parts and structural frames. Its compatibility with welding and other fabrication processes enhances its utility.

Considerations for International Buyers: Buyers in regions like Europe must comply with stringent safety and quality standards, such as ASTM and ISO certifications. Understanding local regulations regarding steel sourcing and usage is also critical.

Summary Table of Material Selection for CNC Routers

| Material | Typical Use Case for CNC Routers China | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture, decorative items | Cost-effective and easy to shape | Susceptible to warping and moisture | Low |

| Aluminum | Aerospace, automotive components | High strength-to-weight ratio | Complex machining requirements | Medium |

| Acrylic | Signage, display cases | Excellent finish and clarity | Prone to scratching | Medium |

| Steel | Industrial machinery parts | High durability and strength | Heavy and challenging to machine | High |

This guide provides a comprehensive overview of material selection for CNC routers, helping international B2B buyers make informed decisions that align with their operational needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc routers china

What Are the Main Stages in the Manufacturing Process of CNC Routers in China?

The manufacturing of CNC routers in China involves several critical stages designed to ensure high-quality output and efficiency. These stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for CNC Router Production?

Material preparation is the foundational step in manufacturing CNC routers. It involves selecting high-quality raw materials, such as aluminum, steel, and composite materials. Suppliers often source these materials from reputable vendors to ensure durability and performance. Advanced cutting and machining techniques are employed to shape the materials into components that meet precise specifications. This step may also include treatments to enhance material properties, such as anodizing aluminum for corrosion resistance.

What Forming Techniques Are Used in CNC Router Manufacturing?

Forming techniques vary based on the specific components being produced but typically include CNC machining, laser cutting, and plasma cutting. CNC machining is particularly prevalent for creating intricate parts with high tolerances. Laser cutting is employed for its precision and ability to handle various materials, while plasma cutting is used for thicker metals. These techniques not only enhance the accuracy of the components but also reduce material waste, making the manufacturing process more sustainable.

How is Assembly Conducted in CNC Router Manufacturing?

Once the individual parts are formed, they undergo a meticulous assembly process. This stage requires skilled technicians who ensure that all components fit together seamlessly. Automated assembly lines may also be employed to enhance efficiency. During this phase, the integration of electronic components, such as motors and control systems, is critical. Proper alignment and calibration are performed to ensure optimal performance of the CNC router.

What Finishing Processes Are Commonly Used for CNC Routers?

Finishing processes enhance both the aesthetic and functional properties of CNC routers. Common finishing techniques include powder coating, painting, and surface polishing. These processes not only provide a protective layer to the machine but also improve its appearance, making it more appealing to buyers. Quality control checks are conducted during finishing to identify any defects or inconsistencies.

What Quality Assurance Practices Are Implemented in CNC Router Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product meets international standards and customer expectations. Manufacturers in China often adhere to various quality management systems, with ISO 9001 being the most recognized standard.

Which International Standards Should B2B Buyers Be Aware Of?

ISO 9001 certification is crucial for manufacturers as it demonstrates a commitment to quality management practices. Other relevant certifications include CE marking, which indicates compliance with European safety and environmental standards, and API certification for certain industrial applications. B2B buyers should ensure that their suppliers possess these certifications, as they reflect the manufacturer’s adherence to quality and safety protocols.

What Are the Key Quality Control Checkpoints During Production?

Quality control checkpoints are strategically placed throughout the manufacturing process to monitor quality at different stages. These typically include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conducting checks during the manufacturing process to identify and rectify issues in real-time.

- Final Quality Control (FQC): Performing comprehensive inspections on the finished product before shipment, including functionality tests and dimensional checks.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must adopt a proactive approach to verify the quality control processes of their suppliers. Here are some actionable steps:

What Are Effective Methods for Supplier Audits?

Conducting supplier audits is one of the most effective ways to ensure compliance with quality standards. Buyers should request audits that assess manufacturing processes, quality management systems, and compliance with international standards. These audits can be performed by third-party organizations specializing in quality assurance.

How Can Buyers Review Quality Control Reports?

Buyers should request access to quality control reports, which document the results of inspections and tests conducted during the manufacturing process. These reports should detail any non-conformance issues, corrective actions taken, and overall performance metrics. Analyzing these documents can provide insights into the reliability and consistency of the manufacturer.

Are There Third-Party Inspection Services Available?

Engaging third-party inspection services can offer an additional layer of assurance. These independent organizations can perform on-site inspections to verify that the manufacturing processes align with the agreed-upon quality standards. They can also conduct random sampling and testing of products to ensure compliance before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in international trade is essential. Factors such as cultural differences, regulatory requirements, and logistical challenges can impact the quality assurance process.

How Do Regional Regulations Affect Quality Assurance?

Different regions may have specific regulatory requirements that manufacturers must comply with. For example, buyers in Europe may require CE certification for compliance with EU regulations, while buyers in Africa may need to ensure that products meet local safety standards. Familiarizing oneself with these regulations can help buyers make informed purchasing decisions.

What Should Buyers Consider Regarding Logistics and Quality?

Logistics also plays a crucial role in maintaining quality during transportation. Buyers should ensure that manufacturers have robust packaging and shipping practices to prevent damage during transit. It may also be beneficial to include clauses in contracts that specify quality expectations upon delivery.

In conclusion, understanding the manufacturing processes and quality assurance measures for CNC routers in China is vital for B2B buyers. By focusing on these aspects, buyers can make informed decisions and foster successful partnerships with suppliers, ultimately enhancing their business operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc routers china’

This guide serves as a practical checklist for B2B buyers looking to procure CNC routers from China. With numerous manufacturers and models available, navigating this market can be overwhelming. By following these steps, you can ensure a smooth sourcing process, minimize risks, and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clearly outline the technical specifications required for your CNC router. Consider factors like the type of materials you’ll be working with (wood, metal, plastic), the desired precision, and the machine’s operational capabilities (cutting, engraving, milling). Defining these parameters will help you narrow down options that best fit your business needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for manufacturers with a strong online presence and positive reviews. Use platforms like Alibaba or industry-specific directories, and pay attention to supplier ratings and feedback from previous buyers. This research is vital to ensure you are dealing with credible companies that can deliver quality products.

Step 3: Evaluate Supplier Certifications

✅ Verify Supplier Certifications

Ensure that the suppliers you consider have the necessary certifications, such as ISO 9001 for quality management systems. Certifications indicate a commitment to quality and can serve as a proxy for reliability. Additionally, check for compliance with international standards relevant to your industry, which can affect your import and operational processes.

Step 4: Request Detailed Quotations

Once you’ve shortlisted potential suppliers, request detailed quotations that include pricing, shipping costs, and payment terms. Compare these quotes not only for cost but also for the value offered, such as warranty periods and post-purchase support. A comprehensive quotation can reveal more about the supplier’s transparency and willingness to engage in a long-term partnership.

Step 5: Assess After-Sales Support

🔧 Investigate After-Sales Support

After-sales support is crucial for the successful operation of your CNC router. Inquire about the availability of training, installation services, and technical assistance. Suppliers that offer robust after-sales support can help you minimize downtime and address issues that may arise during operation.

Step 6: Conduct Factory Visits or Virtual Tours

If feasible, arrange for factory visits or request virtual tours of the manufacturing facilities. This allows you to inspect production processes, quality control measures, and labor practices. A firsthand view of the supplier’s operations can significantly enhance your confidence in their capabilities and commitment to quality.

Step 7: Finalize Contracts with Clear Terms

Once you have chosen a supplier, ensure that all agreements are documented in a clear contract. This should include specifications, delivery timelines, payment terms, and warranty conditions. A well-defined contract protects both parties and establishes a framework for resolving potential disputes.

By following this checklist, international B2B buyers can strategically navigate the procurement process for CNC routers from China, ensuring they select the right machine and supplier for their specific needs.

Comprehensive Cost and Pricing Analysis for cnc routers china Sourcing

What Are the Key Cost Components in CNC Router Manufacturing from China?

When sourcing CNC routers from China, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality and type of materials (such as steel, aluminum, and electronic components) significantly impact the overall cost. Higher-quality materials may incur a premium but can enhance durability and performance.

-

Labor: Labor costs in China are generally lower than in Western countries. However, skilled labor for CNC machining and assembly can add to costs, especially for complex machines requiring precision.

-

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, and administrative costs. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: Custom tooling is often necessary for specialized CNC router designs. The initial investment in tooling can be substantial but is essential for achieving specific functionalities.

-

Quality Control (QC): Ensuring that products meet international quality standards involves rigorous QC processes. This may require additional labor and testing equipment, contributing to the overall cost.

-

Logistics: Transportation costs, including shipping fees and customs duties, can vary significantly depending on the destination country. It is vital to factor in these expenses when calculating total procurement costs.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the margin can provide insights into pricing negotiations.

How Do Price Influencers Affect CNC Router Costs?

Several factors influence the pricing of CNC routers sourced from China:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating favorable MOQs can be beneficial for businesses looking to optimize costs.

-

Specifications and Customization: Custom features or higher specifications (e.g., additional axes, enhanced software) will increase the price. Buyers should clearly define their requirements to avoid unnecessary costs.

-

Material Choices: The type of materials selected can drastically affect the price. For instance, routers made with high-grade materials may have higher upfront costs but offer better longevity.

-

Quality and Certifications: Products meeting international standards (like CE, ISO) may carry a premium due to the additional compliance costs. However, these certifications can also reduce long-term risks.

-

Supplier Factors: Established manufacturers with a solid reputation may charge higher prices, reflecting their reliability and service quality. Conversely, newer or less-known suppliers might offer lower prices but come with higher risks.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is essential, as they determine who pays for shipping and risk at different points in the supply chain. This can significantly impact total costs.

What Are the Best Buyer Tips for Sourcing CNC Routers from China?

International B2B buyers should consider the following strategies to enhance their sourcing experience:

-

Negotiate Effectively: Always negotiate pricing, especially for bulk orders. Suppliers may have flexibility in pricing, particularly if they see potential for long-term business.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider maintenance, operational efficiency, and potential downtime costs. A more expensive machine might offer lower TCO in the long run.

-

Understand Pricing Nuances: Currency fluctuations and international shipping costs can affect pricing. Staying informed about these variables can lead to better budgeting and purchasing decisions.

-

Research Suppliers Thoroughly: Assess potential suppliers based on their experience, customer reviews, and product quality. Request samples or references to ensure that the products meet your expectations.

-

Consider After-Sales Support: Reliable customer service and support are essential, especially for complex machinery. Ensure that the supplier offers adequate training and service options.

-

Be Aware of Import Regulations: Familiarize yourself with your country’s import regulations to avoid unexpected tariffs and delays that could impact overall costs.

Conclusion

Sourcing CNC routers from China can be a cost-effective solution for international buyers, provided they understand the intricacies of cost structures and pricing influencers. By considering these factors, businesses can make informed decisions that align with their operational needs and budget constraints. Always remember that indicative prices can vary widely, so thorough research and negotiation are key to achieving the best value.

Alternatives Analysis: Comparing cnc routers china With Other Solutions

Understanding Alternatives in CNC Technology

When it comes to sourcing CNC routers, particularly from China, it’s crucial for international B2B buyers to consider various alternatives that can meet their operational needs. These alternatives can range from different types of CNC machinery to advanced manufacturing methods that provide similar functionalities. In this analysis, we will compare CNC routers manufactured in China with two alternative solutions: CNC milling machines and laser cutting machines. This will give buyers a clearer perspective on their options.

Comparison Table

| Comparison Aspect | CNC Routers China | CNC Milling Machines | Laser Cutting Machines |

|---|---|---|---|

| Performance | High precision for wood, plastics, and soft metals | Excellent for hard metals and intricate designs | Fast and efficient for thin materials, precise cutting |

| Cost | Generally lower, starting from $3,000 | Moderate to high, starting from $5,000 | Varies widely, typically $5,000 – $20,000 |

| Ease of Implementation | User-friendly, often includes training | Requires skilled operators, training needed | Moderate; user training for software and operation required |

| Maintenance | Low; minimal upkeep needed | Moderate; regular calibration and maintenance required | Low; mostly software updates and occasional part replacements |

| Best Use Case | Ideal for woodworking, signage, and prototyping | Best for metal fabrication and complex machining | Suitable for textiles, acrylic, and thin metals |

Detailed Breakdown of Alternatives

CNC Milling Machines

CNC milling machines are robust alternatives known for their ability to work with harder materials like metals and alloys. These machines excel in producing complex parts with intricate designs, making them ideal for industries that require high precision and durability. However, the initial investment can be significantly higher than CNC routers, and they require skilled operators to maximize their capabilities. Maintenance can also be more demanding, as regular calibration is essential to ensure optimal performance.

Laser Cutting Machines

Laser cutting machines offer a different approach to material processing, utilizing focused light beams to cut or engrave materials. They are particularly advantageous for thin materials such as textiles, plastics, and metals. The speed of operation is one of their strongest points, allowing for rapid production cycles. However, the cost can vary widely based on the machine’s capabilities, and they might not be suitable for thicker materials. Additionally, while they require less physical maintenance, operators need to be trained in the specific software and safety protocols associated with laser technology.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right CNC solution requires a careful evaluation of your specific business needs, budget, and the materials you plan to work with. If your focus is on woodworking or creating prototypes, CNC routers from China may offer the best value in terms of cost and ease of use. Conversely, if your operations involve heavy metal fabrication or require intricate designs, investing in CNC milling machines might be the better option. For projects involving thinner materials, laser cutting machines could provide unparalleled speed and precision. By understanding the strengths and limitations of each alternative, B2B buyers can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for cnc routers china

What Are the Key Technical Properties of CNC Routers from China?

Understanding the essential technical specifications of CNC routers is crucial for making informed purchasing decisions. Here are several critical properties that B2B buyers should consider:

-

Material Grade

– The material grade of a CNC router affects its durability and performance. Common materials include aluminum, steel, and cast iron. High-grade materials enhance the machine’s longevity and ability to withstand rigorous operations, particularly in industrial settings. This is vital for businesses in sectors like manufacturing and metalworking, where equipment wear can lead to increased downtime and costs. -

Tolerance

– Tolerance refers to the permissible limit of variation in a physical dimension. High tolerance levels (e.g., ±0.01 mm) are essential for precision machining, especially in applications requiring intricate designs. For buyers in fields such as aerospace or automotive manufacturing, precise tolerances can directly impact product quality and safety. -

Spindle Power

– Spindle power, typically measured in kilowatts (KW), indicates the machine’s cutting capability. Higher spindle power allows for faster cutting speeds and the ability to work with harder materials. This is particularly important for businesses needing to optimize production speed while maintaining quality. -

Working Area

– The working area defines the maximum size of materials the CNC router can accommodate. Depending on the intended application—whether woodworking, metal fabrication, or engraving—buyers must assess if the router’s working area meets their operational requirements. A larger working area can enhance versatility and reduce the need for multiple machines. -

Control System

– The control system dictates the machine’s ease of use and programming capabilities. Advanced systems with user-friendly interfaces and compatibility with various software can significantly reduce training time and operational errors. Businesses should consider the learning curve associated with different systems when selecting equipment. -

Cooling System

– A cooling system is essential for maintaining optimal operating temperatures during machining processes, especially when working with metals. Effective cooling minimizes thermal distortion and prolongs tool life, which is crucial for maintaining production efficiency and reducing costs.

What Are Common Trade Terms Used in the CNC Router Industry?

Familiarity with industry jargon can streamline communication and negotiations with suppliers. Here are several key terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

– OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers seeking customized machines, as it affects product quality and service levels. -

MOQ (Minimum Order Quantity)

– MOQ is the minimum number of units a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, especially for businesses looking to scale operations without incurring excess costs. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and details on specific products. It is a critical step in the procurement process, allowing buyers to compare costs and features before making a purchase decision. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery obligations, which is particularly important for international transactions. -

Lead Time

– Lead time refers to the time taken from placing an order to delivery. Understanding lead times is vital for project planning and inventory management, particularly in industries where timely delivery is crucial to maintaining production schedules. -

Warranty

– A warranty is a guarantee from the manufacturer regarding the condition and performance of the CNC router. Understanding warranty terms can protect businesses from unexpected repair costs and ensure long-term equipment reliability.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing CNC routers from China, ultimately optimizing their manufacturing processes and ensuring cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the cnc routers china Sector

What Are the Key Market Dynamics and Trends Influencing CNC Routers from China?

The global CNC router market is experiencing significant growth driven by technological advancements, increasing automation across industries, and a rising demand for precision manufacturing. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. One notable trend is the shift towards compact, multi-functional machines that can handle various materials, including wood, metal, and plastics. Manufacturers are increasingly offering customizable solutions tailored to specific industrial needs, which is particularly appealing to businesses looking to optimize production efficiency.

Moreover, the growing emphasis on Industry 4.0 is pushing manufacturers to integrate smart technologies into CNC routers. Features such as IoT connectivity, real-time monitoring, and advanced software solutions are becoming standard. This evolution not only enhances operational efficiency but also allows for better data management and analytics, which are critical for decision-making in B2B environments. As a result, international buyers are advised to assess the technological capabilities of CNC routers to ensure they align with their operational goals.

Another emerging trend is the focus on affordability without compromising quality. As competition intensifies, Chinese manufacturers are offering a wider range of budget-friendly options, making advanced CNC technology accessible to small and medium-sized enterprises (SMEs). This democratization of technology is particularly significant for buyers in emerging markets who seek cost-effective solutions to scale their operations.

How Important Is Sustainability and Ethical Sourcing for CNC Routers?

Sustainability and ethical sourcing are increasingly important considerations for international B2B buyers in the CNC router market. The environmental impact of manufacturing processes, including waste generation and energy consumption, is under scrutiny. Buyers are encouraged to seek out suppliers who prioritize sustainable practices, such as using eco-friendly materials and implementing energy-efficient production methods.

Furthermore, the rise of ethical supply chains is reshaping buyer-supplier relationships. Companies are now more inclined to partner with manufacturers who adhere to social responsibility standards, ensuring fair labor practices and transparency in their operations. Certifications related to sustainability, such as ISO 14001 for environmental management, can serve as indicators of a supplier’s commitment to ethical sourcing.

In the context of CNC routers, sourcing from manufacturers who utilize sustainable materials not only aligns with corporate social responsibility goals but also enhances brand reputation. Buyers should actively inquire about the materials used in the production of CNC routers, ensuring they are sourced responsibly and contribute to a reduced carbon footprint.

What Is the Evolution of CNC Routers in the Global Market?

The evolution of CNC routers can be traced back to the late 20th century when computer numerical control technology began to revolutionize manufacturing. Initially, CNC routers were primarily used for woodworking applications. However, as the technology advanced, their versatility expanded to include metal fabrication, stone carving, and plastic processing. This diversification has made CNC routers indispensable tools in various industries, from automotive to aerospace.

In recent years, the integration of advanced technologies such as artificial intelligence and machine learning has further transformed CNC routers. These innovations have led to enhanced precision, efficiency, and user-friendliness, catering to both novice and experienced operators. As a result, the global CNC router market is now characterized by a rich landscape of options that cater to diverse business needs, positioning China as a key player in this rapidly evolving industry.

By keeping abreast of these market trends and focusing on sustainability, international B2B buyers can make informed decisions that not only meet their operational requirements but also align with their ethical and environmental goals.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc routers china

-

How do I choose the right CNC router for my business needs?

Selecting the right CNC router involves assessing your specific applications, materials, and production volume. Start by identifying the types of projects you will undertake—be it woodworking, metal fabrication, or engraving. Consider the machine’s capabilities, such as axis configuration (3, 4, or 5-axis), spindle power, and bed size. Additionally, evaluate your budget and ensure the machine aligns with your operational goals and future scalability. Research suppliers that offer customization options to cater to your unique requirements. -

What factors should I consider when vetting CNC router suppliers in China?

When vetting CNC router suppliers, prioritize their experience and reputation in the industry. Look for manufacturers with a track record of quality and customer satisfaction, as evidenced by reviews and case studies. Verify certifications, such as ISO standards, which indicate adherence to international quality management practices. It’s also beneficial to request product samples and visit factories if possible, ensuring that the supplier meets your expectations for quality and service. -

What are the typical minimum order quantities (MOQs) for CNC routers from China?

Minimum order quantities for CNC routers can vary significantly depending on the supplier and the complexity of the machine. Generally, MOQs range from one unit for standard models to several units for customized or specialized machines. It’s essential to discuss your needs with potential suppliers to understand their policies. Some manufacturers may offer flexibility on MOQs for first-time buyers or bulk orders, making it worthwhile to negotiate terms that suit your purchasing strategy. -

What payment terms should I expect when purchasing CNC routers from Chinese suppliers?

Payment terms can vary widely among suppliers, but common arrangements include a 30% deposit with the balance paid before shipment or upon delivery. Some suppliers may offer letter of credit (LC) options for larger orders, providing security for both parties. It’s crucial to clarify payment methods accepted (e.g., bank transfer, PayPal) and ensure that all terms are documented in your purchase agreement. Understanding these terms upfront can help mitigate financial risks associated with international transactions. -

How can I ensure quality assurance (QA) for CNC routers sourced from China?

To ensure quality assurance, establish clear specifications and standards with your supplier before production begins. Request detailed documentation of the manufacturing process, including quality control measures in place. Many suppliers will provide pre-shipment inspections or allow third-party inspections to verify compliance with your standards. Additionally, consider sourcing from manufacturers with ISO certifications, as they are more likely to adhere to international quality standards. -

What logistics options are available for shipping CNC routers from China to my country?

Shipping options for CNC routers typically include sea freight, air freight, and express courier services, with sea freight being the most economical for larger machines. Factors influencing your choice include budget, urgency, and the destination’s infrastructure. Work with your supplier to determine the best shipping method and understand the associated costs, including customs duties and taxes. It’s advisable to partner with a logistics provider experienced in handling heavy machinery to streamline the process. -

Can CNC routers from China be customized to meet specific project requirements?

Yes, many Chinese manufacturers offer customization options for CNC routers to cater to specific project needs. Customizations can include alterations to size, features, and software compatibility. When discussing your requirements, provide detailed specifications and examples of what you need. Engaging in open communication with the supplier during the design phase will help ensure the final product aligns with your operational expectations. -

What after-sales support can I expect when purchasing CNC routers from China?

After-sales support varies by supplier but typically includes installation assistance, training, and access to technical support. Many manufacturers offer online resources, such as manuals and video tutorials, to help you operate the machine effectively. It’s essential to clarify the level of support provided before purchase, including warranties and service agreements. A robust after-sales support system can significantly enhance your operational efficiency and machine longevity.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc routers china

In the dynamic landscape of CNC routers from China, strategic sourcing remains a critical component for international B2B buyers aiming to enhance operational efficiency and competitiveness. With a diverse range of high-quality machines available, businesses can tailor their investments to meet specific production needs—whether it’s for woodworking, metal fabrication, or intricate engraving tasks. Key takeaways highlight the importance of understanding your operational requirements and budget constraints when selecting CNC routers, ensuring that the equipment aligns with both current and future business goals.

Moreover, sourcing from reputable Chinese manufacturers provides not only cost advantages but also access to cutting-edge technology and robust support systems, including installation and training services. This strategic approach enables businesses to minimize risks, reduce material waste, and ultimately drive productivity.

As we look ahead, it’s crucial for buyers from Africa, South America, the Middle East, and Europe to engage actively with suppliers, leveraging opportunities for collaboration and innovation. Embrace the potential of CNC routers to transform your manufacturing processes and position your business for sustainable growth in an increasingly competitive global market. Take the next step—explore your sourcing options today and unlock the full potential of CNC technology.